When truck owners begin to notice front-end issues, especially related to the differential, it often signals a much bigger problem than just wear and tear. While some manufacturers have moved towards advanced engineering choices like gasketless front differentials, others still struggle with traditional setups that are prone to leaks.

The difference between these two systems lies in their ability to withstand pressure, handle temperature changes, and hold fluid without fault. The importance of having a reliable front differential cannot be overstated, as it plays a critical role in distributing power to the front wheels, especially in four-wheel-drive trucks.

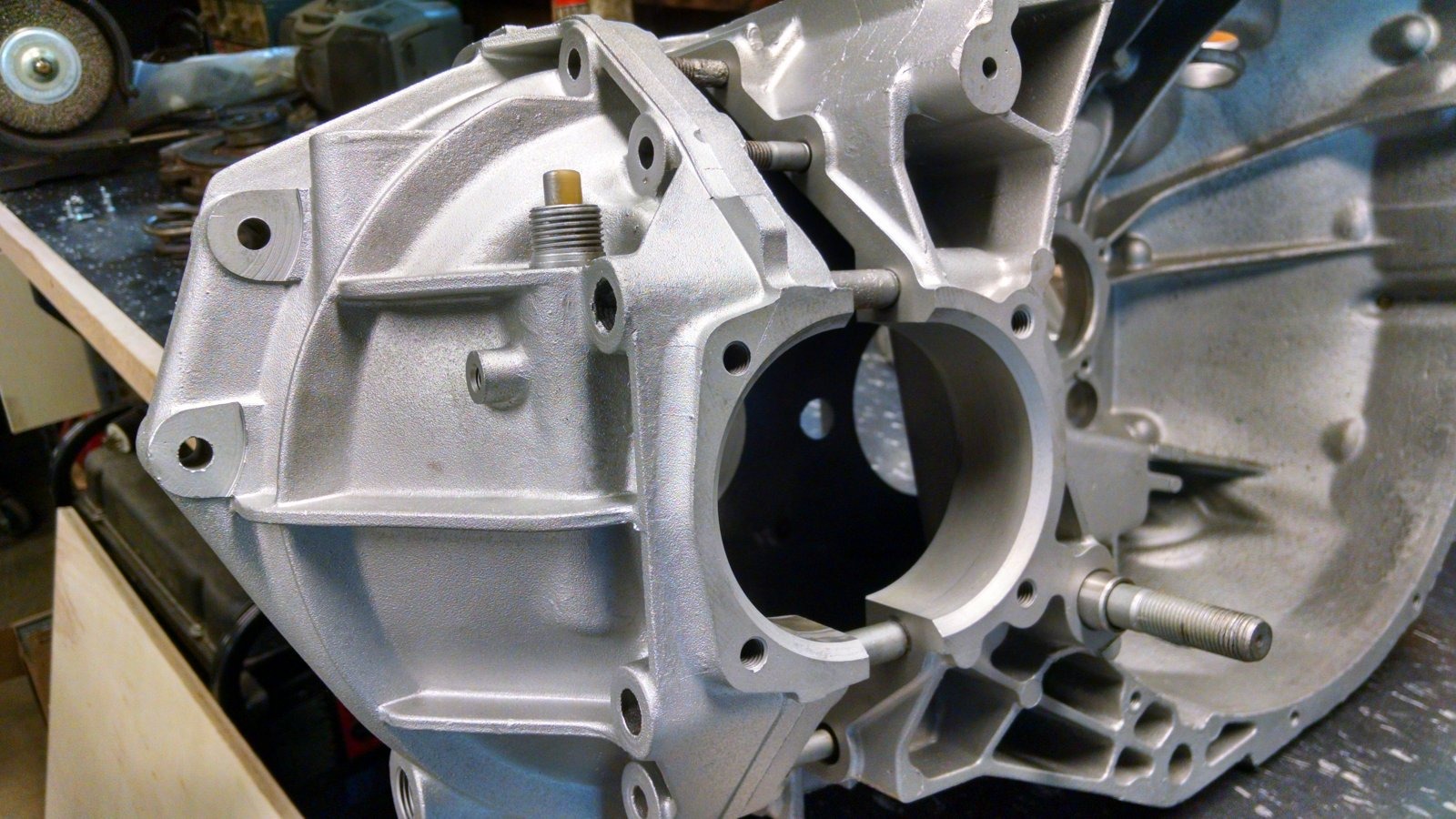

A gasketless front differential relies on precision machining and high-grade sealing surfaces instead of conventional gaskets. This design choice reduces the chances of leaks and long-term deterioration.

With fewer parts to fail and tighter tolerances, these systems can offer longer service intervals and lower maintenance costs for truck owners. These differentials are usually found in newer or more premium truck models, where the focus has shifted towards durability and reliability under extreme driving conditions.

On the contrary, traditional front ends that still depend on gasket-based systems are more likely to face issues with leaking fluid, especially when subjected to rough usage or inconsistent maintenance.

After some time, gasket materials wear out due to exposure to heat, pressure, and oil saturation, leading to minor leaks that can turn into major mechanical failures if left unchecked. A leaking front differential not only poses a threat to the internal components of the axle but can also affect drivability, fuel efficiency, and safety.

For individuals who use their trucks for towing, hauling, or regular off-road driving, understanding which models are designed to prevent these common issues can be the difference between stress-free driving and frequent visits to the workshop.

We will cover five trucks that come with gasketless front differentials, showcasing modern engineering that helps to keep them sealed and dependable.

At the same time, we will also take a look at five truck models known for leaky front ends, either due to their outdated design, weak materials, or poor long-term durability. Each entry offers insight into what to expect based on engineering decisions, model history, and real-world performance.

5 Trucks with Gasketless Front Differentials

1. 2023 Toyota Tundra

Toyota’s 2023 Tundra comes with several improvements, and one of its strongest areas is the design of its front differential. Toyota moved away from traditional gaskets in favour of machined mating surfaces and advanced sealant technology.

This upgrade helps to prevent the common issue of leaking differential fluid. By using metal-to-metal contact with applied sealant during assembly, the front end stays sealed for a much longer time, even under pressure or off-road stress.

This setup reduces the risk of warping or degradation in the long run since there are no rubber or cork gaskets that can shrink or crack. For owners who plan to put their trucks through difficult terrain, such as mountain passes or gravel roads, this is a big benefit. It also helps maintain lubrication around the differential gears, which keeps the components cool and operating smoothly.

Toyota’s engineering team designed the new front axle system to handle torque loads without affecting the seal. Since the system is not dependent on old-fashioned gaskets, there’s less need for replacement during routine service. Many users who have upgraded to the 2023 model report a lack of front-end seepage, even after heavy usage in high-humidity zones or snow-covered paths.

In terms of cost savings, the gasketless differential means fewer parts to replace over the lifetime of the vehicle. Repairs due to leaks in earlier models were expensive, especially when the front differential had to be removed and opened.

The 2023 design cuts back on that need. It also makes it easier for technicians to service the front axle since they are not cleaning off old gaskets or applying new ones. The new setup improves long-term durability, making the 2023 Toyota Tundra a strong choice for buyers who want to avoid common front-end failures.

2. 2024 Ford F-150

Ford redesigned the F-150 in recent years to improve toughness, and the 2024 version has gone a step further by replacing older gasket-based systems with a gasketless front differential.

Instead of depending on rubber or composite gaskets, this model uses high-precision components and sealant compounds to join surfaces tightly. The idea is to form a seal so effective that fluid loss becomes a rare issue under normal use.

This setup benefits both drivers and mechanics. Drivers experience better reliability during off-road trips or heavy towing, and technicians no longer have to deal with degrading gaskets during scheduled service.

The manufacturing method behind the front differential involves closely machined joints with durable fasteners, reducing the chance of fluid escaping during high torque situations or temperature changes.

Ford’s move towards this design aligns with its goal of making the F-150 stronger and easier to maintain. The gasketless system contributes to better long-term durability and less downtime due to leaks.

Since there’s no soft gasket to expand or contract with heat, the seal remains firm under various driving conditions, including long-distance hauling and city commutes.

The design also improves the oil retention ability of the front end, which is crucial for the gear’s lifespan. Consistent lubrication means less wear, cooler operation, and fewer mechanical failures.

This is especially helpful in cold regions where rubber gaskets in older trucks often stiffen or crack. Ford owners who use their trucks in snow-heavy states benefit from the added protection offered by this newer sealing method.

Maintenance for this type of differential also takes less time and costs less over the years. There’s no need to scrape off leftover gasket material or worry about replacing parts that degrade with age.

For those looking at a 2024 F-150 as a daily workhorse or weekend trail companion, the gasketless front differential design gives added confidence that the truck can stay sealed and running well.

Also Read: 5 Cars That Stay Valuable Enough to Buy New vs 5 That You Should Always Buy Used

3. 2022 Chevrolet Silverado 1500

The 2022 Chevrolet Silverado 1500 stands out not just for its performance but also for improvements under the chassis. One of the biggest upgrades comes in the form of a gasketless front differential design.

Chevrolet introduced a new system that does not rely on traditional gasket materials, instead using CNC-machined surfaces and high-strength sealants to secure the housing.

This change was partly inspired by years of customer complaints about front-end fluid leaks in earlier models. By removing the gasket altogether, Chevrolet reduced the number of wear-prone parts and improved sealing strength. The result is a differential that resists leaks even under stress, like off-road driving or long-term towing.

The design works well under various driving conditions because it minimizes the chances of warping or surface breakdown that often lead to leaks. Because there’s no rubber to dry out or split, the system holds up better during extreme heat or cold. Silverado owners now get better peace of mind knowing that fluid isn’t slowly dripping away without notice.

This advancement also saves time during service checks. Without the need to open the differential housing to replace gaskets, the maintenance schedule becomes more streamlined. Dealerships and repair shops report shorter servicing times and fewer repeat visits for the same issue.

On the road, the gasketless design contributes to smoother operation because internal components stay properly lubricated. The differential remains cooler, and metal wear is reduced, especially during extended highway drives or during climbs with heavy payloads.

The Silverado 1500 continues to be a strong competitor in its class, and this modern approach to sealing the front differential puts it ahead of many rivals still using older methods. Those who want strong underbody protection and reduced leak risks will find this feature very valuable.

4. 2023 Ram 2500

Ram has consistently focused on building heavy-duty trucks that can manage tough jobs, and the 2023 Ram 2500 delivers with strength and thoughtful engineering.

A big part of that improvement comes from removing traditional gasket use in the front differential. Ram engineers turned to a gasketless design that involves direct metal mating surfaces sealed with high-performance compound sealants.

This upgrade supports durability for drivers who frequently push their trucks through rough terrain or load-heavy applications. With no soft gasket material present, there’s less vulnerability to heat damage or pressure distortion. As a result, fluid leaks become rare, which extends the life of the differential components and reduces maintenance demands.

The front axle is subjected to massive torque, especially in four-wheel-drive mode or while towing. Having a leak-resistant design makes a difference in long-term reliability. The gasketless approach removes concerns over shrinking, cracking, or gasket wear that usually come after years of heavy use.

Ram’s design team also worked on improving the entire strength of the differential casing. This ensures a tight, consistent seal even when the truck is pushed to its limits. Users who rely on the Ram 2500 for farm work, commercial use, or recreational towing benefit from this solid, fluid-tight performance.

Mechanics report that maintenance is easier because there is no need to remove worn gaskets or prepare surfaces for new ones. The gasketless system is sealed for longer durations, meaning fewer front-end inspections and more time spent on the road.

Combined with the Ram 2500’s general toughness and load-bearing capacity, this feature helps to increase the truck’s appeal for anyone needing a dependable heavy-duty pickup.

This type of build ensures peace of mind and reduces unexpected breakdowns linked to fluid loss. For truck owners who want performance without regular underbody fluid issues, the 2023 Ram 2500 stands out for its well-designed and gasket-free front differential.

5. 2023 GMC Sierra 1500 AT4

GMC’s Sierra 1500 AT4 trim for the 2023 model year is built for off-road strength and comfort, and one of its standout mechanical features is the front differential without a gasket. GMC avoided traditional materials that wear out in the long run and instead focused on precision-fitted components and strong chemical sealing solutions.

This change helps to control fluid retention more effectively, especially in extreme weather conditions or after frequent off-road use.

When trucks face trails full of rocks, mud, or steep inclines, the pressure on the front axle system increases. The Sierra 1500 AT4’s front differential is built to hold its seal tightly, with no need for periodic gasket replacements.

GMC’s engineering department used precision manufacturing tools to ensure that surfaces match perfectly, creating a tighter seal. This removes the weak points often found in traditional gasket-based designs. The front differential retains its fluid and provides stable lubrication to all gears and shafts without frequent servicing.

For drivers who enjoy outdoor activities or need a vehicle that can handle different terrains, this feature brings added reassurance.

Fewer leaks mean less chance of contamination or mechanical wear, both of which can shorten a differential’s life span. This system keeps things clean and secure, offering strong performance with reduced long-term repair costs.

The gasketless design also contributes to quieter operation since the internal parts are better lubricated over longer periods. It’s not just a matter of keeping fluid inside but also maintaining the perfect environment for the front-end parts to function well.

In total, the 2023 GMC Sierra 1500 AT4 shows that it’s possible to combine rugged performance with thoughtful mechanical design. Its gasketless front differential helps to maintain dependable performance while also lowering the cost and frequency of maintenance, especially for those who take their trucks far from paved roads.

5 Trucks with Leaky Front Ends

1. 2015 Nissan Frontier

The 2015 Nissan Frontier may be valued for its compact build and affordability, but its mechanical design features a traditional gasket-based front differential that has raised some concerns among long-term owners.

This model uses rubber or paper-type gaskets to seal the front differential housing, and in the long run, these materials begin to show wear. Exposure to heat, road debris, and general usage causes the gasket to become brittle, allowing oil to seep out gradually.

This type of leakage might seem small at first, but it can grow into a more serious problem when left unchecked. A drop in fluid level affects how well the gears and bearings inside the differential perform. When the gear teeth run without proper lubrication, they begin to grind and heat up, causing damage that might result in full differential replacement.

Drivers of the Frontier often notice small oil puddles beneath the front of the vehicle or detect a burning smell after driving. These are signs that fluid is leaking, either through the gasket or around the housing bolts. In many cases, tightening the bolts or applying temporary sealant does little to fix the problem because the original gasket material has failed.

Replacing the gasket involves removing the differential cover, cleaning the mating surfaces, and installing a new seal. This process takes time and may require tools not available to the average truck owner.

Frequent gasket failures result in higher maintenance costs in the long run and greater frustration, especially when the vehicle is used for outdoor activities or light commercial work.

While the Frontier remains a reliable truck in many areas, its use of a gasket-dependent front differential system continues to be a weak point. Those considering this model for long-term ownership should stay aware of its front-end servicing requirements and budget for occasional repairs related to front differential leaks.

2. 2016 Ford Explorer

The 2016 Ford Explorer stands as a popular family SUV with decent off-road capability, but its front differential design has had leakage issues reported by many users.

This model uses gaskets made from rubber-like materials, which are placed between the front differential cover and its housing. Over the years, these gaskets begin to harden, shrink, or change due to heat exposure and axle pressure.

A common complaint from Explorer owners is the appearance of spots or stains on driveways, especially after long trips. The leak may begin slowly, but if the gasket is not replaced or reinforced in time, the fluid can drop below safe levels. This creates a problem because the front differential relies on oil to prevent gear teeth from wearing down or overheating.

As the gasket begins to fail, small gaps form along the seal line, especially where the casing meets bolts. Vibration from normal driving makes the problem worse, especially if the vehicle is driven on rough terrain.

Ford owners report having to check and top off their front differential oil more often than they expected. In colder climates, the problem is worse because the gasket material becomes less flexible and more prone to cracking.

Repairing this issue involves removing the front cover and scraping off the worn gasket before applying a new one. While this sounds simple, the process requires lifting the vehicle, draining fluid, and using special tools to access tight spaces. It’s not a job most casual drivers are prepared to handle at home.

Many 2016 Explorers have gone through front-end service earlier than expected due to these issues. The lack of a more permanent sealing method means that gasket wear is something owners must track carefully. While the Explorer offers a smooth ride and interior comfort, its outdated front differential design can become a frustrating maintenance problem.

3. 2014 Chevrolet Tahoe

The 2014 Chevrolet Tahoe, though appreciated for its power and interior space, has a reputation for front differential leaks after several years on the road. This model uses a traditional gasket between the differential housing and the cover.

With time, especially under heavy loads or frequent stop-and-go driving, the gasket begins to deteriorate, which leads to fluid escaping from the front end. Owners often begin noticing oil stains near the front axle or a wet film on the differential housing.

This is usually a clear sign that the gasket has started breaking down. It is a rubber-based gasket that does not always respond well to temperature changes or vibration. Once compromised, it cannot maintain a tight seal under pressure.

Another contributing factor is the engine’s weight distribution and towing capability. The Tahoe is built for pulling trailers and carrying passengers, and all that stress puts more strain on the differential. If the gasket is not in perfect condition, small cracks and leaks become more common. This leads to lubrication loss, gear whine, and eventually internal damage.

To correct the leak, mechanics must remove the differential cover, clean off the old gasket, and install a new one with fresh fluid. Unfortunately, many Tahoe owners have had to repeat this repair more than once if they use the vehicle heavily. In some situations, mechanics also recommend resealing the entire housing using a combination of a new gasket and gasket maker to hold the fluid in place.

This model’s front differential issue does not affect every vehicle, but it is common enough to warrant attention. It becomes more noticeable around 80,000 to 100,000 miles, depending on how the vehicle is driven. For anyone considering buying a used 2014 Tahoe, it is wise to ask about front-end service history or prepare for potential repairs connected to gasket leaks.

4. 2017 Jeep Grand Cherokee

Jeep’s 2017 Grand Cherokee delivers strong off-road ability and highway comfort, but it also suffers from front-end differential fluid issues in models with traditional gasket seals.

The design of the front differential relies on a stamped metal cover sealed with a molded rubber gasket, which tends to weaken after several years of exposure to rough conditions.

This rubber gasket is shaped to fit the housing, but it does not always age well. High engine heat, water splashes from off-road terrain, and vibrations during driving lead to a gradual breakdown of its flexibility.

When this happens, small gaps form between the cover and the housing, and fluid begins to escape slowly. Drivers sometimes mistake this for an engine or transmission leak until they trace it back to the front axle.

The seepage might not be heavy at first, but it causes issues by lowering oil levels inside the differential. As the gears lose consistent lubrication, friction builds up, resulting in premature wear. On longer drives, the differential can overheat, leading to costly repairs or even axle damage if not addressed in time.

Replacing the gasket requires removing the front differential cover and scraping away any remaining gasket material, a process that is both messy and time-consuming.

The job is made harder by tight clearances around the axle, especially on 4×4 models. Some owners have chosen to switch from factory gaskets to aftermarket sealing solutions that include both gasket and RTV sealant for longer protection.

This model’s gasket issue does not make it a poor performer, but it does create an extra step in long-term care. Owners who use their Grand Cherokees for towing or frequent off-road drives should pay close attention to front-end fluid levels.

While the SUV handles well under various driving conditions, the use of a rubber gasket in the front differential remains a common complaint among those familiar with the platform.

Also Read: 5 Performance Cars That Stay Valuable And 5 That Become Worthless

5. 2018 Honda Ridgeline

Honda’s 2018 Ridgeline is known for blending truck utility with car-like comfort. However, it also faces trouble with fluid leaks from the front differential due to its reliance on gasket materials that are prone to wear.

This truck uses a paper-type or rubber gasket in its front differential assembly, which creates issues after the vehicle has been driven for a few years, especially in mixed climate conditions.

This gasket system works well when new, forming a seal between the differential housing and its cover. But after a while, road heat, axle stress, and vibrations cause the material to shrink or lose its elasticity.

As a result, tiny openings appear around the edges, and gear oil begins to leak out. These leaks are often first noticed as damp spots around the front axle or a faint burnt oil smell during warm drives.

Because the Ridgeline is designed more for light-duty work and city driving, many drivers are surprised when the front end develops such an issue. Although it is not designed for off-roading like other pickups, the front differential still undergoes pressure when the all-wheel-drive system is active. When fluid levels drop, gear movement inside the differential becomes noisy, and wear begins to accelerate.

Fixing the leak involves cleaning off the old gasket and applying a replacement, a task that often requires removing skid plates and other components. For drivers unfamiliar with undercarriage work, it is not a quick repair. This problem tends to show up most often on trucks that have passed 70,000 miles or have been exposed to cold winters and wet roads.

The Ridgeline remains a strong performer for comfort and daily utility, but its use of gasket material in the front differential is one point where Honda’s design could be improved. Owners who want to avoid long-term problems should check for leaks during service and be ready for a possible reseal job.