Inline six engines have earned a special place in automotive history, not only for their smooth power delivery but also for their incredible longevity. For decades, manufacturers have relied on this engine layout in everything from family sedans to heavy duty trucks.

When built with durability in mind and properly maintained, some inline six engines have proven capable of running for hundreds of thousands of miles with remarkable consistency.

One of the biggest advantages of the inline six design is balance. The natural mechanical harmony of six cylinders arranged in a straight line reduces vibration and stress on internal components.

Less vibration means less wear over time, which directly contributes to long term reliability. These engines often feel smooth even after years of use, a sign of well managed internal forces.

Another factor is simplicity. Many legendary inline six engines were designed during eras when reliability mattered more than squeezing out every last bit of horsepower. They used strong blocks, conservative tuning, and straightforward mechanical layouts. This made them easier to maintain and less likely to suffer catastrophic failures.

Cooling and lubrication systems in these engines also tend to be robust. With long engine blocks, engineers often designed efficient coolant flow and durable oiling systems to keep temperatures and friction under control. When owners follow basic maintenance schedules, these engines can keep running well past typical expectations.

Inline six engines also benefit from strong enthusiast and professional support. Their long production runs mean parts are widely available and mechanics are familiar with their design. This makes it practical to repair and maintain them for decades.

Here are ten inline six engines that have become famous for extreme longevity. We will start with two legendary examples known around the world for their toughness and ability to survive the harshest conditions.

Also Read: Top 10 High-End Sedans That Combine Comfort With Serious Performance

1. Toyota 2JZ GE and 2JZ GTE

The Toyota 2JZ engine family is widely considered one of the most durable and long lasting inline six designs ever produced. Found in a range of Toyota vehicles, the naturally aspirated 2JZ GE and the twin turbo 2JZ GTE both share a strong foundation that has earned global respect for reliability.

One of the main reasons for the 2JZ’s longevity is its robust cast iron block. Unlike many modern engines that prioritize light weight, the 2JZ was built for strength.

The block can handle significant stress and heat without warping or cracking, which allows it to survive long periods of hard use. Even in stock form, these engines often reach very high mileage with minimal internal wear when properly maintained.

The bottom end design is another major strength. Strong connecting rods, a durable crankshaft, and well designed bearings contribute to long term reliability. The engine was engineered with a safety margin that allows it to handle more power than it was originally rated for, which is why it remains popular with enthusiasts seeking performance upgrades.

Cooling and oiling systems are also well thought out. The engine maintains stable operating temperatures when radiators and water pumps are in good condition. Regular oil changes help protect internal components, and the oiling system distributes lubrication effectively throughout the engine.

The cylinder head design supports smooth airflow and reliable operation. Valve train components are durable when serviced properly, and the engine generally avoids many of the complex failure points seen in newer designs. This mechanical simplicity helps extend service life.

Another factor in the 2JZ’s reputation is the large global community that supports it. Parts availability is strong, and technical knowledge is widespread. Owners know how to maintain these engines and address small issues before they become major problems.

Real world examples of 2JZ engines surpassing extremely high mileage are common. Many continue to run smoothly decades after production. With its combination of strong construction, conservative engineering, and excellent support, the 2JZ stands as one of the most celebrated inline six engines for extreme longevity.

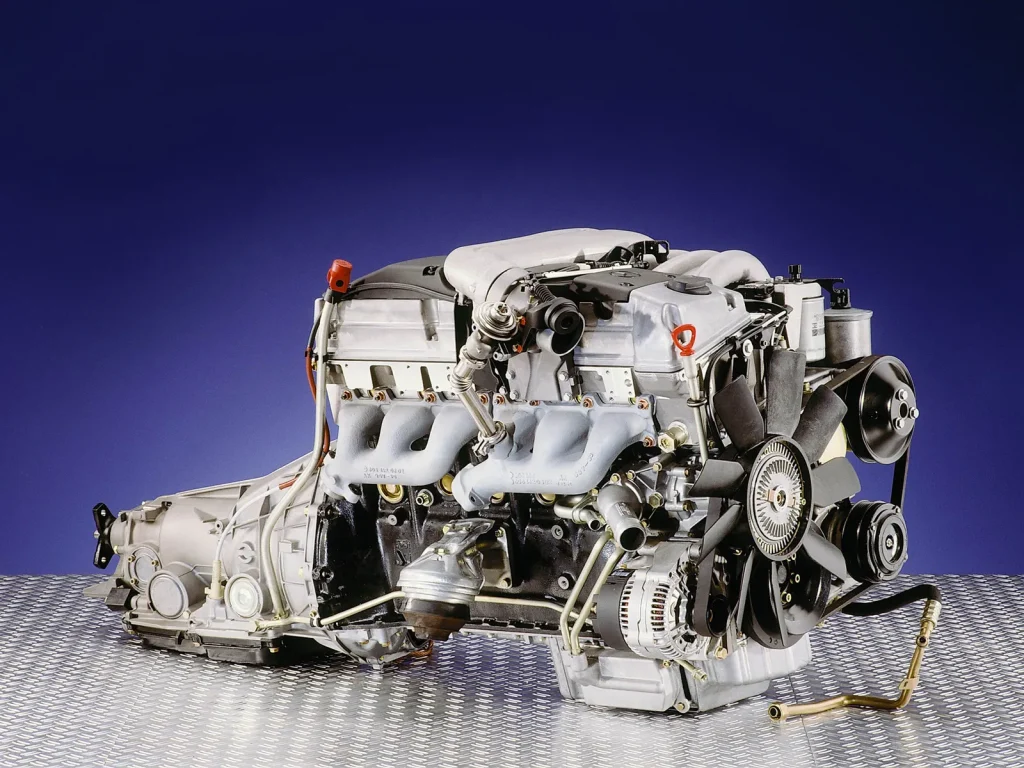

2. BMW M30

The BMW M30 inline six is one of the longest running and most respected engines in the company’s history. Produced for several decades, it powered a wide range of BMW models and became known for its strength, smoothness, and ability to accumulate very high mileage when properly cared for.

A major reason for the M30’s durability is its solid construction. The engine uses a cast iron block and an aluminum cylinder head, a combination that balances strength and heat management. The block is known for its toughness, and internal components are designed to handle long term use without excessive wear.

The engine’s design is relatively simple compared to many modern units. Fewer complex systems mean fewer potential failure points. When owners keep up with oil changes and cooling system maintenance, the M30 often continues to run reliably for many years. Stable oil pressure and good lubrication are key to preserving internal components.

Cooling system care is especially important in older engines, and the M30 responds well to preventative maintenance. Replacing radiators, water pumps, and hoses before failure helps maintain proper operating temperatures. Avoiding overheating significantly extends the engine’s lifespan.

The M30 also benefits from conservative tuning in many applications. Power output is strong but not extreme, which reduces stress on pistons, rods, and bearings. This balance between performance and durability contributes to its long service life.

Another factor is the engine’s smooth operation. The inherent balance of the inline six layout reduces vibration and mechanical stress, helping internal parts last longer. Even high mileage engines often retain a refined feel when properly maintained.

Parts availability remains good due to the engine’s long production run. Enthusiasts and specialists have extensive experience with the M30, making repairs and maintenance more manageable. This support network helps keep many examples on the road decades after they were built.

The BMW M30’s blend of strength, simplicity, and smooth performance has earned it a place among the most durable inline six engines ever made. With proper care, it has proven capable of delivering reliable service far beyond what many drivers expect.

3. Mercedes Benz OM606

The Mercedes Benz OM606 is widely regarded as one of the most durable diesel inline six engines ever produced. Built during an era when Mercedes focused heavily on long term reliability, this engine earned a reputation for surviving extreme mileage with proper maintenance.

Its combination of strong construction and conservative tuning has made it a favorite among drivers who value longevity above all else.

One of the main reasons for the OM606’s toughness is its cast iron block. Diesel engines operate under high compression, and this engine was designed to handle those stresses over many years. The block resists warping and cracking, even under heavy loads, which helps maintain internal integrity as mileage climbs.

The bottom end is equally robust. Strong connecting rods, a durable crankshaft, and high quality bearings allow the engine to operate smoothly over long distances. These components were engineered with a safety margin, meaning the engine is not constantly working at its limits during normal driving.

Fuel system durability also plays a role. Mechanical injection systems in many OM606 versions are known for their reliability and simplicity. With clean fuel and regular servicing, these systems can operate for a very long time without major failures. This reduces the number of complicated electronic issues that can affect newer diesel engines.

Cooling system care remains important, but the OM606’s design helps maintain stable temperatures when properly maintained. Replacing water pumps, thermostats, and hoses at regular intervals helps prevent overheating, which is one of the few factors that can shorten engine life.

Lubrication quality is another key to longevity. Regular oil changes with the correct oil help protect internal components from wear. Because the engine was designed for long service intervals, it responds well to consistent, high quality maintenance.

Many examples of the OM606 have surpassed extremely high mileage while still running smoothly. Its reputation has spread worldwide, and parts availability remains good thanks to the engine’s popularity.

The OM606 stands as a prime example of Mercedes engineering focused on durability, making it one of the most celebrated inline six engines for long term reliability.

4. Ford 300 Inline Six

The Ford 300 cubic inch inline six is one of the most legendary engines ever used in American trucks. Known for its durability, simplicity, and strong low end torque, this engine built a reputation for lasting well beyond typical expectations. It became a workhorse powerplant that owners trusted for decades of heavy use.

A major factor in the Ford 300’s longevity is its heavy duty cast iron block and head. This engine was built to handle tough conditions, from hauling heavy loads to operating in demanding work environments. The strong construction allows it to resist wear and maintain structural integrity even after many years of service.

The engine’s low revving nature also contributes to its durability. Designed to produce torque at low engine speeds, it rarely operates at high RPM in normal use. Lower engine speeds mean less internal stress, which helps pistons, rods, and bearings last longer.

Mechanical simplicity is another advantage. The Ford 300 uses straightforward systems that are easy to maintain and repair. Fewer complex components reduce the chances of major failures and make it easier for owners to keep the engine running well over time.

Cooling and lubrication systems are robust as well. When owners maintain proper coolant levels and change oil regularly, the engine tends to run at stable temperatures and maintain good internal lubrication. These basic maintenance practices go a long way toward extending its lifespan.

Parts availability and widespread familiarity also help. Because the engine was produced in large numbers for many years, replacement parts are easy to find and affordable. Mechanics know how to service it, which keeps repair costs reasonable.

Real world examples of Ford 300 engines reaching extremely high mileage are common. Many continue to run reliably in work trucks long after other components have been replaced. Its combination of strength, simplicity, and torque-focused design has made it one of the most respected inline six engines ever built.

5. Jeep 4.0 Liter Inline Six

The Jeep 4.0 liter inline six is one of the most famous engines ever installed in sport utility vehicles and off road vehicles.

Known for its toughness and ability to run reliably in harsh conditions, it developed a reputation for longevity that few modern engines can match. This engine became a symbol of durable American engineering and remains highly respected among enthusiasts.

One of the main reasons for the 4.0’s durability is its strong cast iron block and head. Built to withstand off road use and heavy loads, the engine was designed with a focus on strength rather than light weight. This robust construction helps it resist wear and maintain compression even after many years of use.

The engine’s design is also relatively simple. Compared to newer engines with complex electronics and advanced systems, the 4.0 uses straightforward mechanical components that are easier to maintain. This simplicity reduces the chances of major failures and makes it more forgiving of minor maintenance delays.

Torque focused tuning is another advantage. The engine produces strong low end torque and does not rely on high RPM operation to deliver performance. Lower engine speeds reduce internal stress on pistons, rods, and bearings, which contributes to longer service life.

Cooling system care is important, but the engine is generally tolerant when maintained properly. Replacing water pumps, radiators, and hoses before failure helps prevent overheating. When temperatures are kept under control, the engine continues to run smoothly for very high mileages.

Oil changes are equally critical. Consistent lubrication protects internal components and reduces wear over time. Owners who follow regular service schedules often see engines that continue running well past typical expectations.

Another factor is widespread parts availability and mechanical familiarity. Because the engine was used for many years, parts are affordable and easy to find. Mechanics are familiar with its design, which makes repairs straightforward.

Many examples of the Jeep 4.0 inline six have surpassed extremely high mileage while still operating reliably. Its combination of strong construction, simple design, and torque rich character has earned it a place among the most celebrated inline six engines for long term durability.

6. Toyota FZ Series Inline Six

The Toyota FZ series inline six, most notably the 1FZ FE, is known for its incredible durability in demanding environments. Used in heavy duty utility vehicles and off road platforms, this engine was built to handle tough conditions where reliability is more important than cutting edge performance. Its reputation for longevity is well earned.

One of the key reasons for the FZ engine’s long life is its heavy duty construction. The cast iron block provides excellent strength, allowing the engine to handle high loads and long periods of operation without structural issues. Internal components are designed for endurance rather than maximum power output.

The engine’s conservative tuning also plays a major role. Power delivery is smooth and predictable, with a focus on torque and reliability rather than high revving performance. This reduces stress on internal parts and helps the engine maintain its integrity over time.

Cooling systems in vehicles equipped with the FZ engine are built for harsh conditions. When maintained properly, these systems help keep engine temperatures stable even during extended off road use or heavy towing. Stable operating temperatures are critical for long term engine health.

Lubrication is another strength. Regular oil changes with the correct oil help protect bearings, pistons, and camshaft components from wear. Because the engine is not highly stressed in stock form, proper lubrication allows it to run reliably for many years.

Mechanical simplicity is also important. While modern enough to be efficient, the FZ engine avoids unnecessary complexity. This makes it easier to maintain and less prone to electronic related issues as it ages.

Parts availability and global support further enhance its longevity. These engines are used worldwide, and many have accumulated extremely high mileage in challenging conditions. Owners and mechanics know how to care for them, which helps keep them running for decades.

The Toyota FZ series inline six stands as a prime example of an engine built for endurance. Its combination of strength, conservative design, and proven reliability has earned it a place among the most respected inline six engines for extreme longevity.

7. Nissan RB Series Inline Six

The Nissan RB series inline six engines have become famous not only for their performance potential but also for their long term durability when properly maintained.

Built with strong internal components and a solid iron block, these engines earned a reputation for surviving high mileage as well as increased power levels. Their combination of strength and smooth operation has made them respected worldwide.

One of the key reasons for the RB engine’s longevity is its cast iron block. This heavy duty foundation allows the engine to handle stress and heat without warping or cracking. Even under spirited driving, the block maintains structural integrity, which is critical for long term reliability.

The bottom end components are also built with durability in mind. Strong crankshafts, connecting rods, and pistons allow the engine to run smoothly over many years. When oil changes are performed regularly and quality lubricants are used, internal wear remains low.

Cooling system care is important, especially in turbocharged versions, but the engine responds well to proper maintenance. Radiators, water pumps, and hoses should be kept in good condition to prevent overheating. Stable operating temperatures help extend the life of internal components.

The engine’s smooth nature also contributes to longevity. Inline six engines are naturally balanced, which reduces vibration and mechanical stress. Lower vibration levels help protect bearings and other moving parts from excessive wear.

Another factor is the large enthusiast and professional support network. Because the RB series is popular, parts are widely available and technical knowledge is extensive. Owners know how to address common maintenance needs and prevent small issues from becoming major problems.

Many RB engines have accumulated high mileage in both daily driving and performance applications. When maintained properly and not pushed beyond their limits without upgrades, they can provide many years of dependable service.

Their blend of performance capability and solid construction has secured their place among the most respected inline six engines for long term reliability.

8. Chevrolet Stovebolt Inline Six

The Chevrolet Stovebolt inline six is one of the earliest American engines to earn a reputation for extreme durability. Produced for decades in various forms, it powered countless cars and trucks and became known for its ability to run reliably under tough conditions. Its simple design and rugged construction helped it become a symbol of long lasting engineering.

One of the main reasons for the Stovebolt’s longevity is its cast iron block and head. Built during a time when strength and reliability were priorities, the engine was designed to handle years of daily use. Thick castings and durable components helped it resist wear even when maintenance was not perfect.

The engine’s low compression and modest power output also contributed to its long life. Because it was not highly stressed, internal components experienced less strain. This allowed pistons, rods, and bearings to last longer than in more aggressive performance engines.

Mechanical simplicity is another key factor. The Stovebolt uses straightforward systems that are easy to understand and repair. Owners with basic mechanical knowledge can perform many maintenance tasks themselves, which helps keep the engine in good condition over time.

Cooling and lubrication systems are simple but effective. When coolant and oil levels are maintained and changed regularly, the engine tends to operate within safe temperature ranges and maintain proper lubrication. These basic maintenance practices are often enough to keep the engine running for decades.

Parts availability remains good thanks to the engine’s long production run and popularity with restorers. Mechanics and enthusiasts have extensive experience with its design, making repairs manageable even today.

Many Stovebolt engines have survived extremely high mileage and long service lives in both cars and trucks. Its combination of rugged construction, simple engineering, and forgiving nature has made it one of the most celebrated inline six engines for longevity in automotive history.

9. Cummins 5.9 Liter 12 Valve Inline Six

The Cummins 5.9 liter 12 valve inline six diesel engine is widely regarded as one of the most durable powerplants ever installed in a production vehicle.

Known for its mechanical simplicity and heavy duty construction, this engine has built a reputation for extreme longevity in demanding work environments. Many examples have surpassed very high mileage while still running reliably.

A major reason for the engine’s durability is its cast iron block and head. Built to handle high compression and heavy loads, the engine is designed with strength as a top priority. The internal components are robust, allowing it to operate under stress for extended periods without excessive wear.

The mechanical fuel injection system is another key factor. Unlike modern electronic systems, the 12 valve Cummins uses a straightforward injection pump that is known for reliability when maintained properly. This simplicity reduces the number of potential electronic failures and makes the engine easier to service.

The engine’s low revving nature also contributes to its long life. Designed to produce strong torque at low engine speeds, it rarely operates at high RPM during normal use. Lower engine speeds mean reduced stress on moving parts, which helps extend service life.

Cooling and lubrication systems are equally important. When owners maintain proper coolant levels and perform regular oil changes, the engine maintains stable operating temperatures and good internal lubrication. These basic practices go a long way toward preventing premature wear.

Another factor in the engine’s longevity is widespread support. Because it is so popular, parts are widely available and mechanics are familiar with its design. This makes repairs more affordable and encourages owners to maintain their engines rather than replace them.

Real world examples of the Cummins 5.9 liter 12 valve running for extremely high mileages are common. Its combination of heavy duty construction, mechanical simplicity, and torque focused design has made it one of the most celebrated inline six engines for long term durability.

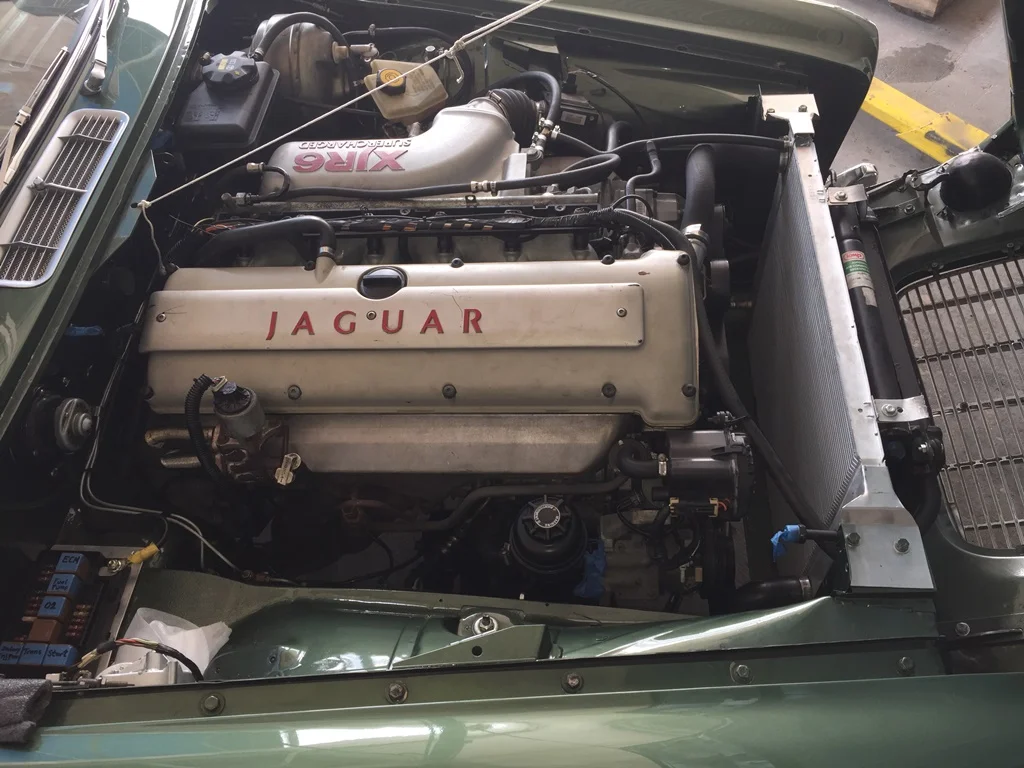

10. Jaguar AJ6 Inline Six

The Jaguar AJ6 inline six engine stands out as a refined yet durable design that helped restore confidence in Jaguar reliability. Developed with modern engineering methods and high quality materials, the AJ6 combined smooth performance with long term dependability, earning it recognition among engines known for longevity.

One of the key strengths of the AJ6 is its strong block and head construction. Designed to handle sustained use without excessive wear, the engine balances performance and durability. Proper cooling and lubrication allow it to maintain internal integrity over many years of service.

The engine’s smooth operation is another important factor. As an inline six, it benefits from natural balance that reduces vibration. Lower vibration levels help protect bearings and other moving parts from stress, contributing to long service life.

Fuel injection and engine management systems in the AJ6 were advanced for their time yet generally reliable. When sensors and wiring are maintained, these systems help the engine run efficiently and smoothly, reducing strain and wear.

Cooling system maintenance remains important, but the AJ6 responds well to preventative care. Replacing water pumps, thermostats, and hoses at appropriate intervals helps prevent overheating, which is one of the few issues that can shorten engine life.

Lubrication quality is equally critical. Regular oil changes protect camshafts, bearings, and other internal components. Owners who follow service schedules often see engines that continue to run smoothly for very high mileages.

Parts availability and specialist knowledge support long term ownership. Because the engine was used in multiple Jaguar models, technical expertise remains accessible. This makes it practical to keep these engines running for decades.

The Jaguar AJ6 proves that an engine can deliver both refinement and durability. Its combination of smooth performance, solid engineering, and proven reliability secures its place among the most celebrated inline six engines known for extreme longevity.

Also Read: Top 10 Affordable Muscle Cars From The 1970s Still Available Today