Not every engine becomes famous for the right reasons. While General Motors has produced many strong and reliable powerplants over the decades, it has also built a handful that developed reputations for frequent repairs, expensive fixes, or long-term durability concerns.

For owners, these engines often turned what should have been routine maintenance into repeated trips to the workshop.

In many cases, the problems were not about performance or power. Some of these engines actually delivered good fuel economy or strong output when new.

The trouble usually came from design choices that led to weak internal components, poor sealing systems, or complex features that did not age well. As mileage piled up, small issues sometimes turned into major repair bills.

Another factor is how modern engines are packed tightly into engine bays and filled with sensors, variable valve systems, and emissions equipment.

When one part fails, it can affect several others, increasing both labor time and cost. For certain GM engines, specific patterns of failure became common enough that mechanics began to recognize them immediately.

It is important to note that not every example of these engines is guaranteed to be problematic. Maintenance history, driving style, and production variations all play a role.

However, these particular engines earned widespread reputations among owners and technicians for being more demanding and expensive to keep in good shape than most.

Here are ten GM engines that became known less for their strengths and more for the maintenance headaches they often brought, starting with two that many mechanics can identify just from the sound of their common issues.

Also Read: 10 Proven Naturally Aspirated Engines Famous for Extreme Longevity

1. 2.4L Ecotec Four Cylinder

The 2.4 liter Ecotec four cylinder engine was used in a wide range of GM cars and crossovers, and while it offered decent fuel economy and smooth operation when new, it became infamous in many circles for serious oil consumption problems.

Owners frequently reported that their engines burned oil at an alarming rate, sometimes without obvious external leaks.

One of the main causes was related to piston ring design. In some versions of this engine, the rings did not effectively control oil, allowing it to enter the combustion chamber and burn. This not only led to low oil levels between changes, but also increased the risk of internal engine damage if drivers did not constantly monitor and top up their oil.

As oil consumption increased, other issues often followed. Running low on oil could accelerate wear on timing chains and internal bearings. Timing chain stretch or failure became another common complaint, sometimes leading to rough running, warning lights, or in severe cases, major engine damage that required costly repairs.

Carbon buildup was also a concern in certain applications. Excess oil entering the combustion process could contribute to deposits that affected performance and long term reliability. Drivers sometimes experienced misfires, rough idling, or reduced efficiency as these deposits accumulated over time.

Repairing these problems was rarely cheap. Fixes often involved extensive internal engine work, including piston and ring replacement, or complete engine rebuilds in severe cases. For many owners, the cost of repair approached or exceeded the value of the vehicle, which made the situation even more frustrating.

While some well maintained examples have survived with high mileage, the 2.4 Ecotec developed a strong reputation as an engine that demanded close attention and often delivered expensive surprises.

That legacy has made it one of the most talked about GM engines when the subject of maintenance nightmares comes up.

2. 3.6L V6 with Early Timing Chain Issues

The 3.6 liter V6 used in many GM vehicles was praised for its power and smoothness, but early versions became well known for timing chain problems that could lead to major maintenance headaches. This engine used a complex chain driven camshaft setup, and in certain years, the components proved more fragile than expected.

Over time, timing chains in affected engines could stretch beyond acceptable limits. When this happened, the engine’s computer would detect that camshaft timing was no longer within specification and trigger warning lights. Drivers often noticed check engine lights, rough running, or reduced performance as the problem progressed.

Replacing timing chains on this engine is not a simple job. The engine’s design makes access difficult, leading to high labor costs. In many cases, multiple chains, guides, and tensioners needed replacement at once. For owners, this turned what might sound like a minor issue into a repair bill that could run into thousands.

Oil change intervals also played a role. Some engines were more sensitive to oil quality and level than drivers realized. Extended intervals or low oil levels could accelerate wear on timing chain components, making failures more likely at lower mileage than expected.

If ignored, timing chain problems could lead to more serious engine damage. Incorrect valve timing can cause poor performance and, in extreme cases, internal contact between valves and pistons. That risk made early diagnosis and repair essential, but also increased the stress and cost for owners.

Later updates improved the design, but the reputation stuck. For many mechanics and drivers, the early 3.6 V6 became synonymous with expensive timing chain repairs, earning its place as one of GM’s more maintenance intensive engines from that period.

3. 1.4L Turbo Ecotec Four Cylinder

The 1.4 liter turbocharged Ecotec engine was widely used in small GM cars and crossovers, where it delivered good fuel economy and respectable performance for its size.

On paper, it looked like a smart modern engine. In reality, it developed a reputation for multiple reliability concerns that could lead to frequent and sometimes costly maintenance.

One of the most common complaints involved cooling system components. Plastic housings, water outlets, and thermostat assemblies were known to crack or leak over time.

Coolant leaks could appear suddenly, sometimes leading to overheating if not caught quickly. Replacing these parts was not always extremely expensive individually, but repeated failures added up and frustrated many owners.

Turbocharger related issues were another source of trouble. The small turbo worked hard to provide adequate power, and over time some units developed problems such as oil leaks, worn bearings, or boost control issues. When a turbo fails, replacement can be costly, especially when combined with labor in tightly packed engine bays.

Positive crankcase ventilation system faults also became a frequent topic among owners. Failures in this system could lead to rough running, oil leaks, or increased oil consumption. In some cases, pressure buildup caused seals to fail, which then required additional repairs beyond the original problem.

Carbon buildup on intake valves was another concern, particularly in direct injected versions. Without fuel washing over the valves, deposits could accumulate and affect performance. Cleaning these deposits often required specialized service, adding to maintenance costs over the life of the engine.

While many drivers experienced years of acceptable service, the combination of cooling system weaknesses, turbo complexity, and other recurring issues made the 1.4 turbo Ecotec feel like an engine that demanded constant attention.

For budget minded buyers expecting low cost ownership, it sometimes turned into an unwelcome maintenance burden.

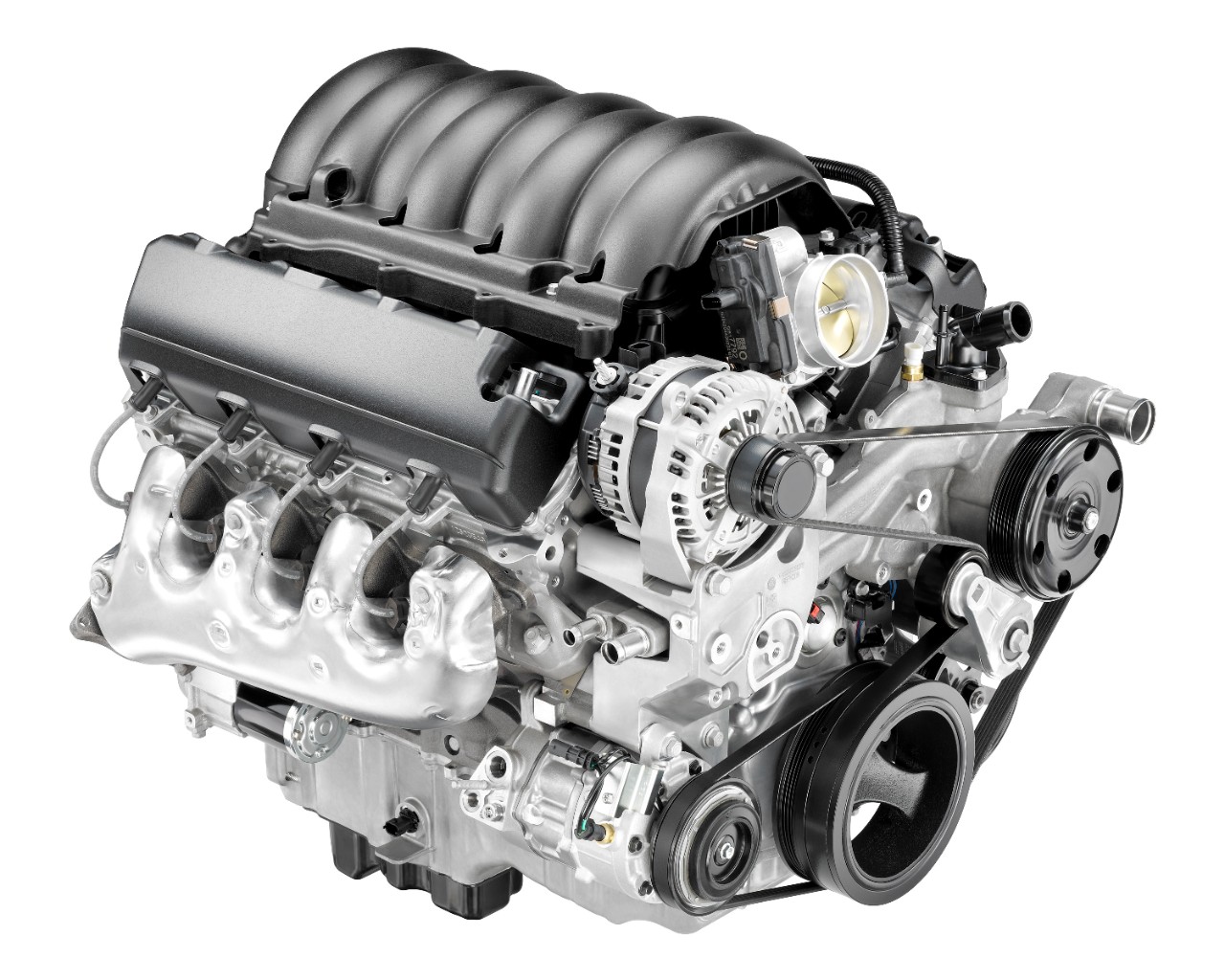

4. 5.3L V8 with Active Fuel Management

The 5.3 liter V8 with Active Fuel Management, used in many GM trucks and SUVs, is a powerful and efficient engine on paper. However, its cylinder deactivation system became a major source of long term reliability complaints, turning what should have been a durable V8 into a maintenance headache for some owners.

Active Fuel Management allows the engine to run on fewer cylinders under light load to improve fuel economy.

While the idea is clever, the additional lifters and oil control components required for this system introduced new failure points. Over time, some of these specialized lifters were prone to collapse or stick, leading to misfires and rough operation.

When a lifter fails, the repair is rarely simple. Accessing and replacing affected components often requires significant engine disassembly. In many cases, camshaft damage can also occur, increasing both parts and labor costs. For truck owners expecting long term toughness, these repairs could come as an unpleasant surprise.

Oil consumption was another complaint tied to this system in certain engines. Some drivers noticed that their trucks used more oil than expected, which could contribute to additional wear if not carefully monitored. Combined with lifter issues, this created a sense that the engine needed more vigilance than older, simpler V8 designs.

The problem was especially frustrating because the rest of the engine was often quite strong. Many of these trucks were used for towing and work, roles where reliability is crucial. Unexpected valvetrain failures could sideline vehicles that owners depended on daily.

Although not every 5.3 with Active Fuel Management experienced serious trouble, enough did to create a lasting reputation. For many mechanics, it became one of the more common modern GM engines associated with expensive internal repairs and long term maintenance concerns.

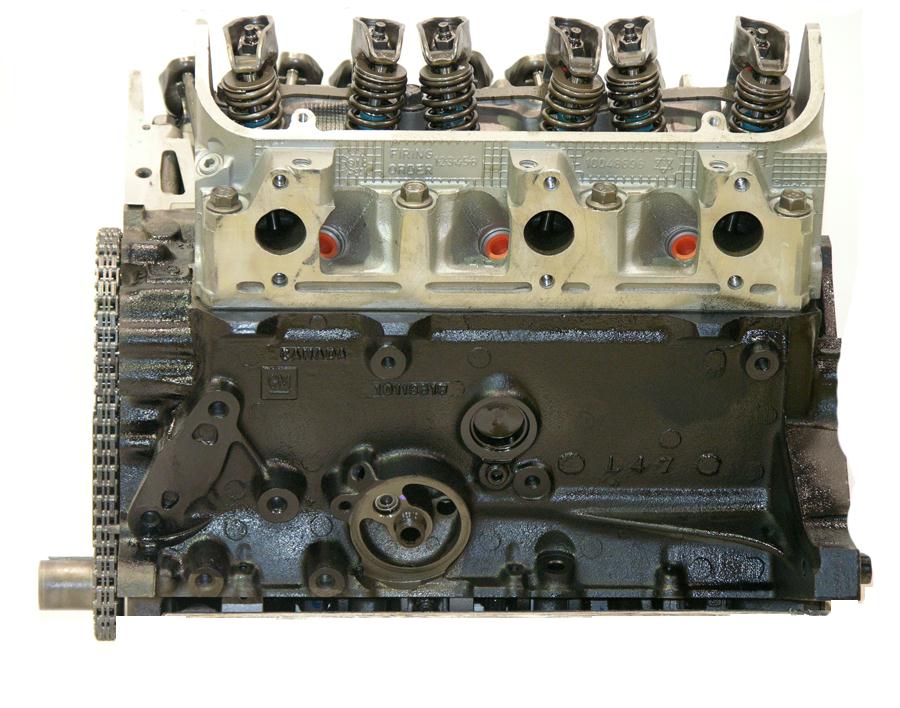

5. 3.1L V6 from the Late 1990s and Early 2000s

The 3.1 liter V6 used in many GM sedans and minivans during the late 1990s and early 2000s became widely known for intake manifold gasket failures. While the engine itself was fairly simple and offered decent everyday performance, this particular issue turned routine ownership into a repeating maintenance concern for many drivers.

The problem centered on the design and materials of the intake manifold gaskets. Over time, these gaskets could deteriorate and begin to leak coolant internally or externally.

Internal leaks were especially troublesome because coolant could mix with engine oil, reducing lubrication quality and increasing the risk of bearing wear and other internal damage.

Drivers often noticed symptoms such as unexplained coolant loss, overheating, or milky oil on the dipstick. If not addressed quickly, the engine could suffer significant internal wear. Even when caught early, the repair required removing the intake manifold, which involved several hours of labor and associated costs.

Unfortunately, this was not always a one time repair. Some replacement gaskets also failed after years of use, leading to repeat visits to the shop. For owners expecting a low cost, dependable family car, these recurring issues created frustration and unexpected expenses.

The cooling system’s sensitivity to leaks also meant that a small gasket failure could quickly turn into a larger problem. Overheating events could warp components or damage other parts of the engine, multiplying the repair bill beyond the original gasket job.

While many 3.1 V6 engines survived with proper care and timely repairs, their reputation was shaped by how common and inconvenient these gasket failures became. For many mechanics, this engine is still remembered as one that frequently arrived with coolant leaks and worried owners.

6. 3.4L V6 with Similar Intake Gasket Problems

Closely related to the 3.1, the 3.4 liter V6 used in various GM cars, vans, and SUVs shared many of the same strengths and weaknesses. Like its smaller sibling, it became notorious for intake manifold gasket issues that often led to coolant leaks and costly repairs.

The larger displacement did not solve the underlying gasket design concerns. Over time, the sealing surfaces could fail, allowing coolant to escape either externally or into the engine. Internal leaks were again the most dangerous, as they could contaminate engine oil and reduce its ability to protect moving parts.

Owners sometimes first noticed a sweet smell, small puddles under the vehicle, or an engine running hotter than usual. In more severe cases, overheating or poor lubrication caused additional damage, turning what started as a gasket problem into a more extensive repair situation.

Repairing the intake manifold gasket on the 3.4 required significant labor, as many components had to be removed to access the affected area. For older vehicles with lower market value, the cost of repair could feel especially painful, leading some owners to delay service and risk further engine damage.

Even after repair, some drivers worried about long term reliability. Although improved replacement gaskets were available, the engine’s reputation had already been shaped by years of widespread failures.

This made it one of the more frequently discussed GM engines when the topic of maintenance headaches came up.

The 3.4 V6 is a reminder that even engines with solid basic designs can develop lasting reputations if a single weak point affects a large number of vehicles. For many owners, intake gasket trouble turned what should have been routine transportation into an ongoing maintenance challenge.

7. 2.2L Ecotec with Timing Chain Tensioner Issues

The 2.2 liter Ecotec four cylinder engine was used in a variety of compact GM vehicles and was generally praised for decent fuel economy and simple design. However, certain versions developed a reputation for timing chain tensioner problems that could lead to serious engine damage if not addressed in time.

The timing chain system relies on proper tension to keep the camshafts and crankshaft synchronized. In some of these engines, the tensioner could wear prematurely or fail to maintain correct pressure. When this happened, the chain could develop slack, leading to rattling noises on startup or during operation.

If the issue was caught early, replacing the tensioner and related components could prevent further damage.

Unfortunately, many drivers did not recognize the early warning signs. Continued operation with a loose timing chain could allow it to skip teeth or jump timing, which in interference engines can cause valves and pistons to collide.

Such internal contact often leads to bent valves, damaged pistons, or even complete engine failure.

At that point, repairs become far more expensive, often involving major engine work or full replacement. What began as a relatively small component failure could turn into a catastrophic and costly situation.

Accessing the timing chain components was also labor intensive. Even preventive repairs could be expensive due to the amount of disassembly required. For owners of budget friendly compact cars, these repair bills often felt disproportionate to the vehicle’s value.

While many 2.2 Ecotec engines ran reliably for years, the timing chain tensioner issue left a lasting mark on its reputation. Among mechanics, it became known as an engine where unusual noises should never be ignored, because the consequences of delay could be severe.

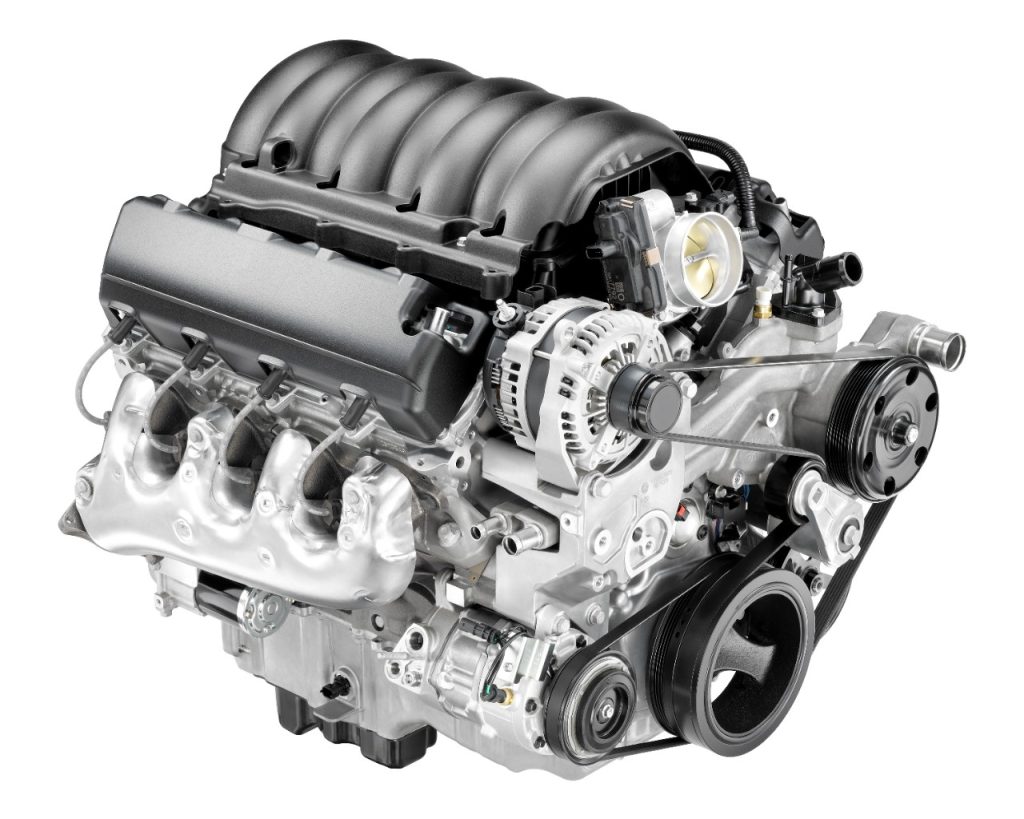

8. 6.2L V8 with Early Active Fuel Management Concerns

The 6.2 liter V8 used in certain GM performance cars, trucks, and SUVs is often praised for its strong power and smooth delivery.

However, versions equipped with early forms of Active Fuel Management developed concerns similar to those seen in smaller V8s, leading to maintenance issues that surprised some owners.

Active Fuel Management systems use special lifters and oil control systems to deactivate cylinders under light load. In some engines, these components proved vulnerable to wear or failure over time. When a lifter malfunctioned, drivers might notice ticking noises, misfires, or a sudden drop in performance.

Repairing a failed lifter in this engine can be expensive. Accessing the valvetrain often requires significant disassembly, and in some cases camshaft damage accompanies the lifter failure. This increases both parts and labor costs, turning a single component issue into a major repair.

Oil consumption was also reported in certain applications. When oil control is not ideal, low oil levels can worsen wear on valvetrain components, increasing the risk of further failures. Owners who were not vigilant about checking oil levels sometimes faced compounded problems.

These issues were especially frustrating because the 6.2 V8 is otherwise a strong and capable engine. Many vehicles using it were marketed as premium or performance oriented, leading buyers to expect high durability along with high output.

Although later improvements addressed some concerns, early versions of the 6.2 with Active Fuel Management earned a reputation for costly internal repairs. For some owners, the promise of powerful V8 performance came with unexpected long term maintenance challenges.

9. 2.0L Turbo Four Cylinder in Early Applications

The 2.0 liter turbocharged four cylinder used in several early GM performance and premium models delivered strong power for its size, but it also developed a reputation in some applications for reliability concerns that could lead to expensive maintenance over time.

Turbocharged engines operate under higher heat and pressure than naturally aspirated ones, and this engine was no exception.

In certain vehicles, owners reported issues with turbocharger components such as worn bearings, oil leaks, or boost control problems. When a turbo fails, replacement costs can be significant, especially when labor is factored in.

High pressure fuel system components were another source of trouble in some cases. Direct injection systems rely on precise fuel delivery, and failures in pumps or injectors could lead to rough running, misfires, or reduced performance. Diagnosing these issues sometimes required specialized equipment and added to repair expenses.

Carbon buildup on intake valves also became a known maintenance concern. Because fuel is injected directly into the combustion chamber, the backs of the intake valves do not get cleaned by fuel.

Over time, deposits can accumulate and affect airflow, causing hesitation, reduced efficiency, or check engine lights. Cleaning this buildup can require labor intensive service.

Cooling system components and sensors in some early versions also contributed to the engine’s maintenance reputation. Failures in these areas could lead to overheating or drivability issues if not caught early, adding to the list of potential repair items owners had to watch for.

While many examples of this engine performed well, the combination of turbo complexity, direct injection maintenance, and occasional component failures made it feel more demanding than some drivers expected. For budget-minded owners, these recurring concerns gave it a reputation as a high-maintenance choice.

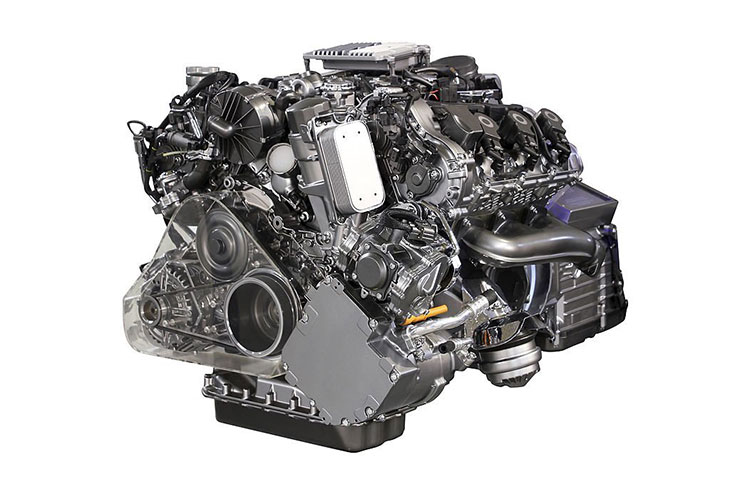

10. 5.7L Diesel V8 in Oldsmobile Applications

The 5.7 liter diesel V8 used in certain Oldsmobile and GM models decades ago remains one of the most infamous engines in the company’s history.

Originally derived from a gasoline V8 design, it struggled to meet the demands of diesel operation, leading to widespread reliability problems that severely damaged its reputation.

One of the major issues was related to head bolt design and block strength. The engine was not originally engineered from the ground up as a diesel, and the stresses of high compression diesel combustion exposed weaknesses. Head gasket failures were common, and in severe cases, block damage could occur.

Fuel system reliability was another challenge. Diesel injection systems require precise operation, and problems in pumps or injectors often led to poor running, hard starting, or excessive smoke. Repairs could be costly and complicated, especially at a time when many mechanics were less familiar with passenger car diesels.

Owners also faced issues with cooling and lubrication under heavy loads. When these systems did not perform perfectly, engine wear accelerated. Combined with the head gasket and block concerns, this created a situation where long term durability was far below expectations for a diesel engine.

The result was a wave of dissatisfied customers and expensive repairs, often at relatively low mileage. The engine’s problems were so widespread that they became a cautionary tale in automotive history about adapting gasoline designs for diesel use without sufficient reinforcement.

Even today, the 5.7 diesel V8 from this era is remembered as one of GM’s most troublesome engines. Its legacy is tied more to maintenance nightmares than innovation, firmly earning its place on this list.

General Motors has produced many respected and long lasting engines, but a few have become known more for costly repairs and recurring issues than for durability.

These engines often delivered decent performance or fuel economy when new, yet design weaknesses or complex systems led to long term maintenance headaches for many owners.

Several four cylinder engines earned attention for oil consumption and timing related problems. The 2.4-litre Ecotec became widely known for excessive oil burning linked to piston ring design, which sometimes led to timing chain wear and internal damage if oil levels were not carefully monitored.

The 2.2 liter Ecotec in certain versions also developed timing chain tensioner issues, where a relatively small component failure could escalate into major engine damage if ignored.

Turbocharged small engines added another layer of complexity. The 1.4 liter turbo Ecotec and early 2.0 liter turbo four cylinder offered good power for their size but introduced concerns with cooling system parts, turbocharger wear, carbon buildup, and high pressure fuel components.

These issues did not affect every vehicle, but they occurred often enough to give these engines a reputation for being more demanding and expensive to maintain than expected.

V6 engines were not immune. The 3.6 liter V6 in early versions became known for timing chain stretch, leading to expensive repairs due to the engine’s complex layout.

Older pushrod V6 engines like the 3.1 and 3.4 liter models developed widespread intake manifold gasket failures that could allow coolant leaks and even internal engine damage if not repaired quickly.

Some V8s also developed troublesome reputations, particularly those with early Active Fuel Management systems. Both the 5.3 and certain 6.2 liter V8 engines experienced lifter and valvetrain issues in some cases, turning what should have been durable truck and performance engines into sources of costly internal repairs.

Finally, the infamous 5.7 liter diesel V8 used in older GM passenger cars stands as a historic example of a design that struggled from the start. Head gasket failures, block weaknesses, and fuel system problems made it one of the most problematic engines GM ever offered.

Together, these engines highlight how design choices, new technologies, and material weaknesses can turn otherwise capable powerplants into long term maintenance challenges for owners.

Also Read: 10 Luxury Cars With Diesel Engines That Are Actually Cool