When buying a car, most people focus on performance, reliability, or technology, but corrosion resistance is just as critical, especially for long-term ownership. Rust is not merely cosmetic. Once it takes hold, it can compromise structural integrity, safety, and resale value.

In regions with harsh winters, coastal air, or heavy road salt, corrosion can shorten a vehicle’s usable life by years, even decades. This is where smart engineering, material choice, and factory protection make a measurable difference.

In “5 Cars That Resist Rust Better vs 5 That Don’t,” we highlight vehicles that showcase excellent corrosion resistance through galvanization, coatings, and thoughtful design, and contrast them with models that gained unfortunate reputations for premature rust due to cost-cutting, flawed drainage, or inadequate protection.

The comparison shows that rust resistance is not tied to price alone. It is the result of deliberate engineering decisions that either protect a car for the long haul or leave it vulnerable from day one.

5 Cars That Resist Rust Better

1. Volvo S60: Class-Leading Rust Resistance with Scandinavian Refinement

The Volvo S60 is widely recognized as one of the most corrosion-resistant sedans in its class, a result of engineering developed for harsh Scandinavian climates. Designed to endure snow, moisture, and heavy road salt, the S60 uses thick, high-quality galvanized steel across much of its body structure. This zinc-coated steel forms a sacrificial barrier that slows oxidation before rust can take hold.

Volvo reinforces this foundation with factory-applied anti-corrosion treatments injected into doors, cavities, and closed sections, along with durable underbody coatings that protect the chassis and sills from debris and moisture.

A multi-stage paint process adds another protective layer, while careful body engineering reduces metal overlaps where water and dirt typically become trapped.

Corrosion-resistant materials, including aluminum suspension components, further enhance durability. While protection is excellent, early S60 models built between 2001 and 2009 have shown isolated strut tower rust, making routine inspections and prompt repair of paint damage important in salt-heavy regions.

Mechanically, the S60 prioritizes comfort and refinement over outright sportiness. Non-hybrid versions use a 247-hp turbocharged four-cylinder engine with front-wheel or all-wheel drive.

Acceleration is smooth but reserved, with a 0–60 mph time of about 6.1 seconds, slower than more performance-focused rivals. Plug-in hybrid models improve responsiveness significantly, cutting the sprint to roughly 4.1 seconds while still emphasizing composure rather than aggression.

Fuel economy is competitive, reaching up to 35 mpg on the highway in non-hybrid form, while the plug-in hybrid offers strong electric-only capability and reduced fuel use in daily driving. Inside, the S60 delivers a high-quality, minimalist cabin with excellent seats, refined materials, and thoughtful details.

Digital instrumentation, a Google-based infotainment system with smartphone integration, and advanced driver-assistance features are standard. The Volvo S60 blends exceptional rust resistance with comfort, safety, and understated luxury, making it well-suited for drivers seeking durability and long-term peace of mind.

2. Audi Q5: Rust Resistance, Engineering, and Modern SUV Appeal

Audi has a long-standing reputation for corrosion-resistant vehicles, dating back to the mid-1980s when it pioneered fully galvanized body shells. Modern Audis, including the Q5, benefit from this legacy with thick, double-sided zinc coatings that protect steel panels from rust.

The Q5’s corrosion resilience is further enhanced by advanced e-coating processes and high engineering standards, creating a robust barrier against environmental damage. These measures make the Q5 highly durable, even in harsh, high-salt conditions.

Despite its strengths, the Q5 does have some known vulnerabilities. Rear subframes on certain models are prone to rust, often caused by trapped moisture under plastic covers. Severe paint damage or scratches can also lead to localized corrosion over time. To mitigate these risks, owners in harsh climates sometimes use aftermarket treatments, such as Lanoguard or POR15, particularly on exposed subframe components.

The Audi Q5 itself is a mid-sized luxury SUV that has maintained strong sales through multiple generations. The second-generation Q5, launched in 2016 and facelifted in 2021, sold 298,000 units in its final year, significantly outselling the A6.

The third-generation Q5, introduced alongside the Q5 Sportback, continues this success. While the Sportback features a coupe-like sloping roofline, it loses less than 1% of boot space, and in Europe, the Sportback variant has become more popular than the standard SUV.

The new Q5 emphasizes aerodynamics and a sportier stance, with a larger, higher-positioned Singleframe grille, functional air curtains, and updated LED lighting, including optional OLED lights with customizable signatures. UK wheel options range from 19 to 21 inches, and color choices go beyond the usual greys to shades like Grenadine Red, Navarra Blue, and Sakhir Gold.

Under the hood, the base Q5 offers two 201bhp 2.0-liter turbocharged engines, petrol or diesel, paired with a 48-volt mild hybrid system and a seven-speed dual-clutch gearbox. Quattro all-wheel drive is standard, with a plug-in hybrid variant arriving in 2025, offering up to 362bhp in combined output. Performance-focused SQ5 models use a 3.0-liter turbo V6 hybrid setup for 362bhp and 406 lb-ft of torque.

The interior has undergone major upgrades with the ‘Digital Stage,’ featuring an 11.9-inch Virtual Cockpit and a 14.5-inch central touchscreen, with optional passenger-side displays. Five seats, ambient lighting, and premium materials create a refined cabin, though boot space is slightly reduced compared to previous generations.

Pricing starts at $64,000 for the entry-level petrol Sport trims and rises to $95,000 for the SQ5. Key rivals include the BMW X3, Mercedes GLC, Volvo XC60, and Land Rover Discovery Sport. The Q5 blends Audi’s renowned rust resistance, engineering excellence, and modern luxury SUV appeal, making it a versatile option in the premium SUV segment.

3. Lexus RX: Superior Rust Resistance and Comfortable Luxury SUV

As Toyota’s luxury division, Lexus has a strong reputation for building vehicles that resist rust and maintain their finish even in humid or coastal climates. The Lexus RX exemplifies this with high-quality manufacturing, extensive use of galvanized steel, premium anti-corrosion materials, and thorough factory-applied protective coatings.

These measures, combined with rigorous quality control, ensure the RX remains durable over the long term. Additional aftermarket treatments, such as oil-based or lanolin-based sprays like Krown or Fluid Film, can further protect the underbody, frame rails, and cavity panels, particularly in areas prone to road salt.

The RX350 pairs this durable construction with a practical and comfortable drivetrain. It comes standard with a 275-hp turbocharged 2.5-liter four-cylinder engine, an eight-speed automatic transmission, and front-wheel drive, while all-wheel drive is optional. Acceleration is smooth but understated, with an estimated 0–60 mph time of around seven seconds.

The SUV is softly sprung for a luxurious ride, prioritizing comfort and refinement over sporty handling, making it ideal for buyers seeking drama-free daily driving. Maximum towing capacity reaches 3,500 pounds with the optional towing package, placing it on par with competitors like the Mercedes-Benz GLC and Volvo XC60.

Fuel economy is competitive, with EPA ratings of 22 mpg city and 29 mpg highway for front-wheel-drive models, and 21/28 mpg for all-wheel drive. While midpack in efficiency among luxury compact SUVs, it balances performance with reasonable fuel consumption.

Inside, the RX offers a modern and elegant cabin. First-row occupants enjoy high-quality materials, ambient lighting, and open-pore wood trim, while the rear provides adequate space for adults and a 40/20/40 split-folding second-row seat for flexible cargo arrangements.

Cargo capacity is generous, accommodating luggage, groceries, or gear for trips. Infotainment is handled via a standard 9.8-inch touchscreen or optional 14-inch display, with wireless Apple CarPlay and Android Auto connectivity. Premium audio options include a 12-speaker system.

Safety is comprehensive, with standard automated emergency braking that detects pedestrians and cyclists, adaptive cruise control with lane-centering, and lane-departure warning with lane-keeping assist. Warranty coverage includes a four-year/50,000-mile limited warranty, a six-year/70,000-mile powertrain warranty, and one year of complimentary maintenance.

The Lexus RX combines exceptional corrosion resistance with a refined, comfortable driving experience, practical interior space, and modern safety and infotainment features, making it a reliable and appealing choice in the luxury compact SUV segment.

4. Volkswagen Golf: Rust Resistance, Practicality, and Everyday Versatility

The Volkswagen Golf has earned a strong reputation for durability and rust resistance, particularly from the fifth generation onward. Volkswagen employs extensive use of electrolytically galvanized sheet steel, multi-step anti-corrosion paint processes, cavity wax applications, and robust underbody coatings.

These methods, combined with rigorous factory testing simulating 12 years of wear in just six months, ensure the Golf remains protected against moisture, road salt, and environmental damage. Key corrosion-resistant features include galvanized steel panels, advanced painting techniques, structural design that minimizes moisture entrapment, and factory-applied waxes.

Despite these precautions, older models may develop rust on arches, sills, or suspension components over extended exposure, making preventative care such as aftermarket undercoating and regular washing advisable.

The Golf is celebrated as a practical, all-around family hatchback. The latest eighth-generation model balances comfort, functionality, and moderate performance, though it is not the most engaging car on twisty roads.

Its compact yet practical design allows it to compete with both mainstream hatchbacks, like the Vauxhall Astra and Toyota Corolla, and premium rivals, including the BMW 1 Series and Mercedes A-Class. Interior quality remains high, with soft-touch plastics, a solid build, and thoughtful storage solutions.

A 12.9-inch infotainment touchscreen is standard, featuring Volkswagen’s latest software, wireless Apple CarPlay and Android Auto, and voice-activated controls. Optional features include adjustable dampers, Matrix LED headlights, and winter packs for heated seats and steering. Cargo space measures 381 liters, expandable to 1,237 liters with the rear seats folded.

The Golf’s engine lineup caters to a wide range of drivers. Standard petrol and diesel engines offer smooth, efficient performance, while plug-in hybrid models provide up to 88 miles of electric-only range.

Higher-performance variants, such as the GTI, GTE, and Golf R, deliver spirited driving dynamics without compromising comfort on longer journeys. Fuel economy ranges from 50 mpg for smaller petrol engines to over 60 mpg for diesels, with the hybrid offering exceptionally low running costs in urban use.

Safety and reliability are strong points. Euro NCAP awarded the Golf five stars for crash protection, and standard features include automatic emergency braking, lane assist, adaptive cruise control, and multiple airbags. Volkswagen provides a three-year/60,000-mile warranty, which is adequate but shorter than competitors like the Toyota Corolla.

The Volkswagen Golf blends long-lasting corrosion resistance with solid practicality, comfortable daily driving, and broad engine choices. It remains a versatile, dependable option for families and individuals seeking a well-rounded compact hatchback.

5. Honda CR-V: Enhanced Rust Resistance and Practical Compact SUV

The Honda CR-V, particularly from the third generation (2007–2011) onward, has seen significant improvements in corrosion resistance compared to earlier models.

While early Hondas were prone to rust, Honda implemented advanced manufacturing techniques in the mid-2000s, including electro-deposition (E-coating), galvanized steel panels, and durable arch liners to protect the wheel wells from road salt and debris.

These measures, combined with modern paint technology and improved factory sealing, have greatly reduced susceptibility to corrosion. Nevertheless, third-generation CR-Vs in salt-belt regions experienced rear subframe rust, prompting a major recall.

Surface rust can also appear around rear wheel wells, tailgates, and suspension components, making regular undercarriage cleaning and optional anti-rust undercoating highly recommended for longevity.

The CR-V remains a practical, comfortable, and versatile compact SUV. Standard models come with a 190-hp turbocharged 1.5-liter four-cylinder engine paired with a continuously variable automatic transmission (CVT) and either front- or all-wheel drive.

While acceleration is moderate, 0–60 mph in roughly 8.1 seconds, the SUV prioritizes smooth, stable, and comfortable daily driving rather than sporty handling. Hill-descent control and traction-management systems improve low-speed off-road performance, while 18-inch wheels provide balanced ride comfort. Towing capacity reaches up to 1,500 pounds with optional accessories.

Fuel economy is competitive, with EPA estimates of 28/34 mpg city/highway for front-wheel-drive models and 26/31 mpg for all-wheel drive. Real-world testing shows an AWD CR-V achieving approximately 31 mpg on highway routes.

Inside, the CR-V features a modern, driver-focused cabin with honeycomb-textured dash inserts, a partially digital gauge cluster in LX and EX trims, and a 10.2-inch digital display in the EX-L.

Front seats are designed to minimize fatigue, and rear passengers enjoy ample legroom. Cargo space measures 39 cubic feet behind the second row, expandable with the adjustable load floor. Infotainment includes a standard 9-inch touchscreen with Apple CarPlay, Android Auto, navigation, wireless charging, and rear USB-C ports.

Safety is comprehensive, with standard forward-collision warning, automated emergency braking, lane-keeping assist, adaptive cruise control, and driver-attention monitoring. Warranty coverage includes a three-year/36,000-mile limited warranty, a five-year/60,000-mile powertrain warranty, and one year or 12,000 miles of complimentary scheduled maintenance.

The Honda CR-V combines improved rust resistance with a practical, comfortable, and feature-rich package. Its reliability, safety systems, and versatile interior make it a solid choice in the compact SUV segment for families and daily drivers alike.

Also Read: 5 Cars With Simple Long-Term Maintenance vs 5 With Complex Upkeep

5 That Don’t

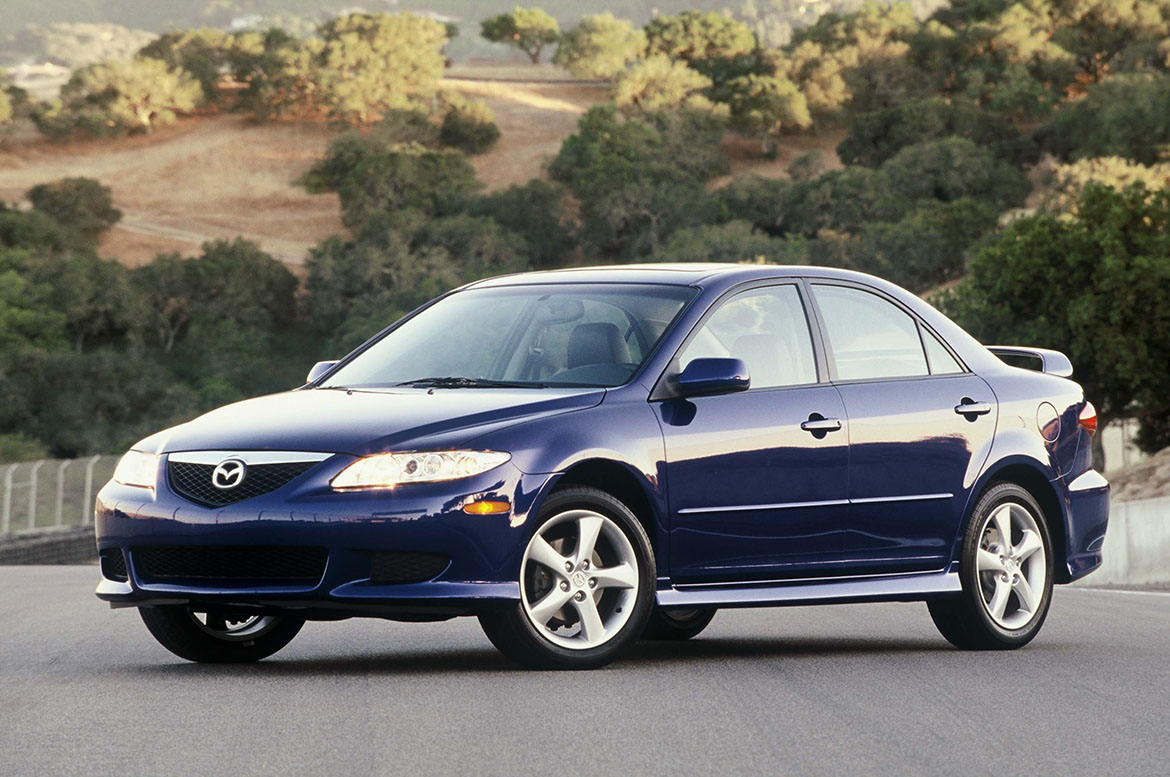

1. Mazda 6 (2004–2012): Rust-Prone Models Require Vigilance

The 2004–2012 Mazda 6 is well-known for severe rust problems, especially around the rear fenders, rocker panels, and front subframe. These issues result from insufficient factory protection, fragile paint, and design features that trap moisture against exposed metal.

Early Mazda 6 models from 2004 to 2008 did not receive the same level of anti-corrosion treatments as competitors. While many manufacturers used heavy galvanization and robust undersealing, Mazda’s steel was more vulnerable to oxidation.

The paint applied during this period was thin and easily chipped by road debris. Once the paint was damaged, the underlying steel, often of lower-grade composition, quickly developed surface and structural rust.

The vehicle’s design contributed to the problem. Rear wheel arches and rocker panels have crevices that collect mud, wet dirt, and road salt. These areas act as moisture traps that accelerate corrosion. Even minor features, such as air conditioning condensation dripping onto the front subframe, increased exposure to moisture, and caused early rusting of critical structural components.

Second-generation models from 2009 to 2012 faced the most serious issues. Insufficient paint on the front suspension subframe led to internal rotting, which could result in suspension parts detaching or the steering rack failing. These problems prompted widespread recalls in regions where road salt is heavily used during winter.

Preventative measures are essential. Prospective owners should inspect the rear arches and front subframe for perforation or brittle metal. Any 2009–2012 model must have completed the official recall repairs for subframe corrosion. Regular maintenance, including annual oil-based undercoating, can help protect the metal from moisture and salt, extending the vehicle’s lifespan.

The Mazda 6 of this generation offers attractive styling and engaging driving dynamics, but requires careful inspection and proactive maintenance to avoid serious rust-related issues and ensure safety.

2. Toyota Tundra (Mid-2000s): Severe Frame Rust Risks

The first-generation Toyota Tundra, particularly models from 2000 to 2006, is notorious for severe frame rust that led to a major class-action lawsuit and extensive recalls. Despite Toyota’s reputation for reliability, these trucks suffered from catastrophic corrosion due to inadequate factory rustproofing, supplier manufacturing defects, and design flaws in the steel frames.

A key factor was insufficient protective coating. Many frames did not receive adequate anti-corrosion treatment at the factory, and in some cases, the coating itself trapped moisture against the metal, accelerating rust.

This problem was compounded by Dana Holding Corporation, the frame supplier, which failed to properly prepare or coat the steel. Holes drilled in the frames or enclosed boxed sections were particularly prone to internal corrosion.

The Tundra’s frame design further worsened the issue. Boxed steel sections allowed water, debris, and road salt to enter but made drainage difficult, creating ideal conditions for rust. Vulnerable points included rear cross-members, leaf spring hangers, and the inside of frame rails near the rear wheels.

These issues were especially severe in northern states where road salt and wet conditions accelerated corrosion. Additionally, the steel used in early frames was more prone to oxidation than competitors, which worsened structural deterioration.

Toyota responded with a long-term safety recall and Special Service Campaigns. Owners of affected trucks could have severely corroded frames replaced at no cost. While the engines and transmissions remained reliable, early Tundras often required extensive repairs to the frame, suspension, and brake lines.

Mid-2000s Toyota Tundras offer durable powertrains but carry a significant risk of structural failure if rust is present. Buyers and current owners should thoroughly inspect frame rails, rear cross-members, and suspension attachment points, particularly in trucks used in cold-weather, salt-heavy regions. Regular maintenance, undercoating, and early remediation are essential to prolong the lifespan of these vehicles.

3. Mercedes-Benz E-Class W210 (1995–2002): Mechanical Durability Overshadowed by Rust

The Mercedes-Benz E-Class W210, produced from 1995 to 2002, is a mechanically robust car known for engines and drivetrains that can exceed 500,000 miles, yet it is infamous for severe rust issues. Doors, fenders, wheel arches, and even structural spring mounts were highly susceptible to corrosion, making this generation a cautionary tale in bodywork durability.

Several factors contributed to the W210’s rust problems. Mercedes-Benz shifted from solvent-based to water-based paints in the early 1990s to meet environmental regulations. While greener, the early application process at the Sindelfingen plant was inconsistent, producing thinner coatings with weaker chemical bonds.

This allowed moisture to penetrate the paint and expose the underlying metal to corrosion, unlike the previous W124 generation, which had far more robust protection.

Corporate strategy changes also played a role. During Jürgen Schrempp’s tenure, Mercedes adopted “target costing,” prioritizing profit margins over engineering.

Cheaper, lower-grade steel replaced higher-quality materials, and cavity waxing and underbody protection were reduced. This left key structural components, such as sills, pillars, and wheel arches, vulnerable to internal corrosion that often went unnoticed until visible damage appeared.

Design flaws further exacerbated rust formation. Front spring perches were welded with thick mastic sealant that eventually cracked, trapping water and salt, risking suspension failure. Door and window seals allowed moisture to sit against poorly primed metal, while plastic wheel arch liners rubbed paint and created micro-abrasions that accelerated fender rust.

The W210 is therefore a dual-natured vehicle: mechanically dependable yet structurally compromised by poor corrosion resistance. Owners benefit from durable engines and drivetrains, but the car’s bodywork requires careful inspection and maintenance, particularly in areas exposed to water, salt, and debris. This generation remains a classic example of a car whose engineering longevity is tragically undermined by preventable rust.

4. Ford Focus Mk1 and Mk2: Practical Engineering Undermined by Premature Rust

Early generations of the Ford Focus, specifically the Mk1 and Mk2 models, earned a strong reputation for sharp handling, dependable engines, and everyday practicality.

Unfortunately, these strengths were often overshadowed by widespread corrosion problems, especially in Rust Belt regions where road salt and moisture accelerated deterioration. In many cases, the body structure succumbed to rust long before the mechanical components showed serious wear.

The most significant contributor to rust in early Focus models was flawed drainage and body design that created moisture traps. Rear wheel arches were particularly vulnerable due to plastic liners that allowed dirt, salt, and water to collect between the liner and the metal body.

This buildup formed a damp “mud shelf” that encouraged corrosion from the inside out. On Mk2 models, water draining from the windshield flowed into front wing channels with inadequate drainage, causing moisture to pool where the wing meets the sill. Over time, this led to severe corrosion in a structurally important area.

Doors and tailgates also suffered from poor water management. Moisture frequently pooled at the bottom seams of doors and rear hatches, attacking the metal from within. Certain trim elements, such as chrome tailgate strips on higher-spec models, further trapped water and accelerated rot in hidden areas.

Manufacturing choices in the early 2000s compounded these issues. To keep costs low, Ford applied relatively thin paint and minimal protective coatings, particularly in concealed areas like inner wings and sills.

While the Focus body was galvanized, the zinc layer was often insufficient in bent, welded, or stressed areas where protection wore away more quickly. Once exposed, bare steel corroded rapidly in wet or salty environments.

Key areas requiring close inspection include the sills and rocker panels, which can suffer structural rot, the rear subframe and suspension mounts, and the lips of the wheel arches, where bubbling paint often signals more serious damage.

Regular maintenance, including pressure washing wheel arches and applying annual underbody protection, is critical to slowing corrosion. Without proactive care, rust can become the defining and ultimately terminal issue for early Ford Focus models.

5. Jeep Wrangler JK (2007–2018): Off-Road Toughness with Hidden Rust Risks

The Jeep Wrangler JK is celebrated for its rugged off-road capability and classic body-on-frame construction, but it is also well known for significant rust issues, particularly underneath the vehicle. These problems are largely tied to the Wrangler’s boxed steel frame and limited factory corrosion protection, which together create ideal conditions for hidden, structural rust.

At the core of the issue is what owners often call the “inside-out” rust problem. The JK uses a fully boxed frame to provide strength and torsional rigidity for off-road use. However, the frame includes multiple access holes that allow mud, sand, snow, and road salt to enter.

Once inside, this debris retains moisture against bare or lightly protected steel. Because the interior of the frame lacks sufficient drainage and protective coatings, corrosion often develops unseen until it becomes severe. In many cases, the frame may appear solid externally while suffering major internal deterioration.

Several areas are especially vulnerable. The frame rails around control arm mounts and transmission skid plates frequently trap debris, and corrosion here can compromise critical suspension mounting points.

Floor pans are another common trouble spot, as water can leak into the cabin through soft tops or worn door seals, soaking carpets and allowing rust to form from the inside. The gas tank skid plate is notorious for collecting salt and grime, often becoming one of the first components to rot. Door hinges also suffer, as chipped paint exposes steel to the elements and leads to surface rust.

Preventing rust on a Wrangler JK requires consistent and proactive maintenance. Many owners regularly flush the undercarriage with water to remove salt and mud, sometimes using lawn sprinklers placed beneath the vehicle. Some also add small drainage holes at low points in the frame to reduce water retention.

Long-term protection is best achieved with oil-based or lanolin-based rust inhibitors such as Fluid Film, Woolwax, or professionally applied treatments like Krown. Without these measures, rust can quietly undermine the structural integrity of an otherwise capable off-road vehicle.

The cars featured in this comparison make one thing clear: rust resistance is rarely accidental. Vehicles that hold up well over time benefit from robust galvanization, effective drainage design, quality paint systems, and thorough underbody protection.

Brands like Volvo, Lexus, Audi, and Volkswagen demonstrate how corrosion prevention can be engineered into a vehicle from the outset, preserving both safety and value across years of use.

On the other side, the rust-prone models show how design compromises, supplier issues, or insufficient coatings can undermine otherwise solid mechanical platforms. In many cases, these cars offer great engines, handling, or comfort, but their long-term durability is compromised by corrosion that begins out of sight and worsens quietly.

Rust resistance should be a key consideration when buying new or used, especially in challenging climates. A car that resists corrosion well does more than look better with age. It lasts longer, costs less to maintain, and remains safer to drive. In the long run, smart rust protection is one of the most valuable features a car can have.

Also Read: Top 10 Cars Under $20K That Fool Everyone Into Thinking You’re Rich