As the automotive industry continues to advance with innovations designed to improve the quality of today’s vehicles making them more fuel-efficient, lowering emissions, and sometimes even increasing power new technologies are also being employed to enhance designs and engines.

One of the most common questions potential buyers ask when considering a vehicle is, “How reliable is it?” Consumers typically seek a car that will offer dependable performance and won’t break down unexpectedly.

Car manufacturers are always striving to develop vehicles that outperform their competitors. A key factor in achieving this goal is producing reliable engines capable of enduring many more miles with proper care and maintenance.

This updated list showcases engines known for their longevity and durability, able to withstand decades of use on the road. A car serves as our primary mode of transportation, getting us from point A to point B, often with a bit of enjoyment added to the journey.

Most Reliable Car Engines

If it can’t fulfill this basic role, what’s the point? Of course, this doesn’t apply if it’s a project car you’re building with specific goals in mind.

Even then, you’d still have a daily driver, and reliability would be a top priority. With that in mind, we’ve compiled a list of the most reliable car engines ever made.

Lexus 2UR-GSE

The Lexus 2UR-GSE is another standout engine, a 32-valve DOHC V8 introduced by Toyota in 2006 to replace the aging UZ engine.

Designed with advanced technologies for improved fuel efficiency, such as dual VVTi and direct injection (D4-S), the 2UR-GSE has become a key player in Lexus’ performance lineup.

It powers several high-performance models, including the Lexus IS F, RC F, GS F, and the LC 500. The engine boasts a 5.0-liter displacement, producing between 422 and 482 horsepower and 371 to 399 lb-ft of torque, running on gasoline.

Known for its durability, the 2UR-GSE has a unique build structure compared to other UR engines. Despite being built for performance, it remains impressively reliable, often surpassing 200,000 miles with proper maintenance.

This makes it a reliable powerhouse, especially for a performance-focused engine, demonstrating the perfect blend of power and dependability.

The Toyota/Lexus 2UR-GSE is a 5.0-liter V-8 engine that you may recognize from various Lexus models, including the original Lexus IS F, GS F, RC F, LC 500, and the current IS 500 F Sport Performance.

I consider this engine one of the greatest and most underrated V-8s ever produced, known for its remarkable performance and refinement. Lexus, typically associated with producing luxurious, reliable, and comfortable cars that focus on quality and detail, was once also known for manufacturing some of the more unexciting vehicles in the market.

However, the introduction of the 2UR-GSE marked a significant turning point, helping transform Lexus into a brand known for producing some of the most exciting and enjoyable cars on the road.

One of the standout features of the 2UR-GSE is that it is a naturally aspirated engine, meaning it doesn’t rely on turbochargers or superchargers to force air into the combustion chamber.

In the past, internal combustion engines were predominantly naturally aspirated, where air naturally flows into the intake, allowing for a complete and efficient combustion cycle with a stoichiometric ratio of 14.7 parts air to one part fuel.

Although forced induction has been around for a long time, it was initially reserved for specific applications, such as diesel engines or high-performance vehicles.

Over time, forced induction became more common, but still, it was not nearly as ubiquitous as it is in modern cars. Today, almost every automobile is equipped with a turbocharged engine, with some even utilizing superchargers.

While superchargers remain primarily for high-performance applications, turbochargers have become commonplace in everything from basic crossover SUVs to fast luxury cars, helping automakers meet fuel economy and emissions standards.

As a result, naturally aspirated engines like the 2UR-GSE are becoming increasingly rare, making it a unique and special option in today’s automotive landscape.

So, why is the naturally aspirated 2UR-GSE engine considered superior to forced-induction engines? The answer lies in the way these engines deliver power.

Naturally aspirated engines, such as the 2UR-GSE in the Lexus F models and IS 500 F Sport Performance, offer a more linear and immediate power delivery without the turbo lag or power plateau commonly associated with turbocharged and supercharged engines.

Forced induction engines, while capable of producing substantial power, often suffer from “turbo lag,” a delay in the engine’s power output as it revs up from lower speeds to its redline, making the driving experience less immediate and responsive. The 2UR-GSE, on the other hand, provides a more natural and consistent powerband, contributing to its appeal among driving enthusiasts.

Also Read: 10 Ford’s Best V8 Engines Ranked by Real-World Longevity and Proven Reliability

BMW M57 Diesel

The BMW M57 Diesel engine is another example of a highly reliable engine from the brand. While BMW is sometimes associated with complex engineering that raises concerns about reliability, the M57 diesel engine stands out for its dependability.

This 3.0-liter turbocharged, water-cooled straight inline-six diesel engine is equipped with common rail injection. Over the years, BMW made two revisions to the engine, adding different turbochargers to boost power output.

Though diesel engines may not be as popular in some countries that favor gasoline models, the M57 was used in several notable BMW models, such as the E39 525d, E46 330d, and E90 325d.

Known for its durability, the M57 Diesel offers substantial power while remaining one of BMW’s most dependable engines. However, some owners have experienced issues such as carbon build-up, glow plug failures, and occasional turbocharger problems.

BMW has long been a name synonymous with performance and engineering excellence, and among the many impressive engines the company has produced, the M57 stands out as one of the most celebrated.

This engine won the 2.5–3.0 liter category at the International Engine of the Year competition from 1999 to 2002 and again in 2009, gaining a reputation for its robustness and outstanding performance.

As a result, the BMW M57 has developed a dedicated following among car enthusiasts and owners. Introduced in 1998, the BMW M57 is a straight-six diesel engine that features a common rail injection system and a turbocharger.

Over time, it has seen various updates, with its initial horsepower output of 148 increasing to 282 by 2006. Known for its combination of power, efficiency, and durability, the M57 is widely regarded as a reliable engine, though it does come with some common issues that potential owners should be aware of.

One of the main problems that can affect the M57 engine is related to the swirl flaps, small metal components in the intake manifold designed to improve the air-fuel mixture at lower engine speeds.

These flaps can break off, leading to serious damage to the cylinders, pistons, and valves if they get sucked into the engine. Additionally, carbon deposits can accumulate on the swirl flaps, which obstructs airflow, reducing the engine’s performance and fuel economy.

The most effective solution to this issue is to completely remove the swirl flaps and replace them with blanking plates or a new intake manifold without swirl flaps. Another potential issue is the turbocharger, which is responsible for boosting the air pressure in the engine and increasing power output.

If the turbocharger fails—due to reasons like oil leaks, worn bearings, cracked housings, or faulty wastegates—it can result in a loss of power, black smoke from the exhaust, loud noises, or excessive oil consumption. Regular inspection and timely replacement of the turbocharger can help prevent these problems.

The injectors, responsible for spraying fuel into the combustion chambers, can also wear out over time. Malfunctioning injectors may cause poor starting, rough idling, misfires, exhaust smoke, or reduced power.

Cleaning or replacing the injectors when necessary can help maintain engine performance. Finally, the glow plugs, which heat the cylinders before the engine starts, especially in cold conditions, may fail due to age, corrosion, or electrical issues.

When a glow plug fails, it can cause difficulty starting, white smoke from the exhaust, or increased emissions. Regular checks of the glow plugs are recommended, and faulty plugs should be replaced promptly to ensure the engine runs smoothly.

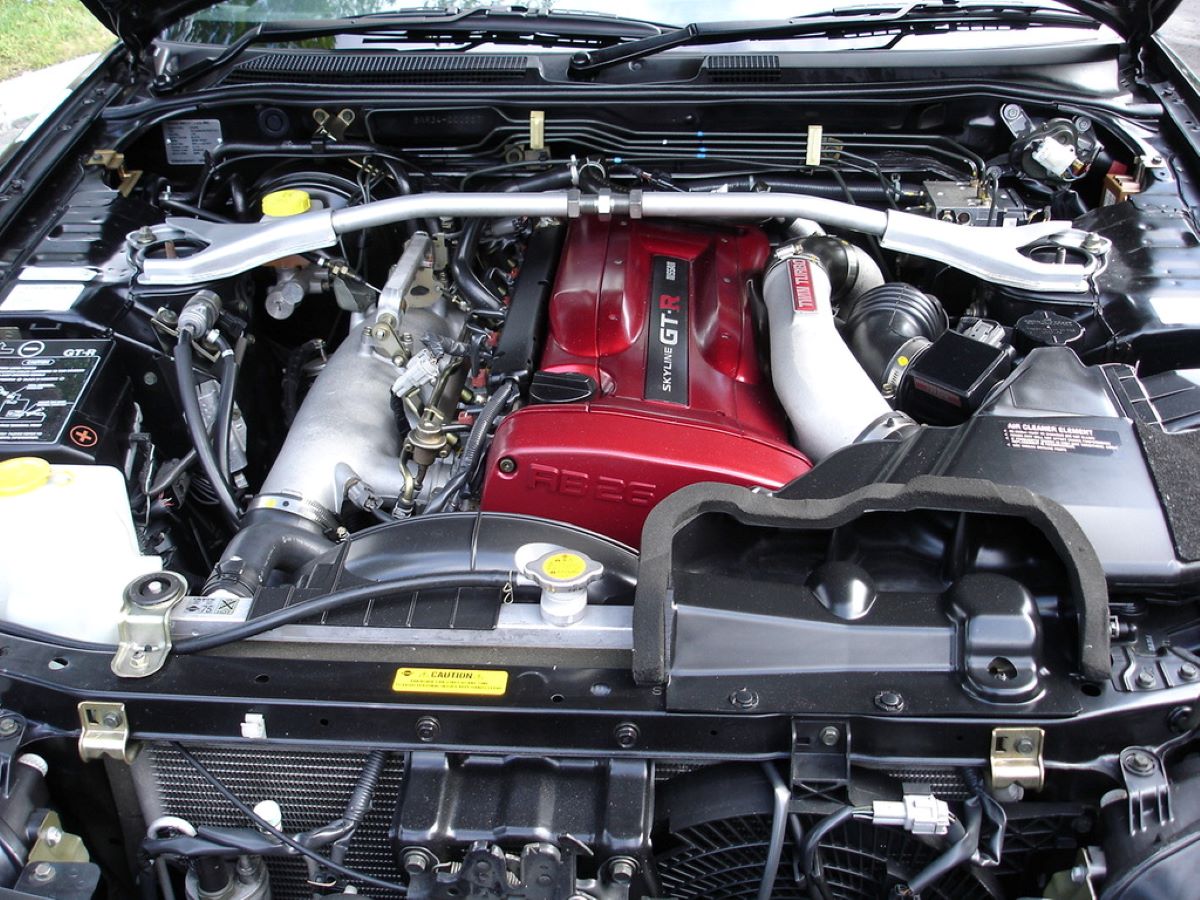

Nissan RB26DETT Engine

The Nissan RB26DETT engine is another engine known for its reliability, particularly in its stock form. Built as a performance engine, it became famous for its role in the Nissan Skyline GT-R models.

While there are numerous versions of the RB26, what makes the RB26DETT unique is its oil port on the cylinder block, a feature not present in other RB engines.

This oil port helps protect the engine, enhancing its overall reliability. The RB26DETT’s iron block and forged internals make it a strong and durable engine, with significant tuning potential.

That said, some RB26DETT engines have faced issues such as overheating, faulty oil pumps, and piston ring failures, though these are generally less common in unmodified engines.

The Nissan RB engine series originated in the mid-1980s, with its name derived from the phrase “Response Balance.” The first iteration of the RB engine debuted in the fifth-generation Nissan Laurel and would eventually evolve into one of the most legendary engine platforms in the history of tuner culture.

Its presence in iconic models like the Skyline GT-R, paired with its ongoing reverence in the tuning community, solidified the RB26DETT as a true icon of Japanese automotive engineering.

Beyond the “Response Balance” moniker, the designation RB26DETT carries deeper meaning through its alphanumeric code. The “26” denotes the engine’s 2.6-liter displacement.

The “D” indicates a dual overhead camshaft design, while the “E” stands for electronic fuel injection. Finally, the “TT” confirms that the engine features twin turbochargers, enhancing its power and performance capabilities.

The RB26DETT first made its debut when Nissan engineers decided to revive a performance legend. For the first time in decades, the revered “GT-R” badge was being reintroduced to the Skyline lineup.

This occurred with the launch of the R32 Nissan Skyline GT-R in 1989, a model that quickly earned the nickname “Godzilla” within motorsport circles due to its dominant presence on the track. While the car’s advanced all-wheel-drive system certainly contributed to its success, it was the RB26DETT that served as the heart of its performance.

In the R32 GT-R, the RB26DETT was officially rated at “276 horsepower.” Those quotation marks are intentional and worth a quick dive into context. During the late 1980s, Japanese automakers entered into an informal “gentlemen’s agreement” to cap performance car output at 276 horsepower in the name of public safety.

However, many of these vehicles, once tested on dynamometers, often produced significantly more power than advertised—sometimes far more. Whether that discrepancy was deliberate or not is up for debate, though it happened to coincide with an era in which high-performance Japanese sports cars began taking global markets by storm.

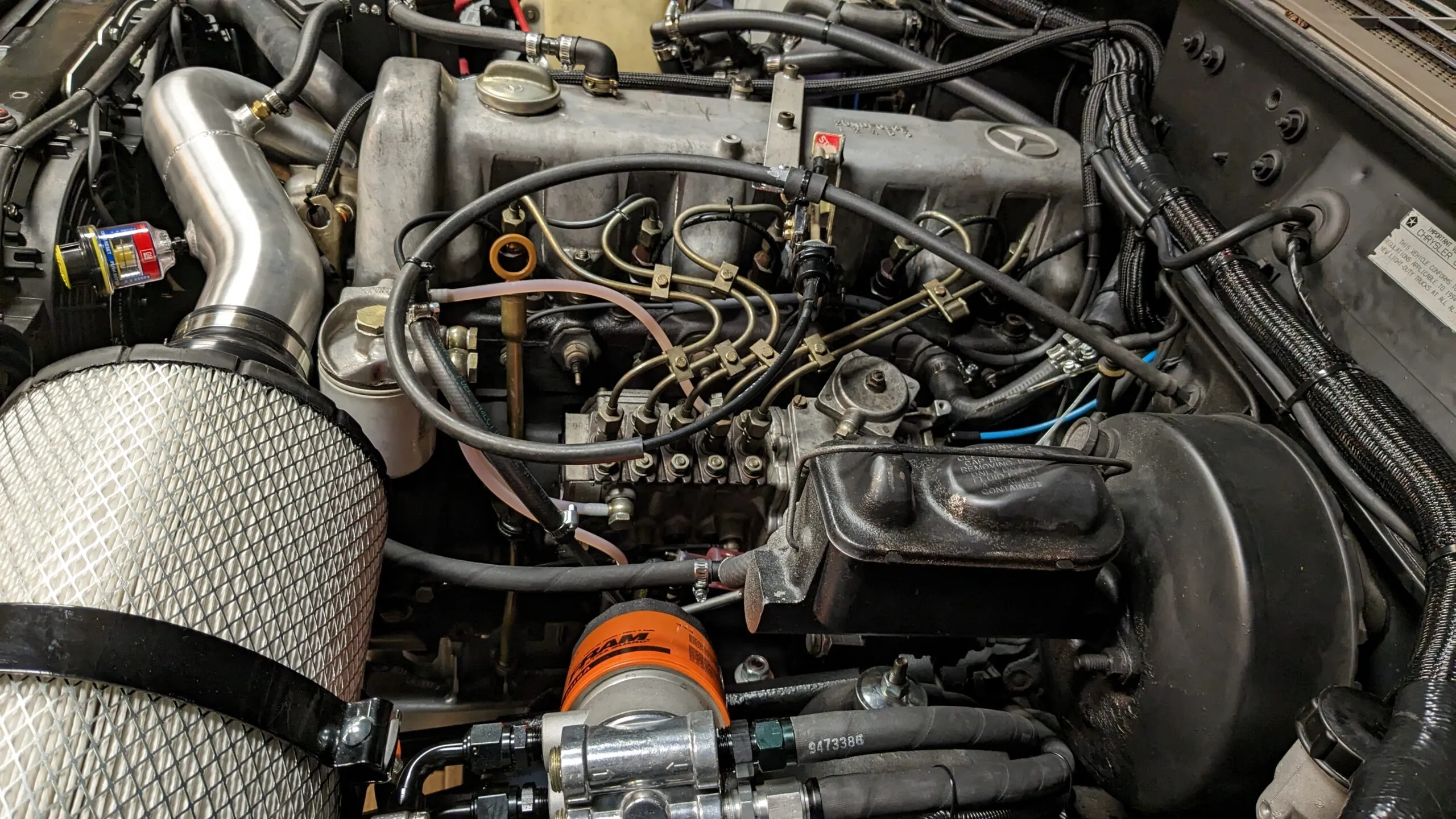

Mercedes-Benz OM617 Diesel Engine

The Mercedes-Benz OM617 diesel engine is highly regarded for its reliability and was used across a wide range of models, including the Mercedes-Benz 300 D, Mercedes-Benz 300SD Turbo, Mercedes-Benz G-Class (W460/W461), and Mercedes-Benz 300CD.

Produced from 1974 to 1991, this inline-five engine has a 3.0-liter displacement, offering between 80 and 230 horsepower and 124 to 184 lb-ft of torque. It became legendary for its durability, with the ability to exceed half a million miles without requiring a rebuild.

The OM617 was used in various models during the ’70s and ’80s, providing not only reliability but also sufficient power for its era. To maintain such longevity, regular maintenance is essential, such as replacing timing chains, motor mounts, and performing routine oil changes.

This level of upkeep is standard for any vehicle, as no car is completely maintenance-free, ensuring that the OM617 continues to perform well for many years.

Also Read: 13 Engines That Made Japanese Cars Unstoppable and Changed Performance Culture Forever

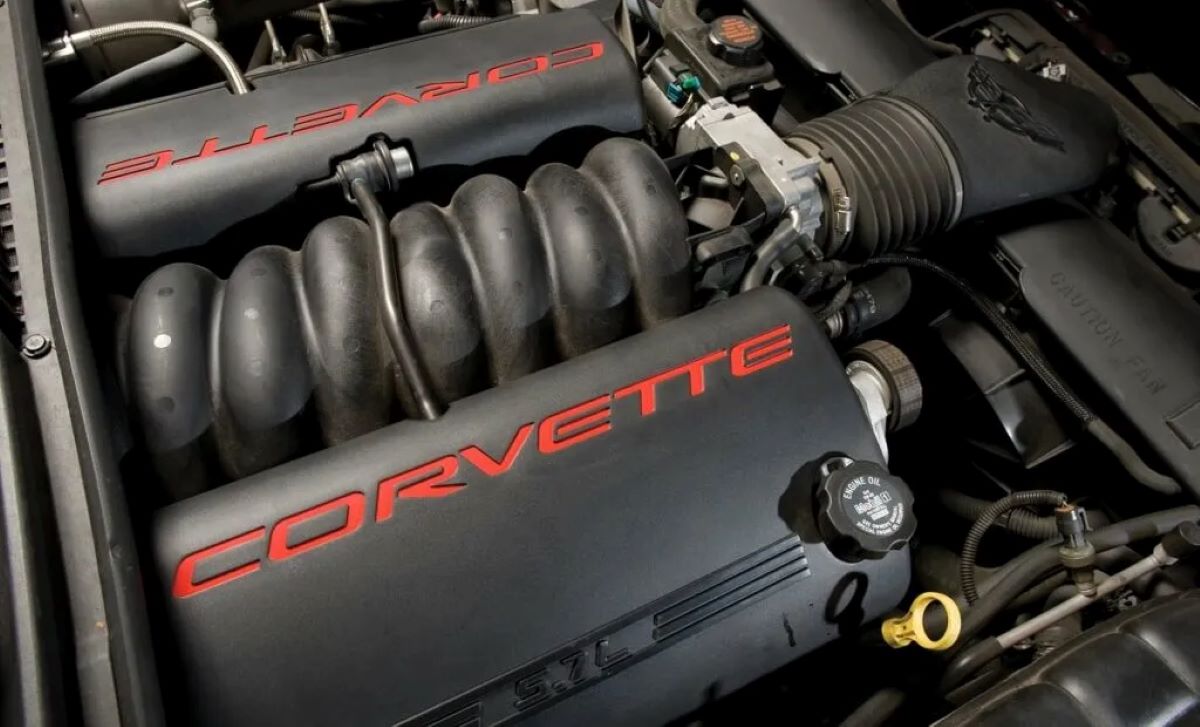

General Motors LS Engine

The General Motors LS engine is widely regarded as one of the greatest V8 engines ever made, first introduced by GM in 1997. It has consistently evolved over the years, offering power, durability, and reliability.

This modern V8 engine family remains a top choice due to its consistent performance. GM continues to produce the LS engines, ensuring they are readily available for enthusiasts and builders.

The company offers three crate engine options: the LS3, LS376/480, and LS376/525, all of which deliver over 430 horsepower and 425 lb-ft of torque. The most powerful variant produces an impressive 525 horsepower and 486 lb-ft of torque.

One of the significant advantages of the LS engine is the ease of part replacement, which allows owners to modify and increase the engine’s power if desired.

It has been used in a variety of performance cars, including the Chevrolet Corvette C5, C5 Z06, C6 Corvette ZR1, C7 Corvette Z06, C7 Corvette ZR1, and the Camaro ZL1.

The LS engine has earned a reputation for reliability, consistently being found in some of the best American performance cars.

While it is known for its dependability, there are occasional issues such as oil consumption, cracked cylinder heads, and failed camshaft phasers. Despite these minor problems, the LS engine remains a favorite for its outstanding durability and performance.

Most Horrible Engines of All Time

We’ve already explored some of the worst engines ever created, but instead of focusing solely on classic failures or modern disappointments, we’ve compiled a list that spans both.

Some of these engines were doomed to catastrophic failure from the start, while others simply failed to live up to expectations.

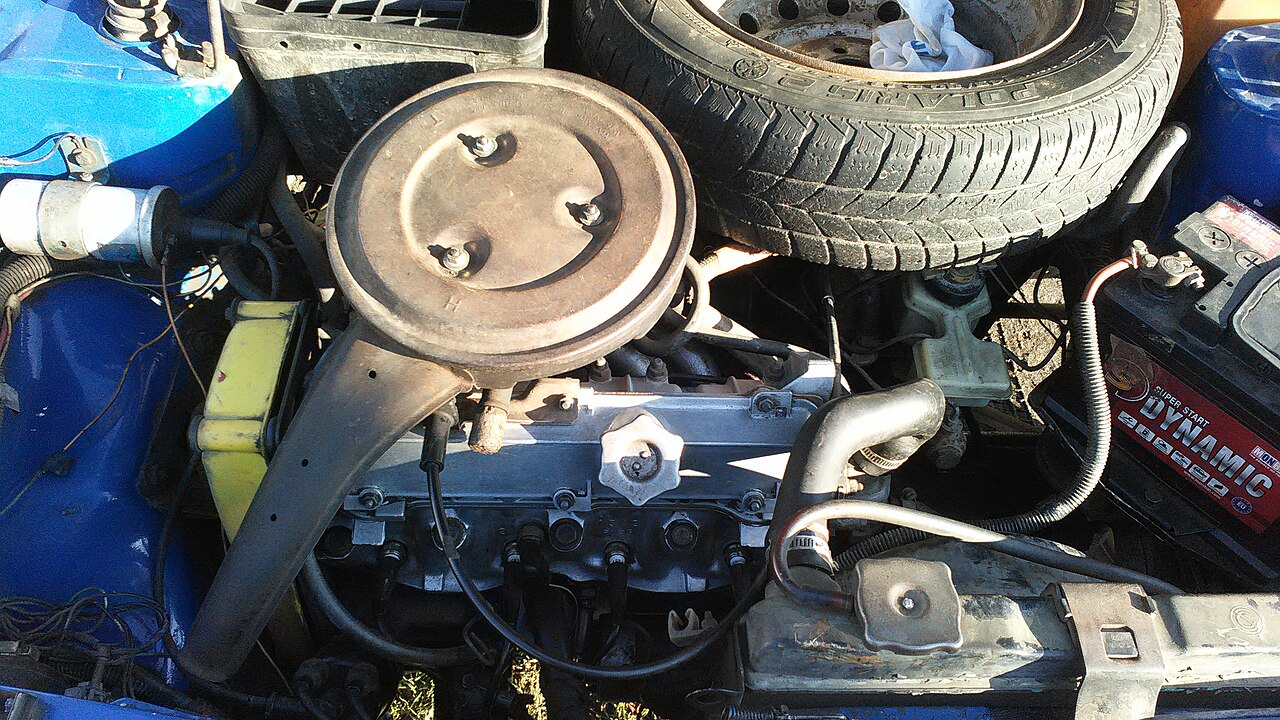

Chevy 2.2-liter Ecotec

The newer 2.2-liter Ecotec engines are perfectly reliable, but it’s the pre-2006 generation that deserves attention for all the wrong reasons. This four-cylinder engine gained a notorious reputation for lacking power and reliability.

It was offered in a wide range of vehicles, from the Chevrolet Cavalier to the S-10 pickup. During its time, critics strongly advised buyers to avoid these engines, citing their underperformance.

The engine’s lack of power and durability were bad enough, but one of its most significant flaws was the tendency for the freeze plugs to corrode after only 50,000 miles.

As the editors at Hot Rod put it, “It’s no wonder GM used absolutely no engineering or design from this engine when developing the (new) Ecotec.”

The Ecotec 2.2-liter engine, recognized as General Motors’ first truly global powerplant, offers impressive fuel efficiency and low emissions, all while maintaining strong reliability, durability, and minimal noise and vibration.

This lightweight, aluminum, four-valve overhead cam engine was introduced for the 2002 model year and is available in the Chevrolet Cavalier, Oldsmobile Alero, Pontiac Sunfire and Grand Am, as well as the Saturn L-Series and VUE.

In the Chevrolet, Oldsmobile, and Pontiac models, the engine delivers 140 horsepower and 150 lb-ft of peak torque. The Saturn VUE variant is slightly more powerful, producing 143 horsepower and 152 lb-ft of torque, while the L-Series version is rated at 135 horsepower and 142 lb-ft of torque.

The Ecotec 2.2-liter features a modular design that allows for future enhancements such as turbocharging, variable valve timing, and direct gasoline injection. One of the standout qualities of this engine is its low maintenance requirement—routine service is limited to just oil and filter changes.

For North American vehicles, the engine is produced at GM’s Tonawanda, New York facility—one of the world’s largest engine plants. Globally, this engine has already proven its merit, having debuted in the 2000 Saturn L-Series and powering numerous 2001 European models including the Opel Vectra, Astra, Zafira, and Speedster.

Compact and efficient, the Ecotec 2.2-liter makes use of lightweight aluminum for both the cylinder head and engine block, employing the lost foam casting process. Thanks to its modern design, the engine weighs only 139 kilograms (307 pounds, depending on application).

The compact nature of the engine extends to its construction as well. Its two overhead camshafts actuate the intake and exhaust valves via roller finger follower rocker arms, resulting in a streamlined cylinder head design.

The camshafts are driven by a single 12.5-millimeter-wide roller chain rather than a broader toothed rubber belt, contributing to a shorter overall engine length and mass savings.

The engine’s stroke measures 94.6 millimeters and its bore is 86 millimeters. In total, its dimensions are compact: 665 mm in length, 642 mm in width, and 655 mm in height (26.2 x 25.3 x 25.8 inches).

Another key attribute of the Ecotec 2.2-liter is its remarkably smooth operation and minimal vibration. This is achieved with counter-rotating balance shafts built into the cylinder block that neutralize the vertical imbalances typical of inline four-cylinder engines.

Structural rigidity and noise reduction are further supported by the use of a structural oil pan, a box-like lower crankcase, a multi-layer steel (MLS) head gasket, and long 163-millimeter (6.25-inch) cylinder head bolts

. The transmission connects with a 360-degree mounting flange to increase overall powertrain rigidity. Additionally, all engine accessories are mounted directly to the engine structure without brackets, helping eliminate vibration and noise.

When it comes to maintenance, the Ecotec 2.2-liter is designed with simplicity in mind. Its timing chain, supported by a hydraulic tensioner, requires no maintenance throughout its service life.

The high-performance ignition module is integrated into the cylinder head cover and features two individual coils mounted directly above the platinum spark plugs—removing the need for spark plug wires and further reducing maintenance demands.

The finger follower valvetrain uses hydraulic lash adjusters, eliminating the need for periodic adjustment. Overall, aside from routine oil and fully recyclable filter changes, the Ecotec 2.2-liter engine requires no additional scheduled maintenance.

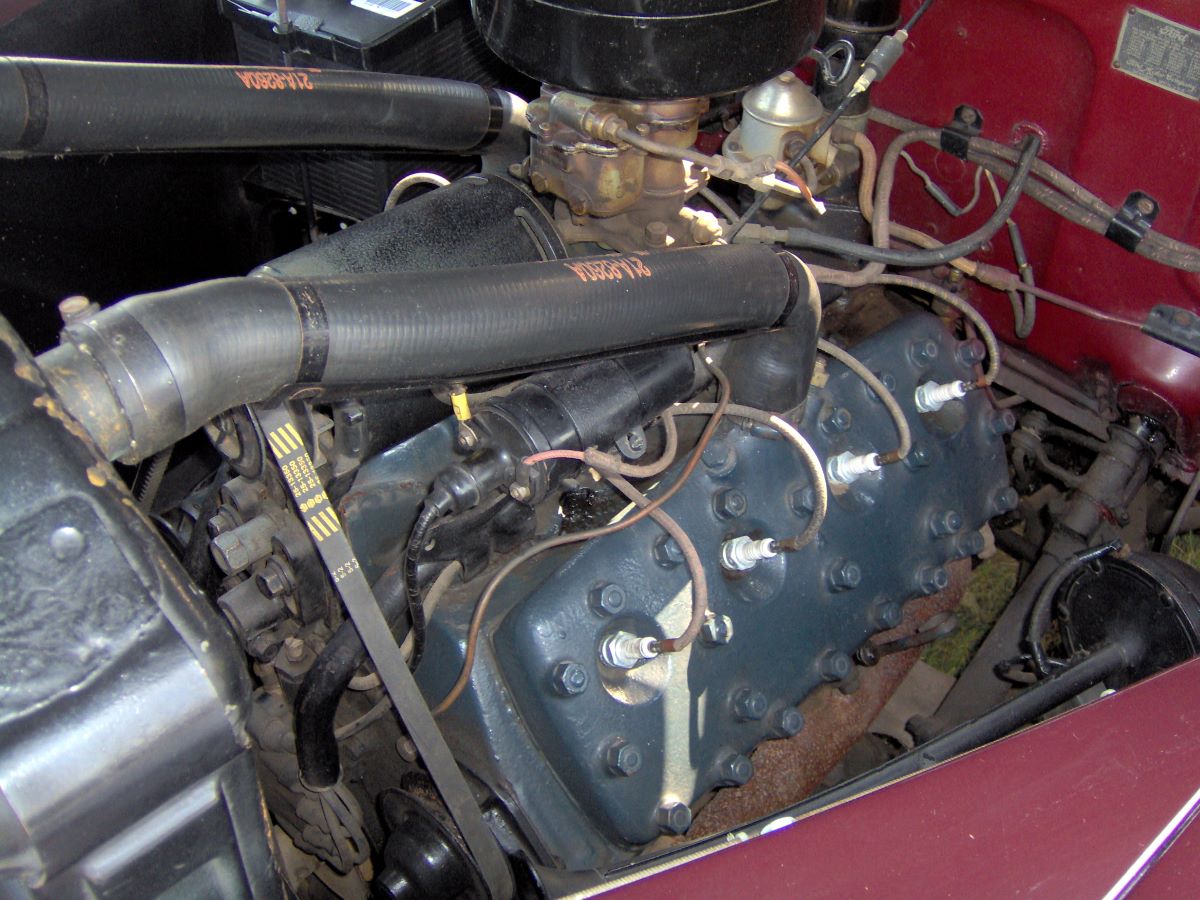

The First Ford V8

The Ford flathead, as the first production V8 engine from Ford, was a landmark in automotive history, remaining in production for over two decades.

It helped usher in a new era of faster American transportation. However, the early versions of this V8 engine were riddled with issues. The piston rings weren’t made from properly hardened steel, causing the engine to burn oil excessively.

Additionally, due to flaws in the cooling system design, the rear cylinders consistently ran hotter than the front six. The intake manifold struggled to properly mix the fuel with air, resulting in one bank of cylinders running too rich while the other ran too lean.

As a result, it wasn’t uncommon for this engine to burn a quart of oil every 100 miles, and issues with the ignition and water pump were frequent.

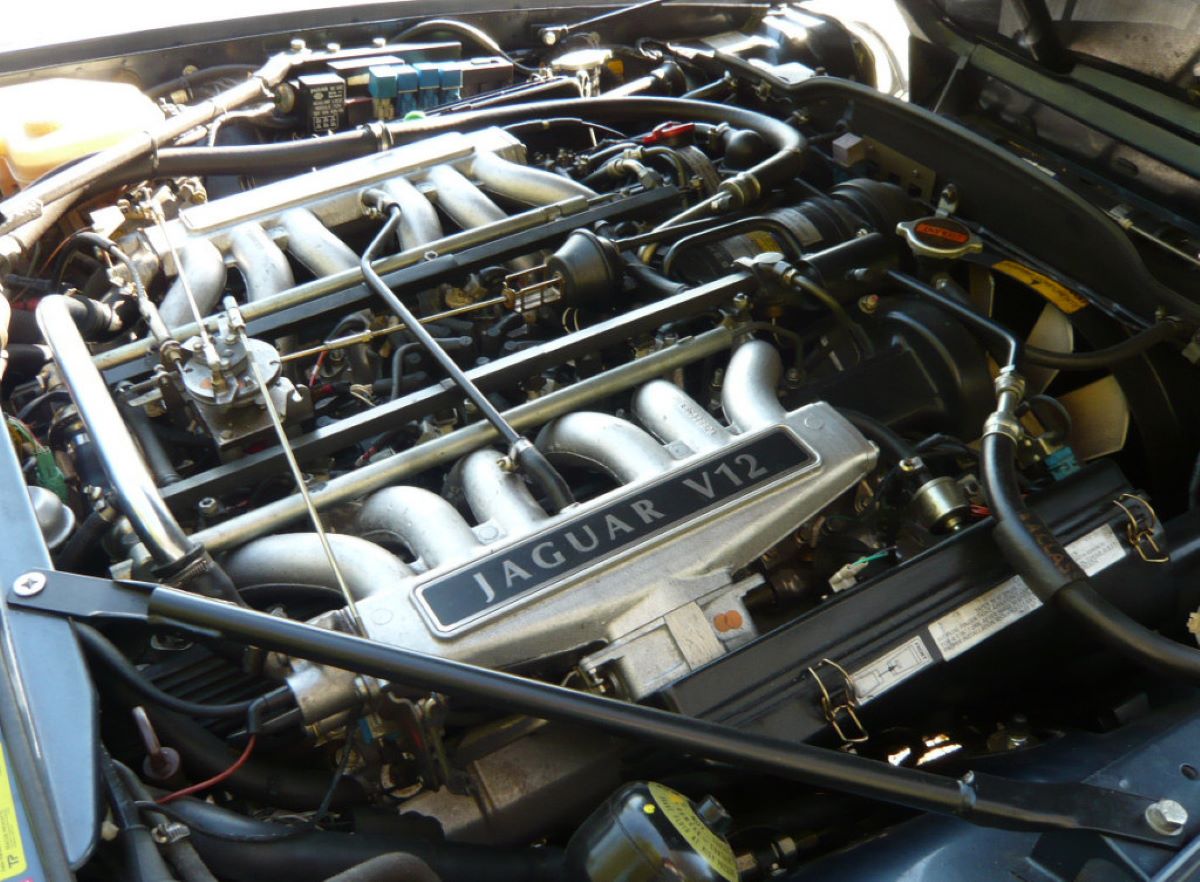

Jaguar V12

The majority of issues with the Jaguar V12 engine are caused by heat. The proximity of the ignition and fuel systems to each other made both components prone to failure over time.

While this design was chosen to address space constraints, many still view these engines as ticking time bombs. The V12’s electrical system was also negatively impacted by heat, with wiring near the engine unraveling and frying, which led to various electrical issues.

Early models of this engine also had intakes that were surrounded by a tangle of rubber hoses, which often cracked and caused leaks.

The Jaguar V12, born in 1971, traces its lineage back to motorsport—just as any truly great engine should—and remained in production until 1997.

Over its lengthy production run, the Jaguar V12 saw its displacement increase from the original 5.3 liters to 6.0 liters in its road-going form. In its racing iterations, it expanded even further, reaching up to 7.4 liters.

Throughout the years, this engine found a home in legendary vehicles like the E-Type and XJS, as well as in the luxurious XJ12 sedan and its upscale sibling, the Daimler Double-Six. It was also featured in the original concept version of the XJ220, before that project transitioned to a V6 powertrain.

In motorsports, Jaguar’s official factory team, Tom Walkinshaw Racing (TWR), used the V12 to great success. It notably powered the XJR-9, which won the 1988 24 Hours of Le Mans. The V12 continued its racing legacy in cars like the XJR-12 and even the Lister Storm, which was based on the Jaguar XJS.

The engine’s reach extended beyond the track as well—it was used in a replica of the iconic Spitfire aircraft and, in its turbocharged form, pushed beyond 1,000 horsepower for use in powerboat racing.

Despite the V8’s popularity in the United States, Jaguar didn’t initially embrace it. Instead, when expanding its lineup, the company set its sights on a V12 as early as 1951, intending to produce it alongside their inline-six engine, the XK.

A V8 needs a two-plane crankshaft with wide outer crankshaft balance weights to eliminate its out-of-balance couple.”

Since Jaguar had already successfully developed a straight-six engine, the logical evolution was to essentially pair two of them in a 60-degree ‘V’ configuration, sharing a single crankshaft.

This work started in 1952. However, the resulting V12, which used a double overhead camshaft (DOHC) layout, proved to be too wide for practical use in cars at that time.

As a result, Jaguar temporarily shelved the V12 project and turned its attention to developing a massive 9.25-liter V8 for the British military, designed to power tanks and their transport vehicles.

For its consumer vehicles, Jaguar continued relying on its proven straight-six, which had already secured Le Mans victories in the C-Type—shown above—and was slated for use in the upcoming D-Type. At that point, the company lacked both the financial resources and the necessity to bring the V12 into production.

Subaru 2.0 and 2.5-liter (non-turbo)

The 2.0- and 2.5-liter naturally aspirated boxer engines from Subaru have attracted significant scrutiny in recent years due to excessive oil consumption. Initially, it was brushed off as a characteristic of “Subaru engines,” with owners being told to add a quart of synthetic oil every few thousand miles.

However, the concept of a brand-new engine burning oil right from the start raised concerns. In fact, it prompted government intervention. In 2016, Subaru admitted its fault and agreed to reimburse owners for repair costs while extending warranty periods.

The company acknowledged that defective piston rings in some 2011–2015 vehicles led to excessive oil consumption, sparking a lawsuit in which Subaru was accused of being aware of the problem but failing to inform owners. This resulted in dealerships having to replace many engine blocks.

Yugo 55

In late 1983, the Yugo 55 was equipped with a 1.1-liter carbureted engine that produced an underwhelming 55 horsepower, earning it one of the worst reliability ratings in automotive history.

With a top speed of just 86 miles per hour if you were lucky and going downhill the Yugo 55 was the slowest car in the United States at the time.

A unique and critical maintenance issue with the Yugo 55 was the need to replace the timing belt every 40,000 miles to prevent it from snapping and causing engine damage.

Additionally, the car required premium gasoline, which was an unusual specification, and its air pump-powered carburetor was inefficient, harming both performance and longevity.

In the spring of 1992, Yugo ceased operations after the EPA revealed that every vehicle sold in the United States by the company failed to meet exhaust emissions standards.

The Yugo 55A, produced from 1987 to 1992, is a compact front-wheel-drive car powered by a naturally aspirated, inline four-cylinder petrol engine with a displacement of 1116 cm³ (68.1 cu-in). Identified by engine code “128 A0 64,” the engine uses a Weber 32 ICEV carburetor and is transversely mounted.

It delivers 55 PS (54 HP / 40 kW) at 6000 rpm and generates a peak torque of 77 Nm (56 lb-ft) at 3000 rpm. The engine features a bore and stroke of 80.0 mm by 55.5 mm, a compression ratio of 9.2:1, and an eight-valve layout. Power is transmitted through a 5-speed manual gearbox.

In terms of performance, the Yugo 55A has a top speed of 145 km/h (90 mph). It offers respectable fuel efficiency for its class, consuming 7.5 liters per 100 kilometers, which equates to 38 miles per gallon in the UK or 31 miles per gallon in the US.

Though specific body details are not listed, the Yugo 55A was designed to be a straightforward, budget-friendly vehicle with low operating costs and practical engineering. Throughout its production years, it served as a reliable and accessible choice in the small car segment.