The internal combustion engine (ICE) is one of the most significant technological achievements of the modern world, driving everything from everyday vehicles to heavy machinery, ships, and planes.

For over a century, ICEs have evolved, offering more power, efficiency, and sophistication. However, despite these advancements, not all engines are built with the same expectations for longevity.

Some engines are known for their remarkable durability and resilience, often lasting several hundred thousand miles or more with proper maintenance. Others, however, seem to break down prematurely, sometimes leaving their owners frustrated and facing expensive repairs.

So, why is there such a stark difference in engine reliability? Some engines are designed to last a lifetime, while others are created with an inherently shorter lifespan in mind.

In this article, we will explore the various factors that influence engine durability, from engineering decisions to cost considerations, performance demands, and market dynamics. We’ll also examine how consumer expectations and vehicle purpose impact the design and longevity of engines.

Also Read: Why Farmers Swear by These Engines for Decades?

The Basics of Engine Design

To understand why some engines break down faster than others, we first need to explore the fundamentals of engine design. All engines are built with several critical considerations in mind:

-

Performance: How much power and torque should the engine produce?

-

Efficiency: What is the ideal fuel consumption rate, and how can emissions be minimized?

-

Durability: How long should the engine last before it requires significant repairs or replacement?

-

Cost: How can the engine be made to meet performance standards without exceeding manufacturing or repair costs?

Each of these considerations is in constant conflict with the others. For example, designing an engine for maximum power usually involves pushing it to higher performance limits, which can reduce its lifespan.

Conversely, engines designed for fuel efficiency often prioritize low stress on components, which might limit their performance potential. Similarly, cost constraints can lead to compromises on material quality, resulting in engines that are more prone to wear and tear.

While many consumers are attracted to high-performance vehicles, the true test of an engine’s worth often comes down to its longevity. But how does this tie into the real-world designs that often come with either extended life or a short-term focus?

Why Some Engines Are Designed to Fail

The concept of “planned obsolescence” refers to the practice of designing a product with an expected end-of-life, beyond which it is either difficult or impossible to repair.

In the case of engines, this can occur in various ways, ranging from intentional design flaws to the impact of market demands and cost-cutting measures. Let’s break down how some engines are “designed to fail” — whether by intention or through design compromises.

Planned Obsolescence

Planned obsolescence is often a result of corporate strategies aimed at maximizing profit. While it may not always be explicit, some manufacturers design engines with limited lifespans in order to:

-

Drive repeat sales.

-

Encourage consumers to upgrade or replace their vehicles sooner.

-

Ensure that repair costs exceed the value of the engine, incentivizing consumers to replace their cars instead.

In many cases, this planned failure is built into the engine’s design — such as the use of low-quality materials, or components that are difficult to repair.

For example, early 2000s turbocharged engines in certain small cars (like the Ford EcoBoost) were notorious for turbo failure and oil leaks, pushing owners into costly repairs or early replacements after about 80,000–100,000 miles.

While the intention behind planned obsolescence is often to boost sales, this strategy can lead to customer dissatisfaction, especially if owners find themselves needing to replace or repair their engine sooner than expected.

Cost-Cutting Measures

Mass production often requires automakers to make compromises on quality in order to reduce costs. Some of these compromises might involve:

-

Cheaper materials: Using lower-grade metals or plastics can reduce production costs, but may result in components that wear out more quickly.

-

Simplified manufacturing processes: While these processes may speed up production, they can lead to less durable engine components, such as thin-walled pistons or aluminum engine blocks that lack the robustness of cast-iron versions.

-

Lack of durability testing: To meet tight cost and production timelines, some engines may not undergo the same rigorous testing that would ensure their durability in the long run.

These cost-driven decisions contribute to engines that are more susceptible to failure over time, especially if they are not properly maintained.

Performance Over Durability

High-performance engines are designed to extract as much power as possible from the engine block, which often results in significant wear. This is particularly true for sports cars, racing engines, and luxury vehicles that are engineered to maximize output. Some examples include:

-

Turbocharged engines: While turbochargers can significantly boost engine power, they also add additional strain to the engine, increasing the likelihood of overheating and mechanical failure.

-

High-revving engines: Engines that operate at very high RPMs, such as those found in Formula 1 cars or certain sports vehicles, are often built for maximum power but suffer from shorter lifespans due to the stress on the components.

-

Fuel efficiency and emissions regulations: In some cases, automakers might focus on optimizing engines for lower emissions and fuel consumption, which can mean compromising on long-term durability in favor of meeting regulatory standards.

While performance-driven engines may delight in the short term, they are typically more prone to failure as they operate under conditions that push them to their limits.

Why Some Engines Are Built to Last

In contrast to engines designed with limited lifespans, some engines are known for their incredible durability. These engines are built with longevity in mind, and their design decisions reflect this focus. Let’s explore what makes these engines different and why they can often last well beyond their expected service life.

Understressed Design

One of the main reasons certain engines last longer is that they are built with a design that keeps the engine components operating well within their material limits. These engines:

-

Operate at lower stress levels: The design might prioritize a lower compression ratio, a more conservative use of forced induction (e.g., no turbocharging), and larger tolerances for wear.

-

Use over-engineered components: For example, heavy-duty engine blocks, forged steel crankshafts, and thicker cylinder walls can ensure that an engine can handle higher forces without breaking down.

-

Maintain conservative power levels: By not pushing the engine to its limits, manufacturers can ensure that the engine components aren’t subjected to high levels of wear.

This conservative approach can significantly extend the lifespan of an engine, as it avoids the constant strain and stress that often leads to premature failure in high-performance engines.

High-Quality Materials

Another factor that contributes to an engine’s longevity is the choice of materials used in its construction. High-quality, durable materials can help engines withstand the rigors of long-term use. Examples include:

-

Forged steel components: Forged parts are stronger and more durable than their cast counterparts.

-

High-strength alloys: Engines built with high-strength alloys (such as aluminum-silicon alloy) can better handle the heat and pressures of combustion without deteriorating as quickly.

-

Cast iron engine blocks: While heavier than aluminum, cast iron is often more durable and better at dissipating heat, which extends the engine’s lifespan.

By opting for these materials, manufacturers ensure that their engines can endure thousands of miles of use without showing signs of significant wear.

Simple and Reliable Designs

Engines that are designed for longevity tend to be simpler and less complex. By avoiding overly complicated systems and technologies, manufacturers can reduce the chances of failure. Features such as:

-

Naturally aspirated engines (no forced induction).

-

Simple port fuel injection (as opposed to direct injection, which is more complex and harder to maintain).

-

Fixed camshaft timing (instead of adjustable or variable valve timing).

Simplicity is the key to longevity, as each additional system or component introduces more points of potential failure. By using proven, straightforward designs, manufacturers can ensure that the engine operates reliably for hundreds of thousands of miles.

Routine Maintenance and Serviceability

Engines that are designed for longevity are often built with maintenance and serviceability in mind. Components that are easily accessible and replaceable make it easier for owners to keep the engine in good working condition. Features such as:

-

Easy access to oil filters and other regularly replaced parts.

-

Timing chains that last longer and are easier to replace than belts.

-

Service intervals that are practical for long-term maintenance.

Engines that are easy to service tend to last longer simply because owners can perform the necessary maintenance to keep them in good condition.

Real-World Examples: Engines That Last vs. Engines That Fail

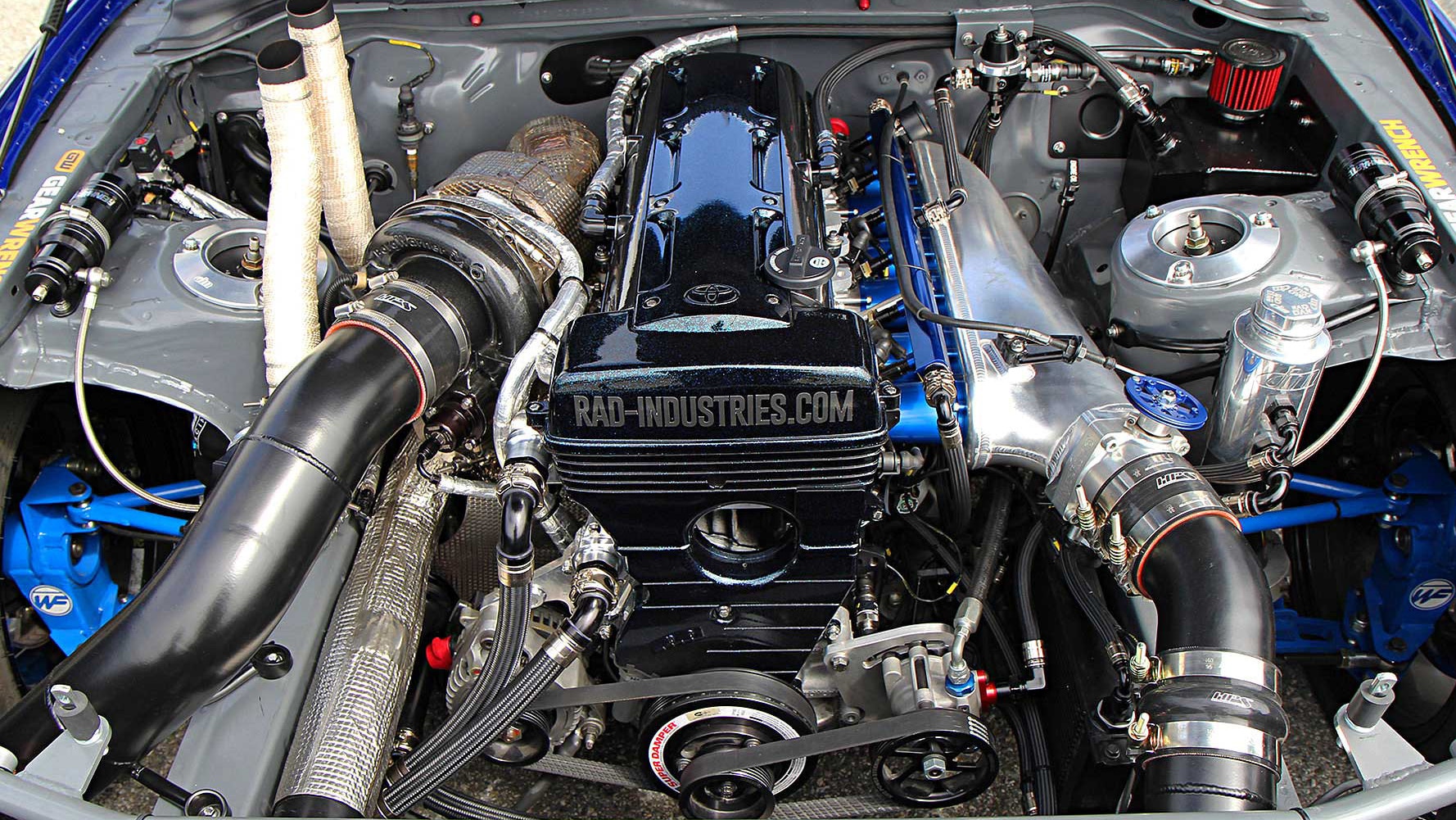

Reliable: The Toyota 2JZ-GTE

One of the most famous examples of a durable engine is the Toyota 2JZ-GTE, a 3.0L inline-six engine found in the Toyota Supra. It is renowned for its:

-

Overbuilt components, including an iron block and forged internals.

-

High boost capacity, enabling it to handle significant increases in power without internal damage.

-

Extreme reliability, with many examples surpassing 500,000 miles.

This engine is a prime example of the benefits of an over-engineered, naturally aspirated design that prioritizes durability.

Fragile: The Volkswagen 1.4 TSI

On the other hand, the Volkswagen 1.4 TSI engine is known for its performance issues. Common problems include:

-

Turbocharger failure.

-

Timing chain issues, particularly in early models.

-

Excessive oil consumption.

Despite its relatively high performance, the 1.4 TSI suffers from design flaws that result in reduced durability, especially under heavy use.

Maintenance and Repair Impact

Regardless of the engine’s initial design, proper maintenance plays a crucial role in ensuring longevity. Even the best-engineered engine can fail prematurely if it is poorly maintained. Regular oil changes, coolant flushes, and timely repairs can significantly extend an engine’s lifespan.

Conversely, even the most fragile engine can sometimes surprise its owner with remarkable longevity if it receives proper care. Engine longevity is not solely a result of design; maintenance is key.

The Future: Electric Motors and Reliability

As the automotive world shifts towards electric vehicles (EVs), the traditional debate about engine reliability might soon be less about internal combustion engines and more about electric motors.

Electric motors are simpler, with far fewer moving parts and no need for oil changes, timing belts, or complex valve systems. This simplicity suggests that, moving forward, electric vehicles may have a much lower risk of failure and require less frequent repairs.

The difference between engines designed to break and those designed to last boils down to a variety of factors, including engineering philosophy, performance goals, materials used, and maintenance requirements.

While some manufacturers design engines with longevity in mind, others prioritize performance, cost, or emissions compliance, sometimes at the expense of durability.

Ultimately, a combination of well-engineered design and consistent maintenance is key to ensuring an engine lasts. And as the automotive industry shifts towards electric powertrains, the next generation of vehicles may offer a new era of reliability and longevity.

For now, understanding these factors can help consumers make informed choices about the vehicles they drive and the engines that power them.

Also Read: Why Diesel Engines in Africa Last Longer Than in the US