When it comes to cars, nothing hits harder than engine failure — emotionally, financially, and practically. An engine is the heart of your vehicle, and whether you’re a high-mileage warrior or someone who just wants their ride to age gracefully, engine reliability should be at the top of your checklist.

Yet not all engines are created equal. Some powerplants are so bulletproof, they’ll outlive the car itself (and maybe even you). Others? Well, they seem built to self-destruct the moment your warranty expires.

This article is your no-BS guide to both ends of that spectrum. We’re spotlighting 5 engines that are built to last 500,000 miles—yes, half a million—with proper care.

These are the iron-lunged legends that don’t flinch at abuse and thrive on long hauls. Then, on the flip side, we’re calling out 5 engines that break down far too often—the ones that rack up shop bills and test your patience more than they should.

Whether you’re buying your next daily driver, looking to hold onto your current ride for the long haul, or just love geeking out over mechanical longevity and failure rates, this list cuts through the fluff.

Engines That Easily Last 500K Miles

These aren’t just opinions—they’re built on real-world owner experiences, mechanic testimonials, and years of performance data. We’re not here to sugar-coat bad engineering or hype up overrated motors. We’re here to tell it like it is.

Let’s dive into the engines that keep going, and the ones that will make you wish you never turned the key.

1. Toyota 2UZ-FE (4.7L) V8

Used in: Toyota Land Cruiser, Sequoia, Tundra, Lexus GX470

Toyota’s 2UZ-FE V8 is the gold standard for long-lasting performance. Designed with a cast-iron block and overbuilt components, it’s known to clock over 500,000 miles in harsh environments.

Many Land Cruisers with this engine are still active in off-road fleets worldwide. Its smooth torque curve, solid timing belt setup, and legendary Toyota reliability make it nearly bulletproof.

Toyota’s 4.7-liter V8 engine, a prominent member of the UZ family, is known for its durability and design tailored for heavy-duty use. The 2UZ-FE was engineered specifically for large trucks and SUVs, which explains its larger displacement, low-rev operation, and high torque output.

Unlike its siblings—the 1UZ-FE and 3UZ-FE—which feature aluminum cylinder blocks, the 2UZ-FE utilizes a cast iron block. This material choice provides enhanced durability and comes at a lower cost, but it significantly increases the engine’s overall weight.

Structurally, however, the 2UZ shares its block design and dimensions with the others in the UZ family, apart from its larger bore and stroke. It retains a 90-degree V-angle, a 21-mm cylinder bank offset, and a bore pitch of 105.5 mm.

The internals include a steel crankshaft with eight counterweights and five main journals (compared to six in the 1UZ), forged and sintered connecting rods, and aluminum alloy pistons with tin-plated skirts to help reduce friction.

Mounted atop each cylinder bank are aluminum cylinder heads, each equipped with intake and exhaust camshafts operating four valves per cylinder. The camshaft actuation follows the same principle used in the 1UZ: the intake cams are powered by a timing belt, while the exhaust cams are gear-driven off the intake cams.

The valvetrain design remains consistent, with intake and exhaust valves arranged on opposite sides at a 21.55-degree angle. Intake valves measure 34.5 mm and exhaust valves 29.0 mm in diameter—dimensions identical to the VVT-i version of the 1UZ-FE. The 2UZ-FE also uses solid steel valve lifters, which require routine adjustment for proper valve clearance.

In its early form, the 2UZ-FE came with a basic aluminum intake manifold featuring long runners. Between the intake manifold and each cylinder head were two metal gaskets with a heat-barrier gasket sandwiched in between.

Initially, a traditional throttle body was used, but Toyota transitioned to the ETCS-i (Electronic Throttle Control System – intelligent) in late 2002. From its launch, the engine featured sequential multiport fuel injection (SFI), with eight four-hole injectors—one per cylinder—alongside a mass air flow sensor and two air-fuel ratio sensors.

It was also equipped with Toyota’s Direct Ignition System (DIS), delivering spark via individual ignition coils and iridium plugs. Additional components include dual knock sensors and an Electronic Spark Advance system, which dynamically manages ignition timing to prevent detonation.

All 2UZ-FE engines produced after 2007 incorporated Variable Valve Timing with intelligence, or VVT-i. This system monitors and adjusts critical engine parameters—such as throttle position, coolant temperature, and air intake volume—to optimize intake camshaft timing. The result is improved performance and efficiency across all RPM ranges.

Another major addition was a plastic intake manifold with a variable-length intake runner system, regulated by Toyota’s Acoustic Control Induction System (ACIS). The ACIS adjusts the intake path in two stages: a longer path for low RPM and a shorter one for higher engine speeds.

Internally, the VVT-i version of the 2UZ-FE introduced lighter pistons and oil squirters to keep piston temperatures under control. The compression ratio was raised to 10.0:1, enhancing combustion efficiency. By 2010, the VVT-i version had fully replaced the earlier 2UZ-FE models. However, starting in 2008, Toyota began phasing out the 4.7-liter V8 in favor of newer engines like the 5.7-liter 3UR-FE and 4.6-liter 1UR-FE.

Also Read: 10 Classic Car Engines That Still Start on First Try

2. Cummins 5.9L 12-Valve Diesel (6BT)

Used in: Dodge Ram 2500 and 3500 (1989–1998)

The Cummins 6BT is one of the most respected diesel engines in truck history. Its mechanical injection system, forged internals, and minimal electronics make it incredibly durable and simple to repair.

With proper oil changes and cooling system care, it’s not unusual to see these motors hit 750,000 miles especially in commercial use.

If you happened to be in the market for a brand-new Dodge Ram truck back in 1989—also known as the First Generation—you had some solid choices under the hood. You could go with a reliable 360 cubic inch gasoline-powered V8, or you could opt for something that felt like it belonged in a semi-truck: the 5.9-liter Cummins diesel.

When Dodge started dropping these engines into their Ram pickups, sales surged. Buyers were eager to get their hands on this torque-heavy powerplant, especially when paired with either a robust five-speed manual transmission or a heavy-duty variant of the A727 three-speed automatic. The 5.9-liter Cummins quickly became the engine of choice.

What made the 5.9-liter Cummins stand out from other diesels of its era was that it offered direct injection—something none of its competitors had. It didn’t rely on glow plugs and wasn’t naturally aspirated.

This beast came factory-equipped with a turbocharger (the Holset H1C), and buyers gravitated toward it for its reputation for reliability, impressive torque output (for that time), and strong fuel efficiency. “If you can believe it, their 160-horsepower and 400 lb-ft of torque rating was class-leading performance.”

Over the course of its 18-year production run, the inline-six Cummins saw multiple changes to its fuel injection system—each built by Bosch.

The original 12-valve version used a camshaft-driven, rotary-style injection pump known as the “VE” pump. That unit earned a reputation for long-term dependability, but it came with limitations—namely, it offered the least power potential among the Cummins pump family.

While there are definitely ways to boost the horsepower and torque of a VE-pump-equipped 5.9-liter Cummins, it’s not the go-to choice for performance builds. With just a handful of common tools, you can increase fueling enough to gain about 70 horsepower over stock. Still, this pump is pretty conservative when it comes to how much fuel it will actually deliver.

Even after adjusting the pump, the factory fuel injectors tend to restrict performance even more, acting as a bottleneck. That said, there’s no shortage of aftermarket parts available to help unlock more power and torque.

Upgrades like better injectors, performance turbos, and internal pump modifications—such as governor springs and fuel pins—can make a noticeable difference. So, while the VE pump may not offer the most impressive performance gains out of the box, VE-equipped Cummins trucks with the right mods can absolutely become more exciting and enjoyable to drive.

3. Honda J35 V6

Used in: Honda Pilot, Odyssey, Accord, Ridgeline, Acura MDX

The J35 V6 may not seem like a high-mileage candidate, but owners regularly report well over 300K miles with no major issues and many break the 500K mark.

Honda’s precision engineering, smooth operation, and timing belt serviceability make this V6 a standout, particularly in vehicles that see highway miles.

The J35 is a 3.5-liter V6 gasoline engine that made its debut in the 1998 Honda Odyssey. This newly developed J35A six-cylinder engine was derived from the 3.2-liter J-series variant known as the J32A.

Over time, the J35 found its way into numerous larger and heavier Honda vehicles—including sedans, SUVs, pickups—as well as various Acura models. Through the years, the J35 has seen extensive refinement, and its latest evolution, the J35Y, represents a substantial leap forward in fuel economy, performance, and emissions compared to earlier versions.

The J35A remained in production for nearly fourteen years, from 1998 to 2012. Sharing design cues with the J32A, the J35A features a compact aluminum cylinder block with a 60-degree angle between the banks.

Its deck height measures 235 mm. While the bore and piston sizes carried over from its predecessor, the crankshaft was upgraded to a forged unit with a longer 93 mm stroke. This effectively turned the J32 into a stroked version, featuring lightweight 158.5 mm connecting rods.

Sitting atop the block are aluminum cylinder heads, each configured with four valves per cylinder and a single overhead camshaft. The camshafts are operated by a timing belt.

The valvetrain incorporates Honda’s VTEC system, and valve actuation is handled by roller rocker arms—there are no hydraulic lifters in this setup. “The J35A1 features 34 mm intake valves and 29 mm exhaust valves.” Its intake system includes a one-stage aluminum intake manifold and a 55 mm throttle body. “This engine also had a 9.4:1 compression ratio.”

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

4. Mercedes-Benz OM617 3.0L Diesel I5

Used in: Mercedes 240D, 300D, 300SD (1970s–1980s)

This old-school diesel is slow, but indestructible. The OM617 is legendary for its mechanical simplicity and reliability.

Many of these engines are still running strong after half a million miles, especially in Africa and the Middle East where spare parts are scarce but diesel is abundant.

Regular valve adjustments and fuel filter swaps are all it takes to keep it humming. Some engines have earned a reputation for lasting well beyond the half-million-mile mark with consistent upkeep—and Mercedes-Benz diesel engines are often at the top of that list.

One standout in this category is the OM617A, the turbocharged variant of the five-cylinder OM617 engine from Mercedes-Benz. During the 2000s, owners of Mercedes vehicles equipped with this engine were reporting mileages reaching up to 600,000, with many claiming their cars could go even farther as long as regular maintenance was performed.

When Mercedes-Benz introduced the turbocharged OM617 into the W116 chassis for select non-European markets, it marked the creation of the world’s first turbocharged diesel-powered sedan. Over the course of its production, three slightly different versions of the turbo OM617 were released.

However, it was the mid-cycle update to the original version that brought the most noticeable gains in performance. Mercedes used this engine platform across three key vehicle lines: the 1978–1980 W116 models, the 1981–1985 W126 S-Class sedans, and several cars built on the W123 platform from 1978 through 1986.

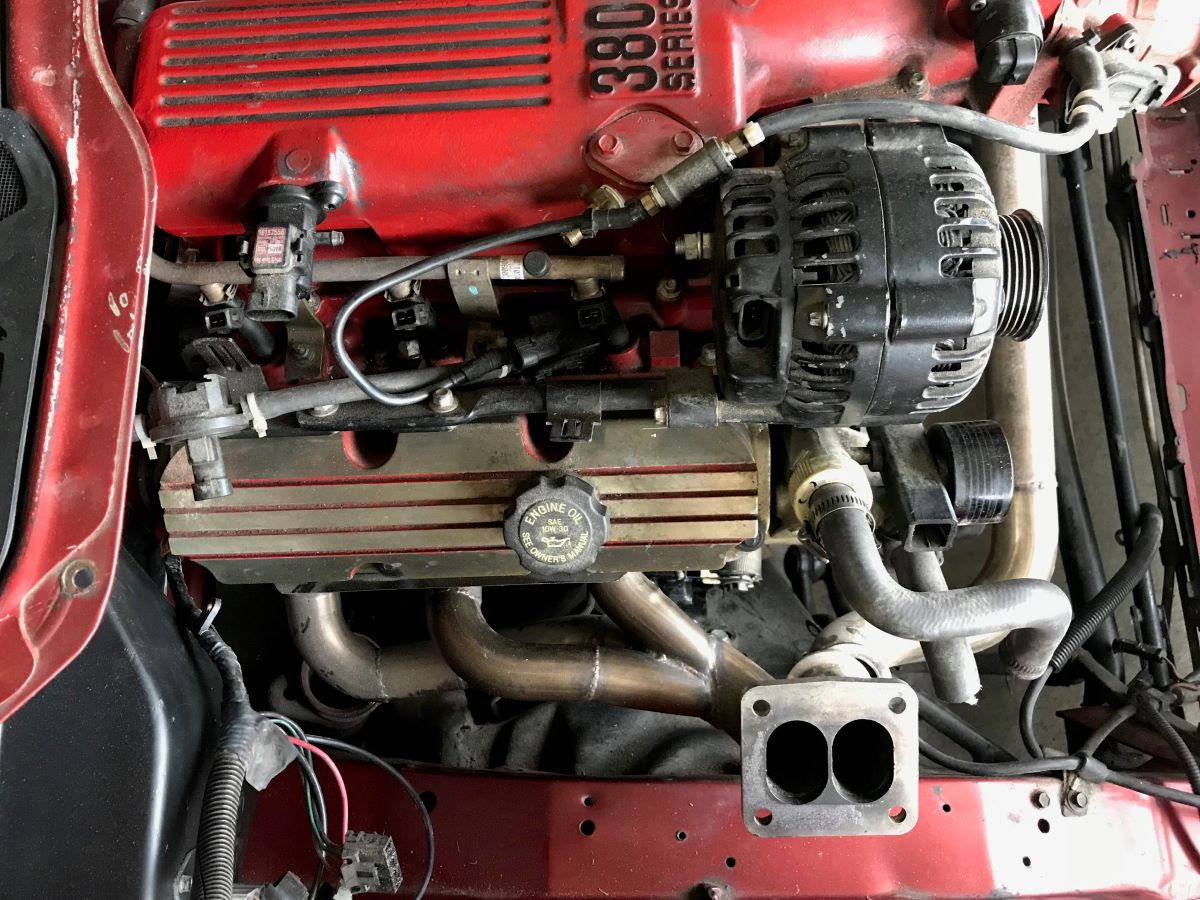

5. General Motors 3800 Series II V6 (L36)

Used in: Buick LeSabre, Pontiac Bonneville, Chevrolet Impala

The GM 3800 V6 is one of the most dependable gas engines ever built.

With iron block construction, a strong intake design, and decades of refinement, this engine frequently hits 300K–500K miles with minimal issues. As long as the plastic intake manifold is replaced early, it runs forever. It’s not flashy but it refuses to die.

Among modern automotive powerplants, General Motors’ renowned “3800” V6 holds its place among legends. It stands alongside Oldsmobile’s 1949 Rocket V8, Chevrolet’s legendary small-block V8, and even Studebaker’s innovative supercharged engines from the late 1950s to early 1960s.

But unlike those motors remembered for their dramatic flair or engineering spectacle, the 3800 made its mark through subtle strength.

There was nothing flashy about it—no outrageous design, no bold marketing hype. It simply delivered. It was a quiet workhorse, embodying dependable performance, long-term reliability, and the kind of mechanical “character” that builds trust over time.

That character mattered more than personality. It’s what made the 3800 an engine drivers could count on. It’s akin to what Paul Newman’s character was told in The Hustler (1962)—that raw skill wasn’t enough to reach the top; he needed “character.” The 3800 didn’t boast or show off, but it stood the test of time with quiet confidence.

Over more than forty years of production—including its early predecessors—it earned a reputation for solid quality, excellent fuel economy, cost-effective manufacturing, and mechanical durability. Not many engines have come close to matching those benchmarks.

In total, GM built approximately 25 million 3800 engines. The engine’s lineage traces all the way back to 1962, and its evolution was anything but straightforward. It began as a bold but flawed experiment: a 215-cubic inch aluminum V8 that GM had developed for compact cars across its Buick, Oldsmobile, and Pontiac divisions.

At the time, aluminum casting for engine blocks was still in its infancy, and the process yielded inconsistent quality. After only two years, GM scrapped the aluminum V8. But they didn’t discard the core design. Instead, they reworked it into a cast-iron V6—a design that became the foundation for the Fireball V6, first used in the 1962 Buick Special.

That engine—essentially the 215 V8 minus two cylinders and now made from cast iron—shared many internal components with its predecessor. Thanks to thin-wall casting techniques, the V6 remained relatively light despite the material switch. It was a surprise move by GM, considering they had mostly reserved V6s for truck applications. Passenger cars rarely saw V6 powerplants in the U.S. market, though some European brands had begun exploring the layout.

One quirk of this new engine was its irregular firing pattern. The 90-degree V6 block angle didn’t align smoothly with the firing order, which followed a 120-degree rhythm. This mismatch caused vibration, and without a balance shaft, it ran with a coarse edge. Rather than re-engineering the internals, GM tried to mask the roughness with soft engine mounts.

The result was a distinct low-end rumble—something that, over time, became a signature characteristic. Some saw it as a unique trait, adding sonic character to an otherwise unremarkable engine note. Others viewed it as a flaw—a rough idle that detracted from refinement.

The first version of the V6 displaced 198 cubic inches, but by 1964 it had grown to 225 cid. In 1967, GM sold the tooling and rights for the engine to Kaiser-Jeep Corp., which needed a compact and powerful motor for its Jeep CJ models.

The engine was renamed the Dauntless 225 and fit perfectly under the CJ’s small hood, where an inline-six simply wouldn’t fit. Later, in the wake of the 1973–74 oil crisis, GM revisited its earlier priorities.

With fuel efficiency now front and center, they needed to downsize across their lineup. GM reached out to American Motors—who had purchased Jeep from Kaiser in 1970—to see if they’d resume production of the Dauntless V6 for GM cars. AMC wasn’t interested in restarting manufacturing but did agree to sell the engine rights back to GM.

What followed was a long, evolutionary journey for the 3800 that cemented its legacy as one of the most reliable and respected V6 engines in automotive history. It might not have turned heads at car shows, but under the hood, it got the job done—year after year, mile after mile. And that’s exactly why it’s still talked about with respect today.

Engines That Constantly Break Down

While a handful of powerplants earn legendary status for longevity and bulletproof engineering, others build a reputation for leaving drivers stranded, bleeding wallets dry with constant repairs, and souring entire model lineups.

These engines aren’t just problematic; they’re repeat offenders. They frustrate owners, tank resale values, and often become cautionary tales in online forums and mechanic bays alike.

This list doesn’t deal in exaggeration or hearsay — these are engines that have proven, time and again, that reliability was either an afterthought or simply missed the mark.

1. Chrysler 2.7L V6 (LH and early Sebring engines)

Used in: Chrysler Sebring, Dodge Intrepid, Chrysler Concorde

This engine is infamous for oil sludge buildup, timing chain tensioner failures, and premature water pump leaks.

The 2.7L’s internal water pump can fail and leak coolant directly into the oil system, destroying the bearings. Even with good maintenance, these engines rarely make it past 120K miles without major issues.

The 2.7L V6 engine, most commonly linked to Chrysler’s LH platform, debuted in the mid-1990s as the company’s answer to the rising demand for engines that could offer both efficiency and power.

Chrysler intended this engine to strike a middle ground — something that could perform well without compromising on fuel economy. As a result, it became a go-to option across a variety of sedans and minivans from Chrysler, Dodge, and Plymouth throughout its production lifespan.

The engine’s blueprint focused on smooth performance and long-term dependability. It was built with a Dual Overhead Camshaft (DOHC) setup and used lightweight aluminum materials in its construction.

This design not only enhanced its performance capabilities but also helped maintain a solid weight-to-power ratio. With respectable horsepower output, the 2.7L V6 proved itself adequate for everyday driving and long highway trips alike.

2. BMW N63 4.4L Twin-Turbo V8

Used in: BMW 550i, 750i, X5, X6 (2008–2014)

The N63 V8 was BMW’s first production twin-turbo V8, but it’s plagued with problems timing chain stretch, valve stem seal failures, and turbocharger oil starvation are all common.

BMW even issued a “Customer Care Package” to address the systemic failures. It’s not uncommon for these engines to require thousands in repairs before hitting 100K miles.

The BMW N63 engine is a twin-turbocharged V8 that has powered some of the most luxurious and high-performance vehicles in BMW’s lineup since its debut in 2008. Originally launched in the E71 X6 and F01 750i, this engine has since been featured in a wide array of BMW models, including the 5 Series, 6 Series, and the more recent G05 X5, G06 X6, and G07 X7.

Technically, the N63 features a 4.4-liter V8 configuration, with a smaller 4.0-liter version reserved for Chinese markets. It has an 89 mm bore and an 88.3 mm stroke, with a dual overhead camshaft valvetrain and BMW’s Dual VANOS variable valve timing system.

With a compression ratio of 10:1 and a weight of approximately 503 pounds, the engine produces between 402 and 523 horsepower, along with torque ranging from 443 to 553 lb-ft, depending on the specific model and application.

3. Subaru 2.5L EJ25 (Non-Turbo)

Used in: Subaru Outback, Forester, Legacy (1996–2011)

The EJ25 non-turbo is a box of mixed reliability. While the turbo variants are stronger, the naturally aspirated versions have chronic head gasket failures particularly in Phase I and II designs.

Replacing the gasket is costly and usually happens around 100K–150K miles, sometimes sooner. Many owners deal with repeated coolant leaks and overheating.

The Subaru EJ25 is a 2.5-liter engine built at Subaru’s Gunma Oizumi Plant and stands as a prominent member of the EJ engine series. Among the EJ family—which includes the EJ15, EJ16, EJ18, EJ20, and EJ22—the EJ25 is both the largest in displacement and the most widely used. Its 2.5-liter capacity makes it a staple across numerous Subaru models.

To break down the engine code for clarity: the first two letters, “EJ,” identify the engine family, while the numbers that follow—”25″ in this case—represent the engine’s displacement in deciliters (2.5 liters). So, “EJ25” refers specifically to a 2.5-liter engine from the EJ series.

The EJ25 is a flat-four, or “boxer,” engine that began initial production in 1989. However, it wasn’t until around the middle of 1996 that Subaru fully brought the engine to market, launching the naturally aspirated version in the Subaru Legacy for the U.S. market.

The engine gained significant traction in the enthusiast community during the mid-2000s when the first U.S.-spec Impreza WRX STI (built on the GDB chassis) was equipped with this powerplant.

To this day, the EJ25 remains a popular choice for engine swaps and tuning, thanks to its proven durability and solid internal components. Whether it’s performance upgrades or motorsport builds, the EJ25 continues to be a go-to engine for Subaru enthusiasts.

4. Ford 5.4L Triton V8 (2V & 3V variants)

Used in: Ford F-150, Expedition, Lincoln Navigator

Despite powering millions of trucks, the Triton V8 suffers from serious issues especially the 3-valve version. Spark plugs can seize or break off in the head, cam phasers fail, and oiling issues lead to premature top-end wear.

These engines can work well when cared for meticulously, but many fall apart before 150K miles due to design flaws.

The Ford 5.4 Triton V8 is a member of Ford’s Modular V8 engine family—a 5.4-liter naturally aspirated eight-cylinder gasoline engine that made its debut in the 1997 Ford F-150.

Fundamentally, the 5.4-liter engine is a stroked version of the 4.6-liter Modular V8, as both share a similar overall design and architecture. Over its production run, the 5.4L came in three primary variants: the 5.4 SOHC V8 with either 2-valve or 3-valve cylinder heads, and the more performance-oriented 5.4L DOHC 4-valve V8.

The 2-valve and 3-valve versions were most commonly found in Ford’s F-Series pickup trucks, serving as reliable workhorse engines. On the other hand, the 5.4L DOHC 4-valve variant was reserved for Ford’s high-performance and luxury vehicles.

This more powerful version powered some of the brand’s most iconic models, including the Ford GT supercar, the Ford Shelby GT500, the Ford Mustang SVT Cobra R, and several Lincoln luxury cars.

5. Mazda 2.3L DISI Turbo (MZR)

Used in: Mazdaspeed3, Mazdaspeed6

While fun to drive, this engine is not built for longevity. The direct injection turbo setup suffers from high oil consumption, cracked pistons, and stretched timing chains.

Owners often report catastrophic engine failure before reaching 100K miles, especially if modifications or neglect enter the picture. Even stock, it’s a high-risk engine.

The Mazda 2.3L DISI Turbo engine, also known as the L3-VDT, is the turbocharged variant of the 2.3 MZR/L3-VE. Introduced in 2005, this engine was developed as the high-performance powerplant for the Mazdaspeed6 (also known as the Mazda6 MPS).

Following its debut, the L3-VDT was also featured in other Mazda performance models, including the Mazda CX-7 and the Mazdaspeed3 (Mazda3 MPS). Production of this engine ceased in 2012.

The 2.3 DISI engine shares its aluminum alloy cylinder block with the naturally aspirated version, utilizing cast-iron sleeves and a cassette-style balancer unit.

In its turbocharged form, the engine was outfitted with a forged steel crankshaft featuring eight counterweights, sinter-forged connecting rods, and redesigned pistons tailored for direct injection. Additionally, oil jets were integrated into the block to help lubricate and cool the pistons effectively.

Longevity depends on maintenance, but the engine’s design plays a major role. If you’re aiming for a half-million-mile powertrain, tried-and-true engines like Toyota’s 2UZ-FE or the Cummins 6BT are unbeatable.

On the other hand, steering clear of engines with known internal flaws like Chrysler’s 2.7L or BMW’s N63 can save you endless grief and repair bills. Choose wisely, and your engine may outlive the car itself.