Factory floors have long been the domain of robotic automation, their presence so commonplace that their origins are often overlooked. These industrial machines, however, are typically specialized tools, their physical form reduced to essential functions. A transformative shift is underway as companies worldwide develop humanoid robots, machines with the potential to mimic human form and function.

These advanced robots are poised to revolutionize manufacturing, offering versatility and adaptability unmatched by their predecessors. Equipped with the capacity to manipulate objects, handle challenging situations, and potentially even understand and respond to human cues, humanoid robots could become indispensable collaborators on the factory floor.

Their integration promises to redefine industrial processes, increase efficiency, and potentially enhance worker safety. As research and development in this field accelerate, the factory of the future may be populated by a dynamic interplay of human and humanoid labor, challenging traditional notions of industrial production.

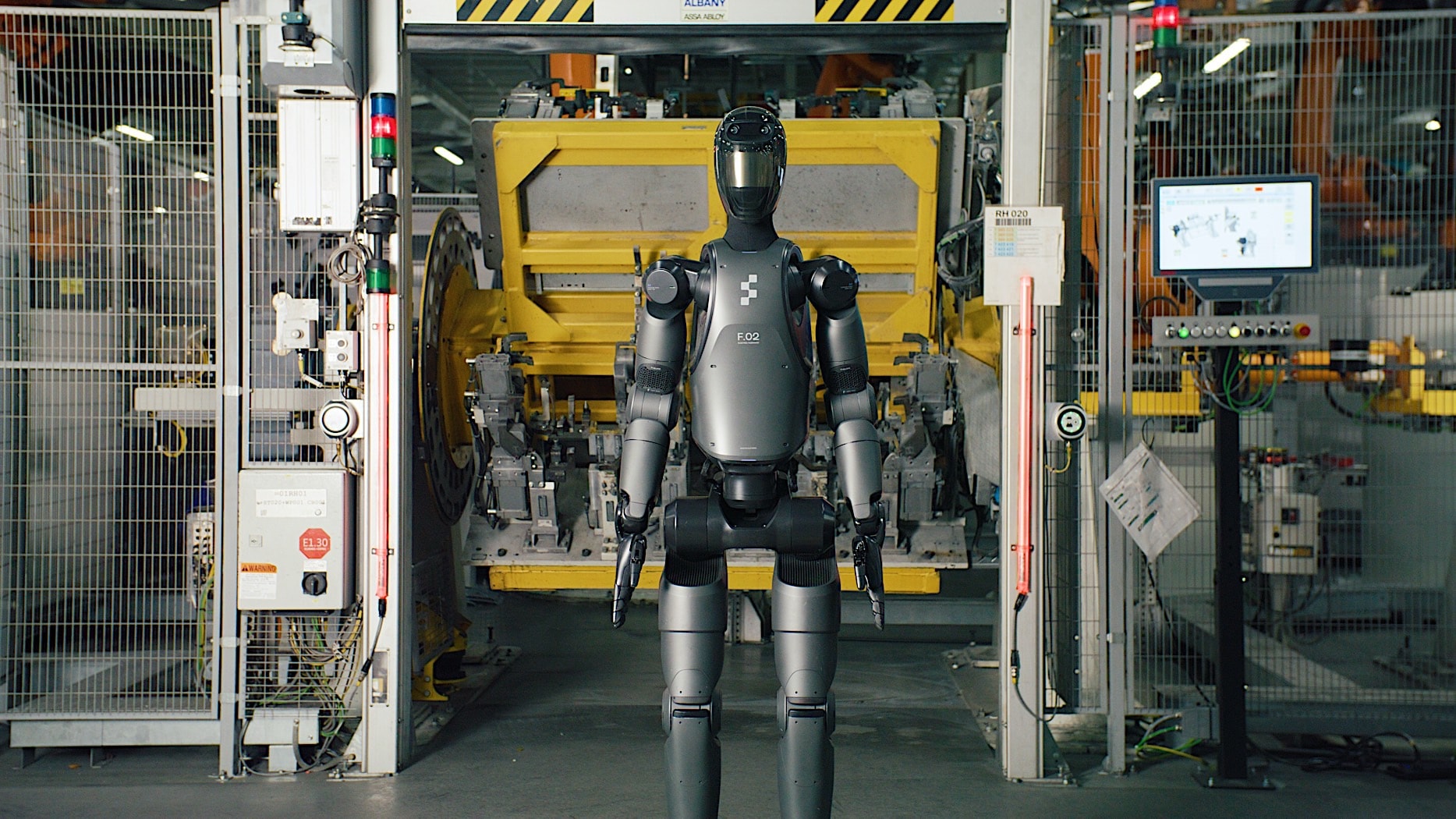

The automotive industry is on the brink of a transformative shift, driven by the rapid advancement of robotics. While the concept of humanoid robots in manufacturing remains largely speculative, BMW has taken a significant stride toward realizing this vision. Their recent collaboration with a California-based robotics company has resulted in the deployment of Figure 02, a sophisticated humanoid robot, on their assembly line.

This groundbreaking achievement marks a pivotal moment, showcasing the potential for robots to not only complement human workers but also take on complex tasks previously thought exclusive to human capabilities. A marvel of engineering, stands at human height and possesses an uncanny resemblance to its organic counterparts.

Equipped with advanced sensors, cameras, and remarkably dexterous hands, this robot has demonstrated an ability to interact with the assembly environment with precision and efficiency. As it maneuvers through the complex procedures involved in making cars, it offers a look into a future where human-robot collaboration becomes the norm.

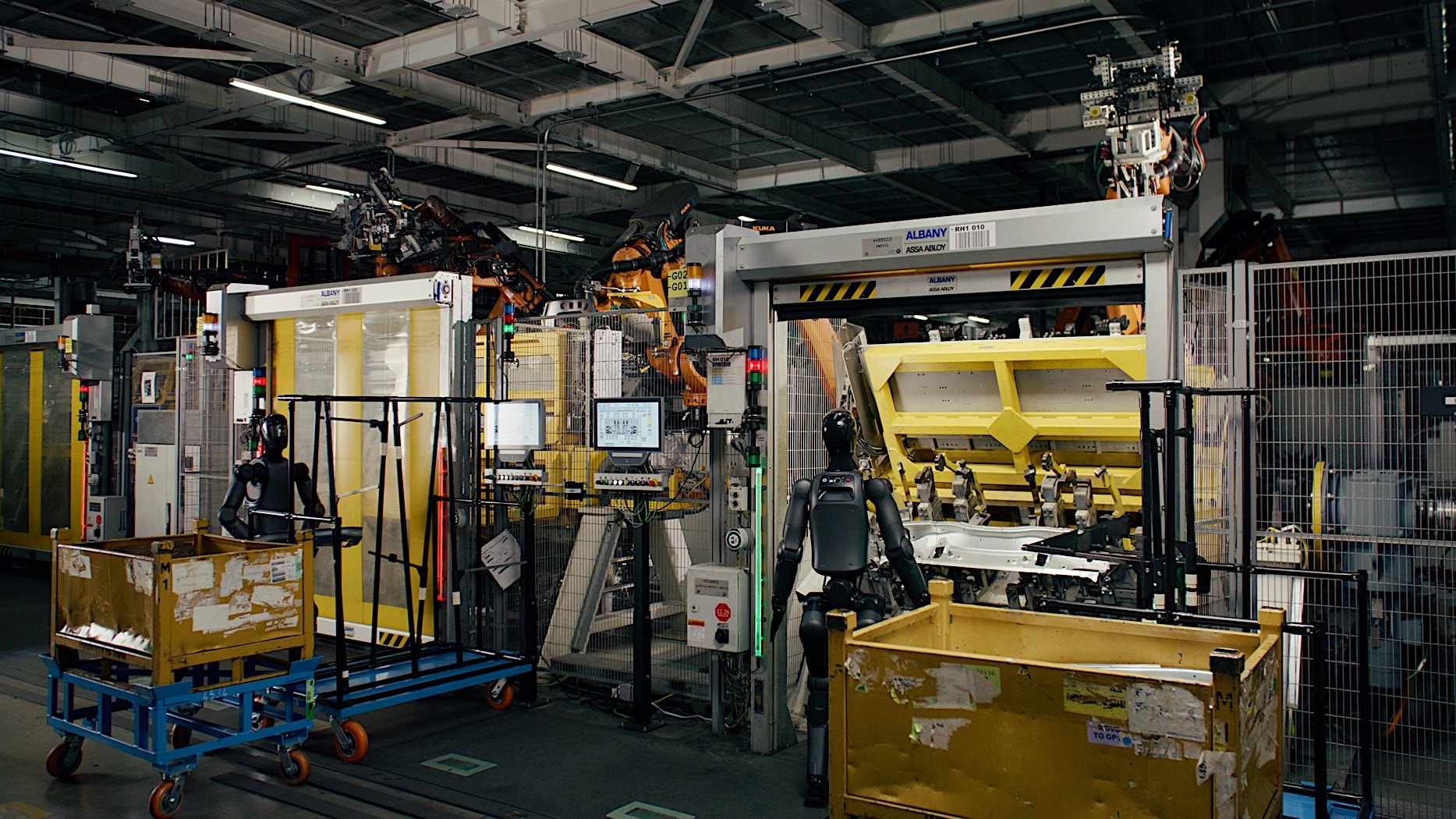

While Mercedes-Benz is gearing up to introduce its humanoid robot, Apollo, primarily for logistics and assembly kit management, BMW’s integration of Figure 02 into the core production process signifies a bolder and more ambitious approach.

This development underscores the accelerating pace of technological innovation within the automotive industry. As robots like Figure 02 continue to evolve, it is conceivable that they will play an increasingly vital role in shaping the factories of tomorrow. The implications for productivity, efficiency, and worker safety are profound.

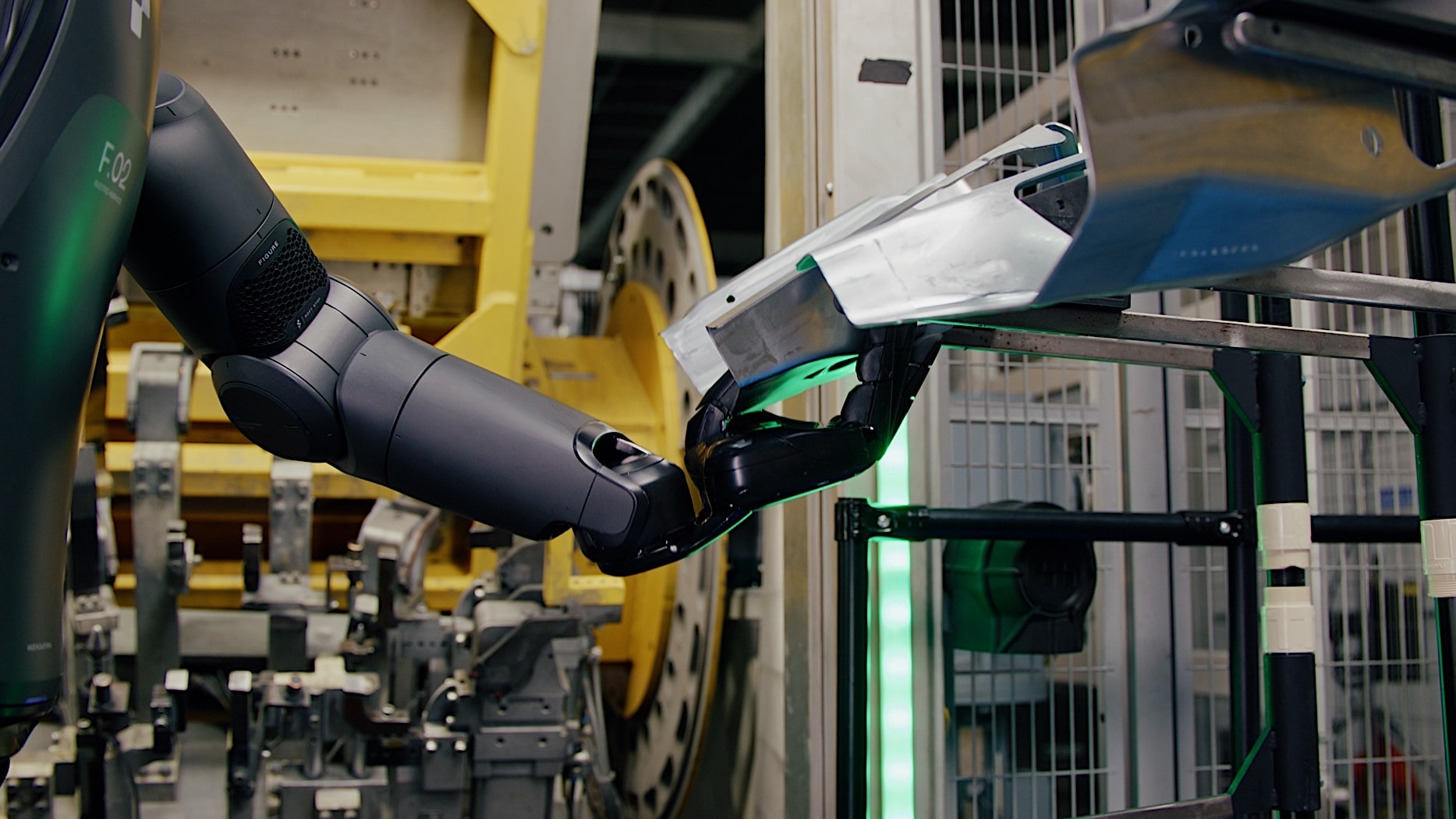

However, the integration of such advanced technology also raises important questions about the future of work and the skills required of the human workforce. With a strength equivalent to a human and unparalleled dexterity, the robot excelled in manufacturing trials at BMW, where it precisely inserted sheet metal components into designated fixtures for subsequent chassis assembly.

This pioneering project, though concluded, has provided invaluable insights into the potential of humanoid robots to address the challenges associated with physically demanding, ergonomically unfavorable, or hazardous industrial processes. Positioned as the world’s most advanced commercially available humanoid robot.

Its successful deployment in a real-world manufacturing environment marks a pivotal moment, signaling the dawn of a new era where human-like robots collaborate seamlessly with human workers to enhance productivity, safety, and efficiency.