After years of grappling with technical hurdles, Tesla has reportedly achieved a major milestone in its quest to master dry electrode coating for its 4680 battery cells. This breakthrough signifies a potential game-changer for Tesla’s ambitions in in-house battery production.

By significantly reducing manufacturing costs, the new development could accelerate the rollout of these next-generation batteries. According to industry reports, Tesla is targeting the end of 2024 for bringing the improved 4680 cells to market. This news comes on the heels of a period marked by significant uncertainty surrounding Tesla’s battery strategy.

Recent reports and workforce reductions sparked speculation that the company might be entirely abandoning its internal battery development efforts, especially considering the longstanding challenges in perfecting dry electrode coating technology.

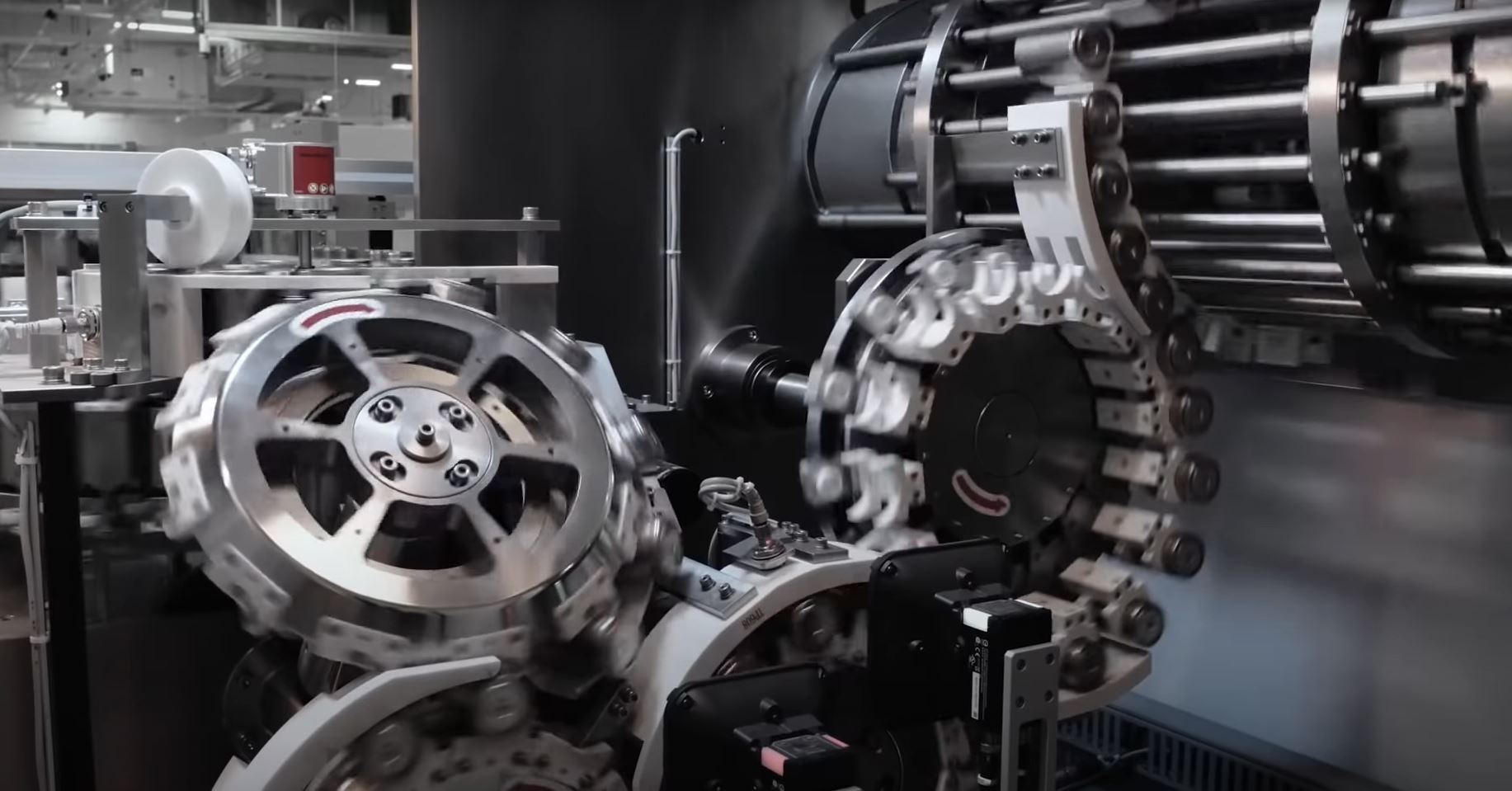

Tesla’s acquisition of Maxwell Technologies in 2019 was a strategic move fueled by the potential of its dry electrode coating process for battery manufacturing. However, translating that potential into reality proved to be a formidable obstacle.

Now, with this apparent breakthrough, Tesla seems poised to unlock the cost-saving and efficiency benefits promised by dry electrode coating, potentially transforming the economics of battery production.

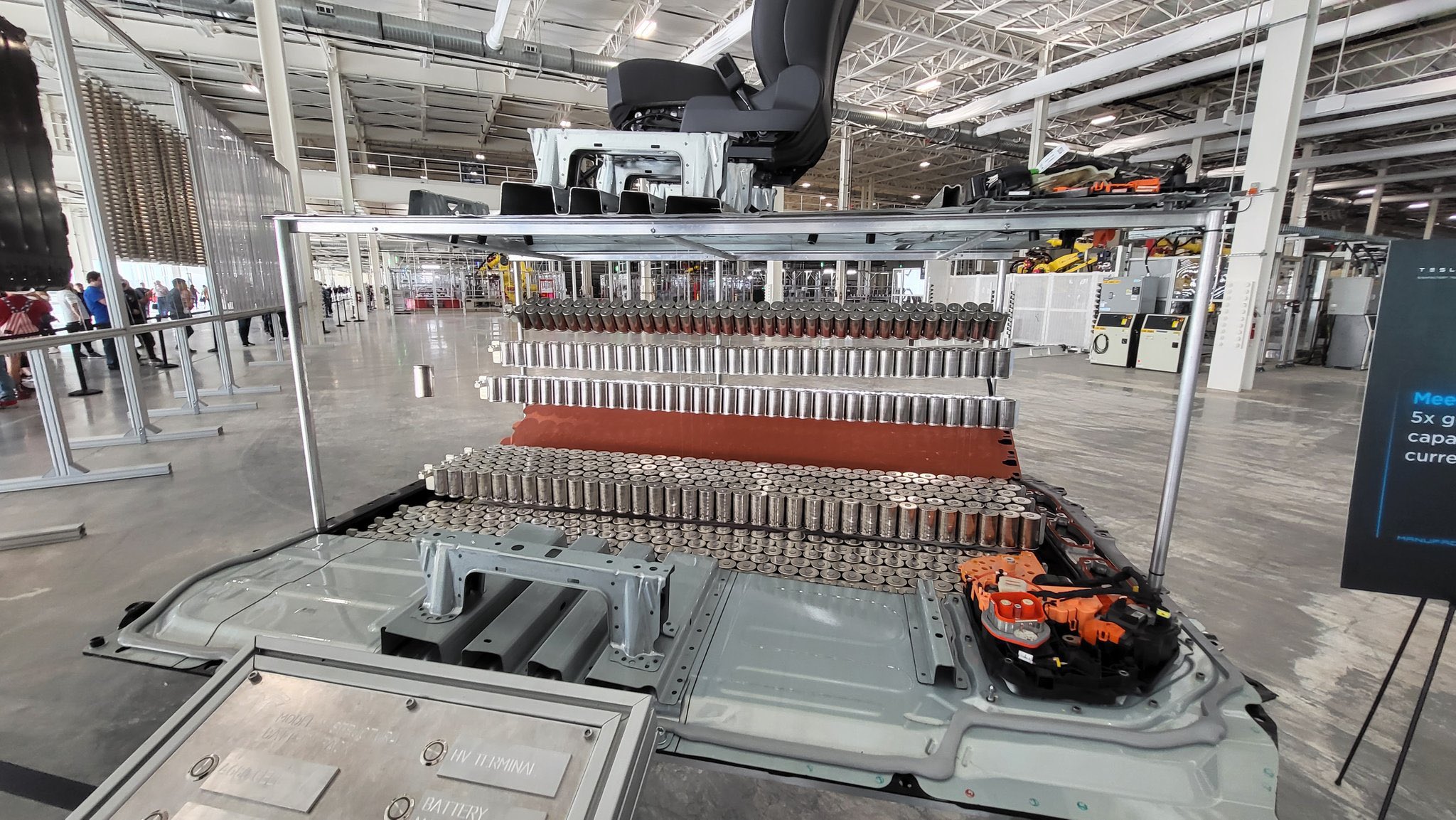

Tesla’s 4680 battery holds the promise of a significant leap forward in electric vehicle technology, boasting advantages in range, charging speed, and ultimately affordability. However, a key hurdle has been the incomplete implementation of the Dry Electrode Process (DBE) for the cathode, the more expensive component.

While the anode currently benefits from DBE’s cost-saving advantages, cathode production has relied on traditional wet methods and external suppliers, driving costs up compared to Tesla’s earlier 2170 cell design.

Recent reports offer a glimmer of hope. Tesla seems to have cracked the code on mass-producing DBE cathodes, potentially unlocking substantial cost reductions and ushering in a new era of battery affordability.

This achievement, if realized, could be a game-changer for Tesla’s battery ambitions. By overcoming this technical hurdle, Tesla can position the 4680 cells as a more compelling option within the electric vehicle market, potentially accelerating the transition to clean transportation.

But the road ahead isn’t without its challenges. Scaling up DBE cathode production efficiently will require further optimization, and Tesla will need to demonstrate the process can be translated from the lab to the factory floor without sacrificing quality or yield. Nevertheless, this reported breakthrough signifies a major step forward for Tesla’s battery technology and its potential to reshape the electric vehicle world.