Ford’s EcoBoost engine family was launched with a bold promise: to deliver the power of a larger displacement engine with the efficiency and emissions of a smaller one.

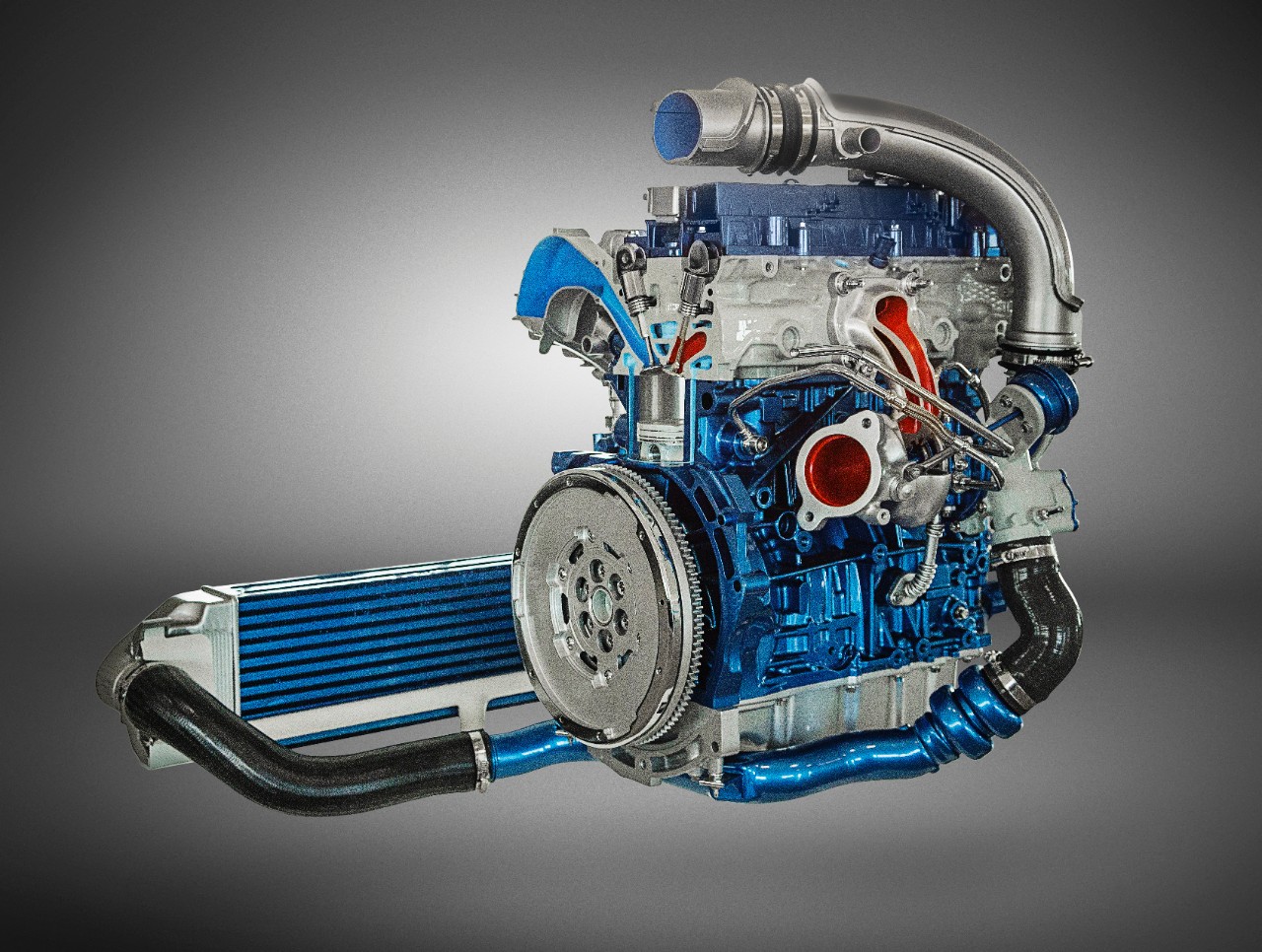

Touting advanced turbocharging, direct fuel injection, and variable valve timing, these engines became the cornerstone of Ford’s global strategy to meet increasingly strict fuel economy standards without sacrificing performance.

From fuel-sipping compacts to rowdy off-road trucks and performance icons like the Mustang, EcoBoost powerplants have been at the heart of Ford’s innovation—and controversy.

On paper, the EcoBoost concept is genius. Why haul around a heavy V8 when a turbocharged four or six-cylinder can provide similar, or even superior, performance? In practice, however, not every EcoBoost engine has lived up to the hype.

Some have proven to be incredibly well-engineered, earning praise for their responsiveness, durability, and impressive torque curves. Others, however, have developed reputations for early failures, design flaws, or reliability concerns that leave owners frustrated and mechanics busy.

This article takes a no-nonsense look at the most memorable successes and the most disappointing misfires in the EcoBoost lineup.

From the high-performing variants that genuinely deliver on their promises to the troublesome engines plagued by issues like carbon buildup, coolant intrusion, and turbo lag, we’re breaking it all down. Whether you’re a Ford enthusiast, a potential buyer, or just an engine nerd, this list will give you the clarity you need.

Let’s dive into 5 EcoBoost engines that impress—and 5 that constantly misfire.

EcoBoost Engines That Impress

Whether you’re a Ford fan or just curious about what modern engine tech can really do when it’s done right, these are the EcoBoost powerplants that prove innovation still has a place under the hood.

Let’s take a closer look at the EcoBoost engines that truly impress.

1. 2.3L EcoBoost I4 (Mustang, Focus RS, Bronco)

The 2.3L EcoBoost is a standout among Ford’s turbocharged engines. It delivers a potent mix of performance and efficiency, especially in the Mustang and Focus RS, where it produces upwards of 310–350 horsepower.

Owners praise its broad torque curve and responsiveness. With proper maintenance, it’s also proven to be relatively reliable, making it a favorite among tuners and daily drivers alike.

In 2015, alongside the debut of the second-generation 2.0L EcoBoost, Ford introduced the 2.3L EcoBoost—the most powerful four-cylinder engine in the entire EcoBoost lineup.

This 2.3-liter turbocharged inline-four first appeared in the Lincoln MKC crossover, and by the following year, it had found its way into the Ford Explorer and the high-performance 350-horsepower Ford Focus RS.

However, the engine gained widespread recognition under the hood of the Ford Mustang EcoBoost, where it produced 310 horsepower and 320 lb-ft (434 Nm) of torque. Notably, this marked the first time since the mid-1980s Mustang SVO that Ford brought a turbocharged four-cylinder back into the Mustang lineup.

Fundamentally, the 2.3L EcoBoost is derived from the second-generation 2.0L EcoBoost, making it a true ‘stroker’ engine. Both engines are assembled at Ford’s Valencia plant in Spain. However, the 2.3-liter version received significant upgrades to withstand higher power levels and ensure long-term durability.

At its core, the 2.3L engine features a high-pressure die-cast aluminum open-deck block. While it shares the same bore and deck height as the 2.0L version, this engine benefits from larger oil and coolant passages, along with a structural ladder frame that integrates the main bearing caps to reinforce the block.

The increased displacement comes from a forged 4340 steel crankshaft with a 94 mm stroke—an increase from the 83.1 mm stroke used in the 2.0L engine. Additionally, it uses shorter forged steel connecting rods and lightweight, high-strength pistons.

These pistons feature steel ring carriers, fully floating pins, and a low-friction skirt coating, along with fewer oil drainage holes to improve lubrication and reduce friction.

Special oil jets mounted within the block continuously spray the underside of the pistons to help manage temperature and lubrication. Beneath all that, a chain-driven oil pump, a balance shaft, and a deep-sump die-cast aluminum oil pan with internal baffling help maintain consistent oil flow during spirited driving.

Mounted on top of the block is an aluminum cylinder head fitted with dual overhead camshafts, each driven by chains. The head includes four valves per cylinder, a single GDI fuel injector, and a spark plug per cylinder.

The design also integrates a cast-in exhaust manifold feeding a twin-scroll, internally wastegated turbocharger. Compared to the 2.0L EcoBoost, the exhaust valves are larger—30 mm instead of 28 mm—while the intake valves measure 32.5 mm.

Both valve seats are crafted from high-performance materials. The camshafts feature more aggressive lift and duration profiles and are controlled via Ford’s Twin Independent Variable Cam Timing (Ti-VCT) system. The exhaust camshaft is responsible for driving the high-pressure, cam-driven fuel pump (CDFP).

Complementing the cylinder head is a redesigned plastic intake manifold with increased internal volume, paired with a larger-diameter throttle body.

The twin-scroll turbocharger is engineered to deliver boost quickly, helping flatten the torque curve and eliminate traditional turbo lag. These intake and turbo improvements result in stronger performance, quicker throttle response, improved emissions, and greater overall efficiency.

Also Read: Top 10 EV Features That Come in Useful in Daily Commute

2. 3.5L EcoBoost V6 (F-150, Expedition, Lincoln Navigator)

As the workhorse of Ford’s truck and SUV lineup, the second-generation 3.5L EcoBoost has built a reputation for durability and power.

Producing up to 450 horsepower in high-output trims (like the Raptor), it delivers V8 performance with better fuel economy.

It’s well-suited for towing and hauling, and improved internals in later versions have addressed earlier issues like carbon buildup and timing chain stretch.T

he 3.5L EcoBoost is a turbocharged, gasoline direct-injected 3.5-liter V6 engine that made its debut in 2007, originally introduced under the name TwinForce. The core concept behind this engine was to develop a reliable alternative to high-displacement V8 engines, such as the V8 Coyote-sourced engine.

This newly engineered turbocharged 3.5L V6 delivers power and torque on par with a naturally aspirated 6.0L V8, but with the added benefits of reduced fuel consumption and lower emissions of harmful pollutants into the atmosphere.

Since entering production in 2009 and gradually being integrated across more of Ford’s lineup, the engine found its most prominent home in Ford’s top-selling vehicle: the Ford F-150.

And that makes complete sense—EcoBoost-equipped F-150s offer a lower price point without suffering from the typical drawbacks associated with small-displacement, naturally aspirated 6-cylinder engines, especially when compared to their V8-powered counterparts.

3. 1.0L EcoBoost I3 (Fiesta, Focus, EcoSport)

This tiny three-cylinder engine surprised critics with its efficiency and spirited performance, winning multiple International Engine of the Year awards.

Despite its size, it offers excellent torque at low RPMs and is ideal for urban commuting. Later updates improved its durability, and when well-maintained, it has proven to be economical and fun to drive.

The Ford 1.0 EcoBoost is a turbocharged, direct fuel-injected 1.0-liter inline three-cylinder gasoline engine and represents the smallest member of Ford’s EcoBoost engine family. The 1.0L EcoBoost was first made available in 2012, debuting in the Ford Focus and C-Max.

Today, this power unit is offered in multiple power variants and sees widespread use across various vehicle types. It’s a suitable fit for models ranging from the compact hatchback Ford Fiesta to larger mid-size cars like the Ford Mondeo (D segment). Ford has also developed naturally aspirated alternatives—the 1.0L Fox engine with direct fuel injection or multi-port fuel injection (PFI).

The 1.0 EcoBoost features an open-deck cylinder block constructed from grey cast iron. While cast iron blocks are heavier than aluminum ones, they require up to 50% less energy to reach optimal operating temperature, which contributes positively to emissions reduction.

The engine’s crankshaft, also made of cast iron, includes six counterweights and is supported by four main bearings. A distinctively unbalanced flywheel and front pulley design eliminate the need for a balance shaft. This innovative setup allows the engine to run smoothly without expending energy on balance shaft rotation.

Inside the block, the engine houses cast aluminum pistons with low-friction coatings, along with forged connecting rods. Ford engineers have also enhanced the lubrication system for greater engine efficiency. The 1.0L EcoBoost comes equipped with an electronically controlled variable displacement oil pump.

4. 2.7L EcoBoost V6 (Edge ST, F-150, Fusion Sport)

The 2.7L EcoBoost is a sweet spot in Ford’s lineup smaller and more efficient than the 3.5L, yet still capable of producing 325–335 horsepower.

It offers smooth power delivery and solid reliability in most applications. Owners of the Fusion Sport and Edge ST often report great driving dynamics with minimal issues.

The 2.7L EcoBoost is a direct-injection, turbocharged gasoline engine. This 2.7-liter V6 twin-turbo powerplant is manufactured in the United States at Ford’s Lima plant in Ohio, though it was originally co-developed with the German firm FEV Engineering (it’s worth noting that the 3.5L EcoBoost V6 shares no parts with it).

As with other engines in the EcoBoost lineup, the 2.7L variant was engineered to match the power and torque output of larger-displacement, naturally aspirated V6 and V8 engines—but with significantly improved fuel efficiency and lower emissions.

The 2.7 EcoBoost made its debut in 2015 as a new engine option for the Ford F-150. Since then, it has seen broad adoption across various models in the Ford and Lincoln families, including the Ford Edge Sport, Fusion Sport, and the Lincoln MKX and Continental.

5. 2.0L EcoBoost I4 (Escape, Edge, Fusion, MKZ)

This engine is a workhorse across several Ford and Lincoln models. It provides a good balance of power and economy, making it a solid option for mid-size vehicles.

Especially in its Gen 2 and Gen 3 iterations, the 2.0L EcoBoost has seen improved cooling and internal components, reducing prior concerns and making it a reliable choice.

The Ford 2.0 EcoBoost is a 2.0-liter, four-cylinder gasoline engine featuring turbocharging and direct fuel injection. It is also sometimes referred to as the Ford 2.0 GTDI engine (Gasoline Turbocharged Direct Injection).

Ford Motor Co. launched the first 2.0L EcoBoost in 2010. Today, the engine is available in a wide range of Ford vehicles across the globe, including the Fusion, Focus ST, Edge, Escape, Explorer, and Taurus in North America, the Falcon in Australia, and the Mondeo and S-Max in the European market. Within the EcoBoost engine lineup, there is also a larger four-cylinder option—the 2.3L EcoBoost.

The 2.0L EcoBoost has gone through two generations so far. In 2015, the 2.0 EcoBoost GTDI engine underwent a major redesign. The updated version, known as the twin-scroll 2.0 EcoBoost, shares virtually no components with the earlier design. Despite the significant overhaul, it continues to be produced under the same name, while the original version is being gradually phased out from all vehicle models.

Also Read: 5 SUVs With the Best Headlight Throw and 5 With Dark Spots

EcoBoost Engines That Constantly Misfire

This article takes a hard look at the EcoBoost engines that consistently fall short—the ones that promised high-tech performance but instead delivered headaches, repair bills, and disappointed owners.

We’re not here to sugarcoat it. These are the engines that missed the mark, plagued by design flaws, questionable durability, and patterns of mechanical failure that have tainted the EcoBoost name for some.

1. 1.6L EcoBoost I4 (Escape, Fusion, Fiesta ST)

The 1.6L EcoBoost is infamous for reliability issues. Recurring misfire complaints often stem from coolant intrusion into the cylinders, leading to warped heads and engine failure.

It was also plagued by fires due to poor coolant circulation. Ford eventually issued recalls, but many owners were left with expensive repairs. This engine’s track record makes it one of the most problematic EcoBoost variants.

Ford launched the 1.6L EcoBoost engine in 2010, introducing it in the Ford Focus and Ford C-Max. Alongside the 2.0 EcoBoost, it marked the first turbocharged engine developed by Ford under the framework of the Downsizing strategy.

This powerplant is a 1.6-liter inline four-cylinder gasoline engine, equipped with a turbocharger and a direct fuel injection system. Thanks to its advanced engineering, it was capable of replacing larger engines—such as the 2.0L and 1.8L Duratec—without sacrificing performance, while also delivering better fuel efficiency and reduced emissions.

The engine’s cylinder block features an open-deck design and is constructed from high-strength aluminum alloy. This design contributes to reduced weight and improved thermal balance. The block incorporates very thin cast iron sleeves (liners), which are cast directly into the aluminum cylinder walls.

It is paired with a cast iron crankshaft that includes four counterweights and five main bearings, forged connecting rods, and aluminum hypereutectic pistons with low-friction resin-coated skirts. The piston pins are finished with a diamond-like coating (DLC) for enhanced durability. The aluminum oil pan not only helps reduce weight but also provides additional structural rigidity to the engine block.

2. First-Gen 3.5L EcoBoost V6 (2011–2014 F-150, Explorer Sport)

The early versions of this engine had several issues, including carbon buildup on intake valves due to direct injection, moisture in the intercooler causing misfires under acceleration, and timing chain stretch.

Misfiring was a common complaint, especially when cold or under load. Later revisions solved most of these problems, but early adopters often faced hefty repair bills.

In 2011, Ford introduced a major shift in the powertrain lineup of the Ford F-150. A new, smaller displacement V6 engine was added, featuring twin turbochargers and direct fuel injection.

This engine, known as the 1st Generation 3.5L EcoBoost engine, delivered improved fuel efficiency, greater towing capacity, and better overall drivability compared to the large, naturally aspirated V8 engines that were commonly used at the time.

Since its debut in 2011, the 3.5L EcoBoost has continued to outperform other half-ton truck powertrains, consistently ranking at the top—or very near the top—in terms of towing capability, fuel economy, and overall performance metrics when compared with rival engines.

Over time, the 3.5L EcoBoost has evolved further. It is now available as a hybrid variant called the 3.5L PowerBoost Engine, and there is also a high-output 3.5L EcoBoost engine used in the high-performance Ford Raptor.

In the late 2000s and early 2010s, increasing pressure from the EPA pushed truck manufacturers to design more fuel-efficient and environmentally friendly vehicles.

Even diesel-powered trucks were being required to meet stricter standards, which led to the rise of systems such as Diesel Exhaust Fluids, Diesel Particulate Filters, and EGR technology. Ford’s answer to these demands was a smaller V6 engine equipped with twin turbochargers and direct injection

. The result was a powerful, efficient, and highly capable engine that delivered performance characteristics similar to diesel engines. This engine—the 1st Generation 3.5L EcoBoost—was first introduced in the Ford F-150 in 2011. It remained in production for the F-150 lineup until 2017, when it was succeeded by the 2nd Generation 3.5L EcoBoost engine.

3. 2.0L Gen 1 EcoBoost I4 (2011–2014 Edge, Fusion, Escape)

While the updated versions of the 2.0L EcoBoost are solid, the first generation was prone to problems.

One major flaw was a tendency to overheat, which could cause cylinder head cracks and coolant leaks leading directly to misfires and loss of compression.

It also suffered from turbocharger failures and fuel injector problems that triggered engine misfires across multiple cylinders.

The EcoBoost 2.0L is a turbocharged four-cylinder engine developed by Ford Motor Company and is used across a variety of vehicle types, including subcompact, compact, and midsize cars, as well as utility vehicles—commonly referred to as CUVs and SUVs.

Built with a dual overhead cam (DOHC) configuration in an inline layout, the Ford EcoBoost 2.0L engine traces its architectural roots back to the Ford Duratec 2.0L engine. It has been a member of the Ford EcoBoost lineup of turbocharged engines since 2010.

In 2015, this engine underwent a significant redesign, which was first implemented in the second-generation Ford Edge. It was later introduced in the 2017 Ford Escape during the spring of 2016.

The revised version featured a higher compression ratio (10.0:1 vs 9.2:1), the addition of a twin-scroll turbocharger, and enhancements to both the fuel and oil systems. These improvements enabled the engine to deliver greater low-end torque, making it more suitable for all-wheel-drive systems and light towing demands.

4. 1.5L EcoBoost I4 (Escape, Fusion, Focus)

This engine attempted to replace the problematic 1.6L, but many of the same issues persisted. Misfires, coolant intrusion, and stalling remained common complaints.

In some cases, cracked cylinder heads led to undiagnosed engine damage. Owners reported frequent check engine lights and hesitation during acceleration.

Ford made technical service bulletins and design tweaks, but not before the engine’s reputation was damaged.

n 2013, Ford Motor Company introduced a new addition to its EcoBoost engine lineup: the 1.5-liter EcoBoost. This engine inherited the design DNA of the 1.0-liter EcoBoost inline-three, while also addressing some of the known shortcomings from the earlier 1.6L EcoBoost—particularly those related to cooling system issues.

The 1.5-liter unit is a turbocharged inline four-cylinder gasoline engine with direct injection and incorporates the latest advancements from Ford’s EcoBoost technology portfolio.

It made its debut in the 2014 Ford Fusion (known as the Mondeo starting in 2015), and was subsequently used in other models such as the Ford Focus, C-Max, and Kuga/Escape. Over time, it nearly completely replaced the 1.6-liter version on the market.

The 1.5L engine, like the 1.6L EcoBoost before it, uses an aluminum cylinder block featuring cast iron sleeves. Its open-deck design is engineered for improved cooling efficiency.

Ford equipped this engine with a new cast iron crankshaft that includes four counterweights and five main bearings. The connecting rods are manufactured using a hot-forged powder metal process and feature a cracked rod cap for increased strength.

The aluminum pistons are hypereutectic and come with asymmetrical skirts that include a friction-reducing coating. The cylinder bore remained unchanged, but the displacement was reduced through the use of a shorter stroke crankshaft measuring 76.40 mm.

The engine also features a redesigned aluminum cylinder head that integrates the exhaust manifold. This design helps the engine warm up faster by using exhaust heat while also lowering exhaust temperatures to extend turbocharger life.

Like its predecessor, the head houses 4 valves per cylinder (16 two exhaust valves and two intake valves; 16 valves total), which are actuated by solid buckets and operated through a dual overhead camshaft setup (DOHC).

Both the intake and exhaust camshafts include Ford’s Twin independent Variable Cam Timing (Ti-VCT) for improved performance and efficiency. The 1.5L EcoBoost adopts an innovative camshaft drive system borrowed from the 1.0L I-3 engine.

Although it uses a timing belt, it is an in-oil design—running inside the engine oil—for reduced noise and enhanced durability. In addition, the electronically controlled variable displacement oil pump also is driven by belt-in-oil designed for the entire life of the engine.

EcoBoost engines achieve their high efficiency through the combined use of turbocharging and direct injection. The 1.5L EcoBoost utilizes a high-response Borg Warner low-inertia turbocharger with an active wastegate, as well as a water-to-air charger-intercooler integrated into a plastic intake manifold.

The high-pressure direct fuel injection system delivers fuel directly into the combustion chambers using 6-hole injectors mounted on the head in the center of each cylinder (close to spark plugs).

Engine functions are managed by an electronic drive-by-wire throttle body and Bosch MED17 ECU. Thanks to a close-coupled three-way catalytic converter and the inclusion of advanced technologies, the engine complies with the stringent Euro 6 emissions standards in Europe.

Ford engineers continued advancing the brand’s engine downsizing strategy. In 2018, they launched a completely new 1.5-liter engine based on a three-cylinder configuration: the 1.5L I-3 EcoBoost Dragon engine.

5. 2.3L EcoBoost I4 (Early Focus RS Models)

Though impressive in performance, the 2.3L EcoBoost in early Focus RS models was marred by head gasket failures.

A mismatch between cylinder head design and gasket style led to coolant leakage into the combustion chamber, resulting in consistent misfires and eventual engine failure.

Ford later corrected the issue in production and offered repairs, but the damage to reliability perceptions lingered. Ford’s EcoBoost line has showcased both engineering brilliance and frustrating missteps.

The Ford Focus RS has long stood as a symbol of high-performance engineering in the compact car segment. First introduced in 2002, the RS variant of the Focus was built to deliver a thrilling driving experience by blending everyday usability with exceptional performance.

The third-generation Focus RS, which debuted in 2015, marked a major milestone in the evolution of the model. It featured a turbocharged 2.3-liter EcoBoost engine that offered impressive power and efficiency, further reinforcing the RS’s standing in the world of performance compacts.

The 2.3 EcoBoost engine, stemming from Ford’s modular engine family, was engineered to deliver around 350 horsepower and 350 lb-ft of torque. This level of output made it a serious contender in the competitive hot hatch category.

Advanced technologies such as turbocharging and direct fuel injection helped the engine achieve strong performance numbers while keeping emissions in check. Thanks to sharp handling, a sophisticated all-wheel-drive system, and track-ready dynamics, the Focus RS quickly earned a strong reputation among driving enthusiasts and practical users alike.

However, as is often the case with high-output engines, the Focus RS and its 2.3 EcoBoost powerplant are not without their flaws. Despite the widespread praise, many owners have experienced various reliability issues that can negatively affect overall performance and increase long-term ownership costs.

For current owners or those considering purchasing one, it’s important to understand these common problems to make informed decisions about maintenance and expectations. This article provides a clear breakdown of the known issues tied to the Ford Focus RS 2.3 EcoBoost engine, helping owners and buyers know what they’re dealing with in this high-performance vehicle.

One of the most significant and frequently reported issues with the Focus RS 2.3 EcoBoost engine is turbocharger failure. The turbocharger is essential for increasing engine performance, but it can fail for several reasons.

These include oil starvation, which occurs when there is insufficient lubrication; boost leaks, which result from faulty hoses or connections that compromise boost pressure; and excessive heat, which can damage internal turbo components over time. Any one of these conditions can lead to a noticeable drop in performance or even complete turbo failure.

Engine misfires are another concern among owners. These can be caused by several issues, including faulty spark plugs, which may prevent complete combustion; clogged or malfunctioning fuel injectors that disrupt fuel delivery; or ignition coil failures that result in one or more cylinders misfiring.

These problems can lead to poor engine performance, reduced fuel efficiency, and even long-term engine damage if not addressed promptly.

Cooling system problems also plague some Focus RS models. The cooling system is vital to regulating engine temperature, and failures here can cause serious engine damage.

Common cooling-related issues include coolant leaks, which can lead to overheating; thermostat failures, which prevent the coolant from circulating properly; and water pump failures that compromise the entire cooling process. Any of these issues can result in dangerously high engine temperatures and potential failure if left unchecked.

Oil consumption is another issue owners have reported. Excessive oil usage may be an early warning sign of deeper mechanical problems. Worn piston rings can allow oil to enter the combustion chamber, where it is burned off during operation.

Similarly, failing valve seals can lead to oil leaking into areas it shouldn’t, increasing oil consumption and reducing efficiency. If the issue is not corrected, it can result in low oil levels and potentially severe engine damage.

Although technically not part of the engine, transmission issues can also affect the overall performance of the Focus RS. Manual transmission models, in particular, may suffer from clutch slippage, which leads to loss of power and reduced drivability.

Transmission fluid leaks are another concern, as low fluid levels can result in rough or erratic gear changes, ultimately affecting the car’s performance and longevity.

While the Ford Focus RS 2.3 EcoBoost engine delivers impressive performance and remains a favorite among enthusiasts, understanding these potential issues is key to maintaining its reliability and long-term value.

Owners who are proactive about maintenance and repairs will be in a better position to enjoy all that this iconic hot hatch has to offer without being blindsided by preventable problems.

Engines like the 2.3L and 3.5L EcoBoosts have earned praise for combining power with fuel savings, while others, especially early versions of the 1.6L and 3.5L, have struggled with persistent misfires and major mechanical issues.

When considering an EcoBoost-powered vehicle, buyers should pay close attention to the engine’s generation and known service history to ensure a reliable experience.