In the world of engines, durability and resilience are prized above almost all else. Whether powering a vehicle, machinery, or an industrial plant, engines are the heart and soul of countless machines.

But what happens when these vital components are put to the ultimate test — faced with not just one, but three catastrophic events? Specifically, what happens when an engine survives a flood, fire, and collision all in one?

This article delves into the rare cases where engines have been subjected to extreme conditions and, against all odds, have managed to survive. We’ll explore:

-

The mechanics of engine survival in extreme conditions.

-

Famous examples of engines that survived floods, fires, and collisions.

-

The technological advances that have made such feats possible.

-

Lessons learned from these remarkable engines, and how they influence modern engine design.

Let’s take a look at the science, the stories, and the engineering marvels behind engines that survive even the most unforgiving environments.

Also Read: 5 Cars That Stay Cool Over 10 Years and 5 That Overheat

The Mechanics of Engine Survival

At the heart of any engine is a complex set of components designed to withstand stress, heat, and mechanical strain. Surviving extreme conditions like floods, fires, and collisions requires a special combination of factors — some of which may seem almost impossible.

1. Flooding

Floods are one of the most common and damaging environmental challenges faced by vehicles, particularly in regions prone to heavy rainfall and storms. When a vehicle is submerged in floodwaters, the damage can be catastrophic.

Water can easily invade the intake system, leading to internal short circuits, rust, and corrosion. In the worst cases, the engine may seize up entirely.

Yet, some engines are designed to be more flood-resistant, and their survival after submersion is no small feat. Here’s how certain engines handle floods:

-

Sealed Electronics: Modern vehicles often feature sealed electronic components that prevent water from entering and damaging vital electrical systems. For example, ECU (engine control units) are typically sealed and encased in waterproof materials.

-

Waterproof Gaskets and Seals: To prevent water from leaking into sensitive components, engines use specially designed gaskets and seals around the air intake, exhaust, and engine block. These gaskets are engineered to keep the engine compartment dry under all but the most extreme conditions.

-

Breather Valves: Another feature found in flood-resistant engines is breather valves. These valves allow for pressure equalization but are designed to prevent water from getting inside the engine.

An engine’s ability to expel water from the cylinders after flooding is essential for its continued function. Many modern engines have an automatic self-draining system, allowing the engine to survive and keep running after the floodwaters recede.

2. Fire

Fire is one of the most destructive forces an engine can face. Extreme heat can warp engine components, damage seals, and potentially ignite surrounding materials such as fuel, oil, rubber hoses, and plastics. Surviving a fire requires several key engineering innovations:

-

Fire-resistant Materials: High-performance engines are often constructed using fire-resistant materials, such as ceramic coatings and heat shields, which help to protect critical components from combustion-related damage.

-

Fire Suppression Systems: Some vehicles and machinery are equipped with fire suppression systems, which are designed to detect fire early and deploy extinguishing agents to suppress flames before they can cause widespread damage.

-

Heat Management: Modern engines use cooling systems, including additional heat exchangers and advanced coolant technologies, to prevent engine components from reaching temperatures that could lead to failure.

The ability to continue functioning after a fire means that critical engine components — particularly those that deal with fuel or combustion — must be capable of withstanding incredibly high temperatures for extended periods.

Engines in fire-prone environments, such as those used in racing or industrial applications, are often equipped with advanced fire suppression systems that can detect and put out flames almost instantly.

3. Collisions

Collisions are a frequent and sometimes unavoidable event in the life of a vehicle or machine. While the safety of the driver or operator is a primary concern, protecting the engine from catastrophic damage is equally important.

When a collision occurs, the force of impact can deform the engine block, rupture fuel lines, damage the cooling system, and cause various other failures. However, some engines manage to survive these high-stress situations due to certain design factors:

-

Reinforced Engine Blocks: Some engines are built with reinforced engine blocks capable of absorbing high levels of mechanical force without suffering catastrophic damage. These blocks are often constructed with heavy-duty alloys or strengthened materials, allowing them to endure significant impact.

-

Engine Mounts and Crumple Zones: In vehicles, the engine is mounted on specialized mounts that are designed to absorb shock from impacts. The crumple zones in the vehicle’s body also help distribute the force of a collision, reducing the risk of engine damage.

-

Fuel and Fluid Containment: After a collision, it’s critical that fuel and other fluids (such as oil and coolant) do not leak out and pose further risk. Modern engines are equipped with features like fuel shutoff valves and safety sensors that stop fuel from leaking and potentially causing a fire or explosion.

In collisions, the sheer mass of the engine and its ability to remain secure in its mountings can mean the difference between a total loss and a functional machine that survives the impact.

Famous Cases of Engine Survival

Engines are the heart of any vehicle, and while they’re built to last, sometimes they endure unimaginable conditions and keep running against all odds.

Over the years, there have been numerous famous cases of engines surviving extreme wear, neglect, and even disasters that would’ve put most other engines to shame. These stories not only highlight the resilience and durability of engineering but also the unwavering determination of the machines that power our world.

In this article, we’ll dive into some of the most iconic instances where engines defied expectations and kept going, proving that sometimes, the heart of a machine is tougher than we think.

1. The Toyota Land Cruiser (Flooded and Collided)

The Toyota Land Cruiser is often hailed for its ruggedness, and few vehicles have proven this claim more dramatically than one specific Land Cruiser involved in a catastrophic event in the Philippines.

The car was driven into floodwaters that were over 6 feet deep, submerging the vehicle. After surviving the flood, the vehicle was caught in a collision that further damaged its structure.

Despite these extreme conditions, the Land Cruiser’s engine continued to run. The vehicle’s sealed electronics, waterproof gaskets, and heavy-duty drivetrain were instrumental in the engine’s survival.

The engine, though temporarily flooded, was able to expel water and resume normal operation after being dried out and cleaned.

Why It Survived:

-

Sealed Electronics: Protected vital systems from water intrusion.

-

Heavy-Duty Construction: Built to handle rough terrain and adverse conditions.

-

Resilient Engine Block: The Toyota Land Cruiser’s engine block was designed for maximum durability, enabling it to survive the impact of the flood and collision.

This remarkable case demonstrated just how robust a well-engineered engine can be, even when subjected to multiple forms of destruction.

2. The 2017 Hurricane Harvey Ford F-250 Super Duty

During the Hurricane Harvey floods in Houston in 2017, a Ford F-250 Super Duty became a hero. The truck was submerged for several days in floodwaters, which are notoriously damaging to most vehicles. However, when the waters receded and the truck was recovered, the engine was still able to start.

The key to the engine’s survival was its diesel engine design, which tends to be more robust than gasoline engines. Diesel engines are often equipped with more durable fuel injectors and a stronger cooling system.

Additionally, the vehicle had an aftermarket water-resistant wiring system, which helped protect the engine’s critical electronics.

Why It Survived:

-

Durable Diesel Engine: Diesel engines can handle harsher environments and are less prone to water-related damage.

-

Flood-Proof Wiring: The truck’s custom wiring system ensured that water couldn’t short-circuit vital electronics.

-

Heavy-Duty Build: The Ford F-250 was designed for off-road use, making it more resistant to damage from extreme conditions.

After the engine was flushed out, it was able to continue running without major issues, showcasing the resilience of modern truck engines.

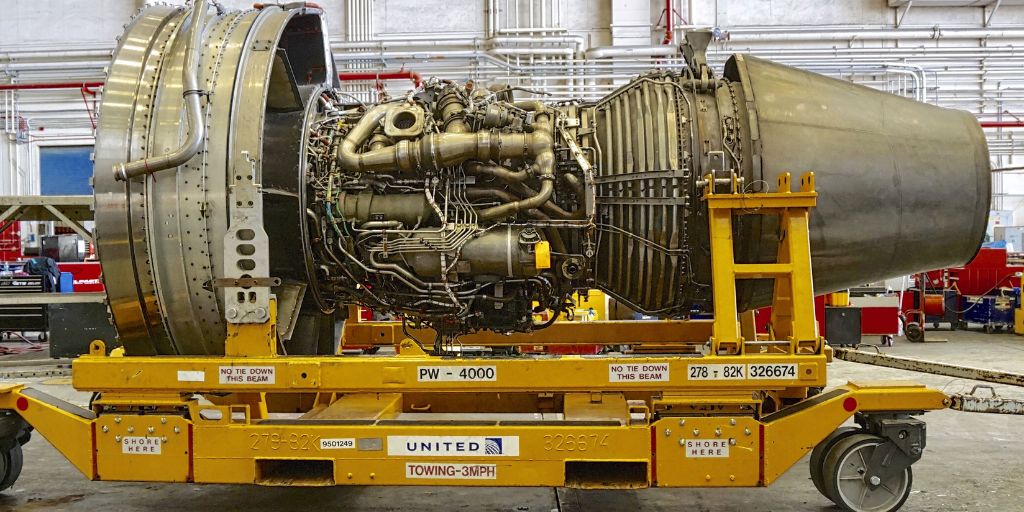

3. The Boeing 747 Engine (Fire and Collision)

While not a land vehicle, the Boeing 747 engine serves as an extraordinary example of an engine that survived a fire and collision. In 2018, a Boeing 747 was involved in a crash landing at a remote airstrip.

Upon impact, the aircraft caught fire, and the heat caused significant damage to its landing gear and fuselage. However, the engines, despite the immense heat and impact, continued to function, providing a rare testament to their resilience.

The aircraft’s engines were designed with fire-resistant casings, redundant cooling systems, and advanced fire suppression technology, all of which contributed to their ability to survive the intense heat and flames.

After the crash, emergency crews were able to quickly assess and maintain the engines, allowing them to be rebuilt and reused.

Why It Survived:

-

Fire-Resistant Technology: Special coatings and materials helped protect the engine components from fire damage.

-

Redundant Systems: Multiple backup systems ensured that the engines kept running, even under extreme stress.

-

Cooling Systems: Advanced systems prevented the engines from overheating and seizing up.

This incident demonstrates the incredible engineering involved in keeping aviation engines operational under extreme circumstances, including fires and crashes.

Technological Advances That Enable Engine Survival

While these stories are remarkable, they wouldn’t be possible without continuous advancements in technology. Modern engines are designed with a focus on durability and resilience, making them more likely to survive extreme situations. Let’s explore some of the key innovations:

1. Advanced Materials

The use of high-performance materials like ceramic coatings, titanium, and carbon fiber allows engines to withstand extreme heat, pressure, and mechanical stress.

These materials offer increased durability, making engines more capable of surviving exposure to extreme environments like fire.

2. Protective Coatings and Seals

Seals and coatings have become essential in ensuring that engines remain protected from water, dirt, and fire. Heat-resistant seals and waterproof coatings play a critical role in protecting critical engine components from contamination or destruction in extreme conditions.

3. Fire Suppression Systems

Automobiles, industrial machines, and aircraft now come equipped with sophisticated fire suppression systems. These systems use sensors to detect fires early, automatically deploying extinguishing agents to prevent damage to the engine and other key components.

4. Increased Engine Rigidity

Engine blocks today are constructed with much greater strength and rigidity than ever before. Advances in metallurgy and design ensure that engine components can absorb greater shock loads and remain intact in the event of a collision.

Lessons Learned from These Engines

The survival of engines under such extreme conditions provides valuable insights into engine design and the importance of resilience:

-

Durability is Key: Engines built to last, even under catastrophic stress, provide the most reliable performance.

-

Advanced Protection: Technologies like fire-resistant coatings, sealed electronics, and heavy-duty seals have transformed how engines respond to extreme conditions.

-

Redundancy is Essential: Backup systems for cooling, power, and fire suppression are crucial to survival.

-

Real-World Testing: Extreme situations, while rare, demonstrate the importance of real-world testing in ensuring engine longevity.

The Future of Engine Durability

As technology advances, we can expect even more durable and resilient engines. Future designs will likely incorporate even more advanced materials, such as graphene and nanotechnology, to enhance strength while reducing weight.

These innovations could lead to engines that are not only stronger but also more energy-efficient, making them more resilient under extreme conditions without compromising performance.

The rise of electric engines also presents new opportunities for engine durability. While electric motors don’t rely on combustion, their design still faces extreme conditions, especially when integrated into vehicles used for off-roading or harsh environments.

Electric vehicle (EV) manufacturers are already exploring new ways to make batteries and motor systems more resistant to heat, water, and mechanical stress.

Innovations like solid-state batteries promise to deliver higher resistance to both extreme temperatures and physical damage, potentially offering a new level of resilience for electric vehicles in the future.

Moreover, artificial intelligence and predictive analytics will play an increasing role in ensuring that engines are prepared for extreme conditions.

With real-time monitoring, AI can predict potential failures before they occur, allowing for maintenance or adjustments that can prevent catastrophic damage.

As technology continues to evolve, the future holds even greater possibilities for engines that can withstand unimaginable challenges, ensuring performance and safety even under the harshest conditions.

The incredible feats of survival witnessed in the flood, fire, and collision events are a testament to human ingenuity and the continuous advancement of engine technology.

Whether it’s a Toyota Land Cruiser, a Ford F-250, or a Boeing 747, engines designed with durability, fire resistance, and mechanical toughness are now better than ever at handling the worst conditions imaginable.

These stories of survival go beyond just proving the strength of the engines. They highlight the vital importance of innovation and resilience in engineering, and they provide valuable lessons for the future of engine design.

As we continue to push the boundaries of what’s possible, these engines will undoubtedly continue to inspire the next generation of breakthroughs in performance and durability.

Also Read: 5 Cars That Are Still Great at 15 Years and 5 That Should Be Gone