Throughout automotive history, a few engines have stood out not for their success—but for how far ahead of the curve they were. These powerplants featured engineering concepts so forward-thinking that the industry, the technology, or the consumers simply weren’t ready for them.

Whether due to cost, complexity, or a lack of supporting systems, these engines often flopped commercially, only to be recognized later as milestones in automotive innovation.

Being “too advanced” can mean many things: introducing electronic systems before mechanics knew how to service them, relying on materials that weren’t reliable yet, or implementing designs so efficient or unique that the surrounding infrastructure—fuel quality, diagnostics, emissions regulations—couldn’t keep up.

In many cases, these engines predated the widespread availability of the computing power or manufacturing precision needed to make them viable at scale.

These weren’t half-baked ideas. Often, they represented the absolute cutting edge of engineering—rotary engines with otherworldly power-to-weight ratios, diesels that rivaled gas engines in performance, or variable valve timing systems before anyone had a name for them. Their designers weren’t wrong. They were just too early.

Over time, many of the ideas pioneered by these engines would become standard—fuel injection, multi-valve heads, turbocharging, and hybrid integration. But when these innovators launched, they confused buyers, confounded technicians, and often hemorrhaged warranty claims.

This article dives into some of the most famous (and infamous) examples of engines that were ahead of their time—exploring what made them special, why they struggled, and how they helped shape the future even if they failed in the present.

Also Read: Engines That Can Run for 500 Hours Without an Oil Change

Mazda Wankel Rotary Engine – Compact Power, Complex Problems

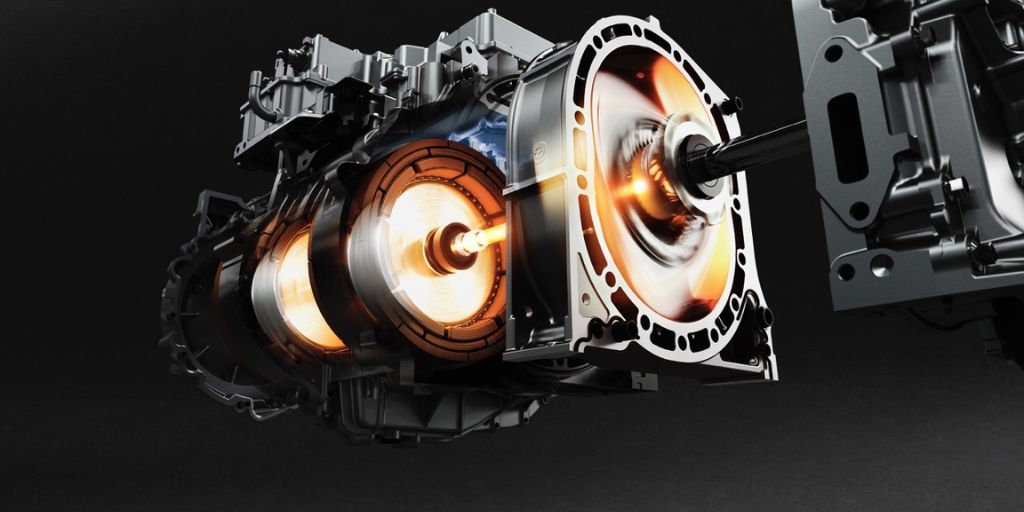

Mazda’s rotary engine was a marvel of minimalism and clever engineering. Based on the Wankel design, it used a triangular rotor that rotated in an oval-like housing, performing intake, compression, combustion, and exhaust in different areas of its motion—unlike the up-and-down motion of pistons.

The simplicity of its design, with fewer moving parts and a high power-to-weight ratio, made it ideal for sports cars.

Advanced Features:

- Smooth, high-revving nature that mimicked aircraft turbine behavior.

- Extremely compact—allowed for low hood lines and balanced weight distribution.

- No conventional valvetrain, reducing mass and mechanical drag.

Why it was too early:

- The apex seals, which form the combustion chamber, were prone to rapid wear and required precise oiling.

- High oil consumption and poor emissions proved problematic during the oil crises and tightening environmental laws.

- Unfamiliarity among mechanics led to servicing mistakes and lack of widespread support.

Despite these flaws, Mazda stuck with the Wankel engine for decades. Though discontinued in mass production, it remains in development as a range extender in hybrid powertrains—an application where its size and simplicity are finally a perfect fit.

Cadillac V8-6-4 (1981) – Cylinder Deactivation Too Early

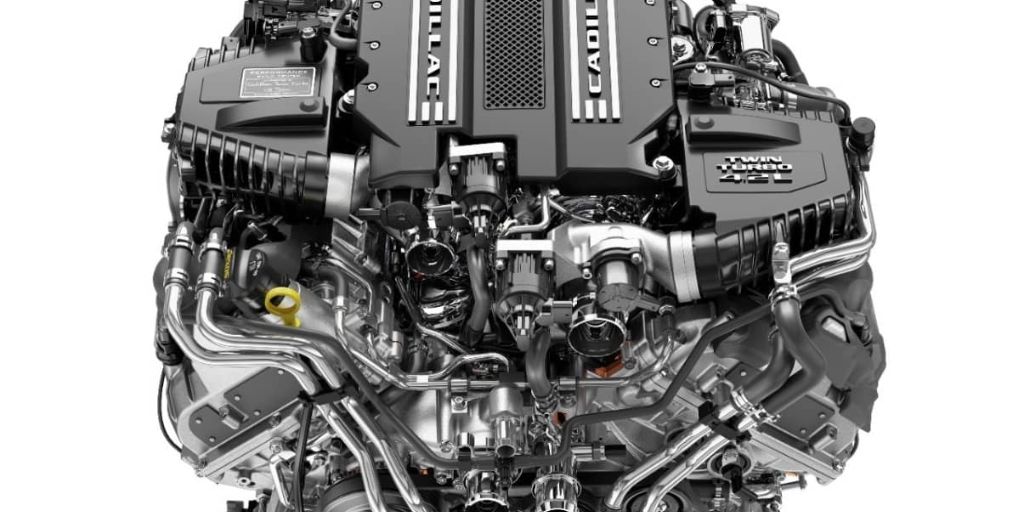

In response to rising fuel prices and emissions regulations, Cadillac introduced the V8-6-4 engine with a radical concept: deactivate up to four cylinders during light loads to save fuel. On paper, it was revolutionary.

Innovative Aspects:

- Electro-hydraulic system that could disable or enable cylinders based on throttle input.

- Provided V8 performance when needed, and smaller-engine efficiency under cruise conditions.

The Problems:

- The engine control module (ECM) was simply not powerful enough. Reaction times were slow, and transitions between modes were jerky.

- Early diagnostic tools were primitive, making troubleshooting a nightmare.

- Consumers didn’t trust the system, and dealers often disabled it entirely.

Modern successors—like GM’s Active Fuel Management and Honda’s Variable Cylinder Management—do exactly what Cadillac tried in 1981, only with far better computing power. The V8-6-4 concept was valid; it was simply too advanced for the electronics of the time.

Honda CVCC – Emissions Innovation Without a Catalyst

Honda’s CVCC (Compound Vortex Controlled Combustion) engine was a standout during the 1970s emissions crunch. While American manufacturers struggled with catalytic converters and air injection systems, Honda achieved cleaner combustion with mechanical engineering.

Key Innovations:

-

Dual-chamber design: a rich mixture ignited in a small pre-chamber, setting off a leaner mixture in the main chamber.

- Avoided the power losses associated with early emissions equipment.

- Delivered excellent fuel economy—up to 40 mpg—without sacrificing drivability.

Why it didn’t last:

- Emissions regulations changed to require catalytic converters regardless of engine design.

- CVCC required complex cylinder head castings that were expensive to produce and maintain.

- The industry moved toward fuel injection and simpler emissions solutions as electronics improved.

Still, CVCC showed that mechanical innovation could achieve clean results before electronic systems became the norm.

Chrysler Turbine Car – Jet Power for the Masses

Between 1963 and 1964, Chrysler built 55 turbine-powered cars as part of a public demonstration program. The engine, based on a gas turbine similar to those in aircraft, ran at over 40,000 RPM and could burn nearly any combustible liquid.

What Made It Special:

- Ran on kerosene, gasoline, diesel, or even perfume.

- Nearly vibration-free operation.

- Minimal moving parts—just one rotating assembly.

Why it failed:

- Turbo lag was massive; throttle response felt delayed.

- Fuel consumption was worse than V8s of the era.

- High exhaust temperatures raised safety concerns.

- Government regulation and high production cost killed feasibility.

Even though the program was eventually scrapped, it pushed the boundaries of what propulsion technology could be—and foreshadowed the flexibility and multi-fuel capability being revisited in hybrid and aviation crossover applications.

Alfa Romeo Twin Spark – Igniting the Future

Alfa Romeo introduced its Twin Spark technology in the late 1980s. Each cylinder had two spark plugs firing in sequence, leading to more complete combustion, smoother power delivery, and better emissions.

Innovations:

- Improved efficiency and torque across the RPM range.

- Allowed for leaner air-fuel mixtures with fewer NOx emissions.

- Smoothed idle and enhanced throttle response in low-displacement engines.

Why it didn’t take off globally:

- Servicing was complex, requiring precise timing control and more expensive ignition components.

- Gains were modest compared to growing multi-valve and turbocharged alternatives.

- Limited support outside of Europe.

However, the core principle of multiple ignition points became popular in high-performance and aviation engines later on.

BMW M70 and VANOS – Too Smart, Too Soon

BMW’s M70 V12 engine and its early VANOS variable valve timing system debuted in the late 1980s and early 1990s. The M70 powered the flagship 750iL and shared architecture with the later McLaren F1 engine.

Key Technologies:

- Drive-by-wire throttle (rare at the time).

- Twin ECUs and ignition systems for redundancy and smooth operation.

- Early adoption of variable valve timing for performance and efficiency.

The Downside:

- Overcomplicated electronics in an era where diagnostics were limited.

- Repair costs were astronomical, and parts availability became an issue.

- The cars they were installed in were already expensive and had limited audiences.

BMW’s innovations would become core technologies in modern engines—but in the late ’80s, they were solutions in search of a problem.

Saab Trionic System – Intelligent Boost Control

Saab’s Trionic engine management system, introduced in the 1990s, combined ignition, fuel, and turbo boost control in a single integrated module. It even used spark plugs to measure combustion efficiency via ion current detection—a tech still unmatched in some ways.

Futuristic Capabilities:

- Real-time monitoring of combustion in each cylinder.

- Knock detection far more advanced than contemporaries.

- Adaptive boost pressure based on environmental and mechanical conditions.

Why it didn’t change the world:

- Complexity made tuning and modification difficult.

- Few technicians were trained to work with it.

- Saab’s declining market share limited its proliferation.

Ironically, many modern ECUs are only now reaching the predictive and reactive control Trionic offered decades ago.

Toyota 1G-GEU – Early Multi-Valve Mastery

In the early 1980s, Toyota released the 1G-GEU—a 2.0L straight-six with DOHC and 24 valves, one of the first production engines to do so. It was a marvel of balance, refinement, and power for such a small displacement.

Advanced Features:

- High-revving six-cylinder design for compact cars.

- Electronic fuel injection and dual-overhead cams long before these were industry standards.

- Set a precedent for modern inline-six performance engines.

Challenges:

- High production cost for a small engine.

- Most drivers couldn’t exploit its top-end-biased power curve.

- Emissions tuning was tricky due to the valvetrain complexity.

Though the 1G-GEU didn’t dominate sales, it laid the foundation for Toyota’s later successes, including the legendary 2JZ engine.

Oldsmobile Diesel V8 – A Good Idea Gone Bad

Oldsmobile’s 5.7L diesel V8 in the late 1970s aimed to deliver better fuel economy during the oil crisis by offering a diesel option in full-size cars.

Why It Was Innovative:

- Diesel power promised better economy for American V8 drivers.

- Could be built using modified gasoline V8 blocks.

- Promised lower emissions and improved highway range.

What Went Wrong:

- Used gasoline engine architecture not suited for diesel pressures.

- Head gasket failures, injector pump issues, and cracked blocks were common.

- Lack of diesel-trained mechanics exacerbated issues.

- Poor reputation destroyed consumer trust in diesel cars in the U.S. for decades.

Despite its flaws, it showed early recognition of diesel’s efficiency potential in passenger cars—a trend Europe would capitalize on far more successfully.

Mitsubishi GDI – Direct Injection Before It Was Ready

Mitsubishi’s Gasoline Direct Injection (GDI) engine debuted in the late 1990s and was the first mass-produced gasoline direct injection engine in a passenger car. It offered excellent fuel economy and strong performance from small-displacement engines.

Ahead of Its Time Because:

- First to use direct injection in affordable consumer vehicles.

- Excellent real-world fuel economy and torque.

- Improved lean-burn performance.

Why It Struggled:

- Emissions compliance was difficult, especially in the U.S.

- High maintenance needs due to carbon buildup on valves.

- Poor consumer understanding and limited mechanic training.

Today, GDI is almost universal in new engines—but Mitsubishi got there a decade too early, with insufficient infrastructure to support it.

Ford Ecoboost – Downsizing and Turbocharging Before the Trend Took Off

Ford’s EcoBoost engine technology, introduced in the 2000s, revolutionized the way consumers thought about performance and efficiency.

The concept behind EcoBoost was simple: turbocharge small, fuel-efficient engines to achieve the power of a larger engine without the fuel consumption.

What Made It Ahead of Its Time:

- Turbocharging allowed for impressive power output from small, fuel-efficient engines.

- Offered better fuel economy compared to naturally aspirated engines of similar output.

- Became a precursor to the modern turbocharged engines dominating the market today.

Why It Was Too Early:

- Consumers were not accustomed to turbocharged small engines in everyday vehicles, leading to some skepticism.

- Reliability concerns emerged in the early years due to the complexity of turbocharging systems, which required regular maintenance.

- Early versions lacked the full integration of advanced electronics and control systems that made later iterations of the technology more efficient.

Today, Ford’s EcoBoost engines have become a key player in their line-up, powering everything from compact cars to full-size trucks. The technology has since been perfected, with better reliability and consumer understanding of turbocharged vehicles.

However, it initially faced resistance because it was seen as a radical departure from traditional engine configurations.

Audi W12 – A V12 with a Twist

Audi’s W12 engine, first introduced in the early 2000s, was a configuration of two narrow-angle V6 engines joined together to form a V12. This made the engine more compact than traditional V12s, allowing for smoother integration into smaller vehicles while maintaining exceptional performance.

Why It Was Advanced:

- It produced incredible power and smoothness, ideal for luxury performance cars.

- Its compactness made it more suitable for smaller engine bays than traditional V12s.

- Combined the best elements of V8 and V12 engines for performance and efficiency.

Challenges:

- The complexity of the W12 design made it expensive to manufacture and maintain.

- The market for such an engine was limited to high-end performance vehicles, which restricted its mass adoption.

- Due to its complexity, repairs were costly, and its weight made some vehicles less efficient in terms of handling and fuel consumption.

Today, the W12 remains a prestigious engine, featured in luxury models like the Audi A8 and the Bugatti Veyron. However, the W12 was a bold step in the evolution of engine design, one that few were ready to adopt in mass-market vehicles.

Automotive history is littered with brilliant innovations that arrived just a little too early. The engines discussed here—whether turbine-powered, rotary-driven, or electronically sophisticated—were all trailblazers.

Their biggest flaw wasn’t mechanical failure or bad engineering; it was being born in a world that wasn’t quite ready to accept them.

In many cases, these engines planted the seeds of ideas that would flourish decades later. The rotary engine foreshadowed modern compact hybrid range extenders.

The Cadillac V8-6-4’s idea of dynamic cylinder deactivation is now standard in pickup trucks and SUVs. Saab’s Trionic system anticipated the advanced, adaptive ECUs now monitoring each millisecond of combustion in real time.

What sets these engines apart is not just their boldness, but their influence. They shaped thinking. They challenged norms.

And while some flopped commercially or became cautionary tales for other automakers, their core concepts lived on—refined and reintroduced with the help of better materials, smarter electronics, and more patient consumers.

In a world increasingly driven by strict emissions, electrification, and digital controls, these engines remind us that innovation is rarely a straight line. Sometimes, being too advanced is just another step in the journey toward better, smarter propulsion.

Also Read: The ‘Unkillable’ Engine That Was Once Used in Both Planes and Cars