Not all car engines are created equal. Some are built to handle serious abuse hard driving, poor maintenance, and extreme conditions while others begin to break down at the first sign of trouble, including something as common as driving in the rain.

Below is a detailed look at five engines that can take a beating and five that are notoriously fragile, especially when exposed to moisture or neglect.

Engines That Love Abuse

Not all engines are created equal. Some scream at high RPMs and fall apart before 100,000 miles. Others? They eat redline for breakfast, run hot, get thrashed in every gear—and still beg for more.

This article is for the mechanical warhorses, the overbuilt legends, and the surprisingly tough powerplants that thrive under punishment. Whether you’re chasing track days, desert runs, or just want something that won’t flinch at a hard life, these are the engines that don’t just survive abuse—they love it.

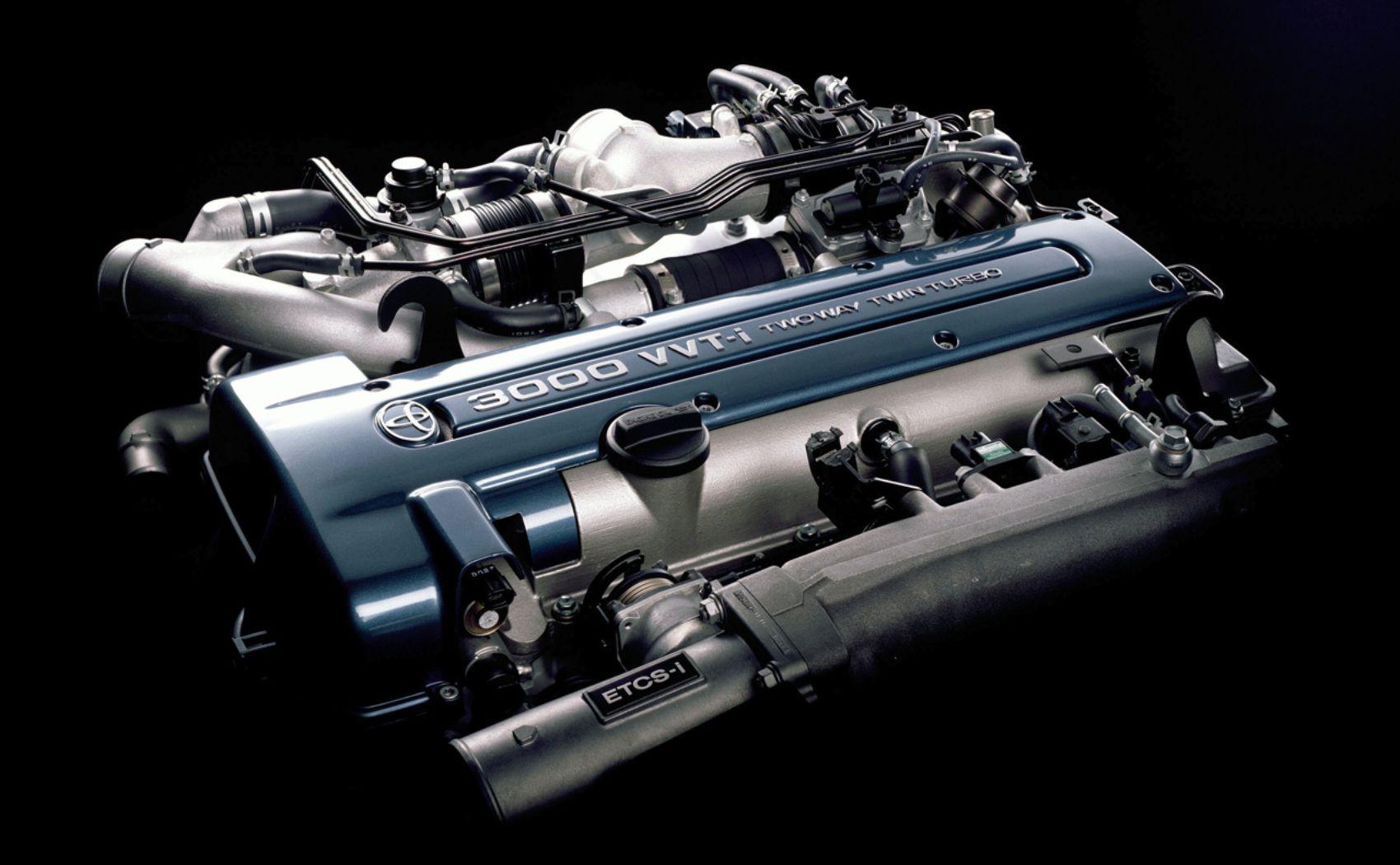

1. Toyota 2JZ-GTE (3.0L Inline-6 Turbo)

Vehicles: Toyota Supra MK4, Toyota Aristo

Toyota’s 2JZ-GTE is legendary for a reason.

This cast-iron block inline-six was overengineered from the factory with a forged bottom end, strong internals, and oiling systems that can handle big horsepower and high revs.

Tuners have pushed this engine past 1,000 horsepower on stock blocks. Abuse it with hard launches, extended pulls, and track use this engine can handle it with proper cooling and oil changes.

The Toyota 2JZ-GTE is a 3.0-liter (2,997 cc, 182.89 cu-in) inline-six, four-stroke, twin-turbocharged, air-intercooled gasoline engine from Toyota’s JZ-family. This engine was produced by the Toyota Motor Corporation at the Tahara Plant in Tahara, Aichi, Japan, from 1991 through 2005.

The 2JZ-GTE is built with a cast-iron block and an aluminum cylinder head that features dual belt-driven overhead camshafts (DOHC) and four valves per cylinder, totaling 24. Starting in 1997, the engine was updated to include Toyota’s VVT-i (Variable Valve Timing with intelligence) on the intake camshaft.

It also comes equipped with a multiport sequential fuel injection system and a twin-turbocharging setup with an intercooler. Both the bore and stroke measure 86.0 mm (3.39 in), and the engine has a compression ratio of 8.5:1.

Though the 2JZ-GE and 2JZ-GTE share the same block, crankshaft, and connecting rods, the GTE version distinguishes itself with recessed piston tops that reduce the compression ratio, as well as the addition of oil spray nozzles to help cool the pistons. It also uses a different cylinder head with redesigned intake and exhaust ports, along with updated cams and valves.

Two generations of the 2JZ-GTE were produced. The first generation, built from 1991 to 1996, utilized sequential twin CT20 turbochargers, an air-to-air side-mounted intercooler, and 440 cc/min injectors.

According to specifications, “The first generation of the 2JZ-GTE engine produced 280 PS (206 kW; 276 HP) at 5,600 rpm of maximum horsepower and 432 Nm (44.0 kg·m; 318.8 ft·lb) at 3,600 rpm peak torque.”

For export models in North America and Europe, the engine came fitted with CT12B turbochargers, revised camshafts, and larger 550 cc/min injectors. As a result, “This engine produced 325 PS (239 kW; 320.5 HP) of maximum output power and 441 Nm (45.0 kg·m; 325.5 ft·lb) of peak torque.”

The second generation of the 2JZ-GTE, introduced in 1997, featured the VVT-i system on the inlet camshaft. While its horsepower output remained unchanged from the first generation, torque saw a slight increase, as noted: “The output power remained the same, but peak torque was increased to 451 Nm (46.0 kg·m; 332.8 ft·lb).”

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

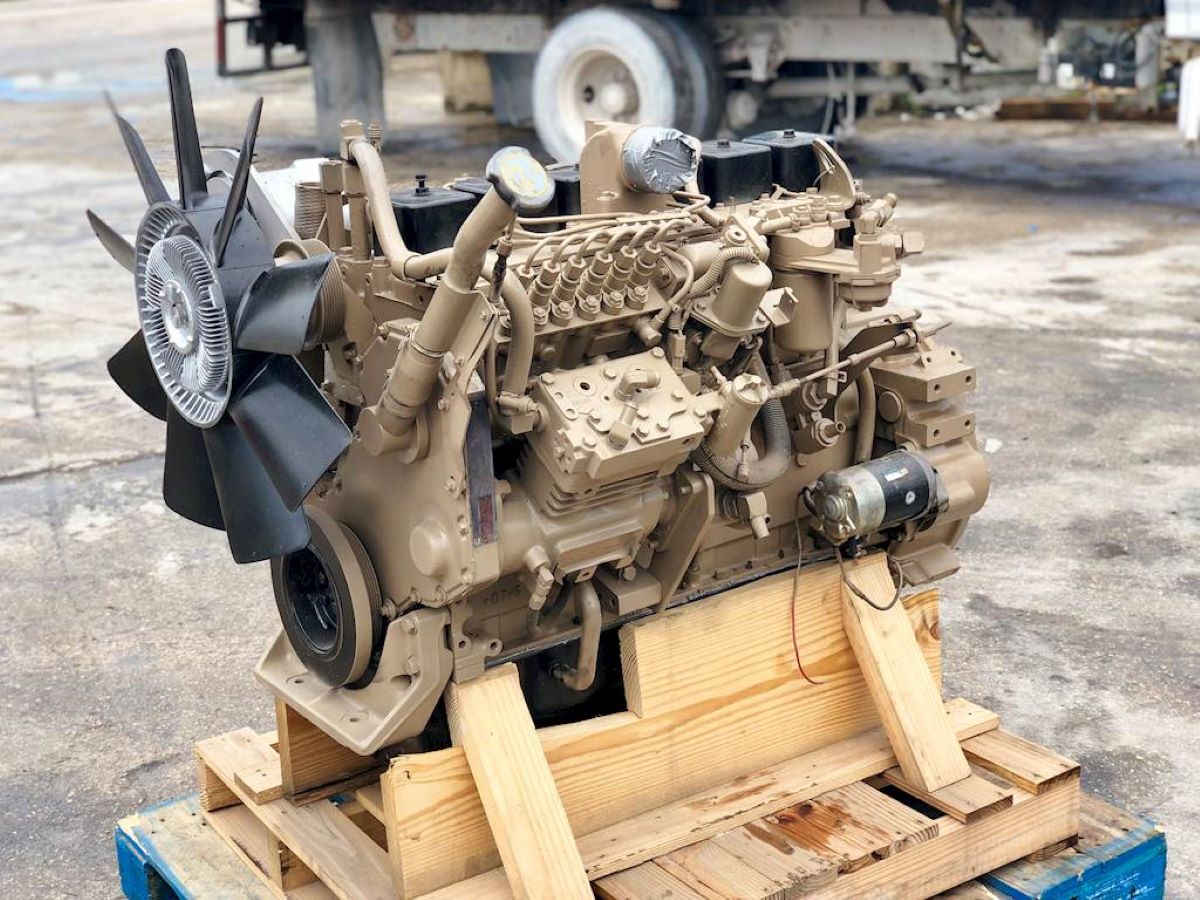

2. Cummins 6BT (5.9L Inline-6 Diesel)

Vehicles: Dodge Ram (1989–1998) industrial equipment

Originally designed for industrial use, the 6BT is a brute. With a simple mechanical fuel system and no electronics in early versions, it’s incredibly robust and easy to maintain.

It can run on low-quality diesel, take massive loads for thousands of hours, and is beloved for its ability to shrug off hard use and poor maintenance.

Cummins introduced the 6BT engine in 1984, originally designing it for use in agricultural equipment. In 1989, Dodge partnered with Cummins to bring the 5.9L Cummins engine to its heavy-duty pickup trucks.

This collaboration quickly gained traction, as the Cummins-powered Dodge Ram became a popular alternative to the large gasoline engines that were common in heavy-duty pickups. Since that milestone, diesel-powered pickups have grown into a massive and competitive market in the United States.

Diesel engines are inherently better suited for heavy towing than gasoline engines, which is a major reason behind their growing dominance in the U.S. truck segment. This article takes a close look at the 6BT Cummins engine—covering its technical specifications, real-world use, and potential for power upgrades.

The 6BT Cummins belongs to the B Series family of engines, which Cummins Inc. began producing in 1984. This family included a variety of engines with different displacements and cylinder configurations, but it was the 5.9-liter inline-six 6BT that ultimately stood out.

Although originally developed for agricultural, industrial, and commercial machinery, the engine found a new audience in 1989 when Dodge installed it in the Dodge Ram, introducing it to the light-duty truck market.

The partnership with Dodge boosted the 6BT’s popularity, turning it into a legend among diesel truck enthusiasts. This collaboration continued until 1998, when the 6BT was replaced by a 24-valve version known as the ISB 5.9L.

The 6BT Cummins is a 5.9-liter inline-six engine featuring an overhead valve (OHV) design with 12 valves, earning it the nickname “12-Valve.” Its layout is loosely comparable to the AMC inline-six engine of the same era.

Constructed with a cast iron block and a cast iron cylinder head, the engine is undeniably heavy—but that weight comes with tremendous strength. In fact, durability is one of the 6BT’s standout features. Many owners have pushed these engines beyond 1,400 horsepower, and stock models have been known to exceed 1,000,000 miles with proper maintenance.

One of the most defining characteristics of the 6BT is its fully mechanical fuel system, which makes it particularly attractive for engine swaps. Because there are only a couple of wires needed to get it running, the swap process is simpler compared to electronically controlled engines.

That simplicity does come with a trade-off, though. “You can’t just plug a tuner into it and produce more horsepower.” Whether that’s a positive or a drawback depends on your needs.

On the plus side, “The simple mechanical fuel injection system is unlikely ever to fail, but you cannot tune it by using a small handheld tuning device.” The mechanical nature of the fuel system ensures reliability, but it limits modern tuning options.

Key specifications of the 6BT Cummins engine include a production range from 1989 to 1998, an inline six-cylinder configuration, and a displacement of 5.9 liters (359 cubic inches). Both the cylinder head and block are made of cast iron. The engine uses an OHV valvetrain design with two valves per cylinder and features a closed deck design.

Bore and stroke measure 102 mm and 120 mm, respectively. From 1989 to 1993, the engine used a Bosch VE44 injection pump; from 1994 to 1998, it used a Bosch P7100. Horsepower ranges from 160 to 215 hp, with torque ranging from 400 to 440 lb-ft.

Although it was the first Cummins “B” engine to be used in light trucks, the 6BT was initially intended for use in Case agricultural machinery. The partnership with Dodge in 1989 led to the 6BT being installed in Dodge’s ¾-ton and 1-ton trucks. In addition to agricultural equipment and Dodge Ram trucks, the 6BT engine also found use in a variety of heavy-duty machines.

Its applications included agricultural equipment, the Dodge Ram ¾ Ton, and the Dodge Ram 1 Ton. In later years, Cummins introduced a more modern 24-valve engine called the QSB (Quantum System B), which was widely used in marine, agricultural, and construction equipment.

When first installed in the 1989 Dodge Ram, the 6BT Cummins produced 160 horsepower at 2,500 rpm and 400 lb-ft of torque at 1,600 rpm.

Although this was less horsepower than typical gasoline engines at the time, the engine more than made up for it with its substantial torque—an essential factor for truck applications. In 1994, models equipped with manual transmissions saw an increase to 175 horsepower and 420 lb-ft of torque.

Then, in 1996, automatic transmission models were upgraded to 180 horsepower and 420 lb-ft, while manual transmission models jumped to 215 horsepower and 440 lb-ft of torque. In the world of trucks, where torque reigns supreme, these figures made the 6BT Cummins a standout performer.

3. Honda K20/K24 (2.0L/2.4L Inline-4)

Vehicles: Honda Civic Si, Acura RSX, Accord, CR-V

Honda’s K-series engines are proof that high-revving doesn’t have to mean fragile. These engines love to scream past 7,000 RPM and can take regular abuse on the track and the street.

Their forged crankshafts and reliable VTEC systems make them favorites in racing and daily drivers alike. The dawn of the 21st century ushered in a wave of technological innovation across the automotive industry, but it also signaled the gradual decline of street-performance cars.

While the 1990s were filled with vehicles that held sporty promise, the models released in the 2000s grew more practical and subdued. Enthusiast-oriented cars either became too expensive for the average buyer or too limited in production to make a real impact.

Amid this shift, Honda remained one of the few manufacturers committed to fun-to-drive vehicles, largely thanks to the widespread success of their VTEC engines. Almost any model in their lineup had the ability to deliver excitement, and, as the saying goes, could put a smile on your face “once that VTEC kicks in.”

This discussion focuses on two standout engines from that era—the K-series, specifically the K20 and K24 variants—as we explore what makes them special and why they continue to have such strong followings.

The K20 and K24 engines enjoy a cult-like status among Honda fans for good reason. While both are praised, the differences between them lie in how they deliver power. The K24 benefits from increased displacement and torque, making it better suited for everyday use. In contrast, the K20 revs higher and is favored for tuning and racing applications.

Though opinions differ, the general consensus is that the K24 is ideal for a stock daily driver, whereas the K20 is preferred when building a performance-oriented machine.

Looking at the K20 in more detail, it becomes clear that spec sheets don’t tell the whole story. Any experienced car enthusiast knows that beyond the horsepower and torque ratings, the seat-of-the-pants feeling is equally important—especially if you aren’t building a track car.

Both engines provide a fun and engaging driving experience, but they go about it in different ways. While numerous comparisons between the K20 and K24 exist—most focusing purely on numbers—we’ll keep it straightforward.

Consider the following for reference: The K20 has a 2.0L displacement, 86mm bore and stroke, and delivers between 150 and 221 horsepower with around 143 lb-ft of torque. The K24, on the other hand, is a 2.4L engine with an 87mm bore and a 99mm stroke, producing roughly 200 horsepower and around 171 lb-ft of torque.

Thanks to its longer stroke, the K24 generates more torque at lower RPMs, but this comes at the cost of a lower rev ceiling. Conversely, the K20 revs higher but produces less torque. That’s about as far as the raw specs take us, so now let’s dig into how those differences translate on the road.

Despite the K24 having bigger numbers on paper, most enthusiasts agree that the K20 is the better performance engine overall. It’s highly tunable, offers a smoother and more linear power curve, and boasts a higher redline.

A common criticism of the K24 is that its surplus of torque in a front-wheel drive layout causes excessive wheel spin in the first three gears, effectively wasting some of that power. So, if your goals include amateur racing, track days, or performance builds, the K20 is the stronger candidate.

However, when it comes to stock performance—especially for daily driving—the K24 makes a strong case for itself. Thanks to its ample low-end torque, it feels livelier around town and better suited to everyday use. That’s not to say the K20 isn’t enjoyable, but the K24’s broader torque band makes it more practical for regular driving conditions.

Still, it’s important to note that this comparison applies to stock engines in stock vehicles. Swapping a K24 into a car that originally came with a K20 doesn’t automatically guarantee a better experience, and the reverse is equally true.

In terms of fitment, discussions around the K20 versus K24 usually revolve around the Honda Civic, a longtime favorite among enthusiasts. The K20 is a direct fit in most Civic models, while the K24 requires more extensive work to install.

That means it’s not only more labor-intensive but also more expensive to swap in. For most, especially those on a tighter budget, modifying the existing K20 engine in a Civic is a more logical and cost-effective path than performing a full K24 swap.

Another layer of complexity in comparing the K20 and K24 comes from the wide range of variants each engine has. Some versions succeeded others, while others were developed and sold in parallel.

To add even more to the mix, Honda’s more recent Earth Dreams models have shifted the characteristics of these engines significantly. While the discussion here centers on the desirable, high-performance variants of both the K20 and K24, it helps to be aware of the broader lineup.

Different trims and versions offer distinct power outputs and VTEC engagement points, so doing your research and selecting the right model is critical if you’re planning to buy or build. Knowing the full spectrum of options will help you avoid mistakes and land on the version that suits your needs best.

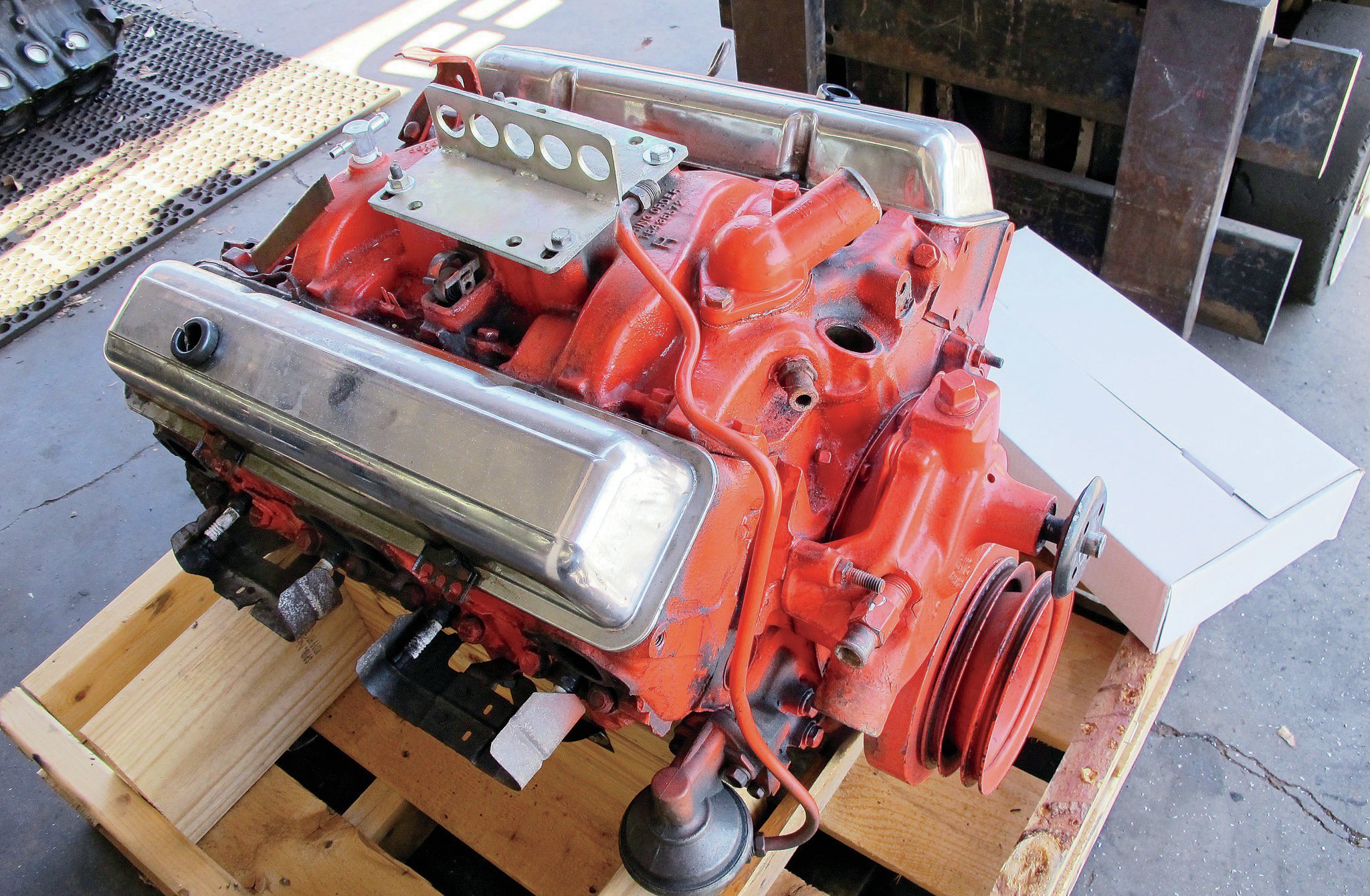

4. Chevrolet LS (All-Gen Small Block V8s)

Vehicles: Chevrolet Corvette, Camaro, Silverado

LS engines are famed for taking a beating and coming back for more. Whether it’s turbocharging a junkyard 5.3L or drag racing with a built 6.0L, the LS platform is strong, reliable, and tolerant of poor treatment.

Known for low-end torque and strong internals, they’re often swapped into everything from drift cars to daily drivers. The General Motors LS engine has left an indelible mark on the automotive world, thanks to its unparalleled combination of power, reliability, and affordability.

Its compact dimensions, lightweight architecture, and robust aftermarket ecosystem have propelled it into the spotlight as a go-to choice for performance upgrades, engine swaps, and motorsport builds. As a result, the LS has solidified its reputation as one of the most influential and iconic engine platforms in automotive history.

Recognizing this seismic shift in enthusiast interest, Holley quickly tuned in and mobilized its network of core brands to respond. The company led the charge by developing an extensive lineup of performance solutions for the LS, including what are widely considered the most comprehensive swap kits available.

But Holley’s commitment didn’t stop at hardware. To fully embrace and support the rapidly expanding LS movement, the company launched a dedicated event series known as LS Fest—an LS-focused celebration that now takes place at multiple locations across the U.S.

This engine guide will take a deeper dive into the LS platform’s design philosophy, its unmatched versatility, and its massive performance potential. It will also break down the most effective parts combinations and upgrade paths, giving enthusiasts the tools and knowledge they need to extract every ounce of capability from this legendary engine family.

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

5. Mercedes-Benz OM617 (3.0L Inline-5 Diesel)

Vehicles: Mercedes W123/W126

The OM617 is a slow but steady workhorse. Known for running hundreds of thousands of miles with minimal maintenance, this engine was made during an era when Mercedes prioritized durability.

It’s not powerful, but it tolerates overheating, bad fuel, and extended oil change intervals better than almost any other diesel of its time.

The 3.0-liter inline five-cylinder Mercedes OM617 engine was produced between 1974 and 1990 and found its way into several iconic models such as the W123, W126, and the Geländewagen SUV.

Over the years, this diesel powerplant saw continuous refinement, resulting in multiple variants. It belongs to the broader diesel R5-family, which includes the OM617, OM602, OM605, OM612, and OM647 engines.

Back in 1974, Mercedes developed this five-cylinder engine using the OM616 four-cylinder diesel as its foundation. The first version of the OM617 was a naturally aspirated pre-chamber diesel, featuring a robust cast-iron cylinder block and a cast-iron, 10-valve cylinder head.

It lacked hydraulic lifters and relied on a dual-row timing chain to operate both a single overhead camshaft and an in-line Bosch M injection pump. In 1979, Mercedes introduced a new cylinder head, raised the compression ratio, and increased the engine’s output from 80 to 88 horsepower.

In 1977, Mercedes introduced a turbocharged version using a Garrett TB03 turbocharger, which debuted on the American-market W116 sedan.

This turbocharged variant was revised again in 1979, resulting in a power bump from 111 to 121 horsepower. Then, in 1982, further upgrades pushed the engine to its most potent form, delivering 125 horsepower and 250 Nm of torque.

The OM617 has earned a legendary reputation for durability and is widely recognized as one of the most reliable engines Mercedes ever produced. It’s not uncommon for these engines to exceed 1,000,000 kilometers in service life, a major reason behind the strong popularity of Mercedes diesel vehicles in North America throughout the 1980s.

The turbocharged version of the OM617 marked a turning point, becoming the first diesel engine Mercedes deemed fit for both its S-Class and mid-range vehicles.

Daimler-Benz was motivated by a desire to comply with U.S. government fuel economy mandates, which led to the introduction of the 300 SD (S-Class Diesel) and 300 CD (Coupe Diesel) models. These included the S-Class W116 and Coupe C123 for the initial versions, and later the S-Class 126 series for the second generation.

5 Engines That Can’t Handle Rain

Engines are supposed to be tough. They’re built to handle high temps, long hauls, and hard revs—but for some powerplants, a little rain is all it takes to bring everything to a screeching halt. Whether it’s poor sealing, vulnerable electronics, or intake designs that seem to invite water in like a welcome guest, some engines just weren’t made to tango with wet weather.

In this article, we’re diving into five engines that famously (or infamously) struggle when the skies open up. If you live where it rains often—or just value mechanical peace of mind—you’ll want to steer clear of these hydro-hating heartbeats. Let’s get into the worst offenders.

1. Chrysler 2.7L V6 (Dodge/Chrysler models)

Vehicles: Chrysler Sebring, Dodge Intrepid, Concorde

This engine has a terrible reputation for sludging and catastrophic failure even when maintained.

However, moisture adds another issue: the poor design of the crankcase ventilation and head gaskets allows water to sneak in and mix with the oil. Driving through a storm or parking in wet climates without maintenance accelerates its demise.

The Chrysler 2.7-liter (ERR) is a naturally aspirated V6 gasoline engine with a displacement of 2.7 liters (2,703 cc or 167.0 cu.in.), produced by Chrysler from 1997 through 2010.

This 2.7L V6 engine was engineered with an aluminum engine block and paired with two aluminum cylinder heads. It utilizes a dual overhead camshaft (DOHC) configuration, featuring four valves per cylinder for a total of 24 valves.

The engine is equipped with a Sequential Multi-Port Electronic Fuel Injection system, along with a Direct Ignition System (DIS) for efficient combustion and performance.

The engine’s redline varies slightly depending on the version: the original is limited to 6,464 rpm, while the LX version increases that threshold to 6,600 rpm.

2. BMW N54 (3.0L Twin-Turbo Inline-6)

Vehicles: BMW 335i, 135i, 535i

While praised for performance, the N54 is a maintenance nightmare. Water intrusion into electrical components like ignition coils, injectors, and high-pressure fuel pumps leads to misfires, limp mode, or total failure.

Even driving through a big puddle can set off a chain of issues if the seals around the engine bay aren’t perfectly intact. The BMW N54 engine, a twin-turbocharged inline-six, was introduced in 2006 and quickly earned a strong reputation for both its performance capabilities and tuning flexibility.

Representing a pivotal shift in BMW’s engineering direction, the N54 marked the brand’s move toward forced induction as a mainstream strategy.

It was developed to provide a balanced combination of power and efficiency, which helped make it a standout choice across several models, such as the 335i, 135i, and Z4. Praised for its impressive output, the N54 routinely delivered horsepower and torque figures that outperformed typical expectations for a six-cylinder engine.

3. Ford 1.6L EcoBoost I4

Vehicles: Ford Escape, Fusion, Fiesta ST

Despite being marketed as a modern turbo engine, the 1.6L EcoBoost has issues with coolant leaks, turbo overheating, and worst of all engine fires.

Water entering the engine bay has been known to accelerate wiring issues and corrosion, making it sensitive to even moderate exposure to rain or road spray.

The Ford EcoBoost turbocharged inline-four (I4) engines are the result of advanced engineering, combining performance and fuel efficiency in a compact package. These engines come in various displacements—1.0L, 1.5L, 1.6L, 2.0L, and 2.3L—tailored to suit different vehicle applications.

Their design includes aluminum blocks and cylinder heads, which help reduce weight and improve cooling efficiency. Equipped with dual overhead camshafts (DOHC) and variable valve timing, they maintain optimal valve control for improved combustion. The direct fuel injection system enhances fuel atomization for better efficiency and power delivery.

Depending on the version, either a single or twin-scroll turbocharger is used to boost output and torque. The ignition system employs coil-on-plug technology to provide accurate spark timing, while a water-cooled system ensures stable thermal performance under varying load conditions.

4. MINI N14 (1.6L Turbocharged I4)

Vehicles: MINI Cooper S (2007–2010)

This engine was plagued with high-pressure fuel pump failures, timing chain issues, and poor sealing around the coil packs.

Rainwater leaking into the engine bay could short out ignition coils, causing misfires and breakdowns. Add carbon buildup and turbo failures to the mix, and it’s a recipe for disaster in wet weather.

The N18 engine introduced several refinements over its predecessor. Notably, the PCV system was redesigned: instead of using an external hose on the passenger side as seen in earlier models, the vacuum line is now routed internally through the valve cover. This modification may help minimize the accumulation of blow-by and other effluents within the intake manifold.

Additionally, the boost line that connects the valve cover to the turbo intake pipe differs from the one used in the N14 engine. Another change in the N18 is the addition of a cosmetic cover placed over the front of the valve cover, giving the engine bay a cleaner, more refined appearance.

5. Volkswagen/Audi EA888 Gen 1 & 2 (2.0L Turbo I4)

Vehicles: Audi A4, VW GTI Mk5/Mk6

While later versions improved, the early EA888 engines had thin timing chains, weak tensioners, and poor PCV systems.

On top of this, they’re known for leaky valve covers and ignition coil failure, often made worse by damp conditions. Rain can seep into the spark plug wells, leading to stuttering and even no-start issues.

While some engines are forged in the fires of abuse and emerge stronger, others seem like they weren’t even tested for basic weather resistance.

The Volkswagen 2.0 TSI / TFSI EA888 engine is a turbocharged 2.0-liter inline-four gasoline engine developed as part of the EA888 series and built upon the foundation of the 1.8 TSI/TFSI.

Production began in March 2008, and the engine was introduced as a replacement for the earlier EA113 family’s 2.0 TSI engines. Much like its 1.8-liter sibling, the 2.0 TSI went through several refinements and upgrades over its lifespan, culminating in three distinct versions of the final production model.

This engine features an aluminum cylinder head and a cast-iron block, which provide a solid balance between durability and weight. Its inline-four configuration is paired with a dual overhead camshaft (DOHC) valvetrain that incorporates four valves per cylinder, contributing to improved airflow and efficiency.

With a bore of 82.5 mm and a stroke of 92.8 mm, the engine’s total displacement measures 2.0 liters (1984 cc). The compression ratio is set at 9.6:1, and the engine weighs approximately 320 pounds.

If you’re shopping for a car or planning to build one for heavy use, knowing the strengths and weaknesses of different engines can save you from future headaches.

Whether you’re looking for an indestructible diesel or avoiding a turbocharged engine that fizzles out in the rain, this guide should help you make a smarter choice.