Inline-six engines have earned a reputation for durability, smoothness, and enduring performance. Unlike V6 configurations that can sometimes struggle with balance or maintenance complications, straight-six designs offer natural harmony in their firing order, translating to less vibration and longer engine life.

These engines have powered everything from luxury sedans to pickup trucks, earning the trust of enthusiasts, mechanics, and commuters alike. Longevity is not simply about parts lasting; it reflects thoughtful engineering, material quality, and design foresight.

Inline-six engines are often praised for their robust construction, straightforward layouts, and ease of service. Owners of vehicles powered by these engines frequently report surpassing 300,000 miles with routine maintenance, a feat rare in other engine designs.

Beyond endurance, many inline-six engines carry a quiet charisma. They deliver a linear power curve, refined operation, and effortless torque at low RPMs. Manufacturers such as BMW, Toyota, and Mercedes-Benz have refined these engines over decades, combining reliability with spirited performance. Some power plants have been adapted across multiple platforms, proving their adaptability and resilience.

This page highlights ten inline-six engines that have earned legendary status by outlasting the cars they inhabit. Each engine is presented with its design philosophy, technical achievements, and the practical benefits that keep owners returning for years.

The aim is to celebrate both engineering excellence and the drivers who experience their enduring performance. These engines exemplify why straight-six configurations continue to hold a place of respect among modern automotive powerplants, representing a benchmark for reliability, refinement, and functional longevity.

1. BMW M54 3.0-Liter Inline-Six

BMW’s M54 engine, produced from 2000 to 2006, is widely celebrated for reliability and versatility. Found in the E46 3 Series, E39 5 Series, and Z4, it combined engineering precision with a smooth, responsive power delivery that owners came to trust.

Its aluminum block and cylinder head construction reduced weight without compromising strength, while the DOHC configuration and variable valve timing allowed for refined efficiency across the rev range. Fuel injection and electronic control modules were engineered with serviceability in mind, giving technicians clear diagnostic access and simplifying repairs.

The M54’s balance resulted in minimal vibration, reducing wear on associated components like the drivetrain and mounts. Torque was available low in the RPM band, providing effortless acceleration in daily driving conditions, while peak power supported spirited performance on highways and winding roads alike.

Owners frequently report surpassing 250,000 miles with proper maintenance. Cooling system upkeep, valve adjustment, and oil changes were straightforward due to thoughtful component placement. Timing chain durability further contributed to its longevity, with few failures under normal use.

Enthusiasts appreciate the engine’s responsiveness and mechanical clarity, which has kept the M54 relevant in the tuning community for years. BMW’s design emphasized modular adaptability. The M54-powered sedans, coupes, and sports roadsters, without major modifications, showcase a flexible architecture that can withstand different operating conditions.

Its reputation extends beyond peak performance; reliability, combined with strong aftermarket support, makes it a blueprint for sustainable engineering. Cars equipped with the M54 remain sought after in used markets, with many examples exceeding 200,000 miles while performing smoothly.

The engine demonstrates that careful design and attention to mechanical harmony can result in power plants that outlive their vehicles, leaving a lasting impression on owners and mechanics alike.

2. Toyota 2JZ-GTE 3.0-Liter Inline-Six

The Toyota 2JZ-GTE engine, installed in the legendary Toyota Supra Mk IV from 1993 to 2002, is widely regarded as a paragon of durability and tunability. Its iron block, twin turbochargers, and reinforced internals were designed to withstand extreme stress, allowing high horsepower outputs without compromising base reliability. The 2JZ-GTE has become a benchmark for long-lasting performance engines, attracting enthusiasts for both stock reliability and aftermarket potential.

Toyota focused on overengineering major components. Forged steel crankshafts, robust connecting rods, and high-quality pistons provided longevity under extreme conditions. The dual overhead camshaft arrangement, coupled with precise fuel injection and strong cooling circuits, allowed for smooth operation at all speeds.

Its high torque output at low RPM made daily driving effortless, while turbocharging delivered exhilarating performance when needed. Maintaining the 2JZ-GTE is straightforward for those familiar with inline-six layouts. Timing components are accessible, and Toyota designed the valve train for minimal adjustments over long intervals.

Oil changes and coolant service follow predictable schedules, supporting reliability beyond 300,000 miles in many examples. The combination of mechanical simplicity and reinforced internals makes it a favorite among professional tuners and street enthusiasts alike.

The engine’s reputation extends into popular culture, where its robust construction and limitless tuning potential have made it an icon. Owners who maintain basic service practices often find the 2JZ-GTE outlasting the chassis of the Supra itself.

Its blend of durability, smooth power delivery, and adaptability has set a standard for what an inline-six engine can achieve, merging performance and longevity in a manner few competitors have matched. The 2JZ-GTE continues to inspire both collectors and engineers seeking dependable, high-performing powerplants.

Also Read: Top 10 Cheap Cars With Engines That Punch Above Their Weight

3. Mercedes-Benz M104 3.2-Liter Inline-Six

Mercedes-Benz M104 engines, produced from the late 1980s through the 1990s, are synonymous with reliability and refinement. These engines powered the W124 E-Class and R129 SL-Class models, offering smooth power delivery and high-mile durability.

Constructed with an aluminum head and a robust iron block, the M104 combined lightweight performance with structural strength, resulting in long-term dependability. Engineering focused on reducing wear through balanced crankshafts, hydraulic lifters, and precision-machined components.

Fuel injection systems were designed for consistent flow and simplicity, minimizing potential issues associated with electronic control. Cooling systems and oil circuits were engineered with redundancy, ensuring the engine could endure extended operation without compromise.

Drivers appreciated the linear torque curve, which provided ample acceleration without requiring constant high revs. The engine’s natural smoothness translated to less stress on the transmission and suspension, extending the entire vehicle’s life.

Servicing intervals were predictable, with timing belts, tensioners, and water pumps designed for routine replacement schedules that emphasized long-term reliability. The M104’s design philosophy included practical accessibility for maintenance.

Major components such as spark plugs, belts, and sensors could be reached without removing multiple assemblies. This attention to serviceability, combined with durable mechanical design, has allowed many M104 engines to surpass 250,000 miles.

Classic Mercedes models equipped with this powerplant remain highly regarded, with enthusiasts praising both its driving refinement and unmatched durability. The M104 illustrates how Mercedes integrated engineering foresight, smooth operation, and practical design to create an inline-six engine that reliably outlasts the vehicles it powers.

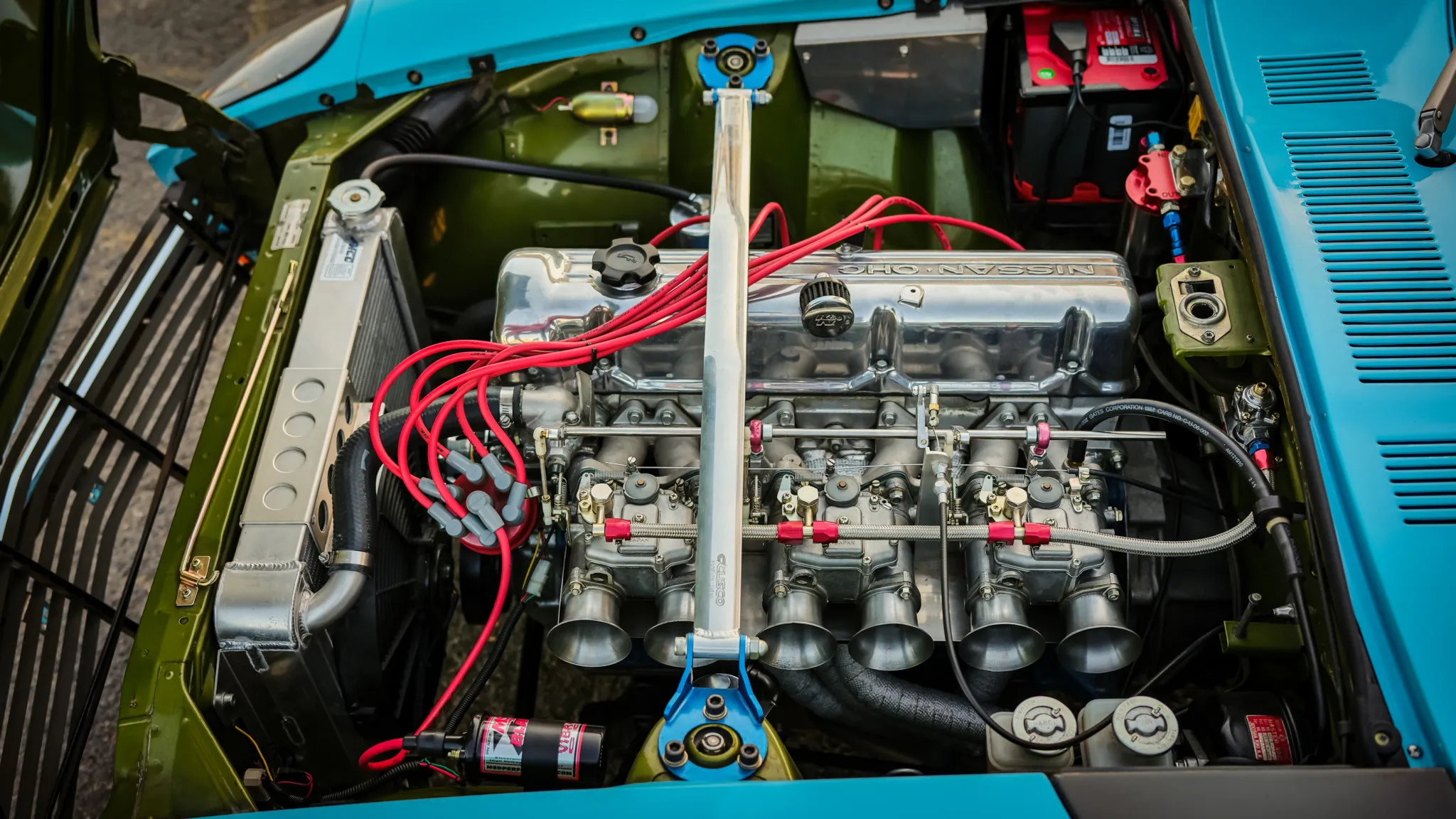

4. Nissan L28 2.8-Liter Inline-Six

The Nissan L28 engine, prominent in the late 1970s and early 1980s, is remembered for longevity and simplicity. Found in the Datsun 280Z sports coupe, the L28 featured a cast-iron block, aluminum head, and robust overhead cam design that offered reliable power and ease of service. Its straightforward architecture made it a favorite for enthusiasts and mechanics alike.

This engine delivered strong low and mid-range torque, ideal for both spirited driving and daily commuting. Carbureted models were simple to maintain, while later fuel-injected versions combined reliability with improved efficiency.

Components such as bearings, valves, and oiling systems were designed to tolerate long-term use without huge wear, allowing the engine to continue operating well past typical service life expectations. Serviceability and tuning flexibility contributed to its reputation.

Owners could easily replace or upgrade carburetors, fuel pumps, or ignition systems. The engine’s simplicity encouraged preventive maintenance, with basic oil and cooling system upkeep allowing many L28s to surpass 200,000 miles. Its mechanical clarity and predictable behavior have earned it respect in both restoration and racing communities.

The L28 remains influential as a testament to thoughtful engineering. Its ability to handle continuous operation, moderate modification, and long-term use without major failure has cemented its legacy as an inline-six that can literally outlive the chassis it inhabits.

Vehicles powered by the L28 continue to be appreciated for their durability, consistent performance, and mechanical honesty, reinforcing the value of conservative engineering combined with attention to component longevity.

5. Jaguar XK 3.8-Liter Inline-Six

Jaguar’s XK engine series, particularly the 3.8-liter variant found in the 1960s Jaguar E-Type, defined British inline-six engineering. This engine paired performance with longevity, featuring an aluminum cylinder head, high-quality bearings, and a well-balanced crankshaft. Its dual overhead camshaft design enabled high rev capability without compromising reliability.

The XK 3.8-Liter delivered smooth power across a broad RPM range, making it suitable for both high-speed cruising and spirited driving. Its design emphasized even heat distribution, precise lubrication, and careful material selection. Maintenance intervals were clearly defined, and the engine responded well to routine service, which contributed to its longevity.

Performance and refinement were married with reliability through robust mechanical choices. Components such as pistons, connecting rods, and timing chains were overbuilt, allowing the engine to operate under stress without failure. Cooling and lubrication systems were designed to support sustained high-speed operation, a requirement for both road and track use.

Owners of E-Types frequently report engines surviving decades, with many examples exceeding 150,000 miles while maintaining power and smoothness. The XK engine demonstrated that inline-six architecture could provide long-term performance, reliability, and mechanical elegance simultaneously.

Its continued presence in restoration projects underscores its reputation as one of the most durable engines ever designed, capable of outlasting the vehicles it powers.

6. Ford Barra 4.0-Liter Inline-Six

The Ford Barra 4.0-liter inline-six engine has established itself as a symbol of endurance and resilience, particularly in Australian vehicles like the Ford Falcon and Territory SUV. Its robust cast iron block, aluminium head, and dual overhead camshaft design were engineered to sustain high mileage under varied driving conditions. The Barra engine emphasizes smooth torque delivery and reliability, making it a preferred choice for both enthusiasts and daily drivers who require dependable performance.

One of the remarkable aspects of the Barra engine is its capacity for forced induction. Turbocharged variants deliver substantial power increases without compromising mechanical integrity, largely because Ford reinforced internal components and optimized cooling systems.

The engine’s architecture minimizes vibrations, distributing mechanical stress evenly across the block and crankshaft, reducing premature wear on ancillary components. Routine service on the Barra is straightforward, with accessible oil filters, spark plugs, and timing chains.

Its timing chain system, unlike belts found in similar engines, provides longevity and less frequent replacement. Cooling efficiency is enhanced through carefully routed coolant passages, which maintain stable operating temperatures even during extended highway travel or spirited driving conditions.

The Barra engine combines everyday usability with performance potential. Its naturally smooth characteristics make urban commuting effortless, while turbocharged variants provide high-end acceleration for spirited driving. Many vehicles powered by the Barra continue to exceed 250,000 miles with attentive maintenance, a testament to Ford’s emphasis on material quality, engineering precision, and component durability.

The engineering philosophy behind the Barra demonstrates that inline-six engines can balance power, refinement, and reliability. It has influenced subsequent Ford powerplants and inspired aftermarket tuning communities to maintain mechanical longevity while increasing output.

Cars equipped with the Barra engine often outlive their expected lifespan, illustrating the enduring qualities of a thoughtfully designed inline-six engine. Its reputation extends across both stock performance and modification circles, proving that durability and versatility can coexist in modern engineering.

7. Chevrolet 250 Inline-Six

Chevrolet’s 250 cubic inch inline-six engine, prominent in trucks and sedans from the 1960s through the 1980s, exemplifies functional reliability and durability. Found in models such as the Chevy C10 and Nova, this engine combined a robust iron block with a smooth overhead valve design to deliver dependable power for decades.

Its simplicity allowed mechanics to service and repair components without specialized tools, contributing to its reputation as an engine that consistently outlives the vehicles it powers. The 250 inline-six produces moderate horsepower but excellent torque, making it suitable for towing, hauling, and everyday commuting. Its mechanical layout emphasizes long-term wear reduction, with well-lubricated bearings, robust pistons, and a straightforward oiling system that reduces maintenance complications.

Cooling efficiency is achieved through a simple yet effective water pump design, ensuring heat is evenly dispersed during sustained operation. Routine maintenance is approachable, even for enthusiasts attempting restorations or modifications.

Carburetor adjustments, ignition tuning, and valve lash settings are easily accessible, encouraging preventive maintenance that extends engine life. Unlike modern engines with intricate electronics, the 250’s mechanical clarity makes it forgiving of minor service delays, contributing to its enduring presence in older vehicles today.

The engine’s reputation for longevity stems from a combination of conservative engineering and material selection. Owners frequently report mileage well over 200,000 with few major interventions, highlighting the Chevrolet 250’s ability to endure daily use, towing, and extended highway driving. Its adaptability across different vehicle platforms, from compact sedans to full-sized pickups, underscores its functional versatility and robust design.

Chevrolet’s 250 inline-six demonstrates that durability does not require complication. It maintains power delivery, tolerates a range of operating conditions, and allows owners to maintain performance without extensive expense.

The engine remains a reference point for enthusiasts and mechanics seeking an inline-six that prioritizes reliability, practical power, and longevity over technological sophistication. Its simplicity, combined with material durability, ensures it continues to outlast the cars it powers.

8. BMW N52 3.0-Liter Inline-Six

BMW’s N52 3.0-liter inline-six, produced between 2004 and 2015, represents a balance between modern technology and mechanical durability. Featuring an aluminum-magnesium composite block, variable valve timing, and direct injection in later models, this engine delivers smooth power and long-term reliability.

It was installed in vehicles including the E90 3 Series, E60 5 Series, and Z4, offering performance without compromising mechanical longevity. The N52 engine was designed to reduce friction, heat stress, and vibration. Lightweight materials and a balanced crankshaft improve efficiency and minimize wear, while the engine’s DOHC layout allows precise control over valve operation.

Cooling systems incorporate dual circuits and efficient water pumps to maintain optimal operating temperatures, ensuring that internal components experience minimal thermal strain. Maintenance is simplified by thoughtful engineering. Spark plugs, oil filters, and drive belts are accessible, making preventive care more manageable for both professional and DIY technicians.

While modern electronics assist with fuel management, the N52 avoids overly complicated systems that could compromise longevity, reflecting BMW’s commitment to reliability alongside refinement. Performance characteristics emphasize smooth torque delivery across the rev range, reducing stress on transmissions and driveline components.

The engine responds predictably, whether driving through urban roads or spirited mountain drives. Many N52 examples exceed 200,000 miles with routine maintenance, demonstrating that advanced engineering can coexist with durability when balanced correctly.

The BMW N52 illustrates that careful attention to materials, design, and serviceability can produce an inline-six engine that remains dependable for years. Its combination of light weight, smooth power delivery, and accessible maintenance has made it a favorite among enthusiasts who desire longevity alongside modern performance.

Vehicles powered by the N52 continue to provide reliable service, confirming that straight-six architecture can meet contemporary expectations for refinement and endurance simultaneously.

9. Toyota 1JZ-GTE 2.5-Liter Inline-Six

The Toyota 1JZ-GTE, produced from 1990 to 2007, is renowned for endurance and robust engineering. Installed in vehicles such as the Toyota Chaser, Soarer, and Aristo, the engine features an iron block, aluminum head, and twin turbochargers.

Its internal components, including forged pistons and reinforced rods, were designed to sustain high horsepower without compromising base reliability, making it one of the most respected inline-six engines ever built. Engine performance is smooth and linear, with substantial torque available from low RPMs.

Cooling circuits and oil pathways are engineered to maintain consistent temperature and lubrication, even during prolonged operation. The DOHC layout and precise fuel injection allow responsive throttle control and predictable power output, ideal for both spirited driving and daily use.

Maintenance routines are approachable. Valve adjustments, timing inspections, and turbo servicing are straightforward for trained technicians, and preventative care can extend engine life far beyond 300,000 miles. The 1JZ-GTE is widely regarded for its capacity to accept forced induction upgrades while retaining base reliability, which has made it a favorite in racing and tuning communities.

Durability, smooth performance, and serviceability contribute to the 1JZ-GTE’s enduring reputation. Many vehicles powered by this engine continue to operate without major intervention decades after production.

Its ability to deliver power reliably, maintain smooth operation, and tolerate performance modifications has cemented it as an engine that outlives its chassis, demonstrating Toyota’s mastery in inline-six engineering and longevity-focused design principles.

Also Read: Top 10 Used Luxury Engines That Refuse to Die

10. Mercedes-Benz OM617 3.0-Liter Diesel Inline-Six

Mercedes-Benz’s OM617 diesel engine, manufactured from 1974 to 1989, has earned an enduring reputation for exceptional reliability. Installed in vehicles such as the W123 300D, this engine combines a cast-iron block, inline-six configuration, and indirect fuel injection to create a powerplant capable of surpassing 500,000 miles with attentive care.

Its engineering emphasizes simplicity, mechanical strength, and fuel efficiency, which allows the engine to remain operational well beyond the expected lifespan of many vehicles. The OM617 delivers abundant torque at low engine speeds, making it particularly suited to heavy sedans, wagons, and light commercial vehicles. Its injection pump and valvetrain are constructed to withstand continuous operation under demanding conditions without failure.

Forged crankshafts and robust bearings provide additional resilience, ensuring the engine maintains structural integrity even during prolonged periods of high load or intensive use. This combination of strength and durability forms the foundation of the OM617’s long-standing reputation.

Routine maintenance for the OM617 is practical and uncomplicated. Standard procedures, including oil changes, fuel injector servicing, and valve adjustments, are accessible and predictable, enabling owners to sustain the engine’s performance over decades.

Unlike modern engines that rely heavily on electronic management systems, the OM617 depends on mechanical engineering principles. This approach reduces potential points of failure while promoting extended service life. Regular attention to these components helps prevent deterioration and maintains operational efficiency.

Material selection, balanced mechanical operation, and conservative design principles contribute to the engine’s extraordinary longevity. Many OM617 units continue to function effectively, often reaching or exceeding 400,000 miles without requiring extensive rebuilds.

Its enduring performance establishes a benchmark for diesel inline-six engines, demonstrating that well-executed engineering and durable construction can produce powerplants that outlast the vehicles they propel.

The OM617 has become a standard reference for engineers, collectors, and automotive enthusiasts seeking evidence of long-term durability. Its ability to deliver consistent power, tolerate prolonged use, and endure heavy loads underscores the value of careful engineering combined with reliable materials.

Vehicles equipped with this engine remain in service decades after production, proving that robust design and practical maintenance create mechanical systems capable of lasting beyond conventional expectations.