In an uncertain world plagued by climate change, political instability, and technological vulnerabilities, doomsday preppers prioritize self-sufficiency and resilience.

At the heart of many prepping strategies lies reliable power generation, the ability to maintain essential operations when conventional infrastructure fails.

Engine selection represents one of the most critical decisions for serious preppers, as these mechanical lifelines provide electricity, mobility, and operational capacity during crisis scenarios.

The ideal prepper engine balances several crucial factors: fuel availability post-disaster, mechanical simplicity for field repairs, longevity without specialized maintenance, adaptability across multiple applications, and resilience against electromagnetic pulses and other threats.

While modern electronic systems offer convenience, many preppers favor older, simpler designs that can function reliably with minimal dependencies.

This guide explores the most valued engine types within prepper communities, examining their advantages, limitations, and practical applications in survival scenarios.

From diesel workhorses and time-tested gasoline generators to alternative power systems that harness natural resources, understanding these mechanical allies provides crucial insight into how prepared individuals plan to navigate potential societal disruptions.

Each engine type represents not just a power source but a fundamental component of resilience strategy, offering the capacity to maintain critical systems when conventional infrastructure becomes unavailable.

Diesel Engines

Diesel engines stand as the cornerstone of serious prepping operations, revered for their exceptional durability and fuel efficiency that outpaces gasoline alternatives by 20-30%.

This efficiency translates directly to extended operational periods during resource scarcity a paramount consideration when resupply may be impossible.

The mechanical design of diesel engines, particularly older models with minimal electronic components, presents a significant advantage in disaster scenarios.

These engines operate through compression ignition rather than spark plugs, eliminating a common failure point and reducing vulnerability to electromagnetic pulse (EMP) events that could disable more sophisticated systems.

The versatility of diesel fuel itself represents another critical advantage. Unlike gasoline, which degrades within months without stabilizers, properly stored diesel remains viable for 18-24 months, providing a significantly extended shelf life for stockpiled supplies.

Diesel’s lower volatility also reduces explosion risks during storage and transportation, a vital safety consideration when handling fuel in improvised conditions.

Additionally, diesel engines can operate on alternative fuels with minimal modification including biodiesel, vegetable oil, and even some animal fats creating flexibility when conventional supplies become unavailable.

Many preppers specifically seek out older diesel engines manufactured before the widespread implementation of computerized engine management systems.

Pre-2007 diesel engines, particularly those in vehicles like the Mercedes 300D, older Ford F-Series with 7.3L Power Stroke engines, and Dodge Ram trucks with Cummins diesels, have developed cult followings in prepper communities.

These engines require only basic electrical systems to operate and can be maintained with mechanical knowledge and standard tools, unlike modern computerized diesels dependent on proprietary diagnostic equipment.

The multifunctionality of diesel engines represents another significant advantage. A single reliable diesel generator can power essential systems for an entire homestead, while vehicle-mounted engines can simultaneously provide transportation, field power through power take-off systems, and even serve as stationary generators with minor modifications.

Military surplus diesel generators, particularly those designed for field operations, are especially prized for their ruggedness, simplicity, and parts availability.

The primary limitations of diesel systems include the higher initial acquisition cost, greater weight, and cold-weather starting difficulties without specialized equipment.

However, many preppers consider these acceptable tradeoffs for the exceptional longevity with properly maintained diesel engines routinely exceeding 500,000 miles of operation and decades of service in stationary applications.

This proven track record of reliability under adverse conditions makes diesel engines an indispensable component in comprehensive preparation strategies focused on long-term sustainability rather than short-term convenience.

Also Read: 5 SUVs That Maintain Power After 100K Miles and 5 That Feel Gutless

Gasoline Engines

Gasoline engines represent the most accessible power solution for beginning preppers, offering lower initial investment costs and widespread availability compared to alternative systems.

The ubiquity of gasoline-powered generators, vehicles, and small equipment in standard retail channels means these systems can be acquired without drawing attention, an important consideration for those who prefer operational security in their preparations.

This accessibility extends to parts and service knowledge, with repair manuals, components, and generalized mechanical expertise readily available throughout most regions.

The operational advantages of gasoline engines include immediate cold-weather starting without preheating requirements, lighter weight-to-power ratios, and higher RPM capabilities, making them ideal for applications requiring mobility and rapid deployment.

Gasoline generators typically produce less noise than comparable diesel units, a tactical advantage when maintaining a low profile during emergency operations.

Smaller gasoline engines, particularly those used in portable generators ranging from 2,000-5,000 watts, can be easily transported between locations as needs change during evolving scenarios.

Many preppers strategically select dual-fuel or tri-fuel conversion kits for their gasoline generators, allowing operation on natural gas or propane when gasoline supplies become unavailable.

These alternative fuels can be stored indefinitely without degradation, addressing gasoline’s primary limitation of short shelf life (typically 6-12 months without stabilizers).

Honda EU series inverter generators have achieved particular prominence in prepper communities for their exceptional fuel efficiency, clean power output suitable for sensitive electronics, and renowned reliability, with many units exceeding 10,000 operating hours with basic maintenance.

Older carbureted gasoline engines, particularly those manufactured before the widespread implementation of electronic fuel injection, maintain particular value among technically-minded preppers.

These systems, including those found in vehicles from the 1970s and early 1980s, can operate without electronic control units and can be repaired with basic mechanical knowledge.

Some preppers maintain dedicated “bug-out vehicles” featuring these older systems, often modified with raised suspensions, auxiliary fuel tanks, and mechanical fuel pumps to maximize reliability during evacuation scenarios.

The primary disadvantages of gasoline engines include higher fuel consumption rates, more frequent maintenance requirements, and vulnerability to fuel degradation.

Gasoline systems generally require more careful winterization procedures to prevent carburetor issues and fuel system problems during storage periods.

Additionally, many modern gasoline engines rely heavily on electronic control systems that may be vulnerable to EMP events or other electronic disruptions without specialized shielding.

Despite these limitations, gasoline engines maintain their position as the most practical entry point for power generation resilience, balancing accessibility with acceptable performance for most short to medium-term emergency scenarios.

Small Two-Stroke and Four-Stroke Engines

Small displacement engines represent a critical redundancy layer in comprehensive prepping strategies, offering exceptional portability and operational flexibility when larger systems become impractical.

These compact power sources typically range from 25cc to 200cc and include essential tools, including chainsaws, water pumps, small generators, and emergency transportation like dirt bikes and ATVs.

Their minimal weight and space requirements allow for storage in limited quarters and rapid deployment during evolving scenarios, making them valuable assets for both bug-out mobility and homestead maintenance.

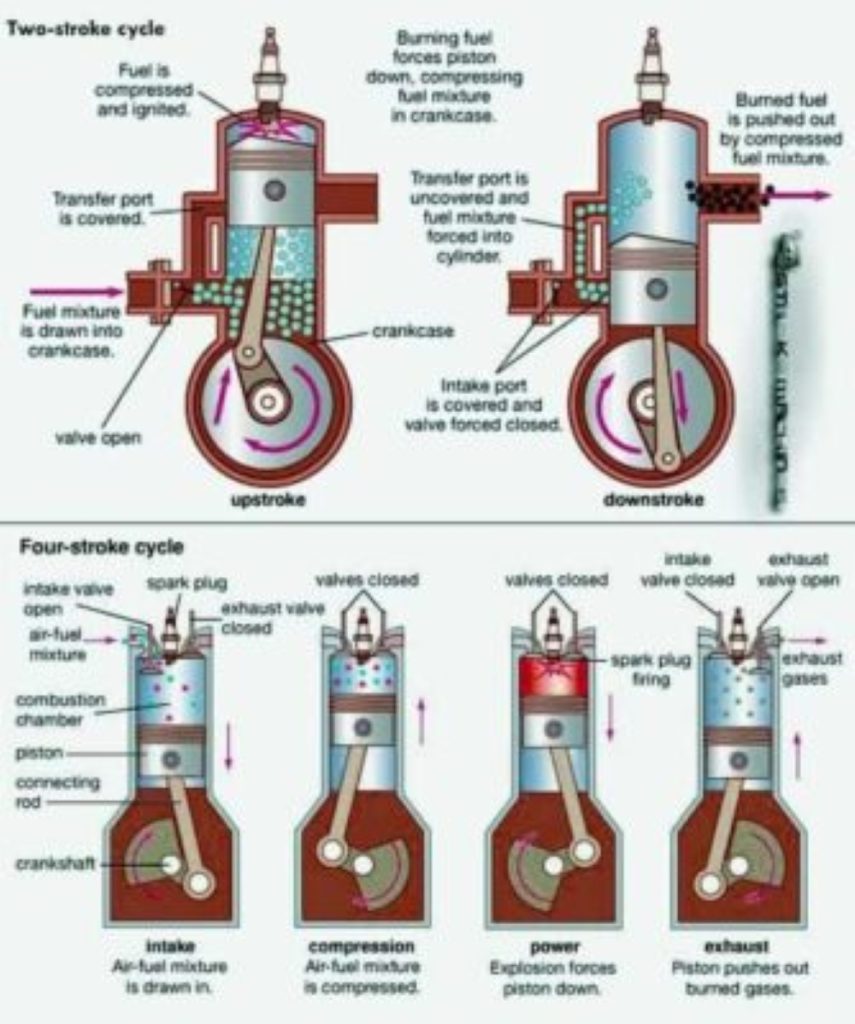

Two-stroke engines maintain specific advantages in prepping applications despite their older technology. Their mechanical simplicity featuring fewer moving parts than four-stroke alternatives, allows for field repairs with basic tools and limited technical knowledge.

The ability to operate in any orientation without oil starvation issues makes two-stroke engines particularly valuable for portable tools used in challenging environments and awkward positions.

While their fuel efficiency typically lags behind four-stroke designs, their higher power-to-weight ratio provides operational advantages in applications where mobility represents the primary concern.

Four-stroke small engines offer superior fuel economy and reduced emissions, extending operational duration from limited fuel supplies—a critical consideration during prolonged emergencies.

Their lower operating temperatures and reduced oil consumption support extended run times without cooldown periods, making them ideal for applications requiring continuous operation, such as water pumping or perimeter lighting.

Modern small four-stroke engines often incorporate fuel injection systems that improve cold-weather starting reliability and altitude performance compared to carbureted alternatives.

The multi-fuel adaptability of small engines provides strategic advantages for preppers concerned with fuel availability. Many small engines can be modified to run on alternative fuels, including propane, natural gas, alcohol, and even wood gas with appropriate conversion systems.

This flexibility allows operators to utilize locally available fuel sources when conventional supplies become unavailable. Companies like Champion Power Equipment have developed commercial multi-fuel systems specifically marketed toward emergency preparedness applications, recognizing the growing demand for fuel adaptability.

Maintenance considerations significantly influence prepper engine selection, with particular value placed on systems requiring minimal specialized tools or proprietary components.

Engines from manufacturers like Honda, Yamaha, and Briggs & Stratton maintain reputations for exceptional reliability with basic maintenance, with documented cases of these engines exceeding 3,000 operating hours in demanding environments.

Many preppers stockpile common wear components, including air filters, spark plugs, carburetors, and recoil starter assemblies creating maintenance redundancy for these critical systems.

Additionally, the standardization of components across product lines from established manufacturers simplifies parts inventory management for those maintaining multiple small engine applications.

Alternative and Sustainable Engine Systems

Beyond conventional internal combustion engines, forward-thinking preppers increasingly incorporate alternative and sustainable power systems that can operate independently of fossil fuel supply chains.

These diversified approaches recognize that true long-term resilience requires transitioning beyond finite resources toward regenerative energy systems that maintain functionality for decades without external inputs.

While often requiring greater initial investment and technical knowledge, these systems offer unparalleled sustainability during prolonged grid-down scenarios.

External combustion engines, particularly modern interpretations of traditional Stirling engine designs, have gained traction among technically sophisticated preppers.

These closed-cycle heat engines can utilize virtually any heat differential to generate mechanical energy, operating effectively on wood, biomass, concentrated solar, or even geothermal heat sources.

Their mechanical simplicity, with few moving parts and minimal maintenance requirements, provides exceptional longevity with documented cases of Stirling engines operating continuously for decades.

Companies like Microgen and Qnergy have developed modern Stirling generators producing 1-10kW of electricity from diverse heat sources, representing viable alternatives to internal combustion systems for stationary power applications.

Steam engine technology, though considered antiquated by conventional standards, maintains specialized applications within prepper communities focused on complete energy independence.

Modern hobby-scale steam systems can convert readily available biomass into mechanical energy with remarkable efficiency when properly designed. These systems operate independently of petroleum infrastructure and can be manufactured from basic materials with intermediate metalworking skills.

The ability to produce both mechanical power and process heat simultaneously (cogeneration) provides operational efficiencies exceeding 80% in well-designed systems far surpassing conventional internal combustion efficiency.

Biogas engines represent another sustainable approach, converting agricultural waste, human waste, and food scraps into methane through anaerobic digestion.

This methane can then power conventional internal combustion engines with minor modifications, creating a closed-loop energy system from otherwise problematic waste streams.

Small-scale biodigesters capable of supporting 3-5kW generators require approximately the waste from 4-6 livestock animals or the food waste from 15-20 people, making them viable for community-scale implementation during prolonged emergencies.

Human-powered mechanical systems, though limited in output, provide ultimate reliability independent of external fuel sources.

Modern developments in this field include high-efficiency hand-crank generators, pedal-powered tools, and spring-tension energy storage systems that can operate critical communications equipment and small appliances through direct human input.

These systems typically produce 50-100 watts of sustained output sufficient for emergency lighting, communication systems, and small electronic devices when other options become unavailable.

While alternative engines typically cannot match the power density of fossil-fuel systems, their integration into comprehensive energy strategies provides crucial redundancy and sustainability.

Many experienced preppers implement layered approaches utilizing conventional engines for immediate needs while developing alternative systems for long-term scenarios.

This strategic diversification acknowledges that different emergency timelines require different solutions, with sustainable systems becoming increasingly valuable as events extend beyond the practical limits of stored fuel reserves.

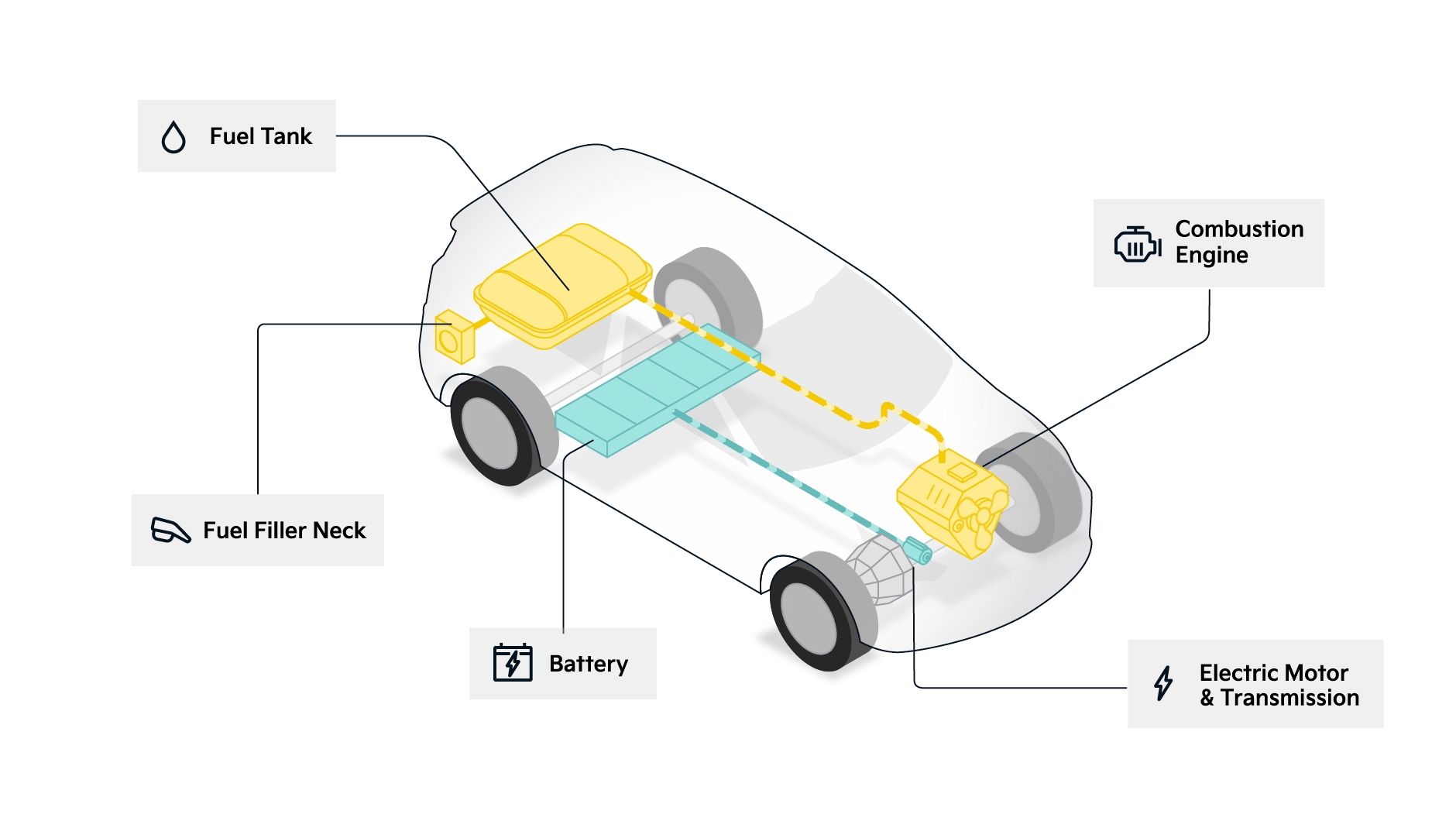

Hybrid and Modernized Systems

The integration of traditional engine reliability with selective modern technologies represents an emerging trend among technically sophisticated preppers seeking optimal resilience without unnecessary complexity.

These hybrid approaches selectively incorporate electronic enhancements that provide meaningful operational advantages while maintaining core mechanical simplicity and field repairability, creating systems that function effectively across diverse emergency scenarios with varying technological availability.

Advanced battery storage systems, particularly lithium iron phosphate (LiFePO4) configurations, have revolutionized prepper power strategies by enabling intermittent engine operation rather than continuous running.

These systems allow generators to operate at optimal efficiency during brief charging cycles, then provide silent power from stored energy reducing fuel consumption by 60-70% compared to traditional constant-operation approaches.

This operational model extends fuel supplies, reduces maintenance intervals, and provides tactical advantages through minimized noise signatures during critical periods.

Modular engine designs with interchangeable components have gained popularity among preppers focused on long-term sustainability. These systems feature standardized mounting platforms, allowing a single engine block to power multiple applications, including generators, water pumps, milling equipment, and transportation.

The Predator engine series from Harbor Freight has developed a significant following for this application, with enthusiasts developing extensive modification knowledge bases for optimizing these affordable engines for emergency use.

The ability to maintain critical functionality by cannibalizing parts from multiple units provides valuable redundancy during prolonged scenarios.

Solar-generator hybrid systems represent another innovation, using photovoltaic arrays as the primary power source while maintaining small engines as backup during extended low-light periods.

These systems utilize intelligent charge controllers that automatically start backup generators when battery levels drop below configured thresholds, then return to solar harvesting when sufficient sunlight becomes available.

This approach maximizes renewable energy utilization while maintaining continuous power availability regardless of weather conditions an important consideration for medical equipment and critical systems requiring uninterrupted operation.

Electronic fuel injection (EFI) retrofits for traditional mechanical engines offer improved fuel efficiency and starting reliability without introducing unnecessary complexity.

Unlike factory computerized systems requiring proprietary diagnostic equipment, simplified aftermarket EFI kits maintain field serviceability while providing 15-20% improved fuel utilization.

Companies including FAST, FiTech, and MegaSquirt have developed systems specifically designed for older engines, creating viable upgrade paths for vintage equipment without sacrificing repairability.

The most sophisticated prepper systems implement redundant control approaches, allowing operation through electronic management under normal conditions while maintaining mechanical fallback capabilities during electronic disruptions.

These dual-mode systems incorporate manual overrides for critical functions, ensuring continued operation even after component failures or electromagnetic interference events.

This layered approach acknowledges that different emergency scenarios may impact technology differently, requiring adaptable systems that function across varying technological conditions rather than optimizing for a single scenario.

Also Read: 5 Crossovers That Rarely Need Suspension Work and 5 That Constantly Do