When it comes to General Motors (GM), the company has built a legacy filled with both triumphs and cautionary tales in the world of engines. From the muscle car glory days to modern fuel-efficient tech, GM has engineered powerplants that are revered for their performance, durability, and simplicity. But not every GM engine is created equal.

Some are reliable workhorses that mechanics swear by — easy to maintain, long-lasting, and built to take a beating. Others, however, are plagued with design flaws, premature failures, and expensive repair bills, earning them a permanent place on every seasoned mechanic’s avoid list.

In this article, we dive into the best and worst of GM’s engine history, based on real-world mechanic experience — not just spec sheets or marketing hype.

GM Engines Mechanics Love

We highlight five GM engines that mechanics genuinely appreciate for their reliability and serviceability, and five that they tend to warn customers about. Whether you’re buying a used GM vehicle, restoring a classic, or just a curious gearhead, this list will help you navigate the hits and misses under GM’s hood.

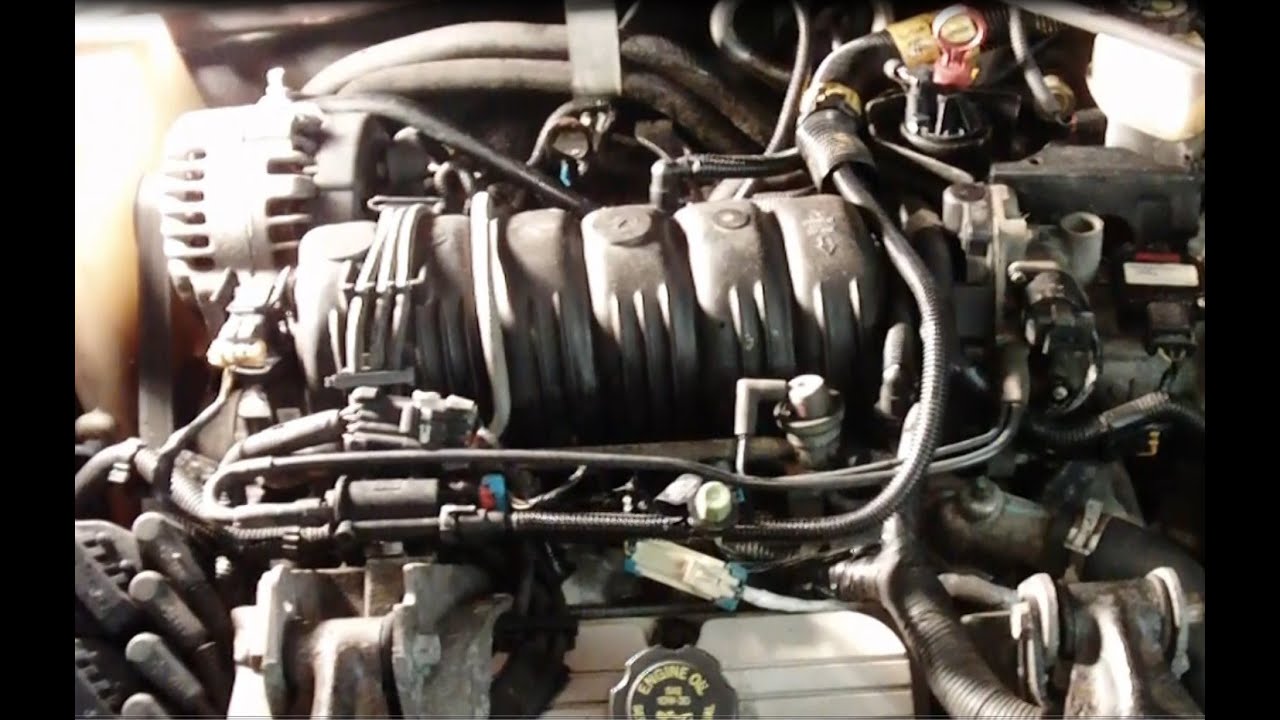

1. 5.3L V8 Vortec (LM7/L59/L33)

The 5.3L Vortec V8, especially the LM7 and L59 iron-block variants, has become a legend for durability and ease of maintenance.

Found in countless Silverado, Tahoe, and Suburban models from the early 2000s, this engine can easily rack up 300,000+ miles with routine oil changes. Its simple pushrod design, cast-iron block, and solid lifters make it a favorite among mechanics for rebuilds and swaps.

The GM 5.3L EcoTec3 is a naturally aspirated 5.3-liter V8 engine featuring a direct fuel injection system. Introduced in 2014, this engine represents the fifth generation of GM’s small block V8 truck engines, taking over from the previous Gen IV Vortec 5300.

The EcoTec3 5.3L V8 comes in several versions, including the widely used L83, the eAssist mild-hybrid variant known as the L8B, the L82 which includes Active Fuel Management, and the L84 equipped with Dynamic Fuel Management.

These engines are commonly found in fourth-generation Chevrolet Silverado and GMC Sierra trucks. The L83, in particular, also powers the 2014 and newer Chevrolet Tahoe and Suburban, as well as the GMC Yukon and Yukon XL. Let’s examine the engineering behind the 5.3L EcoTec3 engine, its common issues, and its overall reliability.

The fifth-generation small-block V8 is constructed entirely from aluminum, making it notably lightweight. Its aluminum cylinder block is cast with iron cylinder liners and features a 90-degree angle between the cylinder banks. The bore spacing measures 4.40 inches (111.8 mm).

The rotating assembly includes a forged-steel crankshaft, powder-metal connecting rods measuring 6.098 inches in length, and lightweight aluminum pistons with specially designed heads for optimized direct injection performance. The engine is also fitted with piston oil jets, or squirters, which help cool the pistons and reduce internal friction—contributing to long-term durability.

The crankshaft is secured using nodular iron main bearing caps, which absorb vibrations more effectively than standard gray iron. It drives a variable-displacement oil pump, marking a notable upgrade for a truck engine.

This new vane-type oil pump delivers flow rates based on engine demands. Furthermore, the lubrication system features dual-pressure control, allowing for efficient oil delivery at low engine speeds while ensuring high pressure at higher RPMs.

Cylinder heads on the 5.3L EcoTec3 are aluminum as well, with two valves per cylinder and 59-cc combustion chambers. The intake ports are straight and rectangular with a slight twist for improved airflow. Like its Vortec predecessor, this V8 utilizes a traditional pushrod valvetrain with a single camshaft mounted within the block.

The pushrods have a larger diameter—measuring 8.7 mm (0.342 inches)—compared to the 7.9 mm pushrods found in earlier Vortec V8 engines. These pushrods activate intake and exhaust valves through low-friction, roller-pivot rocker arms.

The valves themselves are also larger: the intake valves measure 1.928 inches (49 mm) in diameter, and the exhaust valves come in at 1.556 inches (39.5 mm).

Notably, valve lash adjustments aren’t needed, thanks to the use of hydraulic roller lifters. Additionally, the engine is equipped with variable valve timing (VVT), utilizing a dual-equal camshaft phasing system that adjusts timing for both the intake and exhaust valves simultaneously.

2. 3.8L V6 (3800 Series II & III)

Used extensively from the late ’80s through the 2000s in cars like the Buick LeSabre, Pontiac Bonneville, and Chevrolet Impala, the 3.8L V6 is practically indestructible.

Mechanics often point to its timing chain reliability, low maintenance requirements, and the ability to run even when neglected.

It’s not the most refined or powerful engine, but it’s one of the most dependable GM has ever made.

The Buick 3.8L V6—commonly referred to as the Buick 3800—was a product shaped by the priorities of its time. In an era like the late 1970s, when fuel efficiency and emissions standards were taking center stage, Buick set out to prove that the performance of large-displacement V8s could still be matched, but through a different approach.

Evolving directly from the very first V6 engine used in a mass-market passenger car (the Buick Special), the 3.8L V6 marked a significant advancement in American engine development.

Making its debut in 1975, the engine first appeared in the Buick Skylark, Regal, and Century. At the time, it generated a modest 110 horsepower—but that modest output was just the starting point for what would become a much bigger story.

The major breakthrough came with the addition of forced induction to the 231-cubic-inch V6. In an age when turbocharged engines were still rare, the turbocharged Buick V6 stood out as ahead of its time.

Decades before turbochargers became the norm, the 3.8L V6 helped pave the way for a new generation of engines that could be small, powerful, and fuel-efficient all at once. It also reaffirmed that the spirit of muscle cars could survive the era of downsizing and stricter regulations—best exemplified by the success of the legendary Buick Regal GNX.

In this guide, we’ll take a deep dive into the Buick 3800 V6—exploring its origins, technical specifications, known issues, and the performance upgrades that helped make it such a beloved powerplant.

3. 6.0L V8 (LS2/LS3/LY6 Variants)

Whether it’s in a Corvette, Silverado HD, or a fleet van, the 6.0L LS-based engines are known for brute strength and reliability.

The LS2 (performance) and LY6 (truck) versions share an all-aluminum or iron block with high-longevity characteristics.

The architecture allows for easy access during repairs, and mechanics enjoy the abundance of aftermarket support and parts availability.

The LY6 engine is a 6.0-liter Gen IV small-block V8 that powered a variety of GM trucks and SUVs from 2007 to 2010. Branded for marketing as the Vortec 6000, the LY6 came with its own set of specs and characteristics in stock form, which we’ll break down here.

Mechanically, the LY6 shares much in common with other LS and LS-based Vortec engines—a family of powerplants that has made its way into nearly every division of General Motors over the years. Chevrolet, GMC, Pontiac, Cadillac, Buick, and even more unexpected brands like Hummer, Saab, and Isuzu have used LS-derived engines at some point.

Because LS and Vortec engines are so widespread, they’ve become a top choice in the world of performance and engine swaps. Their affordability, availability, and tuning potential have made them a favorite among gearheads.

These engines can generate serious horsepower with the right upgrades. They respond impressively to forced induction like turbochargers and superchargers, and they also benefit from mods such as high-flow cylinder heads, camshaft upgrades, performance intake systems, and nitrous oxide.

A strong aftermarket supports this engine platform, and crate versions are readily available. On top of that, complete used LY6 engines are often easy to find in salvage yards for a reasonable price.

Summit Racing has put together a detailed series of engine-specific guides covering the LS lineup, giving builders and tuners a reliable resource for planning and executing their projects.

4. 4.8L V8 (LR4)

Often overshadowed by its bigger brothers, the 4.8L V8 LR4 is a hidden gem in GM’s lineup. Found in light-duty trucks and vans from the late ’90s through the 2010s, this engine is simple, efficient, and extremely reliable.

It doesn’t produce massive power, but mechanics love how rarely it breaks down and how simple it is to service. The LR4 is a 4.8-liter iron-block truck engine that made its debut in 1999.

Introduced alongside the LM7 and LQ4, the LR4 was part of the first generation of LS-based truck engines. It remained in production for GM pickups, vans, and SUVs through 2007. You’ll also see it referred to as the Vortec 4800.

The specifications and details provided here apply to a stock LR4 engine.

These engines are known for their strength and reliability. They’ve earned a solid reputation among enthusiasts who run them with forced induction or nitrous setups. With reinforced internals, LR4 blocks have proven capable of handling more than 1,000 horsepower.

Mechanically, GM’s LS and LS-based Vortec engines share a lot in common. Over the years, these engines have found their way into nearly every division under the General Motors umbrella: Chevrolet, Pontiac, GMC, Cadillac, Buick—and even more surprising names like Hummer, Isuzu, and Saab have put LS power under the hood.

Thanks to their ubiquity, LS and Vortec engines have become the performance and swap engines of choice in the modern era.

These powerplants have serious tuning potential. They respond well to upgrades such as turbochargers, superchargers, high-performance cylinder heads, intake systems, aggressive camshafts, and nitrous oxide.

The LS swap market has robust aftermarket support. Crate engines are readily available, and used LR4 motors can often be picked up from junkyards at affordable prices.

Summit Racing has produced a collection of in-depth guides for each LS engine variant, providing builders and tuners with a dependable resource to help guide their performance projects.

5. 2.2L Ecotec Inline-4 (L61/LAP/LE5)

Despite GM’s mixed history with four-cylinders, the 2.2L Ecotec has proven to be a robust and economical workhorse. Found in the Chevy Cobalt, Malibu, and Saturn Ion, this engine has minimal timing chain issues and handles high mileage well.

Mechanics appreciate its straightforward layout, good fuel economy, and relative ease of repair compared to other modern inline-fours.

The engine serves as the core of any vehicle, transforming fuel into mechanical energy that drives the car forward. It’s essential to recognize that engines come in various types, each offering specific pros and cons. Gasoline engines remain the most commonly used thanks to their strong power output and smooth performance.

Diesel engines, on the other hand, deliver superior fuel efficiency and are often favored for trucks and heavy-duty applications. Hybrid and electric engines have gained popularity in recent years due to their enhanced fuel economy and lower emissions, making them attractive options for environmentally conscious drivers.

Beyond engine type, displacement is another key factor to consider. Engines with smaller displacement tend to be more fuel-efficient, though they may fall short in terms of raw power and acceleration.

Mid-sized engines strike a practical balance between power and efficiency. Larger displacement engines excel in performance and acceleration but at the cost of higher fuel consumption and greater emissions.

Selecting the appropriate engine displacement depends on a variety of factors, including how the vehicle will be used, individual performance expectations, and overall budget.

GM Engines Mechanics Avoid

Not all engines are created equal—and if there’s anyone who knows that better than anyone, it’s the people who spend their days tearing them apart. While GM has built a legacy around some of the most reliable and powerful engines in automotive history, there are a few outliers that mechanics would rather not see roll into their bay.

These are the engines that inspire groans from seasoned techs—plagued with recurring issues, difficult repairs, questionable design choices, or just downright poor reliability. Whether it’s fragile internals, complicated systems that don’t hold up, or maintenance nightmares, these GM engines have earned their place on the do-not-recommend list.

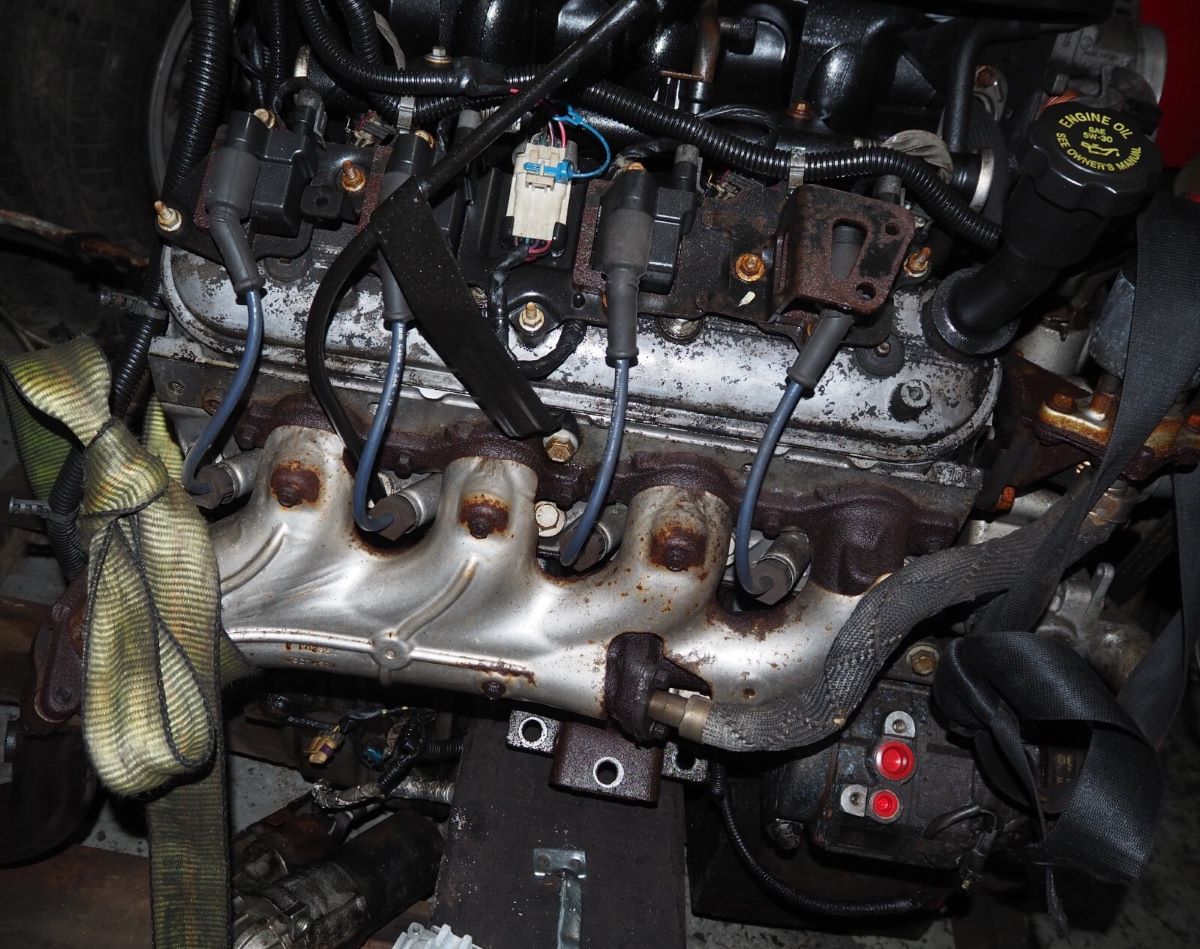

1. 2.4L Ecotec Inline-4 (LE5/LEA/LAT Variants)

Unlike the 2.2L sibling, the 2.4L Ecotec has a notorious reputation for oil consumption, timing chain failure, and premature engine wear.

Found in Chevy Equinox, GMC Terrain, and Malibu models, mechanics dread this engine due to frequent and expensive repairs, often involving full engine replacement before 100,000 miles.

he 2.4 Ecotec is a 2.4-liter, four-cylinder gasoline naturally aspirated engine that debuted in 2006. General Motors produced this 2.4 inline-four for a wide variety of compact and midsize vehicles, such as the Chevrolet Malibu, Equinox, HHR, Saturn Ion, Aura, Vue, Pontiac G5, G6, Buick Regal, and more.

The 2.4 Ecotec remained on the market through 2019. For almost 13 years of production, the engine went through some updates marked with a unique engine code: LE5, LE9, LAF, LEA, LAT, and LUK. Let’s take an in-depth look at the GM/Chevy 2.4L Ecotec engine design, its common problems, reliability, and longevity.

At the basis of the 2.4 LE5 is the 2.2L Ecotec, which has proven itself to be an excellent engine and was one of GM’s highest volume engines at that time.

The 2.4-liter Ecotec LE5 features not only increased displacement but also some new technologies that make it much better in terms of power and efficiency. Like the original 2.2L I-4, the 2.4 Ecotec is an all-aluminum engine. It has a cast aluminum cylinder block with a highly rigid lower crankcase (a reinforced “Gen II” block).

The engine block also features direct-mounted accessories. Early engines were equipped with GKN-forged connecting rods. In July 2007, GM switched to C70 forged connecting rods. Engineers introduced piston-cooling oil jets into the block design.

Oil jets or oil spray squirters continuously spray the underside of each piston, increasing longevity by reducing engine operating temperatures. The new engine had twin counter-rotating balance shafts. They spin at twice the speed of the engine crankshaft to cancel the second-order vibrations.

On top, there is a cast aluminum cylinder head with four valves per cylinder. The engine features a chain-driven, dual overhead camshaft design. Unlike the original 2.2 Ecotec, the 2.4L LE5 version has variable valve technology. Electronically controlled variable valve timing is applied for both intake and exhaust camshafts.

The valvetrain is fitted with hydraulic roller finger followers. The ignition system features centrally located spark plugs and a coil-on-plug design. The 2.4 Ecotec uses conventional sequential port fuel injection controlled by the ECM (all-new Engine Control Module).

The throttle body is also electronically controlled (ETC, or Electronic Throttle Control), where there is no physical connection between the accelerator pedal and the engine throttle. While the cylinder head cover is still made of aluminum, the intake manifold is made of plastic, saving weight and cost.

The LE9 2.4L engine appeared in 2009. This version is basically the same as the LE5 Ecotec. The main difference is that the LE9 is an E85 flexible-fuel compatible engine.

E85 is a clean-burning alternative fuel made from corn and other crops, composed of 85% ethanol alcohol, and gasoline. Because of the corrosive effects of ethanol, the 2.4L LE9 engine has special valves and valve seats that are able to withstand wear. Also, this engine is equipped with unique stainless injectors with a higher maximum fuel flow rate.

2. 3.6L V6 DOHC (LY7/LLT/LFX)

Common in a wide range of vehicles from the Cadillac CTS to the Chevy Traverse, this “High Feature” V6 looks promising on paper but is a headache in reality.

The early LY7 and LLT versions suffer from timing chain stretch, camshaft actuator failures, and oil consumption. Mechanics dislike the complex layout, high labor time for basic repairs, and expensive parts.

When it comes to engine manufacturers, General Motors stands tall as one of the most respected names in the automotive industry. Over the decades, GM has earned a solid reputation for engineering excellence and innovation, producing some of the most dependable and high-performing vehicles on the road. Their engines—whether inline-four, V6, or V8—are known for delivering a thrilling driving experience.

Among their standout powerplants is the 3.6L V6 engine. This engine has received numerous accolades and is often praised for its impressive balance of power and reliability, frequently drawing comparisons to GM’s own V8 engines.

However, despite its strengths, the 3.6L V6 hasn’t been without issues. In this article, we’ll explore the GM 3.6 V6 engine’s common problems, its development history, various versions, and how it holds up in terms of long-term dependability.

The GM 3.6L V6 engine made its debut in the 2004 Cadillac CTS and has since undergone multiple refinements aimed at enhancing reliability and overall performance.

All iterations of this engine follow a 60-degree V6 layout and utilize a dual overhead camshaft (DOHC) valvetrain design, which includes four valves per cylinder—two intake and two exhaust—for a total of 24 valves.

This engine features multi-port fuel injection, variable cam phasing, a forged crankshaft, and precision-engineered connecting rods. It also incorporates a variable-length intake manifold and a coil-on-plug ignition system, all of which contribute to its performance and efficiency.

The 3.6L V6 has gone through several different versions, each marked with a specific engine code. The first of these, the LY7, launched alongside the Cadillac CTS in 2004. Due to its solid performance, the LY7 was adopted by other automakers including Suzuki, GMC, Holden, Saturn, Pontiac, Buick, and Chevrolet. Suzuki referred to it as the N36A.

Depending on the application, output varied, with torque ranging from 225 to 252 lb-ft and horsepower between 211 and 275 hp. The next version, the LLT, added direct fuel injection, improving both power and fuel economy while raising the compression ratio. Released in 2008 and used through 2016, this version appeared in several vehicles, including the Chevy Camaro.

3. Oldsmobile 5.7L Diesel V8 (LF9)

This engine from the late ’70s and early ’80s is infamous for tarnishing GM’s diesel reputation. Based on a gas engine block without proper reinforcement, it frequently blew head gaskets, cracked blocks, and suffered catastrophic failures.

Mechanics of the era often refused to work on them, and few survive today without major overhauls. Oldsmobile developed the 5.7L engine, also known as the 350 Olds, in direct response to the fuel crisis of the late 1970s.

Making its debut in 1978, this 350-cubic-inch diesel engine aimed to deliver the luxurious feel of a full-sized car while achieving fuel economy comparable to that of a compact vehicle.

Officially designated as the LF9 diesel, this engine was installed across a wide range of General Motors vehicles, including those under the Chevrolet, Buick, Pontiac, Oldsmobile, and Cadillac brands, as well as in light-duty Chevrolet and GMC pickup trucks. Despite GM’s ambitions, the engine ultimately earned a reputation for being unreliable and problematic. It became a significant misstep for the company.

Though many of its core issues were eventually addressed, the engine was pulled from production in 1985. Even after its discontinuation, the damage was done—GM’s reputation in the diesel segment suffered lasting harm, with trust only beginning to rebuild more than a decade later.

One of the most persistent myths about the 350 Olds is that it was based on GM’s gasoline-powered 350 engine. While the two engines do share the same cylinder bore and stroke dimensions, the idea that the Oldsmobile diesel was merely a modified version of the 350 gas V8 is entirely inaccurate. Such an approach would have been a catastrophic engineering blunder.

The gasoline version could never have withstood the internal pressures generated by the diesel’s aggressive 22.5:1 compression ratio. General Motors directly addressed these misconceptions by stating: “All of the major parts: block, crankshaft, rods, pistons, and lifters have been strengthened to handle the higher compression ratio.”

The confusion between the two engines likely stems from a few key factors. First, the shared bore and stroke allowed Oldsmobile to manufacture the diesel engine using existing production tooling.

Second, both owners and outside observers—desperate to understand the diesel engine’s chronic failures—naturally pointed fingers at its supposed gas engine roots. The narrative stuck, despite being technically unfounded.

Still, when paired with the right vehicle and a driver with a light foot, the 350 Olds diesel could achieve up to 30 miles per gallon—an impressive feat for its time.

GM made a concerted effort to market the engine by associating it with “prestige” and “status.” Unfortunately, these branding efforts were largely in vain. By the time the engineering flaws were mostly resolved, consumer confidence had already evaporated.

4. 2.5L Iron Duke (Tech IV)

While known for reliability in some circles, many mechanics loathe the Iron Duke due to its archaic design, lack of power, and vibration issues.

Found in everything from the Pontiac Fiero to the Chevy S-10, it wasn’t exactly loved by technicians who had to constantly chase oil leaks, cracked manifolds, and broken timing gears.

Among the lineup of 1970s Pontiac engines, the Iron Duke—also known as the Pontiac 151 four-cylinder—has developed a reputation that is as intriguing as it is divisive.

Though it earned a name for being incredibly durable and ended up powering more than 30 different General Motors vehicles, its specifications left much to be desired. In a decision that still draws criticism more than forty years later, Chevrolet chose to equip the base model of the 1982 Camaro with the Iron Duke. Today, the Iron Duke Camaro is widely regarded as a notorious failure.

But the 1982 Camaro wasn’t the only former muscle car to receive the “honor” of running the Iron Duke engine. Other vehicles, like the Buick Skylark and Pontiac Firebird, were also fitted with the Tech IV version of the Iron Duke during the 1980s. Additionally, it served as the powerplant for the Grumman LLV USPS delivery truck—which speaks volumes about its intended level of performance.

Despite being mocked and looked down upon for years, the Pontiac 151 four-cylinder still holds a certain level of fascination. Its reliability made it a mainstay in over 30 GM models, and it served countless American families for decades.

This guide will take a deep dive into the infamous Iron Duke, breaking down its specifications, design characteristics, performance (or the lack thereof), and long-term dependability. But first, let’s explore the motivation behind its creation and the context in which Pontiac developed the 2.5L Iron Duke during the mid-1970s.

The origin of the Iron Duke is closely tied to the 1973 oil crisis and the subsequent embargo. When OPEC announced a drastic cutback in international oil supplies and a suspension of exports to the U.S., American automakers were forced to reevaluate their strategies.

5. Cadillac Northstar V8 (4.6L L37/Y/N)

The Northstar V8, once billed as GM’s premium high-tech engine, turned into a nightmare for mechanics.

Chronic head gasket failures, oil leaks, and overheating plagued these engines in Cadillacs from the late ’90s to early 2000s.

Head bolt threads would strip from the aluminum block, often rendering the engine unrepairable without expensive heli-coil or stud kits. Few mechanics want to touch them today.

Engineered with an emphasis on responsiveness and performance, the naturally aspirated 4.6L V8 L37 gasoline engine was a central component of the original High-Output Northstar System package. Used across a variety of vehicles between the 1993 and 2011 model years, the L37 was specifically designed for front-wheel-drive (FWD) applications.

It produced up to 300 horsepower and 295 pound-feet of torque, making it one of the most powerful FWD engines developed by a U.S. automaker during its time. In 2005, the engine was rebranded as the Northstar NHP and its power figures were recalculated to meet the updated SAE-certified horsepower ratings.

Vehicles equipped with the L37 engine under the High Output Northstar System also came loaded with several advanced features. These included Variable Valve Timing (VVT), an upgraded GM four-speed automatic transmission, and Road Sensing Suspension (RSS), which actively monitored and adjusted shock absorber damping every 15 milliseconds.

This suspension system was available in both standard and continuously-variable (CV-RSS) versions. Additional components of the package included four-wheel antilock disc brakes for enhanced stopping power and Magnasteer speed-variable power steering.

This steering system combined traditional hydraulic assistance with magnetized “doughnuts” positioned around the output shaft, resulting in a more precise and responsive steering feel at varying speeds.

GM has produced some of the most beloved and most despised engines in automotive history. Engines like the 5.3L Vortec and the 3.8L V6 are favorites in garages across the country due to their reliability and ease of service.

On the flip side, powerplants like the 3.6L DOHC V6 and Northstar V8 leave a trail of costly repairs and frustrated owners. When choosing a GM vehicle, your best bet is to listen to the people who keep them running mechanics know which engines will get you to 300,000 miles and which will be lucky to see 100,000.