Even though turbocharged cars have been around for quite some time, they remain more complex than the average road vehicle.

With the introduction of computer-controlled engines, modern turbo systems require less maintenance than older models. However, proper upkeep is still essential, even for newer vehicles, to ensure their longevity.

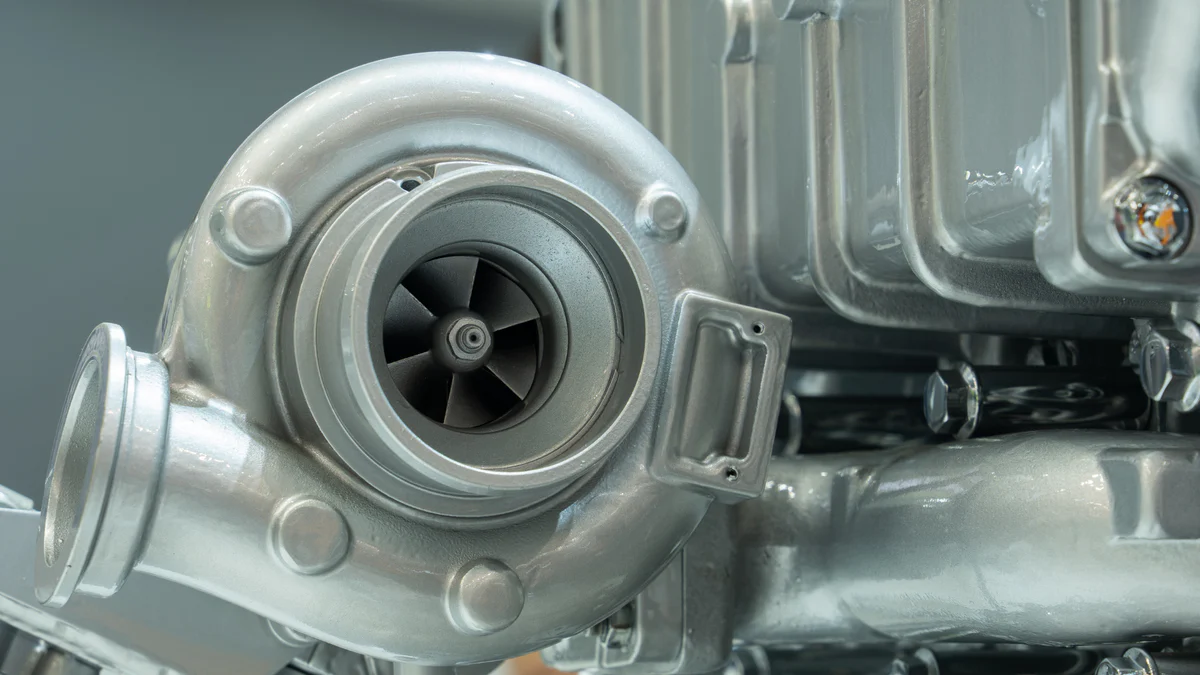

An engine’s combustion process requires three key elements fuel, ignition, and oxygen. A turbocharger functions similarly to a hair dryer, forcing additional air into the engine’s pistons to maximize fuel efficiency over short bursts.

This system operates using a turbine powered by exhaust gases, which draws in air from outside the vehicle to provide the necessary oxygen.

Given the extreme heat, pressure, and movement within the turbo system, it is susceptible to wear and potential failure over time.

What are the best practices to minimize wear on a turbo and reduce emissions? Here are some key maintenance tips:

1. Regular Oil Changes

Proper lubrication is crucial for a turbo’s performance. Older turbochargers relied entirely on oil cooling, while modern versions use coolants as well. However, oil remains an essential component in the system.

It is generally recommended to change the oil every 5,000 miles to keep the turbo well-lubricated. If you drive infrequently, you might be able to extend the interval slightly, but it is always advisable to err on the side of caution.

2. Use High-Quality Oil

Selecting the right oil is just as important as changing it regularly. The best type of oil for your turbo can be found in your vehicle’s owner’s manual.

Synthetic oils are typically more effective for turbocharged engines, and researching online can help you determine the most suitable option for your car. Using low-quality, inexpensive oil will not provide adequate protection for your turbocharger.

3. Choose the Right Fuel

Using low-octane fuel can cause engine knocking, leading to a chain reaction of issues that may result in premature wear on the turbocharger.

Always check the pump to ensure you’re using the correct fuel grade and avoid lower-priced alternatives that don’t meet your vehicle’s specifications.

4. Allow the Engine to Warm Up

Your car’s oil needs to reach an optimal temperature to provide proper lubrication.

It is advisable to let the engine run for 5 to 10 minutes before engaging the turbo at higher speeds. Allowing the vehicle to warm up properly reduces the risk of turbo damage.

5. Rely on the Transmission, Not Just the Turbo

With a turbocharged engine, it’s easy to become overly dependent on the turbo for extra power. While the additional boost can be useful in certain situations, relying too much on the turbo can cause premature wear.

Instead, use the transmission and gear system to gain speed when necessary, rather than constantly engaging the turbo.

6. Maintain a Steady Cruise

Consistently pushing the turbo leads to faster wear. While it’s helpful for reaching highway speeds, once you’ve settled into a cruising speed, avoid excessive acceleration. Using the turbo sparingly will help prolong its lifespan.

7. Let the Turbo Cool Down

After driving at high speeds, suddenly turning off the engine can leave the turbo extremely hot, sometimes glowing red.

If the engine is shut off too quickly, the remaining heat can cause the oil in the turbo to burn and form a thick sludge, potentially clogging the system and leading to damage.

To prevent this, let the engine idle for a couple of minutes at the end of your drive, allowing the turbo to cool gradually before shutting off the vehicle.

8. Avoid Blipping the Throttle

Blipping the throttle involves briefly increasing the engine’s RPMs to match road speed when downshifting.

In a turbocharged vehicle, this practice forces the turbo to work harder than necessary, which can contribute to premature wear.

If you purchase a vehicle with a modified engine or decide to modify it yourself, the manufacturer’s guidelines may no longer apply.

In such cases, it’s best to have a professional assess the system. A specialist can test the turbo’s stress tolerance, heat dissipation, and oil requirements to ensure it operates efficiently.

By understanding these factors, you can determine how to best maintain and utilize your turbo system, maximizing both its performance and lifespan.