In the world of machinery, whether on land, at sea, or in industrial facilities, the longevity and reliability of engines are paramount. One of the most critical aspects of engine maintenance is oil changes.

Engine oil lubricates, cools, and protects moving parts, but over time, it degrades, collects contaminants, and loses its effectiveness.

Traditionally, oil changes are required every 100 to 250 hours of engine operation in heavy machinery or every few thousand miles in automotive applications.

However, certain engines have pushed the boundaries of this expectation. Thanks to advanced engineering, high-quality synthetic oils, and robust filtration systems, some engines can run up to 500 hours or more without needing an oil change.

This breakthrough is not just a feat of mechanical engineering; it’s a practical solution to many real-world challenges where downtime for maintenance is expensive, impractical, or simply not possible.

In this article, we will take an in-depth look at:

-

The science behind long oil change intervals.

-

The industries that benefit most from 500-hour engines.

-

Notable engines across sectors that meet or exceed the 500-hour threshold.

-

The pros and cons of extended oil intervals.

-

What the future holds for oil change technology.

Also Read: The Engines That Have Survived a Flood, Fire, and Collision — All in One

The Science Behind Extended Oil Change Intervals

For an engine to run 500 hours without an oil change, multiple factors need to work together seamlessly. This is not just about pouring in premium oil and hoping for the best; it involves:

1. High-Quality Synthetic Oil

Synthetic oils are engineered to withstand higher temperatures, resist oxidation, and maintain viscosity longer than conventional oils. They are fortified with additives that neutralize acids, prevent sludge, and keep contaminants in suspension until the next oil change.

This type of oil is crucial for long oil change intervals because it has superior resistance to breakdown. The oil’s molecular structure is uniform and engineered to resist breakdown under high stress, which is why it’s the oil of choice for many engines aiming for extended service intervals.

2. Advanced Filtration Systems

Filters have evolved from simple paper elements to multi-layered systems that can trap microscopic particles and even water. Some engines incorporate bypass filters that provide ultra-fine filtration, extending the life of both oil and engine components.

These filters remove contaminants such as soot, carbon, and metal particles, ensuring that the oil remains clean for longer.

In some cases, engines incorporate dual filtration systems, with one primary filter for routine debris and another high-efficiency filter that traps finer particles and water. This dual setup can greatly extend oil life without sacrificing engine performance.

3. Engine Design and Materials

Engines designed for extended oil change intervals often have larger oil capacities, which dilutes contaminants and extends oil life. The larger the oil capacity, the more time it takes for contaminants to accumulate to levels that would degrade the oil’s performance.

Precision machining reduces friction and metal wear, and modern engines are built with durable materials that withstand high stresses over long periods.

For example, ceramic-coated pistons, high-strength alloys, and wear-resistant coatings on critical engine components prevent excessive metal debris from contaminating the oil.

4. Oil Monitoring Technology

Many modern engines include sensors that monitor oil quality in real time, measuring parameters like viscosity, contamination levels, and acidity.

These systems provide alerts when oil starts to degrade, ensuring timely maintenance even if the engine hasn’t reached its scheduled interval.

This is an innovative technology that has become crucial in engines that can operate over extended periods without manual oil changes.

Why 500-Hour Engines Matter

The ability to extend oil change intervals to 500 hours offers significant advantages:

-

Operational Efficiency: Machines can work longer between service stops, maximizing productivity. In industries like agriculture, construction, and shipping, downtime can be extremely costly. Reducing the need for oil changes is an effective way to keep operations running smoothly.

-

Cost Savings: Fewer oil changes mean reduced labor costs and lower spending on oil and filters. For large fleets or high-demand machinery, these savings can be substantial over time. In addition, the downtime required for maintenance is minimized.

-

Environmental Benefits: Less oil consumption and fewer oil changes mean reduced environmental impact. Fewer used oil disposal events result in less contamination and pollution. Moreover, longer oil change intervals reduce the need for producing and transporting oil.

-

Convenience: Especially valuable in remote locations where servicing engines is difficult or impossible on short notice. In areas such as offshore oil rigs or far-flung construction sites, servicing engines can be a logistical challenge. Engines with longer oil change intervals reduce the need for frequent servicing.

Industries like agriculture, construction, marine transport, and power generation particularly benefit from engines that can push these boundaries.

Notable 500-Hour Engines in Heavy Industry: Caterpillar C7.1 Industrial Engine

The Caterpillar C7.1 is a staple in heavy machinery, powering everything from excavators to agricultural harvesters.

Designed to endure rugged environments and constant heavy loads, this engine boasts a 500-hour oil change interval as part of its core appeal. Caterpillar is known for its industrial-grade engines, and the C7.1 is no exception.

Why It Excels:

-

Superior Filtration: Uses Cat Advanced High-Efficiency oil filters that capture even the smallest contaminants.

-

Oil Monitoring: Integrated with Product Link for real-time condition monitoring, allowing operators to track oil quality and engine health remotely.

-

Durability: Built with wear-resistant components that minimize metal particles in oil, ensuring cleaner oil for longer.

This engine is a favorite in industries where downtime equates to massive financial loss, such as construction, mining, and agriculture.

John Deere PowerTech PSS 9.0L Engine

John Deere has a reputation for building engines that are as tough as the jobs they handle. The PowerTech PSS 9.0L, often found in forestry and agricultural machinery, offers 500-hour oil change intervals when paired with John Deere Plus-50 II oil and high-capacity filters.

John Deere’s commitment to innovation in engine technology has made it a leader in the industry.

Key Advantages:

-

Extended Drain Intervals: Thanks to optimized combustion and oil technology, this engine can operate for extended periods without degrading performance.

-

Diagnostic Tools: The Service Advisor software provides predictive maintenance insights, ensuring that any potential issues are caught early.

-

Robust Design: Engineered for continuous operation during peak seasons, the engine is built to last in the toughest conditions.

Farmers and contractors alike appreciate the ability to work an entire season with minimal interruptions, improving productivity and reducing maintenance costs.

Marine Engines with Extended Oil Change Intervals: Volvo Penta D13 Marine Engine

Marine engines have to contend with high moisture levels, salt corrosion, and long operational hours.

The Volvo Penta D13, used in both commercial and pleasure vessels, is engineered for 500-hour oil change intervals under standard conditions. This engine’s design prioritizes durability and long service life in marine environments.

Why It Works:

-

Dual Filtration: Uses high-efficiency filters that ensure the oil stays clean, even in the harshest marine environments.

-

Corrosion Resistance: Marine-specific design incorporates materials and coatings that withstand saltwater corrosion.

-

Advanced Diagnostics: Real-time performance and oil monitoring allow operators to track the condition of the engine and adjust maintenance schedules accordingly.

For long voyages or continuous commercial operations, the peace of mind that comes with extended oil intervals is invaluable.

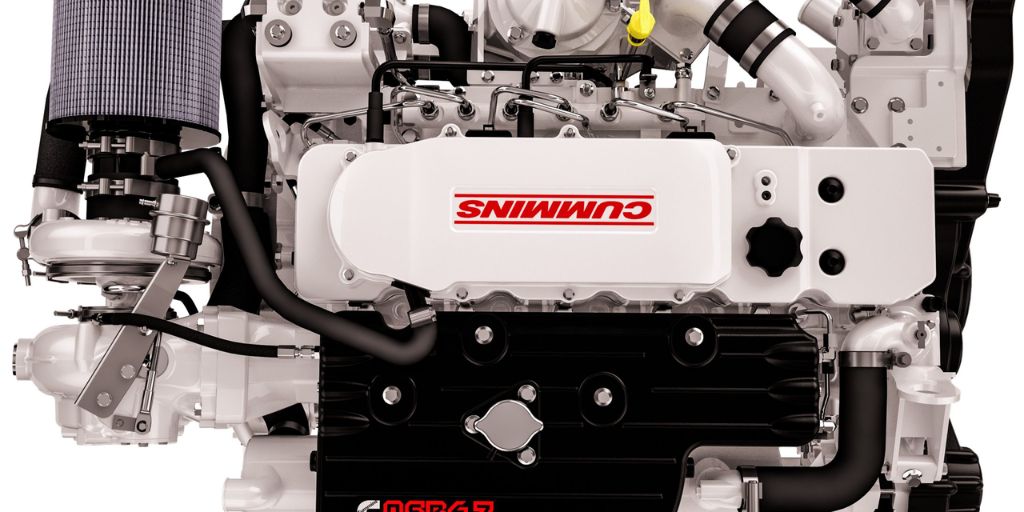

Cummins QSB6.7 Marine Engine

This engine is a workhorse in fishing fleets, pilot boats, and other commercial vessels, offering dependable power with a 500-hour oil change interval.

Cummins engines are known for their resilience and efficiency, and the QSB6.7 exemplifies these qualities in the marine environment.

Standout Features:

-

Common Rail Fuel System: The high-pressure fuel injection system improves combustion, reducing soot production and extending oil life.

-

Smart Controls: Full-authority electronic control of oil pressure ensures optimal performance under all operating conditions.

-

Marine-Grade Materials: Built to withstand constant exposure to salt and moisture, preventing rust and corrosion from degrading engine performance.

This engine is ideal for maritime operations where reliability and efficiency are crucial.

Automotive Engines Making Strides: Mercedes-Benz OM642 Diesel Engine

Although automotive engines rarely hit the 500-hour mark due to mileage-based maintenance schedules, the Mercedes-Benz OM642 diesel engine—used in vehicles like the Sprinter van and E-Class—comes close when measured in hours. Mercedes-Benz’s engineering for longevity is reflected in this engine’s performance.

Innovations:

-

Low-Ash Oils: Specially formulated to extend oil life, the low-ash design ensures minimal carbon buildup, preventing premature oil degradation.

-

Precision Engineering: Tight tolerances reduce oil contamination and increase engine cleanliness.

-

Onboard Diagnostics: Real-time oil condition monitoring helps ensure that oil change intervals are optimized for the engine’s health.

For long-haul drivers and fleet managers, the extended oil change intervals reduce downtime and lower the total cost of ownership. Fleets, in particular, can benefit from reduced maintenance overhead.

The Role of Synthetic Oils

Oils like Mobil Delvac 1, Shell Rotella T6, and John Deere Plus-50 II are integral to extended oil change intervals. These oils have been formulated to provide:

-

Resist Thermal Breakdown: These oils maintain their viscosity even under high temperatures, which are typical in high-performance engines.

-

Fight Contaminants: Additives neutralize acids and suspend debris, keeping the oil clean and effective.

-

Stay Cleaner Longer: These oils are designed to resist sludge and varnish buildup, which typically occurs in engines with long operating hours.

Using the right oil is the key to achieving long intervals between oil changes, as it ensures that the engine stays lubricated, clean, and protected over time.

Challenges and Risks

While 500-hour oil change intervals offer many benefits, there are also risks and challenges:

-

Oil Degradation: Even synthetic oils break down eventually. High temperatures, engine stress, and external factors such as dirt or water ingress can accelerate oil degradation.

-

Contamination Risks: Engines that operate in extremely dusty or wet environments may see oil degradation faster, regardless of the oil type or filtration systems.

-

Maintenance Oversight: Relying solely on long oil change intervals without regular inspections can lead to unnoticed issues that compromise engine performance and lifespan.

What the Future Holds

As engine and lubricant technologies continue to evolve, the industry is pushing toward even longer intervals. Research is focusing on:

-

Nanotechnology: Using nanoparticles in oils to enhance lubrication and reduce friction.

-

Self-Healing Oils: Lubricants that regenerate their protective qualities after use, extending oil life even further.

-

AI Diagnostics: Predictive analytics that optimize maintenance schedules by analyzing data from multiple engine sensors, ensuring that the engine performs optimally without excessive oil changes.

The push for sustainability is also driving innovation. As more engines are designed for longer oil change intervals, manufacturers are working on reducing oil consumption, improving oil disposal methods, and minimizing the environmental footprint.

Engines capable of running 500 hours without an oil change are revolutionizing multiple industries, offering reduced maintenance costs, greater efficiency, and environmental benefits.

Whether it’s a Caterpillar industrial engine, a Volvo Penta marine workhorse, or a high-efficiency diesel in an automotive fleet, these machines prove that with the right engineering and lubrication, long-lasting performance is more than possible—it’s becoming the new standard.

For operators, fleet managers, and vessel owners, investing in engines with extended oil change intervals translates into real-world advantages.

But it’s crucial to combine these advancements with disciplined maintenance practices to ensure the engine remains in peak condition for as long as possible.

With the rapid pace of technological innovation, it’s safe to say that the 500-hour oil change engine is just the beginning of a new era in engine longevity.

Also Read: The Science Behind Engines That Don’t Even Need Water Cooling