Toyota has built its reputation on dependability, and much of that comes down to the performance and longevity of its engines.

Some Toyota powerplants are nearly indestructible, known to easily cross 300,000 miles with just basic maintenance. However, not every engine with a Toyota badge lives up to this legacy.

Some are plagued by oil burning, head gasket issues, or premature wear. Here’s a detailed look at five Toyota engines that run forever and five that definitely don’t.

Toyota has built a rock-solid reputation for producing some of the most reliable vehicles on the road — and much of that praise can be traced directly to what’s under the hood. From bulletproof four-cylinders to stout V8s, Toyota engines are often the reason people hold onto their vehicles for hundreds of thousands of miles.

Toyota Engines That Run Forever

But let’s not pretend they’ve all been perfect. While many Toyota engines have earned a reputation for unmatched longevity, others have struggled with oil consumption, head gasket failures, and other costly issues.

In this article, we’re diving into both sides of Toyota’s engine legacy — highlighting five engines that seem to run forever, and five that prove even Toyota isn’t immune to design flaws and mechanical missteps.

1. 2UZ-FE 4.7L V8

Found in: Toyota Land Cruiser, Sequoia, Tundra, Lexus GX470

The 2UZ-FE is part of Toyota’s UZ engine family and is considered one of the most durable V8s ever made. Built with a cast-iron block and aluminum heads, it thrives on simplicity and overengineering.

Toyota’s UZ-series V8 has long been celebrated by enthusiasts as a remarkably durable option, especially in the context of trucks and SUVs.

While the 1UZ often grabs attention for its sporty characteristics, the 2UZ-FE has carved out its own reputation as a powerhouse for heavy-duty applications. It consistently earns praise for delivering a reliable mix of torque, durability, and solid power. With basic upkeep, many owners report these engines surpassing the 300,000-mile mark without major issues.

This breakdown takes a closer look at the Toyota 2UZ-FE from several angles — key specifications, real-world driving behavior, maintenance expectations, and known trouble spots.

It also includes comparisons with the 1UZ-FE and 3UZ-FE to help clarify its strengths and weaknesses. Whether you’re interested in towing, off-roading, or simply long-term dependability, this review will help you decide if the 4.7L 2UZ-FE fits your specific needs.

Owners routinely report these engines crossing 300,000 miles with no major issues, especially when used in body-on-frame SUVs and trucks. It’s also relatively forgiving with maintenance lapses, thanks to its robust design.

Also Read: 5 EVs With the Best Regenerative Paddles and 5 With Fixed Regeneration

2. 1ZZ-FE 1.8L I4

Found in: Toyota Corolla, Matrix, Celica, Pontiac Vibe

This inline-four was Toyota’s go-to engine for compact cars in the early 2000s. It’s simple, fuel-efficient, and long-lasting.

The 1ZZ-FE uses a timing chain instead of a belt, eliminating a major maintenance concern. With proper oil changes and basic upkeep, it’s not uncommon to see these engines last beyond 350,000 miles. It also avoids many of the oil burning issues seen in some of Toyota’s later small engines.

The 1ZZ-FE was a 1.8-liter inline four-cylinder gasoline engine from Toyota’s ZZ engine family, developed as a successor to the older 1.8L 7A-FE. It debuted in 1998 and remained in production until December 2007.

Primarily designed for front-wheel-drive models like the Toyota Corolla and Toyota Celica GT, the engine also found its way into rear-wheel-drive platforms such as the Toyota MR2 Spyder and the Lotus Elise.

Unlike the 7A-FE, which used a cast iron block, the 1ZZ-FE featured a die-cast aluminum block with 2.0 mm thick, chill-fitted cast iron cylinder liners. The block housed a forged crankshaft with five journals and eight balance weights, along with lightweight connecting rods and aluminum pistons that used full floating-type piston pins.

Atop the block sat a twin-cam aluminum cylinder head with four valves per cylinder — 16 in total — and laser-clad valve seats. The intake valves had a diameter of 32.0 mm with a lift of 9.3 mm, while the exhaust valves measured 27.5 mm with an 8.4 mm lift.

The engine used chain-driven overhead camshafts with an 8 mm pitch roller chain and an automatic tensioner. Starting in 2000, the 1ZZ-FE was equipped with Toyota’s Variable Valve Timing with intelligence (VVT-i), which adjusted only the intake valve timing. The intake manifold was constructed from plastic and featured long, straight runners for improved airflow. A unique TRD variant of the engine came with a cast aluminum intake manifold.

Fuel delivery was managed through sequential electronic fuel injection (EFI) with twelve-hole injector nozzles. Ignition came from a distributorless, coil-on-plug setup known as Toyota Direct Ignition. On the exhaust side, the engine was fitted with a stainless steel exhaust manifold and three-way catalytic converters.

Despite its modern design and wide application, the 1ZZ-FE didn’t earn strong admiration from consumers. By 2007, Toyota had phased it out in favor of the then-new 1.8-liter 2ZR-FE engine.

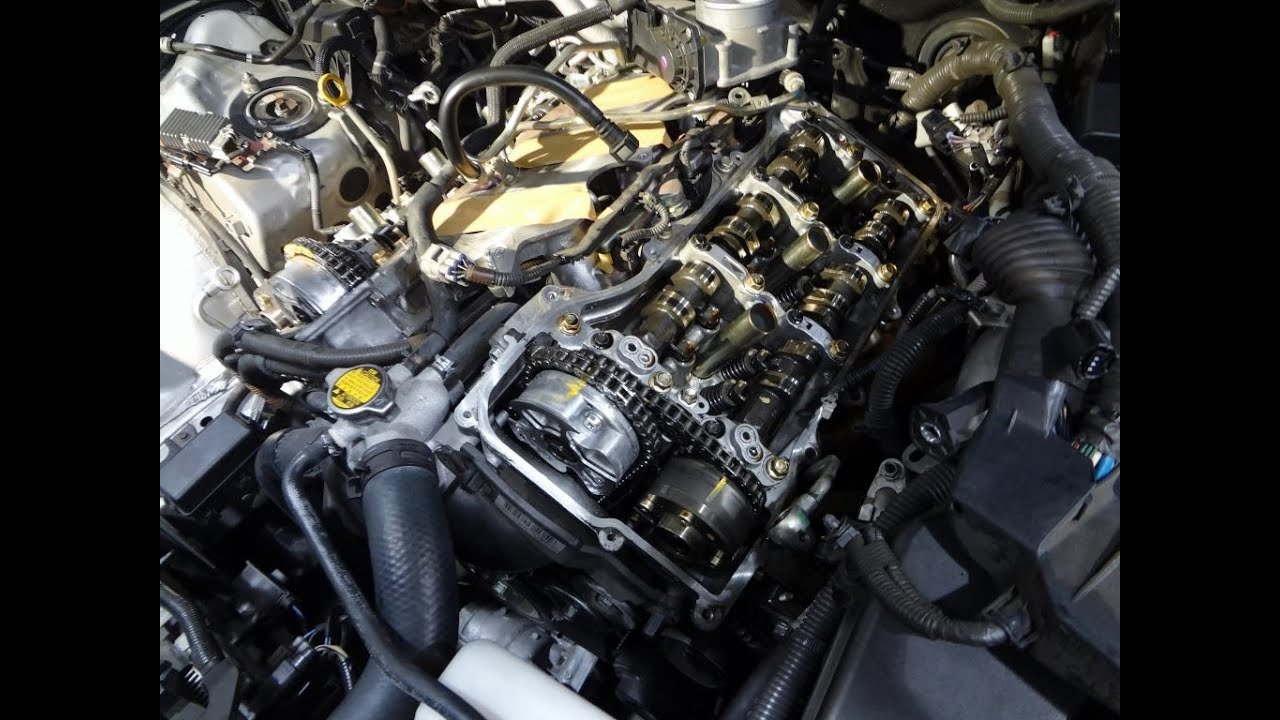

3. 2GR-FE 3.5L V6

Found in: Toyota Camry, Highlander, Avalon, RAV4, Lexus RX350

Toyota’s 2GR-FE V6 is known for blending performance and reliability. While earlier V6s like the 1MZ-FE suffered from oil sludge, the 2GR-FE corrected those flaws with better oiling and materials.

It delivers smooth power, requires minimal intervention beyond oil changes, and can withstand high mileage with ease. Taxi drivers and rideshare owners have reported well over 400,000 miles on original internals.

Beyond Toyota-branded vehicles, the 2GR-FE also found its way into various Lexus models designated with the “350” badge, such as the IS 350, GS 350, and RX 350. Notably, the Lotus Evora S and Exige S were also equipped with this engine, showcasing its versatility.

The 2GR-FE, much like the 1GR-FE, features an open-deck cast aluminum alloy block with spiny-type cast iron liners that are integrated directly into the block. The engine’s V6 configuration uses a 60-degree bank angle.

Internally, it boasts a forged steel crankshaft with five counterweights and forged connecting rods, while the aluminum alloy pistons have resin-coated skirts to reduce friction. Additionally, oil jets are incorporated into the block to help cool the pistons during operation.

Each of the two cylinder heads is made up of three components: the head itself, a camshaft housing, and a valve cover—all crafted from aluminum alloy. These are sealed with steel-laminate type head gaskets.

The engine utilizes a chain-driven dual overhead camshaft (DOHC) layout, with the primary timing chain driving the intake cams, and secondary chains linking the intake cams to the exhaust cams. Toyota’s Dual VVT-i system controls valve timing on both intake and exhaust sides. Roller rocker arms actuate the valves, and hydraulic lash adjusters manage valve clearance automatically.

The intake manifold on the 2GR-FE is made of plastic and includes a variable geometry design. Toyota’s Acoustic Control Induction System (ACIS) adjusts the intake runner length based on engine speed by actuating an air control valve.

Throttle control is handled by the Electronic Throttle Control System – intelligent (ETCS-i), which eliminates a mechanical link between the accelerator pedal and throttle body.

Fuel is delivered through a sequential L-type fuel injection system, while ignition duties are carried out by Toyota’s Direct Ignition System (DIS), with each spark plug receiving its own ignition coil. Exhaust gases exit through stainless steel manifolds and are cleaned by three-way catalytic converters on both banks.

Used predominantly in Lexus models and select Japanese domestic market vehicles, the 2GR-FSE variant incorporates Toyota’s D-4S twin-injection system, combining direct and port fuel injection.

This system requires distinct low- and high-pressure fuel delivery mechanisms. The FSE version also features revised cylinder heads to accommodate high-pressure injectors, now placed on the outer side of the intake valves.

Pistons are made from a high-strength hypereutectic aluminum alloy and have been reshaped to withstand the elevated pressures. The use of direct injection helps cool the air-fuel mixture, allowing for a higher compression ratio of 11.8:1. Like the 2GR-FE, this variant retains ETCS-i, ACIS, and DIS technologies.

The most recent evolution of the 3.5-liter V6 lineup is the 2GR-FKS, introduced in 2015 as the successor to the 2GR-FSE in Lexus vehicles.

In the following years, it was adopted as the standard V6 engine in Toyota models like the Camry and Highlander. While it shares the same fundamental architecture as its predecessor, the 2GR-FKS incorporates Toyota’s latest advancements in engine efficiency and performance.

One of its key innovations is the ability to switch between the traditional Otto cycle and the more fuel-efficient Atkinson cycle, a capability made possible through the use of Variable Valve Timing – Intelligent Wide (VVT-iW) on the intake camshafts. The exhaust camshafts still utilize standard VVT-i.

The engine continues to feature coil-on-plug ignition (DIS), ETCS-i, and ACIS systems, along with the D-4S fuel system that combines both direct and port injection.

Notably, the 2GR-FKS includes significant changes in its exhaust setup—most prominently, exhaust manifolds are now cast directly into the cylinder heads, and the exhaust gas recirculation (EGR) circuit is now cooled for improved emissions control.

Also Read: 5 SUVs With the Best Roof-Rack Load Limits and 5 With Low Ratings

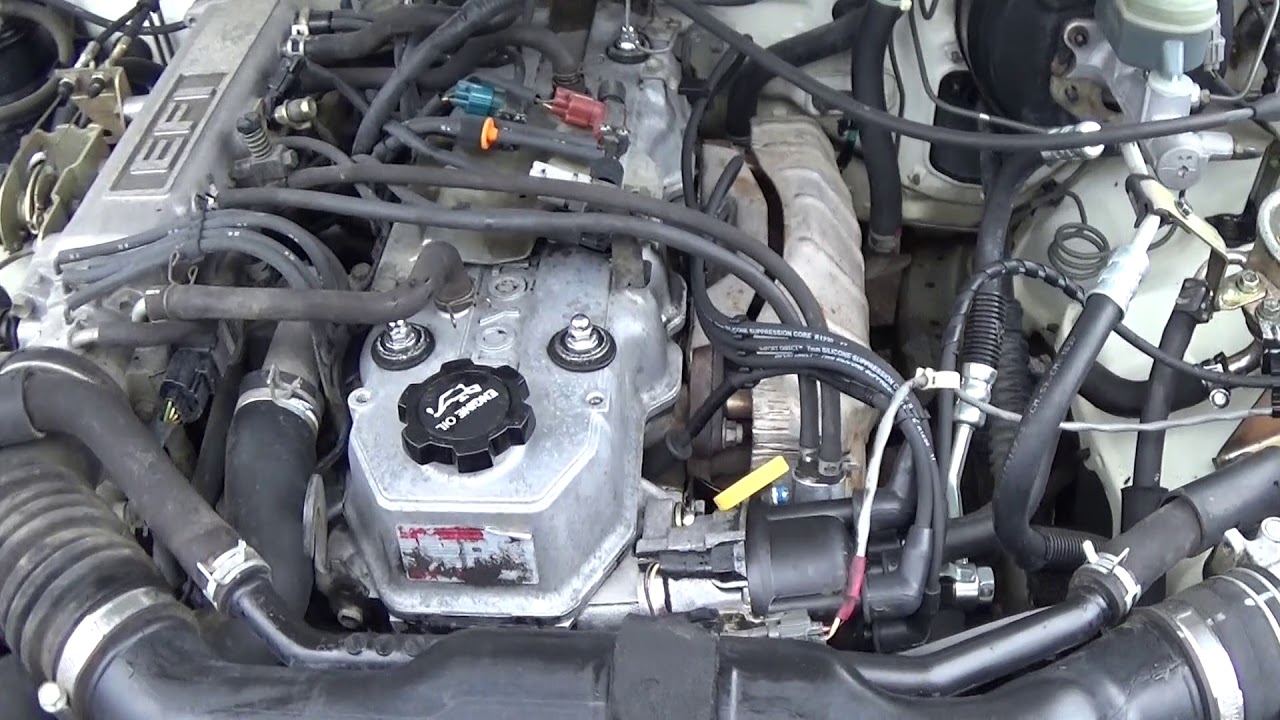

4. 22R/22RE 2.4L I4

Found in: Toyota Pickup, 4Runner

A legend in its own right, the 22R/RE engines are a symbol of Toyota’s 1980s and 1990s reliability. Built like a tank, this naturally aspirated four-cylinder was designed for utility and longevity.

It’s not fast, but it rarely quits. With a cast-iron block and simple mechanicals, these engines often outlast the rest of the vehicle and are still running strong in older pickups and 4Runners with over 400,000 miles.

The Toyota 22R-E is a 2.4-liter (2,366 cc or 144.38 cubic inches) naturally aspirated inline-four gasoline engine belonging to the Toyota R-family. It was produced by Toyota Motor Corporation from 1983 until 1995.

This engine features a robust cast-iron cylinder block paired with an aluminum cylinder head. It uses a single overhead camshaft (SOHC) design and operates with two valves per cylinder, totaling eight valves.

The compression ratio is rated at 9.0:1. The cylinder bore measures 92.0 mm (3.62 inches), while the piston stroke is 89.0 mm (3.5 inches). Fuel delivery is managed through an electronic fuel injection (EFI) system, and the ignition system employs a traditional mechanical distributor.

In 1985, the 22R underwent a major revision. As a result, many of the components introduced in the updated 22R-E—such as the cylinder head, engine block, pistons, timing chain and cover, water pump, and oil pump—are not interchangeable with parts from the earlier, pre-1985 version of the engine.

The 22R-E engine delivered horsepower ranging from 106 PS (78 kW; 105 HP) at 4,800 rpm to 114 PS (84 kW; 113 HP) at the same rpm. Torque output varied between 185 N·m (18.9 kg·m, 136 ft·lb) at 2,800 rpm and 190 N·m (19.4 kg·m, 140 ft·lb) at 3,600 rpm, depending on the specific application and production year.

5. 1HD-T/1HD-FT 4.2L Turbo Diesel I6

Found in: Toyota Land Cruiser (international markets)

While not available in North America, the 1HD series diesels are the heart and soul of Toyota’s overlanding and expedition reputation overseas.

These straight-six turbo diesels are incredibly robust and made to survive in the harshest environments.

From Australia’s outback to African deserts, these engines are known to last half a million miles or more with regular servicing and diesel-friendly care.

The 1HD-FT is a robust 4.2-liter inline-six turbocharged diesel engine developed by Toyota, renowned for its reliability and performance in various demanding conditions.

Introduced in the early 1990s, this powerplant quickly gained a reputation for its durability and efficiency, making it a favorite among off-road enthusiasts and commercial vehicle operators alike. The engine is part of Toyota’s HD series, which is designed for heavy-duty applications, and it reflects the brand’s commitment to engineering excellence.

At its core, the 1HD-FT engine features a cast iron block and aluminum cylinder head, contributing to its strength and longevity.

The turbocharging system enhances its power output while maintaining fuel efficiency, allowing it to deliver impressive torque at low RPMs. This characteristic makes it particularly well-suited for towing and off-road driving, where low-end torque is crucial for navigating challenging terrains.

The engine’s design incorporates a direct fuel injection system, which not only improves fuel atomization but also enhances combustion efficiency, resulting in lower emissions compared to its naturally aspirated predecessors.

Additionally, the 1HD-FT is equipped with a sophisticated cooling system that helps maintain optimal operating temperatures, further extending its lifespan and performance.

Toyota Engines That Don’t Run Forever

Not every Toyota engine is built to last forever. While the brand is famous for its reliability, a few powerplants have developed reputations for premature wear, costly repairs, or outright failure.

In this article, we take a closer look at the Toyota engines that missed the mark—whether due to flawed designs, poor material choices, or just bad luck under the hood.

1. 2AZ-FE 2.4L I4

Found in: Toyota Camry, RAV4, Scion tC

The 2AZ-FE is notorious for excessive oil consumption, sometimes starting as early as 70,000 miles. Toyota even issued service bulletins for some model years due to piston ring design flaws.

Drivers have reported adding a quart of oil every 1,000 miles, and severe cases have required full engine rebuilds or replacements. Despite being widely used, this engine is a stain on Toyota’s otherwise solid small engine history.

The 2.4-liter inline-four 2AZ-FE engine is part of Toyota’s AZ-series and has been in production since 2000. This engine is essentially a larger-displacement version of the 1AZ, designed to take over from the aging 5S engine.

Similar to the 1AZ-FE, the 2AZ features an aluminum cylinder block with cast iron liners. However, the cylinder bore was increased to 88.5 mm, necessitating the use of larger pistons than those found in the 1AZ.

To reduce engine vibration, two internal balance shafts are located within the crankcase. The engine is topped with an aluminum DOHC 16-valve cylinder head and includes Toyota’s VVT-i (Variable Valve Timing with intelligence) system on the intake camshaft only.

A timing chain drives the camshafts, and unlike some other Toyota engines, the 2AZ does not have hydraulic lifters, meaning valve clearance must be adjusted every 60,000 miles (100,000 km). Aside from the displacement, the 1AZ and 2AZ engines are nearly identical in design.

In 2008, Toyota gave the 2AZ-FE a significant update. The revised version delivered increased power and torque, thanks to a bump in the compression ratio from 9.6:1 to 9.8:1 and new camshaft profiles that raised the redline to 6,500 rpm. Oil squirters were added beneath the pistons to aid in cooling.

Engine output varied depending on the model: 161 hp (120 kW) in the Scion tC, 177 hp (132 kW) in the Rav4, and 158 hp (118 kW) in the Camry, Corolla XRS, and Scion xB. That same year, Toyota introduced the 2AR engine, which was intended to replace the 2AZ-FE. Despite this, the 2AZ-FE remains in use in certain markets to this day.

2. 3VZ-E 3.0L V6

Found in: Toyota Pickup, 4Runner (late ’80s–early ’90s)

Though it was meant to be a powerful V6 upgrade in Toyota trucks and SUVs, the 3VZ-E suffered from head gasket failures that were so common Toyota eventually issued a recall.

Poor cooling design and soft head gaskets meant that even well-maintained engines were prone to overheating and internal damage. Compared to the bulletproof 22R, it simply couldn’t compete in long-term durability.

Toyota began producing the 3.0-liter 3VZ-FE engine in 1987, initially introducing it as the powerplant for the Toyota 4Runner. Over time, this engine was also adopted for other Toyota off-road models. While the 3VZ shares some similarities with its predecessor, the 2VZ engine, its increased displacement is not the only distinguishing factor.

The engine’s cast iron cylinder block appears visually similar to the earlier version, but it is actually 20 mm taller, bringing the total block height to 223 mm.

The engine retains a 60-degree V-angle between the cylinder banks. Internally, it features a newly developed forged crankshaft with nine counterweights and an 82 mm stroke, contributing to smoother performance and enhanced durability.

The original version of this engine, the 3VZ-E, came equipped with SOHC aluminum cylinder heads and unique pistons. It had a modest compression ratio of 9.0:1. A more refined and performance-oriented version, the 3VZ-FE, was later introduced and produced from 1992 through 1997.

3. 1MZ-FE 3.0L V6 (early versions)

Found in: Toyota Camry, Avalon, Lexus ES300

While later revisions improved this engine, early 1MZ-FE versions (especially pre-2002) suffered from severe oil sludge issues.

The problem stemmed from poor PCV system design and owners following the extended oil change intervals recommended at the time.

Engines would often seize due to thick, tar-like oil deposits. Despite decent power, these engines didn’t hold up unless maintained obsessively.

The 1MZ-FE is a 3.0-liter V6 gasoline engine that Toyota manufactured from 1993 to 2007, developed as a successor to the 3VZ-FE. At the height of its usage, the 1MZ-FE powered several popular Toyota models, including the Camry, Avalon, and Highlander, as well as various Lexus vehicles.

Toward the end of its production life, the engine was gradually phased out and replaced by the larger 3.3-liter 3MZ-FE from the same MZ engine family.

This MZ-series engine features a lightweight aluminum cylinder block designed with a 60-degree V6 layout and cast-iron cylinder liners that are press-fitted for added durability. The block includes a forged crankshaft supported by four main journals, forged connecting rods, and aluminum alloy pistons.

In the VVT-i versions, the piston skirts received a resin coating to reduce friction. The cylinder heads are made of aluminum and utilize a dual overhead camshaft (DOHC) setup with four valves per cylinder. A timing belt drives the exhaust camshafts, which in turn drive the intake camshafts via gear mechanisms.

The engine uses intake valves measuring 34.0 mm in diameter and exhaust valves measuring 27.3 mm, with both valve stems at 5.5 mm. Two primary configurations of the engine were available: non-VVT-i and VVT-i.

The camshaft specifications for the non-VVT-i version include a duration of 228 degrees for both intake and exhaust, with valve lifts of 7.85 mm (intake) and 7.60 mm (exhaust).

The VVT-i variant features a longer duration of 236 degrees for both intake and exhaust. Notably, the 1MZ-FE does not utilize hydraulic lifters, so valve clearance adjustments are required every 60,000 to 80,000 miles (100,000 to 150,000 km).

Fuel delivery is managed by a multi-port fuel injection (MFI) system, and the engine comes equipped with an aluminum intake manifold that incorporates Toyota’s Acoustic Control Induction System (ACIS), which adjusts intake runner length.

The ACIS setup operates in two stages for most models like the Camry and Avalon, while Lexus models such as the ES 300 feature a three-stage system.

The ignition system is distributor-less (DIS) with six individual coil-on-plug units, one for each cylinder. Non-VVT-i versions of the 1MZ-FE included an exhaust gas recirculation (EGR) system, whereas the VVT-i variants used EGR block-off plates on the exhaust manifolds. All engines in the MZ family were outfitted with stainless steel exhaust manifolds for improved longevity.

4. 8AR-FTS 2.0L Turbo I4

Found in: Lexus IS200t, NX200t, Toyota Crown (select markets)

This more modern turbocharged engine aimed to bring performance and efficiency but ended up underdelivering on both reliability and driving satisfaction.

Early versions experienced issues with carbon buildup, oil leaks, and turbo-related failures. In markets unfamiliar with Toyota engines needing higher maintenance, the 8AR-FTS has proven to be short-lived compared to Toyota’s usually reliable lineup.

The 8AR-FTS is a 2.0-liter turbocharged, direct-injection gasoline engine and part of Toyota’s AR engine family. First introduced in 2015 in the Lexus NX 200t, it marked Toyota’s entry into a new generation of turbocharged engines aimed at achieving greater thermal and fuel efficiency.

This was accomplished through a combination of advanced technologies such as direct fuel injection, an integrated exhaust manifold within the cylinder head, and enhanced turbocharger control. Although the 8AR-FTS shares structural similarities with the naturally aspirated 6AR-FSE engine, it incorporates several unique features that set it apart.

The engine is built around an open-deck, midi-skirt aluminum cylinder block that uses ‘spiny type’ cast iron liners integrated into the aluminum casting. Inside, the block houses twin gear-driven, counter-rotating balance shafts to reduce vibrations. It also features a fully balanced forged steel crankshaft, high-strength steel connecting rods, and lightweight aluminum pistons.

To improve durability, the pistons are cooled using oil jets, which are activated by the engine control module (ECM) depending on operating conditions. A variable discharge oil pump further contributes to overall engine efficiency.

One of the most distinctive aspects of the 8AR-FTS is its innovative cylinder head, which includes an integrated four-into-two exhaust manifold. This manifold design splits the exhaust into two separate channels: one serving cylinders 2 and 3, and the other serving cylinders 1 and 4.

The aluminum cylinder head is fitted with dual overhead camshafts (DOHC) and contains a total of 16 valves. These camshafts are driven by a roller timing chain. The valvetrain also includes roller rocker arms and hydraulic lash adjusters, which maintain constant zero valve clearance for improved reliability and reduced maintenance.

Valve timing is managed through two distinct systems. The exhaust camshaft timing is regulated by Toyota’s VVT-i (Variable Valve Timing with intelligence), while the intake camshaft uses the more advanced VVT-iW (Variable Valve Timing – Intelligent Wide).

This combination allows the engine to seamlessly switch between the traditional Otto cycle and the more fuel-efficient Atkinson cycle, depending on engine speed and load conditions. This dual-cycle capability enhances both power delivery and fuel economy.

Additionally, the intake camshaft features a special four-lobe cam to drive a high-pressure fuel pump mounted directly on the cylinder head. Meanwhile, the exhaust camshaft powers a vacuum pump, further highlighting the engine’s multifunctional design.

5. 3ZR-FE 2.0L I4

Found in: Toyota Corolla, RAV4 (select markets)

A seemingly benign engine, the 3ZR-FE is plagued with excessive oil consumption and valve noise, even with regular maintenance.

Some users have reported complete engine failures under 120,000 miles, largely due to poorly designed piston rings and oil control issues.

It’s especially disappointing because it replaced the older, more reliable 1ZZ-FE but failed to maintain that legendary Toyota durability.

In 2007, Toyota unveiled a new 2.0-liter four-cylinder gasoline engine from its ZR series. The 3ZR variant was introduced as the successor to the 1AZ engine lineup.

Primarily designed for front-wheel-drive vehicles, the 3ZR-FE powers models like the Toyota Corolla, Avensis, and 2WD RAV4. Meanwhile, the 3ZR-FAE is a more versatile powerplant, offered in both FWD and AWD/4WD configurations, such as in the Toyota C-HR and RAV4.

Much like the 1.8-liter 2ZR-FE engine, the 2.0-liter version employs a die-cast aluminum cylinder block reinforced with spiny-type cast iron liners. The compact block design features a narrow 7 mm gap between cylinder bores, contributing to its lightweight and space-efficient structure.

The increase in displacement was achieved by installing a redesigned crankshaft with a stroke length increased by 9.3 mm. Additionally, the crankshaft is mounted with an 8 mm offset toward the intake side of the bore centers.

The cylinder bore diameter remains unchanged. Inside the engine, steel connecting rods and aluminum pistons are used, featuring full floating-type piston pins, resin-coated piston skirts, and low-tension piston rings. The engine block is also equipped with piston oil jets to enhance cooling and durability.

Topping the engine is a 16-valve aluminum cylinder head, driven by a chain-actuated dual overhead camshaft setup. Each cylinder contains two intake and two exhaust valves, operated by hydraulic lash adjusters and low-friction roller rocker arms.

The timing chain has an 8 mm pitch. The 3ZR-FE is equipped with Toyota’s dual VVT-i (Variable Valve Timing with intelligence) system, adjusting both intake and exhaust cam timing for optimal performance.

The more advanced 3ZR-FAE variant not only features dual VVT-i but also includes the Valvematic system, which provides continuous and precise control of intake valve lift and timing. This technology allows the engine to optimize fuel efficiency and performance across a wide range of driving conditions.

Toyota is often synonymous with longevity, and many of its engines can go the distance with routine care. The 2UZ-FE and 22R engines are still setting high-mileage records decades after launch.

But as with any automaker, not every engine has been a home run. Flawed designs like the 2AZ-FE or oil-sludge-prone 1MZ-FE are reminders that even Toyota isn’t immune to engineering missteps.

Knowing which engines to trust can be the difference between a car that runs forever and one that ends up on a flatbed.