While most mechanical components inevitably decline with use, a rare breed of internal combustion engines seems to defy time.

Whether due to robust engineering, clever design, or simply the nature of their materials and tolerances, some engines actually improve with age offering smoother operation, increased efficiency, or even stronger performance after tens of thousands of miles.

These engines may require some break-in period, but once past that, they show their true potential. Here are five engines that somehow get better with age.

1. Toyota 1UZ-FE (4.0L V8)

Vehicles: Lexus LS400, SC400, Toyota Celsior

Production Years: 1989–2002

The Toyota 1UZ-FE is one of the most revered V8s in automotive history.

Built with precision engineering, forged internals, and a reputation for bulletproof durability, this engine seems to loosen up and gain character as the miles add up.

Early examples may feel slightly restrained, but after 50,000–70,000 miles, many owners report the engine becomes significantly smoother and more responsive.

Thanks to tight tolerances and materials designed for long-term performance, carbon deposits actually help seal the combustion chamber over time, improving compression and efficiency.

It’s not unusual to see these engines run effortlessly past 300,000 miles with minimal intervention and in many cases, sounding better with each passing year.

Most car enthusiasts know all about the legendary 2JZ engine. It’s the powerplant that made the Toyota Supra A90 such an icon, and it found its way into several other Toyota models as well. But while the 2JZ gets a lot of the spotlight, it’s far from the only powerhouse Toyota has built.

That’s because Toyota also developed a robust and dependable 32-valve V8 — the UZ engine family. Though this engine line has multiple versions, it all started with the 1UZFE: a 4.0-liter, all-aluminum design that stands among the most reliable engines Lexus has ever produced.

When Toyota set out to create the 1UZFE, it had one goal in mind: to power its high-end luxury cars without sacrificing smoothness or reliability.

After all, this was going into Lexus, Toyota’s upmarket brand, and a troublesome engine would have been a deal-breaker. That’s why Toyota engineered the 1UZFE with four camshafts, a belt-driven setup, and six-bolt main bearings — all in the name of durability and refinement.

The debut of the 1UZFE came in 1989 under the hood of Lexus’ very first vehicle: the Lexus LS 400. From there, the engine found its way into several other Lexus models and even made appearances in a handful of Toyota vehicles. So now, let’s dive into the full list of Toyota cars that relied on the 1UZFE to put power to the pavement.

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

2. BMW M54 Inline-6 (3.0L)

Vehicles: BMW E46 330i, E39 530i, Z3, Z4

Production Years: 2000–2006

BMW’s M54 inline-six engine may have some quirks like oil leaks and a sensitive cooling system but its core mechanicals age like fine wine.

This naturally aspirated straight-six becomes more refined after the first 40,000–60,000 miles, delivering a more linear powerband and an intoxicatingly smooth rev range.

The vanos (variable valve timing) system often feels sharper once broken in properly, and the engine note deepens into a pleasant rasp.

Its cast iron block and aluminum head construction, along with a well-balanced crankshaft, allow the engine to feel “looser” and more responsive with age often outperforming its younger self in both throttle response and fuel economy when properly maintained.

The BMW M54 is a straight-six, dual overhead cam (DOHC) engine produced by BMW from 2000 to 2006, replacing the M52 engine. Unlike its predecessor, the M54 didn’t receive a Technical Update (TU), and its specifications remained unchanged throughout its production run.

Built upon the M52TU foundation, the M54 introduced a few key differences. It featured a fuel system without a return line, a fully electronic throttle, and an electronically controlled thermostat. North American models, unlike earlier ones, now came with an aluminum engine block reinforced with cast-iron liners.

Just like the M52TU, the M54 included BMW’s Double VANOS variable valve timing system, which controlled both intake and exhaust valves, improving performance and efficiency.

It also retained the DISA system—a separate air intake design that adjusted airflow for better low- and mid-range power. On top of that, the M54 featured a cylinder-type knock control system and newly designed catalytic converters.

When engineering the M54, BMW’s goals were clear: cut emissions, improve fuel economy, and boost performance all at once. The engine hit the mark, earning the title of best engine in the 2.0 to 2.5-liter category in both 2003 and 2004.

The M54 first appeared in the 2001 BMW X5 (E53), and as of June 2000, it was installed in the E46 3 Series across multiple body styles: sedan, touring, coupe, convertible, and compact. It also found a home in the BMW Z3 (Coupe and Roadster).

By September of that year, the M54 was powering the E39 5 Series in its 2.5-liter configuration. The engine was later used in several other BMW models, including the E60/E61 5 Series, E65/E66 7 Series, Z4 (Coupe and Roadster), and the X3 E83. Beginning in 2004, BMW began phasing the engine out in favor of the more modern N52 engine.

Technically, the M54 evolved from the sturdy foundation laid by the earlier M50 engine. This newer generation moved to an aluminum cylinder head and block, both of which featured thin-walled cast-iron liners to reduce weight without sacrificing strength.

One notable change that made the engine more user-friendly was the return of standard repair dimensions, making maintenance and overhauls more practical.

The M54 was built around a single crankshaft driving six pistons, with forged connecting rods for extra durability. The timing mechanism relied on a chain connected to two camshafts, which enhanced the engine’s longevity and reliability.

The Double VANOS system allowed the camshafts to rotate relative to their sprockets depending on the engine’s operational conditions. The intake manifold, made from plastic, featured variable-length runners. This design helped create a denser air charge entering the cylinders, improving low-end torque and high-RPM breathing.

Compared to the M52 engine family, the M54 had a shorter exhaust manifold and larger-diameter air ducts. Hydraulic valve lifters—also known as hydro-compensators—were used, eliminating the need for manual valve adjustments.

The engine block was offered in three displacements: 2.2, 2.5, and 3.0 liters. These variants differed only in bore and stroke dimensions.

The valve timing system offered variable opening and closing of both intake and exhaust valves, which helped the engine run smoothly and quietly. The throttle was fully electronic, and sharp accelerator inputs translated directly into rapid increases in engine RPM, reflected clearly on the tachometer.

In vehicles like the BMW 5 Series, the M54 was mounted longitudinally along the car’s axis. Each of the six cylinders was ignited by its own coil-on-plug system, eliminating the need for spark plug wires and improving ignition reliability.

A timing chain drive further improved the M54’s reputation for reliability. The crankshaft was supported by seven main bearings and included twelve counterweights to ensure smooth operation. Lightweight pistons with a short, graphite-coated skirt reduced friction on the cylinder walls, contributing to overall efficiency.

The oil pump and pressure regulator were integrated into the oil stabilizer system, a design that ensured consistent oil delivery under varying engine loads. The complete engine weighed in at 170 kilograms. When paired with a turbocharger, the crankshaft was able to spool up nearly instantly, offering rapid performance response.

Overall, the BMW M54 was a well-designed, durable, and high-performing engine. It was widely regarded as one of BMW’s most reliable powerplants, but it wasn’t without its demands. High-quality fuel and oil are a must, and neglecting routine maintenance or letting small problems linger can quickly lead to major—and expensive—repairs.

Still, compared to previous BMW engines, the M54 resolved many lingering issues and moved the brand forward. The Bavarian engineers succeeded in building a more dependable, more efficient, and more environmentally friendly engine that upheld BMW’s performance heritage without sacrificing reliability.

3. Mazda BP-ZE (1.8L DOHC)

Vehicles: Mazda MX-5 Miata (NA & NB), Familia GTX

Production Years: 1994–2005

Mazda’s BP-ZE engine, especially in Miatas, is renowned for its reliability and rev-happy nature. But what surprises many is how the engine seems to mature with miles.

Early in its life, it may feel a bit tight and restrained. However, once it crosses 50,000–70,000 miles, the engine becomes livelier, more responsive, and even more enjoyable to drive.

This phenomenon comes from a combination of tight factory tolerances loosening slightly over time, along with piston rings and valve seats bedding in properly.

With regular oil changes and occasional timing belt maintenance, the BP-ZE evolves into a smoother and more dynamic performer sometimes even returning better fuel economy than when new.

Mazda’s first genuinely high-performance B-series four-cylinder engine made its debut in 1987 with the release of the BF-series Familia GT-X.

The ’87 Familia GT-X came equipped with the base B6 1.6-litre engine, which features a 78mm bore and 83.6mm stroke, a relatively low static compression ratio of 7.8:1, a dual overhead cam (DOHC) four-valve-per-cylinder head, an IHI turbocharger, an air-to-air intercooler, and multi-point fuel injection

. This engine begins to show its performance character above 3000 rpm, producing 186Nm of torque at 5000 rpm and peaking at 103kW when fueled with premium unleaded. The B6 DOHC turbo engine is designed for transverse mounting and is mated to a five-speed manual transmission that channels power to either the front wheels or all four, depending on the model.

In Australia, the Familia GT-X was introduced as the 323 Turbo, and a Ford-branded twin was offered in the form of the TX3. Additionally, the top-spec Ford Capri convertible was also available with the B6 turbo engine. However, it’s worth noting that locally delivered models were rated slightly lower, producing 100kW when running on standard unleaded petrol.

A naturally aspirated version of the DOHC B6 engine appeared in the 1989 launch of the Eunos Roadster, which is more widely known as the Mazda MX-5 or Miata. The Roadster’s B6-ZE engine features a higher 9.4:1 compression ratio, is mounted longitudinally, and delivers power to the rear wheels. Buyers could choose between manual and automatic transmissions.

This version of the engine produces 88kW and 137Nm at 6500 and 5500 rpm, respectively. It’s also worth mentioning that the naturally aspirated B6 DOHC engine continued to power base-spec versions of the Eunos Roadster until 2005. Australian-delivered models were slightly detuned, offering 85kW and 130Nm.

Atmospheric DOHC and SOHC variants of the B6 engine were also used in front-wheel-drive versions of the Ford Capri, Laser, and Mazda 323. That said, anyone serious about performance would be better off opting for a later-generation, larger-displacement BP engine.

Mazda introduced the BP 1.8-litre engine in late 1989. This engine first appeared in the new BG-series Familia hatch, specifically in its turbocharged GT-X version. The BP engine shares the basic layout of the B6 but features increased bore and stroke dimensions of 83mm and 85mm respectively, bringing total displacement to 1839cc.

The BP engine includes a DOHC, four-valve-per-cylinder head, multi-point injection, a knock sensor, a static compression ratio of 8.2:1, an air-to-air intercooler, and electronically managed turbo boost.

In Japanese-market trim, the BP turbo delivers 132kW at 6000 rpm and 237Nm at just 3000 rpm. Premium unleaded is required to achieve those figures, and performance will drop slightly with regular fuel. This engine is coupled with a standard five-speed manual transmission and an all-wheel-drive system.

The same BP turbo engine configuration was also found in the locally sold KF and KH series Ford TX3 AWD Turbo models. In Australian specification, the engine was rated at 117kW and 206Nm, likely due to the use of lower octane fuel available locally.

In early 1993, Mazda unveiled the high-performance Familia GTR, a homologation special powered by an upgraded BP turbo engine delivering 154kW and 250Nm. But the GTR wasn’t just a mildly boosted GT-X—it was a comprehensive motorsport rework executed by Mazda’s Motorsport Engineering Group.

The engine modifications included reshaped combustion chambers, raised piston crowns (while maintaining the GT-X’s 8.2:1 compression ratio), reinforced connecting rods, a water-to-oil cooler, larger sodium-filled valves, more aggressive camshaft profiles, subtle cylinder head revisions, and a match-ported intake manifold.

In addition, Mazda equipped the GTR engine with a larger capacity ball-bearing turbocharger, a 70 percent larger intercooler, and higher boost pressure. ECU tuning was also refined, and it’s believed that the airflow meter and fuel pump were upgraded to accommodate the performance enhancements.

These revisions allowed the engine to achieve its 154kW and 250Nm peak output at 6000 rpm and 4500 rpm, respectively—figures that come in significantly later than those of the standard GT-X BP turbo engine.

The transmission was a five-speed all-wheel-drive gearbox, similar in layout to the GT-X, but with critical upgrades. The GTR transmission featured shot-peened gears, a strengthened casing, and an upgraded clutch to handle the additional power and stress. Sadly, despite its impressive engineering, the Familia GTR was produced in very limited numbers, making it a rare find today.

Also Read: 5 Trucks With the Lowest Idle-Fuel Use and 5 Guzzling at Stoplights

4. Honda K20/K24 Series (2.0L–2.4L I4)

Vehicles: Honda Civic Si, Accord, CR-V, Acura RSX, TSX

Production Years: 2001–present

Honda’s legendary K-series engines, particularly the K20 and K24 variants, are known for their high-revving character and impressive durability.

What’s less discussed is how these engines actually get better after a long run-in period. Around 60,000–80,000 miles, owners often notice improved VTEC engagement, smoother idle, and an overall stronger mid-range pull.

The reason lies in the valvetrain and piston tolerances these engines are designed to thrive at high RPMs and tight conditions. Over time, the internals settle into their ideal operating tolerances, leading to more efficient combustion and reduced friction.

Many K-series motors go on to see 200,000+ miles with only basic maintenance often pulling just as hard, or even harder, than they did at 20,000 miles.

When it comes to legendary four-cylinder engines, Honda is often one of the first names that comes to mind. Although earlier engine families like the B-Series still enjoy strong aftermarket support and fanfare, the later K-Series has become equally, if not more, iconic in the performance world.

While the K20 tends to receive most of the recognition within the K-Series lineup, the 2.4-liter K24 engine proves to be just as capable, and in many cases, even more so than its smaller sibling.

Over the years, the K24 engine has built a reputation for being exceptionally reliable and robust, with only a few commonly known issues that are easily manageable.

It has also become a favorite among enthusiasts for modification, with a wide array of available upgrades ranging from cylinder head swaps to bolt-on parts. This versatility and durability have earned the K24 a celebrated status within Honda’s engine lineup, and it continues to be a go-to choice for tuners seeking both performance and dependability.

The Honda K24 engine features an inline-four configuration with a 2.4-liter displacement, using a naturally aspirated setup. It comes equipped with a DOHC i-VTEC valvetrain and features an aluminum block and head.

The engine’s bore and stroke measure 83.0mm by 99.0mm, and its compression ratio ranges between 9.6:1 and 11.0:1, depending on the specific version. The long block weighs approximately 283 pounds. Power output varies from 158 to 206 horsepower, with torque figures ranging between 160 and 182 lb-ft.

As part of the broader K-Series family, the K20 and K24 engines share many similarities in terms of architecture and design. However, the most noticeable difference is displacement. The K20 is the 2.0-liter variant with an 8.3-inch deck height and an equal bore and stroke of 86.0mm, resulting in a perfectly square engine configuration.

In contrast, the K24 features a taller 9.1-inch deck height, with a bore of 87.0mm and a longer stroke of 99.0mm, which gives it a larger total displacement of 2.4 liters. This longer stroke not only increases displacement but also impacts the engine’s overall behavior and performance characteristics.

Because the K24 is an undersquare engine—meaning its stroke is longer than its bore—it tends to generate more torque, especially in the lower RPM range. This makes it highly desirable for applications that benefit from strong low-end torque.

However, this design does come with a trade-off: the K24 has a lower redline compared to the K20, which limits its high-RPM potential. This can be a point of contention for enthusiasts who prefer rev-happy engines and prioritize top-end power.

Outside of displacement and stroke, the two engines have only minor mechanical differences. The K20 and K24 each come with unique intake manifolds, and they use slightly different camshafts, valve springs, and spring retainers.

Despite these differences, one of the biggest advantages within the K-Series platform is the modularity between parts. It’s common within the Honda tuning community to mix and match K20 and K24 components to create hybrid builds that combine the best features of both engines.

For those looking to explore the world of Honda’s K-Series engines further, be sure to check out additional resources such as our Honda K20 vs. K24 Engine Guide, the Ultimate Honda K20 Engine Guide, and our comprehensive article on the Best Honda Engines of All Time.

These resources offer more in-depth comparisons, performance insights, and technical breakdowns that can help you understand why the K24 continues to be one of Honda’s most admired and celebrated engines.

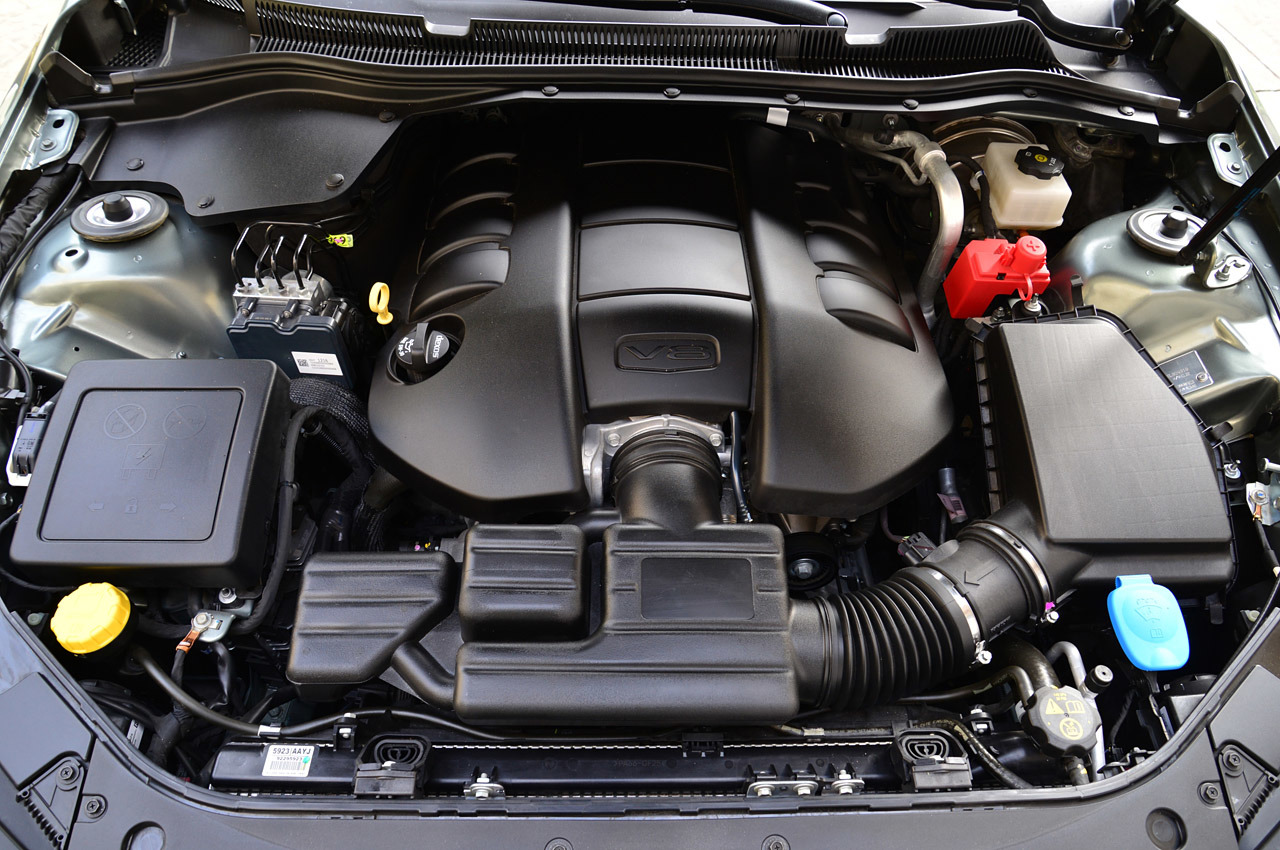

5. Chevrolet LS3 (6.2L V8)

Vehicles: Chevrolet Corvette C6, Camaro SS, Pontiac G8 GXP

Production Years: 2008–2017

The LS3 is part of GM’s iconic LS engine family and has become a go-to swap option for hot-rodders and restomod enthusiasts.

But it’s also a powerplant that truly comes into its own with age. While the LS3 is strong straight from the factory, many owners report a noticeable gain in performance, engine note quality, and throttle responsiveness after the 50,000-mile mark.

That’s because the LS3, with its aluminum block, forged crank, and cathedral-port heads, is slightly overbuilt and benefits from internal friction reduction over time.

As the engine wears in, piston rings seat fully, valves seal more tightly, and oil flow becomes optimized making for a beast that gets more refined and responsive with age. While every engine wears with time, a select few seem to defy expectations by improving as they age.

More than two decades after General Motors first introduced them to the public, the LS-series of small-block V8 engines has reached near-mythical status in the automotive world. Known for their durability, reliability, and the ability to churn out impressive amounts of horsepower and torque, these engines have earned a legendary reputation.

Among the early models in this lineup, the LS3 6.2-liter engine stands out as a key development. Introduced as the successor to the LS2, the LS3 was produced from the 2008 through 2017 model years, and even today, Chevrolet continues to manufacture and sell it as a crate engine.

Depending on the vehicle it was installed in, the LS3 generated between 426 and 436 horsepower and 420 to 428 lb-ft of torque, making it one of the most potent naturally aspirated V8s in its class.

The LS3 made its most notable appearance under the hood of the C6 Corvette from 2008 to 2013, serving as the standard engine during this era. It was also the powerplant of choice for the reborn Corvette Grand Sport, produced between 2010 and 2013.

For Camaro enthusiasts, Chevrolet offered a slightly detuned version of the LS3—known as the L99—for use in the 2010 to 2015 Camaro SS equipped with automatic transmissions.

Manual-transmission Camaro SS models retained the standard LS3. In addition to these, GM also created a family of engines called the Vortec 6200 series, which includes the L92, L9H, and L94. These engines were foundational to the development of the LS3, as GM used the L92 as a base and refined it for performance applications.

The story of the LS3 is rooted in the broader development of GM’s small-block V8s. The journey began in 1997 with the launch of the third-generation LS1 engine. This was followed by the LS6 in 2001 and the fourth-generation LS2 in 2005.

Parallel to the LS-series, GM also released the Vortec line, which shared many mechanical similarities but was geared more toward SUVs and trucks. Typically, the LS-series was reserved for performance cars like the Corvette, Camaro, and Firebird, while the Vortec engines, with their iron blocks and lower output, were deployed in GM’s heavier vehicles.

The LS3 can be considered a hybrid of the Vortec and LS-series fourth-generation small-blocks. GM launched the Vortec 6200 L92 engine in 2007 for use in various GMC and Cadillac trucks and SUVs. They then took that L92 block, upgraded it with a performance intake manifold and higher-flow cylinder heads, and introduced it as the LS3.

Between 2008 and 2013, the LS3 served as the base engine for the C6 Corvette. Initially, it powered the Z51 Corvette from 2008 to 2009, and from 2010 to 2013 it was the engine for the Grand Sport, which replaced the Z51 performance package.

In 2010, GM introduced the L99 variant, a slightly detuned version of the LS3 intended for automatic-transmission Camaro SS models produced between 2010 and 2015. Manual Camaros in the same generation continued to use the standard LS3. From 2014 to 2017, the Chevrolet SS also came equipped with the LS3, extending its performance appeal into the sports sedan segment.

Outside of North America, the LS3 saw life in several models produced by GM’s Australian subsidiary, Holden. From 2009 to 2013, Holden used the LS3 in its high-performance HSV E-Series, replacing the outgoing LS2 engine.

Later, from 2015 to 2017, the LS3 powered the VF-series Commodore, which also served as the basis for the Chevrolet SS in the U.S. market. In the U.K., Vauxhall adopted a version of the LS3 for its VXR8 GTS, sold between 2009 and 2013. The VXR8 GTS was essentially a rebadged HSV E-Series that brought Australian muscle to British shores.

Clearly, the LS3’s impact has been global, with a production run that spanned nearly a decade and extended across multiple continents. American production of the LS3 ended in 2015, with the exception of its continued use in the Holden-based Chevrolet SS, but international production continued until 2017. Today, the legacy of the LS3 lives on, as Chevrolet still offers it in crate form, with several variations available to suit different builds and applications.

As for the technical details, the LS3 belongs to GM’s Gen IV small-block V8 family. It was produced from 2008 to 2017 and features a naturally aspirated 6.2-liter (376 cubic inch) displacement.

The engine uses a 90-degree V8 configuration with a compression ratio of 10.7:1. Its bore and stroke measure 4.065 by 3.622 inches (103.25 x 92 mm). The LS3 employs an overhead valve (OHV) valvetrain with 16 valves and two valves per cylinder.

It is equipped with electronic fuel injection and constructed with a cast aluminum block and aluminum heads. Output ranges between 426 to 436 horsepower and 420 to 428 lb-ft of torque, depending on the specific application and tuning.

With its combination of reliability, performance, and tunability, it’s no wonder the LS3 continues to be celebrated as one of GM’s most successful and versatile V8 engines ever made.

The engines on this list not only endure high mileage but often deliver better performance, smoother operation, and a more rewarding driving experience years down the road.

For enthusiasts and practical drivers alike, these powerplants prove that sometimes, time and miles can be a blessing in disguise so long as you treat the engine right.