BMW has long been the poster child for luxury performance. Precision engineering, exhilarating driving dynamics, and iconic design—these are the traits that have defined the Bavarian brand for decades.

But beneath all the M badges, turbocharged grunt, and smooth inline-six symphonies, there’s a crucial factor that often gets overlooked until it’s too late: the engine’s long-term reliability. Because let’s be real—owning a BMW can either be a dream come true or a nightmare that bleeds your bank account dry.

While some BMW engines go the distance—hitting 200,000+ miles with regular maintenance and only minor hiccups—others seem to be precision-engineered money pits, plagued by recurring issues like oil consumption, VANOS failures, rod bearing disasters, and coolant system implosions.

Whether you’re eyeing a used 3 Series or holding onto your high-mileage X5, knowing which engines are built to last and which ones are quietly planning a mutiny under the hood could save you thousands.

This article breaks it all down with no fluff and no sugar-coating. We’re looking at five BMW engines that have earned a reputation for durability, efficiency, and relatively low maintenance costs. And on the flip side, we’re shining a light on five engines that may seem tempting on paper but tend to greet owners with repair bills that escalate quickly and painfully.

BMW Engines That Last

Whether you’re a diehard BMW enthusiast or a cautious newcomer looking for a smart buy, this guide will help you navigate the best and worst that Bavaria has to offer—before you hand over the keys or sign that title.

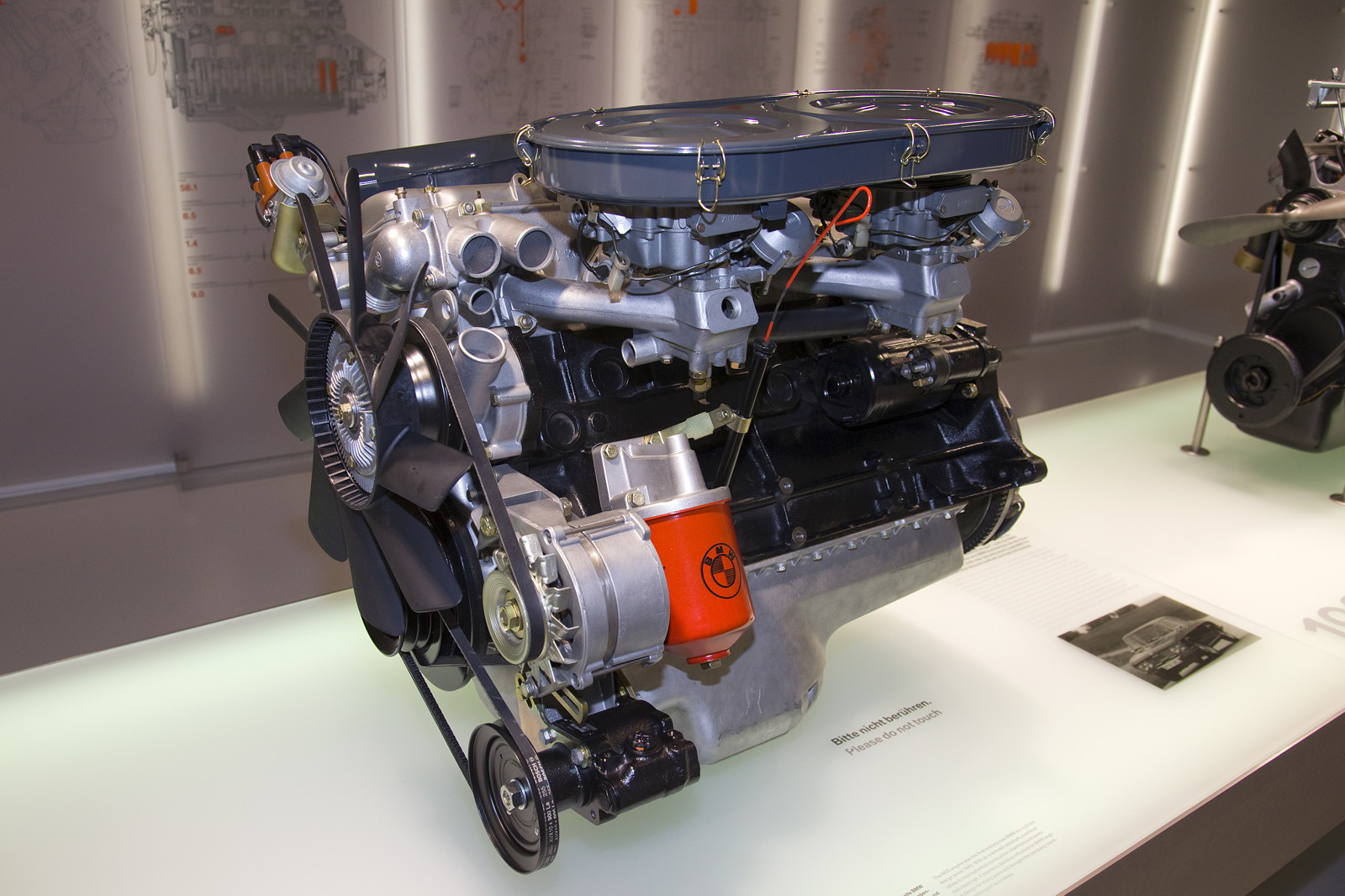

1. M54 (2000–2006) – Straight-6 Reliability Champion

The M54 inline-six is one of BMW’s most respected engines. Found in models like the E46 3 Series, E39 5 Series, and the Z4, this naturally aspirated engine is praised for its balance, smooth power delivery, and remarkable durability.

With proper maintenance, many M54s easily surpass 250,000 miles. It does have minor issues like valve cover gasket leaks and cooling system weaknesses, but it avoids major mechanical failures.

The BMW M54 engine made its debut in the year 2000 and remained in production until 2006, when it was succeeded by the N52. Compared to its predecessor, the M52TU, the M54 introduced several improvements.

These included a newly designed aluminum engine block, a redesigned intake manifold, an upgraded Siemens MS 43 engine management system, a fully independent electronic throttle, and a non-return fuel system. These updates contributed to enhanced performance, efficiency, and emissions compliance for the era.

This article explores everything you need to know about the reliability of the BMW M54. If you’re considering purchasing a classic inline-6 BMW, particularly an E46 model equipped with this engine, it represents an excellent entry point into old-school BMW ownership.

The M54 is widely regarded as a reliable powerplant. Its naturally aspirated inline-6 layout is simple and effective, which lends itself to dependable operation and relatively easy maintenance.

While it is not without flaws, the M54 is often mentioned alongside the N52 as one of BMW’s most dependable engines. The engine boasts robust internal components and a solid engine block design. In fact, it served as the basis for the later and more complex N54 engine, which speaks volumes about the M54’s overbuilt nature.

Many modern BMW engines are plagued by issues like timing chain failures, turbocharger problems, premature rod bearing wear, and complications related to direct fuel injection.

The M54, by contrast, avoids all of these headaches thanks to its simpler, more traditional engineering. This simplicity is precisely what has helped the M54 maintain a reputation for being one of the more dependable engines BMW has produced in the modern era.

Also Read: 5 BMWs That Age Gracefully and 5 That Are Mechanic Magnets

2. N52 (2005–2015) – A Modern Straight-6 Done Right

Replacing the M54, the N52 continued the legacy of reliable naturally aspirated inline-sixes. It features Valvetronic and magnesium-aluminum construction, and powers models like the E90 3 Series and E60 5 Series.

While the electric water pump and oil filter housing gasket can fail, the N52 is otherwise solid. Enthusiasts love it for its low-end torque and long service life often hitting over 200,000 miles with minimal drama.

The BMW N52 engine is a naturally aspirated inline-six-cylinder engine produced by BMW between 2004 and 2015. It was installed in a wide variety of models across the brand’s lineup, including the 1 Series, 3 Series, 5 Series, X3, X5, and Z4.

As the successor to the M54, the N52 was designed to deliver better fuel efficiency while still maintaining the performance and smooth power delivery expected from a BMW straight-six. One of the standout characteristics of the N52 is its lightweight aluminum-magnesium construction, which reduces overall engine weight and improves balance.

There are two main variants of the N52: the N52B25 and the N52B30. The N52B25 has a displacement of 2,497 cc and produces between 177 and 218 horsepower, with torque figures ranging from 230 to 250 Nm. It uses an aluminum R6 cylinder block and a 24-valve aluminum head, with an 82 mm bore and 78.8 mm stroke, and features a high 11:1 compression ratio.

The N52B30, on the other hand, increases displacement to 2,996 cc and delivers between 218 and 272 horsepower, with torque ranging from 270 to 315 Nm. This version uses an 85 mm bore and 88 mm stroke, and slightly lowers the compression ratio to 10.7:1.

Both versions feature Valvetronic variable valve lift, the DISA intake system for improved airflow management, hydraulic valve lifters, and double VANOS variable valve timing. A timing chain replaces the timing belt, enhancing long-term reliability. Both engines are naturally aspirated, lack a turbocharger, and use a 6.5-liter oil capacity with 5W-30 recommended oil.

They run best on mid-grade or premium fuel and meet EURO 4/5 emissions standards. The average lifespan of the N52B25 is about 250,000 kilometers, while the N52B30 typically lasts around 275,000 kilometers.

In terms of performance, the N52 engine is praised for its smooth acceleration and responsive handling. Acceleration from 0 to 60 mph falls in the range of 5.5 to 6.5 seconds, depending on the specific model and drivetrain configuration. Top speeds range between 130 and 155 mph.

Fuel efficiency is also respectable for a naturally aspirated six-cylinder, with city mileage typically between 18–22 mpg and highway mileage between 25–28 mpg. Overall, the BMW N52 is considered one of the brand’s most reliable and refined non-turbocharged engines, offering a strong balance of performance, longevity, and day-to-day usability.

3. B58 (2015–Present) – Turbo Done Right

A standout in BMW’s modern turbocharged era, the B58 inline-six is a significant leap forward in reliability compared to earlier N-series engines.

Found in cars like the G20 340i, G30 540i, and the Toyota Supra, the B58 offers robust internals, minimal carbon buildup, and excellent power.

It avoids the timing chain issues that plagued previous generations and is widely respected for both performance and endurance. The BMW B58 engine stands out as a truly impressive piece of engineering, earning widespread acclaim for its performance, refinement, and reliability.

As a member of BMW’s “modular” engine lineup, the B58 is a 3.0-liter turbocharged inline-six that has established itself as one of the most highly regarded engines in BMW’s contemporary range. It powers a broad spectrum of vehicles, including the 3 Series, Z4, and even the Toyota Supra.

While the B58 is praised for its dependable performance and silky-smooth power delivery, like all engines, it comes with its own set of known issues and areas where performance can be further enhanced.

This comprehensive guide covers everything you should know about the B58—from its core specifications and common problems to top-tier performance upgrades for those looking to push it even further.

The B58 represents a significant evolution in BMW’s inline-six heritage, succeeding the well-known N54 and N55 engines. First launched in 2015, this engine features a single twin-scroll turbocharger, direct fuel injection, and a compact water-to-air intercooler built directly into the intake plenum to maintain consistent cooling.

Built on BMW’s modular engine architecture, the B58 is engineered for both manufacturing efficiency and performance scalability, allowing it to be adapted across a wide variety of BMW models with minimal modification.

What sets the B58 apart is its exceptional combination of smoothness, throttle response, and fuel efficiency. Thanks to BMW’s advancements in turbocharging and fuel delivery, the B58 delivers more power and better economy than its predecessors.

It is remarkably adaptable—equally at home in luxury sedans, sporty coupes, and performance-tuned applications. Whether you’re a casual driver or an enthusiast seeking tuning potential, the B58’s broad capabilities and robust design make it a standout choice in BMW’s modern engine lineup.

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

4. M30 (1968–1994) – BMW’s Tank Engine

The M30 “Big Six” is a legendary engine that powered BMWs for over two decades, including the E28 5 Series and E24 6 Series.

Built like a tank, it’s known for exceptional longevity even under hard use. With a basic design and overbuilt internals, M30s have been known to run well past 300,000 miles. Its simplicity is a huge plus, especially for DIY mechanics.

The BMW M30 engine is a legendary inline-six that firmly cemented its legacy in automotive history. First introduced in the late 1960s, this engine exemplifies BMW’s engineering excellence, blending performance, refinement, and long-term reliability.

Originally developed for the BMW 2500, the M30 swiftly became a central component of BMW’s lineup, powering a wide array of models throughout the 1970s and 1980s.

Renowned for its solid construction and dependable operation, the M30 earned a reputation for delivering a thoroughly engaging driving experience. Its inline-six configuration, naturally balanced by design, ensured smooth and consistent power delivery—something that continues to be celebrated by driving purists.

Over the years, the engine was produced in various displacements ranging from 2.5 to 3.5 liters, offering a versatile range of power outputs and performance profiles to suit different models and driving needs.

5. S54 (2000–2006) – High-Revving and Surprisingly Tough

The S54, found in the E46 M3 and Z4 M, is a high-performance engine that manages to be both exhilarating and durable.

Though it’s a performance engine with tighter tolerances and higher maintenance needs, well-kept S54s often exceed 200,000 miles.

Key is regular oil changes and valve adjustments. It’s a reminder that not all high-strung engines are fragile. The S54 engine stands as a testament to BMW’s engineering excellence, having achieved legendary status among enthusiasts and performance purists alike.

Introduced in the early 2000s, this high-performance inline-six was developed by BMW’s M division and has become a symbol of pure driving excitement. Renowned for its ability to rev high, its distinctive exhaust note, and its potent power delivery, the S54 has carved out a lasting legacy in the world of sports cars.

What truly distinguishes the S54 from other engines of its era is the depth of its engineering. As a naturally aspirated 3.2-liter engine, it exemplifies BMW M’s dedication to pushing the envelope of performance without relying on forced induction.

The engine features a lightweight aluminum block and a DOHC (Dual Overhead Camshaft) layout, which enables precise valve control and optimal airflow. This not only boosts the engine’s performance but also enhances throttle response, giving drivers an intimate connection with the car—a quality that has made it a standout choice for true driving enthusiasts.

Delivering an impressive 333 horsepower at 7,900 RPM and 262 lb-ft of torque at 4,900 RPM, the S54 is built to thrive at high revs. Its willingness to be pushed to the limit makes for a thrilling experience every time the throttle is opened. Beyond sheer numbers, the engine’s sound is an integral part of its appeal—a raspy, mechanical growl that fills the cabin and deepens the bond between driver and machine.

BMW Engines That Drain Your Wallet

BMW might build “The Ultimate Driving Machine,” but not every engine they’ve released lives up to the hype—especially when it comes to reliability and maintenance costs.

Sure, there’s no denying the thrill of a smooth inline-six or the punch of a turbocharged V8, but that adrenaline rush can turn into buyer’s remorse once the check engine light flickers on and the repair bills start stacking up.

1. N54 (2006–2016) – Twin-Turbo Trouble

The N54 engine, found in models like the 335i, 135i, and 535i, was BMW’s first mass-produced turbocharged inline-six. While potent and tunable, it’s plagued by high-pressure fuel pump failures, wastegate rattle, carbon buildup, and leaking injectors.

Repairs can be frequent and expensive. Enthusiasts love its performance, but ownership can feel like playing reliability roulette.

The BMW N54 is a turbocharged inline-six gasoline engine that was in production from 2006 to 2016. It found its way into several popular BMW models, including the 135i, 335i, 535i, and the Z4 35i, and it quickly earned a reputation for both its performance capabilities and its groundbreaking technology.

With a 3.0-liter displacement, the N54 is equipped with twin turbochargers, direct fuel injection, and variable valve timing. It holds the distinction of being the first BMW engine to incorporate direct injection, and it was also among the first turbocharged powerplants to be featured in a modern BMW—marking a major turning point in the brand’s engineering approach.

In its most potent configuration, the N54 could generate up to 300 kW (408 hp) and 600 Nm (443 lb-ft) of torque, offering impressive low-end torque and a seamless, linear power band. While praised for its performance, the N54 was also notorious for some recurring reliability concerns, particularly related to its high-pressure fuel pump and turbocharger components.

In response to these issues, BMW introduced the N55 engine in 2010 as a successor to the N54. The updated engine employed a single twin-scroll turbocharger, which enhanced throttle response and significantly reduced turbo lag. The N55 proved to be more reliable than its predecessor and continued to power a wide range of BMW models through 2019.

2. N20 (2011–2017) – Timing Chain Catastrophe

The N20 turbocharged four-cylinder, used in models like the 328i and X3, brought efficiency and decent torque but also major timing chain issues, particularly in early models.

Failures can result in catastrophic engine damage, often before 100,000 miles. Add water pump failures and oil leaks, and it’s easy to see why mechanics often warn buyers away from this powerplant.

The most commonly reported issue with the BMW N20 engine is the timing chain, particularly in models manufactured before 2015. The root of the problem lies in the material BMW initially used for the timing chain guides. These early guides were constructed from a type of polymer that degraded prematurely.

As the guides wore down or broke, the timing chain would develop slack, potentially causing damage to nearby engine components. In more severe cases, the chain could jump timing significantly enough to cause contact between the pistons and valves, resulting in serious internal damage.

Recognizing the flaw, BMW introduced a revised timing chain design in January 2015, featuring upgraded components that have largely mitigated the issue. For vehicles built prior to this update, BMW extended the warranty on the timing chain and its related components to 7 years or 70,000 miles, though this offer only applied to select models.

Unfortunately, if your N20 engine does not fall under the extended warranty or exceeds its limits in age or mileage, addressing a timing chain issue can be costly. A full replacement job can run over $1,500 at independent repair shops, and nearly double that at a BMW dealership.

While this is considered a demanding DIY project, the parts themselves, including the timing chain and guides, typically cost around $500. In a worst-case scenario, complete timing chain failure could lead to catastrophic engine damage, making proactive replacement critical.

3. N63 (2008–Present) – V8 Nightmare

BMW’s N63 twin-turbo V8 powers luxury and performance models like the 550i, 750i, and X5 xDrive50i.

Despite improvements over the years, early versions are known for oil consumption, turbocharger failures, valve stem seal leaks, and timing chain issues.

BMW even launched a “Customer Care Package” to address widespread failures. It’s powerful, but maintenance and repair costs are sky-high.

The BMW N63 is a turbocharged V8 engine that has earned a prominent place in the automotive world since its debut in 2008. This engine marked a major advancement in both performance and efficiency for BMW, blending cutting-edge engineering with the brand’s signature driving dynamics.

With a displacement of 4.4 liters, the N63 was built to deliver substantial power and torque, making it a standout choice among driving enthusiasts and luxury vehicle owners alike.

A key highlight of the N63 engine is its twin-turbocharger configuration, which enables quick power delivery and sharp throttle response. This setup not only boosts performance but also provides better fuel economy than naturally aspirated engines of comparable displacement.

The inclusion of direct fuel injection further refines combustion efficiency and reduces emissions, keeping the N63 in step with evolving environmental regulations.

Structurally, the engine utilizes an aluminum block paired with aluminum DOHC cylinder heads, offering a combination of lightweight construction and the strength needed for high-performance applications.

The N63 also features BMW’s variable valve timing system, which fine-tunes performance and fuel economy across varying engine loads and speeds, reinforcing its reputation as a well-rounded, high-performance powerplant.

4. S85 (2005–2010) – Exotic Engine, Exotic Bills

Found in the E60 M5 and E63 M6, the S85 V10 is a technological marvel with Formula 1-inspired engineering but it comes with a price.

Common failures include rod bearings, throttle actuators, and SMG transmission issues.

Preventive maintenance alone is expensive, and when things break (and they do), repair costs can easily spiral into five figures.

The BMW S85 engine is a double overhead camshaft (DOHC) V10 that succeeded the S62 engine and was produced between 2005 and 2010. It was specifically engineered for high-performance applications and found in the BMW E60 M5, E61 M5, and E63/64 M6.

The S85B50 stands out with its high-revving nature and achieves an impressive specific output of over 100 hp (70 kW) per liter. With a remarkably high compression ratio of 12.0:1, its design roots are inspired by the BMW Williams Formula 1 engine, reflecting its motorsport heritage.

Manufactured at BMW’s Dingolfing Plant, the S85 features an aluminum block and is configured as a V10 with four valves per cylinder. The engine displaces 4,999 cc and produces 507 horsepower at 7,750 rpm and 520 Nm of torque at 6,200 rpm. With a bore of 92 mm and a stroke of 75.2 mm, it runs on 98-octane fuel and meets Euro 4 emissions standards.

Despite its powerful performance, the engine weighs only 240 kg. The S85 uses 10W-60 engine oil, requiring 9.3 liters per change, with maintenance intervals every 7,000 to 10,000 km.

Official factory data does not specify a precise engine lifespan, but in practice, these engines often exceed 200,000 km. Tuning potential for the S85 is considerable, with achievable figures north of 750 hp, though the maximum reliable limit without compromising engine longevity is not defined.

The S85 was fitted into the BMW M5 E60, M6 E63, and their variants. Gearbox options included the 6-speed manual (CGPP – 6MKPP) and the SMG III automated manual transmission (Getrag 247). The 6-speed manual offers gear ratios from 4.05 in first to 0.87 in sixth, while the SMG III spans from 3.99 in first to 0.83 in seventh, balancing acceleration and cruising efficiency.

When BMW launched the E60 M5, the vehicle had grown significantly in size and weight, rendering the older 400 hp S62 inadequate for staying competitive against rivals like the Audi RS6 and Mercedes-Benz E55/E63 AMG.

Unlike its predecessors that were adaptations of standard engines, the S85B50 was built from the ground up and incorporated innovations from the P84/5 Formula 1 engine used in the Williams FW27.

The S85’s architecture is impressive: it features a lightweight aluminum block with ten cylinders offset by 17 mm and set at a 90° angle. There are no cylinder liners, but oil jets cool the pistons, and the block includes an aluminum crankcase pan.

The crankshaft is a reinforced forged unit, while the connecting rods are lightweight forged components measuring 140.7 mm. Pistons are made from an aluminum alloy, designed for the high 12.0 compression ratio, and feature a compression height of 27.4 mm.

The cylinder heads are also aluminum, housing four valves per cylinder, with hydro-compensators and BMW’s Double-VANOS variable valve timing system—similar to what was used in the earlier S62.

Intake camshafts are set at 60°, exhaust camshafts at 37°, with camshaft phases at 268/260 and lift at 11.7/11.5 mm. The intake valves measure 35 mm, exhaust valves 30.5 mm, both with 5 mm stems.

A unique feature is the use of ten individual throttle bodies arranged in two rows of five, one for each cylinder, along with a receiver optimized for this configuration. The injectors flow 192 cc, and the equal-length 5-1 exhaust headers each feed into a dedicated catalytic converter. Engine management is handled by the DME MS S65 ECU.

All of these technologies contribute to the S85’s ability to generate 507 hp at 7,750 rpm and rev freely to its extreme 8,250 rpm redline, delivering an unmatched naturally aspirated experience. The engine exclusively powered the BMW M5 (E60/E61) and the M6 (E63/E64). A detuned and simplified version, the S65B40, was developed for the smaller M3 in the E92 body style.

Production of the S85 ended in 2010, concluding its use with the end of the E60 M5. It was succeeded by the S63, a twin-turbocharged V8, which debuted in the BMW M5 F10 marking BMW M’s shift from high-revving naturally aspirated engines to force-fed performance.

5. M60 (1992–1996) – Early V8 with Nikasil Woes

The M60 V8, used in the E34 540i and E38 740i, might seem solid at first glance. However, its early versions used Nikasil cylinder linings, which reacted poorly with high-sulfur fuel common in the U.S. at the time.

This led to cylinder wall damage, compression loss, and complete engine replacements. Though the issue is less relevant today, any remaining M60s could still be at risk.

The BMW M60 engine is a series of V8 engines produced between 1992 and 1996, encompassing two main variants: the M60B30 and M60B40. These engines offered displacements of 3.0 liters and 4.0 liters, respectively.

The M60 family was integrated into several BMW models across the 5 Series, 7 Series, and 8 Series during this period, showcasing BMW’s push toward high-performance V8 powerplants in the early 1990s.

Engineered with performance and refinement in mind, the M60 engines were built with an aluminum cylinder block and cylinder heads, making them relatively lightweight compared to earlier cast-iron designs. Each cylinder head contained four valves per cylinder and featured dual overhead camshafts, contributing to improved airflow and combustion efficiency.

Although BMW’s VANOS variable valve timing system is widely associated with many of the brand’s later engines, the original M60 series did not include VANOS, distinguishing it from the next-generation powerplants. Despite the absence of this system, the M60 still delivered smooth and responsive power thanks to its well-balanced engineering.

The M60B30, also referred to as the “30i,” came with a 2,997 cc displacement. It used fuel injection and was capable of delivering 218 horsepower and 290 Nm of torque. The engine had a bore of 84 mm and a stroke of 67.6 mm, with a compression ratio of 10.5:1.

The design did not incorporate additional engine features such as turbocharging or variable valve timing, but it did include hydraulic valve lifters for ease of maintenance and quieter operation. The M60 used a timing chain instead of a belt, which generally contributes to increased reliability over the engine’s lifespan.

In terms of lubrication, the M60B30 required 7.5 liters of 5W-30 engine oil, and it was designed to run on medium-grade or plus-rated fuel. It was compliant with EURO 1 emissions standards at the time of production. The average service life of the M60 engine, when properly maintained, is around 300,000 kilometers, making it one of the more durable V8 engines of its era.

BMW builds some truly incredible engines but knowing which ones are dependable versus those that are money pits can make or break your ownership experience.

If you’re shopping for a used BMW or evaluating a long-term keeper, stick with the likes of the M54, N52, and B58.

On the other hand, steer clear of the N63, N54, and N20 unless you’ve got a spare wallet and a great mechanic on standby.