Small engines are a gamble. On paper, they promise the holy trinity: fuel efficiency, lower emissions, and lower ownership costs. Automakers slap turbochargers on tiny blocks and market them as the future of performance and economy.

You get a zippy, efficient, surprisingly robust powerplant that runs like a dream for 200,000+ miles. Other times, you end up with an overworked mess that guzzles oil, breaks under pressure, and gives up the ghost before your warranty expires.

This article cuts through the marketing spin and puts real-world reliability under the microscope. We’re looking at 5 small engines that punch far above their weight class—the unsung heroes that take abuse, clock miles, and still ask for more.

And then, we’re calling out 5 small engines that fall flat—the ones that looked great on a brochure but couldn’t go the distance without leaving drivers stranded or furious.

If you’re in the market for a car with a small engine, or just want to know which ones earned their stripes—and which ones didn’t—this is your no-BS guide. Let’s dive into the winners and the wrecks.

Small Engines That Perform Big

These compact powerplants deliver real-world performance, stay reliable past 150,000 miles, and don’t throw in the towel when pushed hard. Whether naturally aspirated or turbocharged, the following five engines are proof that small displacement doesn’t mean small capability.

1. Ford 1.0L EcoBoost I3

Don’t let the three-cylinder layout fool you the 1.0L EcoBoost is a turbocharged dynamo. Found in models like the Ford Fiesta and Focus, it offers up to 125 horsepower and a surprisingly broad torque curve.

It’s responsive, eager, and fuel-efficient, with real-world performance that often rivals naturally aspirated 1.6L or 1.8L engines. Plus, it’s earned multiple International Engine of the Year awards for its innovative design and clever engineering.

The 1.0-liter EcoBoost engine stands as a remarkable feat of engineering and is a clear reflection of Ford’s dedication to combining fuel efficiency with capable performance.

Debuting in 2012, this turbocharged three-cylinder engine was developed with the goal of delivering the power and responsiveness of a larger engine while maintaining impressive fuel economy.

Its compact dimensions and lightweight construction make it especially suitable for smaller vehicles, striking a fine balance between everyday drivability and environmental responsibility.

What truly sets this engine apart is its integration of advanced technologies that elevate its real-world capabilities. The EcoBoost system incorporates direct fuel injection, turbocharging, and variable valve timing, working together to extract maximum performance from minimal displacement.

“With an output of around 125 horsepower and 170 lb-ft of torque, it challenges the notion that smaller engines can’t deliver robust performance.”

Beyond just numbers on a spec sheet, this engine delivers a driving experience that is both responsive and engaging, which has made it a favorite among drivers who enjoy spirited driving without the burden of excessive fuel consumption.

Its versatility has led to widespread use across Ford’s global lineup, especially in subcompact and compact vehicles. The Ford Fiesta was one of the first models to adopt the 1.0L EcoBoost engine, where it provided a lively and nimble driving experience perfectly suited for city driving.

The Ford Focus also featured this engine, offering a solid combination of efficiency and fun, catering to drivers looking for a practical yet enjoyable ride. In the Ford EcoSport, the engine’s efficient nature complemented the compact SUV’s urban utility, making it an appealing option for those needing a small footprint without sacrificing too much capability.

The C-Max hybrid took things a step further by combining the 1.0L EcoBoost with an electric motor to enhance fuel efficiency, representing Ford’s forward-thinking approach to eco-conscious mobility. Meanwhile, the Ford Puma, a stylish crossover, employed this engine to attract a younger audience looking for both visual flair and strong performance in a compact package.

In summary, the 1.0L EcoBoost engine has successfully carved out a strong presence within Ford’s portfolio, offering a compelling option for drivers who prioritize fuel economy without giving up engaging performance.

Its application across a diverse range of models highlights both its adaptability and Ford’s strategic effort to deliver efficient, driver-friendly vehicles to a wide range of customers.

Technically designated as the M1DA, the 1.0L EcoBoost engine is a standout in Ford’s engineering lineup, boasting a combination of innovation and performance.

It’s a turbocharged inline-3 with a displacement of 1.0 liters and a compression ratio of 10.0:1. It delivers a maximum of 125 horsepower at 6,000 rpm and 170 lb-ft of torque between 1,400 and 4,500 rpm. The engine features a direct injection fuel system and a single twin-scroll turbocharger for optimized boost delivery and efficiency.

Its valvetrain is a dual overhead cam (DOHC) setup with 12 valves, designed to support smooth airflow and robust power throughout the rev range. Altogether, this engine represents how far modern engineering has pushed the boundaries of what a small displacement powerplant can achieve.

Also Read: 5 Trucks With the Best Storage Under Seats and 5 Wasting Space

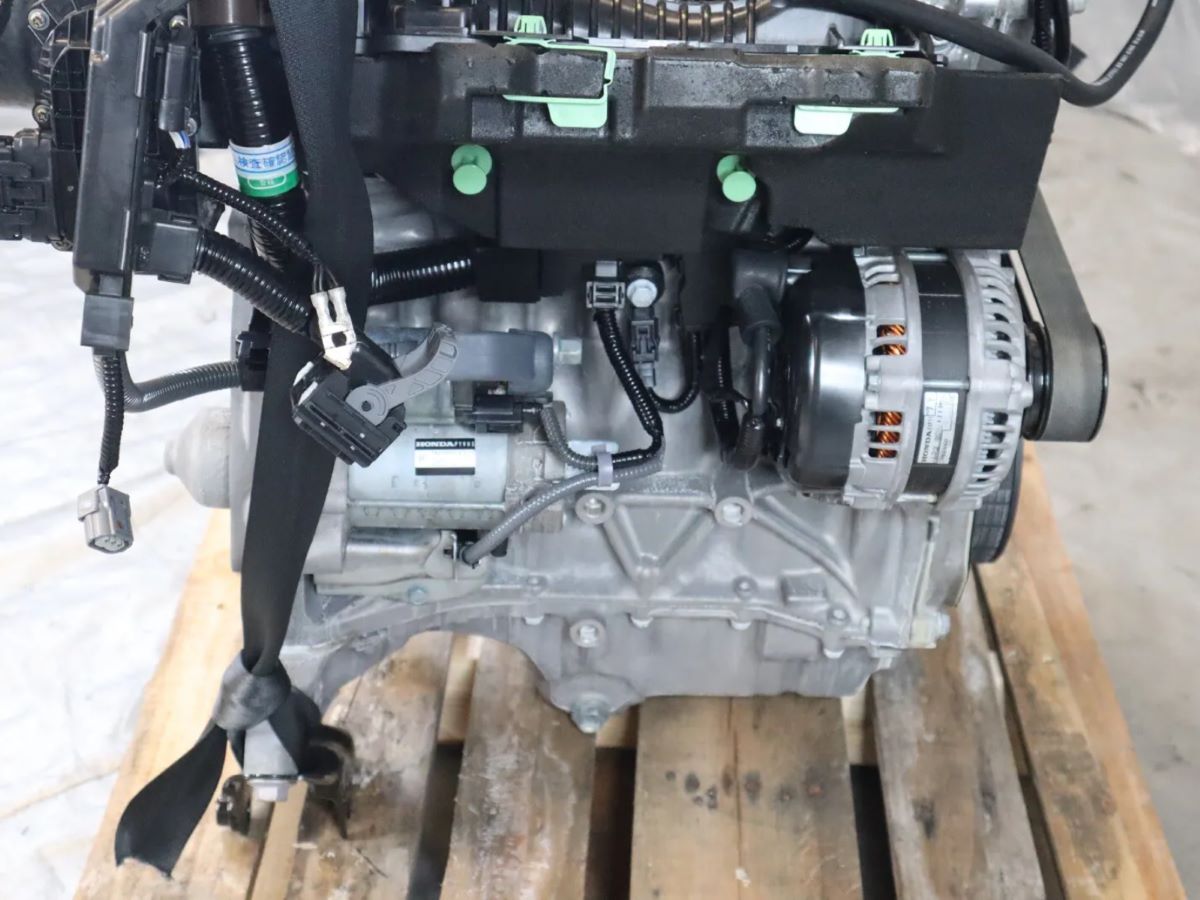

2. Honda 1.5L Turbocharged I4 (L15B7)

Used in the Civic, CR-V, and Accord, Honda’s 1.5L turbocharged four-cylinder engine offers a remarkable blend of power and efficiency.

Producing up to 205 hp in some trims and over 30 mpg combined, it delivers the performance of a much larger engine.

With proper maintenance and oil changes, this motor is known to handle mileage well, making it a top pick for those who want small-engine efficiency without sacrificing fun.

The Honda L15B7 VTC 1.5 turbo engine marks a new direction for Honda in terms of engine design and performance. It features a single turbocharger combined with direct injection, allowing it to extract more power from a smaller displacement.

This innovative setup helps achieve better efficiency and output, but like any modern engine, it comes with its own set of challenges. No engine is flawless, and that certainly applies to the Honda 1.5T engine—especially given the adoption of newer technologies like direct injection.

In this article, I discuss the most common Honda 1.5T engine problems including fuel dilution of the oil, carbon build-up, and spark plugs.

These three issues are the primary concerns we’ll explore in greater depth throughout this article. It’s important to clarify up front that the presence of these problems on this list doesn’t mean every Honda L15B7 engine will develop them.

Engines can vary widely in how they wear and perform over time, depending on factors like driving style, maintenance habits, and environmental conditions.

Additionally, it’s worth remembering that many other potential problems can arise with the 1.5 turbo engine—just as they can with any internal combustion engine. That said, we’re labeling these particular issues as the “most common” because they’re the ones most frequently reported by owners and mechanics.

It doesn’t necessarily mean they are actually very common issues. With that in mind, let’s jump in and take a closer look at the three most common problems associated with the Honda 1.5 Turbo engine.

3. Toyota 1.2L Turbocharged I4 (8NR-FTS)

This compact turbo engine, mainly available in international markets, delivers solid torque low in the rev range, making it feel more robust than its displacement suggests.

Found in the Toyota Auris and C-HR, it uses direct injection and VVT-iW technology to maximize performance. It’s also been praised for its durability and low maintenance costs true to Toyota form.

The 8NR-FTS engine is a new member of Toyota’s NR family. It was introduced in 2015 and became offering first in the Toyota Auris, and later as an option for the Toyota C-HR.

The 8NR-FTS is a 1.2-liter (one of the smallest in the NR-series) four-cylinder gasoline turbocharged engine equipped with direct fuel injection, and it represents Toyota’s next step in thermal and fuel efficiency improvement of internal combustion engines.

The launch of a new powertrain with the concept of a small displacement turbocharged engine (not for Kei cars available only in the domestic Japanese market) appears to have come a bit late.

Perhaps this is due to the desire of the Toyota to look at potential problems and successful solutions of other manufacturers such as VW (1.2 TSI and 1.4 TSI EA111) and Ford (1.0L EcoBoost).

The 8NR-FTS features a lightweight aluminum “open deck” cylinder block with thin cast iron liners that are fused into the block. It includes a water jacket spacer, which enables more intensive coolant circulation near the top of the cylinders.

Compared to naturally aspirated engines in the NR series, the 8NR engine block is reinforced with additional horizontal ribs along its sides.

Like other NR engines, the 1.2L turbo engine has the crankshaft offset by 8 mm relative to the cylinder axis lines. The engine also comes with a newly designed crankshaft featuring 8 counterweights, and T-shaped pistons that include a resin coating on the skirts. The engine is equipped with piston-cooling oil jets controlled by electronics.

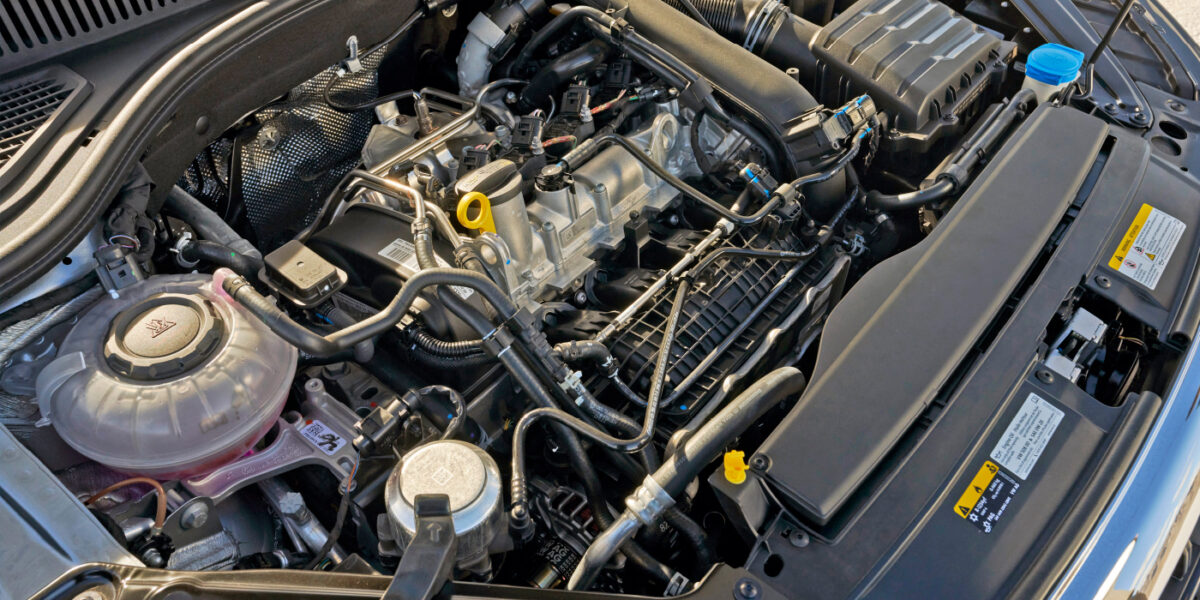

4. Volkswagen 1.4L TSI I4

The 1.4L TSI engine is a global favorite for its peppy performance and broad powerband.

Used in a wide variety of VW Group cars (including the Golf, Jetta, and even some Audis), this engine pairs well with dual-clutch gearboxes and offers brisk acceleration without much turbo lag.

It delivers real-world fuel efficiency along with surprising highway power, making it one of the best-balanced small engines available.

The 1.4 TSI of the EA211 series is a 1.4-liter four-cylinder gasoline turbocharged engine. The new EA211 engine family was designed to use in VW’s MQB platform which involves a certain unification of the engines too.

At first glance, it might appear that the new 1.4 TSI is simply a modified version of the 1.4 TSI EA111 engine, given their similar displacement, power output, and appearance. However, it is in fact an entirely new engine that was developed based on Volkswagen’s accumulated experience in designing and producing previous small turbocharged power units.

One of the major distinctions lies in the engine’s construction. First of all, the 1.4 TSI EA211 has a lightweight aluminum cylinder block with cast iron sleeves (liners) instead of complete cast iron block.

This results in a lighter overall engine. It also features a newly developed die-forged steel crankshaft and connecting rods. The stroke has been increased to 80 mm, while the cylinder bore has been slightly reduced to 74.5 mm (by 2 mm).

These changes contribute to a total weight reduction of 24.5 kg compared to its predecessor. The engine block is now tilted 12 degrees backward, placing the exhaust manifold at the rear near the firewall. That allows achieving more unification between cars built on MQB platform.

The cylinder head is made of aluminum alloy and features a 16-valve DOHC layout with an integrated water-cooled exhaust manifold. Another major change is in the timing mechanism: the camshafts are now driven by a timing belt rather than a chain. The 122 hp versions have variable intake timing only.

The 140+ hp engines incorporate both variable intake and exhaust timing. The engine continues to use hydraulic tappets and roller finger cam followers, provided an automatically valve clearance adjustment and low friction.

Turbocharging has also seen key updates. The engine is equipped with a turbocharger system that incorporates a water-cooled intercooler integrated directly into the intake manifold. The 1.4 TSI uses a dual-loop cooling system: one low-temperature loop circulates coolant through the intercooler and the turbocharger housing.

The integrated exhaust manifold reaches its optimal operating temperature very quickly after the engine is started; it also cools the exhaust gases at full power mode increasing a turbocharger lifespan. The catalytic converter is mounted downstream of the turbocharger for faster warm-up.

Fuel delivery is handled through a direct injection system similar to that of the previous generation. Like the predecessor, the 1.4 TSI of EA211 has direct fuel injection system.

The high-pressure fuel pump delivers a maximum injection pressure of 200 bar. The cylinders are fitted with five-hole injection nozzles that precisely deliver fuel into the combustion chambers, with up to three individual injections per cycle.

Finally, the 1.4 TSI 103 kW (140 hp) variant equipped with the ACT (Active Cylinder Technology) system can switching off two cylinders for a less fuel consumption, improving efficiency under light load conditions.

5. Suzuki 1.0L BoosterJet I3

Found in the Suzuki Baleno, Swift, and Vitara, the BoosterJet is a spirited little motor that makes driving light cars a blast.

Producing around 110 hp, it might not sound like much, but its light weight and strong low-end torque give it a zippy, enthusiastic character. It’s also known for solid fuel economy and reliability in both urban and long-distance driving.

The 1.4 TSI of the EA211 series is a 1.4-liter four-cylinder gasoline turbocharged engine. The new EA211 engine family was designed to use in VW’s MQB platform which involves a certain unification of the engines too.

At first glance, it might appear that the new 1.4 TSI is simply a modified version of the 1.4 TSI EA111 engine, given their similar displacement, power output, and appearance. However, it is in fact an entirely new engine that was developed based on Volkswagen’s accumulated experience in designing and producing previous small turbocharged power units.

One of the major distinctions lies in the engine’s construction. First of all, the 1.4 TSI EA211 has a lightweight aluminum cylinder block with cast iron sleeves (liners) instead of complete cast iron block.

This results in a lighter overall engine. It also features a newly developed die-forged steel crankshaft and connecting rods. The stroke has been increased to 80 mm, while the cylinder bore has been slightly reduced to 74.5 mm (by 2 mm).

These changes contribute to a total weight reduction of 24.5 kg compared to its predecessor. The engine block is now tilted 12 degrees backward, placing the exhaust manifold at the rear near the firewall. That allows achieving more unification between cars built on MQB platform.

The cylinder head is made of aluminum alloy and features a 16-valve DOHC layout with an integrated water-cooled exhaust manifold. Another major change is in the timing mechanism: the camshafts are now driven by a timing belt rather than a chain. The 122 hp versions have variable intake timing only.

The 140+ hp engines incorporate both variable intake and exhaust timing. The engine continues to use hydraulic tappets and roller finger cam followers, provided an automatically valve clearance adjustment and low friction.

Turbocharging has also seen key updates. The engine is equipped with a turbocharger system that incorporates a water-cooled intercooler integrated directly into the intake manifold. The 1.4 TSI uses a dual-loop cooling system: one low-temperature loop circulates coolant through the intercooler and the turbocharger housing.

The integrated exhaust manifold reaches its optimal operating temperature very quickly after the engine is started; it also cools the exhaust gases at full power mode increasing a turbocharger lifespan. The catalytic converter is mounted downstream of the turbocharger for faster warm-up.

Fuel delivery is handled through a direct injection system similar to that of the previous generation. Like the predecessor, the 1.4 TSI of EA211 has direct fuel injection system.

The high-pressure fuel pump delivers a maximum injection pressure of 200 bar. The cylinders are fitted with five-hole injection nozzles that precisely deliver fuel into the combustion chambers, with up to three individual injections per cycle.

Finally, the 1.4 TSI 103 kW (140 hp) variant equipped with the ACT (Active Cylinder Technology) system can switching off two cylinders for a less fuel consumption, improving efficiency under light load conditions.

Also Read: 5 Trucks With the Best Storage Under Seats and 5 Wasting Space

Small Engines That Can’t Handle Mileage

Whether it’s poor engineering, rushed designs, or just asking too much from too little displacement, these five engines are cautionary tales. If you’re hunting for a long-haul daily driver or a used buy you don’t want to regret, these are the small engines you don’t want under the hood.

1. Chevrolet 1.4L Turbocharged I4 (LUJ/LUV)

Used in the Chevy Cruze, Sonic, and Trax, this small turbo engine delivers decent power when new but it’s notorious for long-term reliability issues.

Common problems include turbo failure, oil leaks, timing chain wear, and cooling system troubles. Many owners report expensive repairs before hitting the 100,000-mile mark, making it a small engine that often can’t go the distance.

The 1.4L Turbo Ecotec LUJ/LUV is part of GM’s lineup of small-displacement, power-dense four-cylinder engines. The wide rpm range for maximum torque helps the engine deliver a surprisingly spririted driving experience and performance. Its performance edge comes from the turbocharger, which increases airflow into the engine.

The engine’s power-boosting advantage comes from forcing greater airflow into the engine, and its pressurized charge packs more air into the cylinders, allowing them to process the air and fuel of a larger engine for momentary driving situations.

This gives the engine the ability to behave like a bigger displacement motor when needed, enhancing acceleration and throttle response.

A distinctive feature of the LUJ/LUV engines is the turbocharger’s integration within the exhaust manifold. The turbocharger in the LUJ/LUV is integrated within the exhaust manifold for reduced weight and greater packaging flexibility in smaller vehicles.

This design supports compact packaging and contributes to weight savings, making the engine ideal for space-limited engine bays. GM implemented several weight-reduction measures throughout this engine. The engine incorporates numerous mass-reducing features, including a cast iron block with a hollow frame structure, hollow-cast camshafts, and a plastic intake manifold.

The cylinder block itself is a significant piece of engineering. Cylinder Block: the LUJ/LUV’s cylinder block is made of strong gray cast iron, with five reinforced main bearings.

It offers excellent thermal management properties suitable for the high cylinder pressures associated with turbocharging. The block offers excellent thermal properties that suit the cylinder pressure and loads generated by a turbocharger system. To minimize weight, it features hollow-frame construction, making it about 20 percent lighter than a conventional casting.

Moving to the rotating assembly, the engine includes a robust crankshaft and forged components. Rotating Assembly: with a reinforced, solid-cast crankshaft, the 1.4L Turbo Ecotec offers strength and stiffness, particularly at higher rpm, to support the boosted cylinder pressure of the turbo system.

The connecting rods are forged steel, and the lightweight hypereutectic pistons come with reinforced crowns and specially designed ring packs. The connecting rods are forged steel and the lightweight, hypereutectic pistons are designed with a thicker crown area and a unique ring pack to withstand the boost pressure and heat generated by the turbo system.

Another innovation is the oiling system. Variable-Flow Oil Pump: the 1.4L Turbo Ecotec LUJ/LUV uses a unique variable-flow oiling system that helps maximize fuel efficiency.

This oil pump is crankshaft-driven and adjusts output according to engine load. Rather than the linear operation of a conventional fixed-flow pump, the LUJ/LUV uses a crankshaft-driven oil pump that matches the oil supply to the engine load. This prevents unnecessary energy loss by reducing oil flow when it’s not needed.

The engine’s turbo’s variable-flow pump changes its capacity based on the engine’s demand for oil, thereby preventing energy consumption to pump oil that is not required for proper engine operation.

The oil pan plays a structural role in this engine. Structural Oil Pan: an aluminum oil pan is designed as a key structural component of the engine, adding stiffness that helps improve vibration characteristics. This structural design enhances rigidity and helps improve NVH (noise, vibration, and harshness) behavior under load.

The cylinder head is also advanced. Cylinder Head: an aluminum cylinder head with dual-overhead camshafts and four valves per cylinder is used on the 1.4L Turbo Ecotec. Its intake ports are tuned for performance and combustion efficiency.

The head’s intake port design optimizes performance, efficiency and emissions by promoting greater charge motion of the intake air and a more complete burn of the air/fuel mixture. To handle elevated combustion temps, sodium-filled exhaust valves are used. Sodium-filled exhaust valves are designed for the higher combustion temperatures of the turbo system.

For valve control, the engine uses cam phasing tech. Variable Valve Timing: the dual-overhead camshaft arrangement of the engine employs dual, continuously variable cam phasing to adjust the opening and closing timing of the engine’s valves for optimal performance, fuel efficiency, and emissions across the rpm band.

This improves engine performance and efficiency across a wide rpm range and helps reduce emissions under various loads.

A standout component of the LUJ/LUV is its integrated turbo and exhaust system. Integrated Turbocharger And Exhaust Manifold: the 1.4L Turbo Ecotec LUJ/LUV uses a unique, integrated turbocharger and exhaust manifold. This integration reduces parts count, lowers weight, and enhances responsiveness.

The turbocharger size was chosen with an emphasis on low speed torque and throttle response. It also reduces under-hood temperatures and speeds up engine warm-up.

It requires fewer parts, is lighter than a conventional system, helps lower engine compartment temperatures and helps the engine warm up faster. For durability, the turbocharger is both oil-lubricated and liquid-cooled. The turbocharger is lubricated by engine oil and is liquid cooled for long-term reliability.

Finally, the engine’s thermal control is managed electronically. Electronically Controlled Thermostat: the coolant thermostat’s operating point is electronically controlled to optimize engine temperatures during different phases of operation to enhance fuel efficiency.

The system uses ECU-controlled mapping to adjust engine temperature based on a range of variables, from load to ambient temp. The engine control module monitors sensors and controls the thermostat based on mapping that takes into account the wide range of engine operating conditions, including temperature and load.

2. Fiat 1.4L MultiAir Turbo I4

Found in models like the Fiat 500 Abarth and Dodge Dart, the 1.4L MultiAir turbo engine is lively and fun to drive when it works but reliability is a serious concern.

The MultiAir system can suffer from oil starvation issues, electrical gremlins, and sensor failures. Once you’re past 70,000 miles, expect to spend time and money keeping it running properly.

The Fiat 1.4 Multiair Turbo engine has gained attention for its innovative design and performance capabilities. However, like any engine, it comes with its own set of challenges. Owners and mechanics alike have reported a range of issues that can arise, often leading to frustration and costly repairs. Understanding these problems is crucial for anyone considering this engine or currently facing difficulties with it.

From performance hiccups to unusual noises, the symptoms can vary widely. Some drivers may notice a decrease in power, while others might experience rough idling or stalling. These symptoms can indicate underlying issues that, if left unaddressed, could lead to more severe engine damage.

One of the most alarming symptoms is a noticeable loss of power. This can manifest in various ways, such as sluggish acceleration, difficulty maintaining speed on inclines, or an unresponsive throttle. When the engine struggles to deliver power, it can be frustrating for drivers who expect a peppy performance from a turbocharged engine.

Another common issue is rough idling. This condition can be characterized by inconsistent RPMs while the vehicle is stationary, vibrations felt through the steering wheel or seat, and engine stalling at stoplights or during low-speed maneuvers. Rough idling can be a sign of various problems, including issues with the fuel system or engine management.

3. MINI/BMW 1.6L Turbocharged I4 (N14)

This engine powers early MINI Cooper S models and has earned a poor reputation for long-term reliability. Issues include timing chain tensioner failures, carbon build-up on intake valves, and water pump problems.

While it’s responsive and fun in its prime, the cost of ownership skyrockets as mileage adds up, making it a small engine best avoided if longevity matters.

The N14B16A is a compact yet powerful engine that has made a significant mark in the automotive industry, particularly among enthusiasts of small cars. This 1.6-liter four-cylinder engine is part of BMW’s Mini lineup, renowned for its spirited performance and engaging driving experience.

With its turbocharged design, the N14B16A strikes a balance between efficiency and power, making it a popular choice for drivers seeking a dynamic ride without compromising on fuel economy. At the heart of this engine’s appeal is its lightweight construction and responsive nature. T

he turbocharger enhances its performance, allowing the engine to deliver impressive torque and horsepower figures that defy its small displacement. This makes it suitable for various driving conditions, from urban commuting to spirited country drives. The N14B16A is engineered to provide a fun and engaging driving experience, a hallmark of the Mini brand.

4. Hyundai/Kia 1.6L Gamma GDI I4

While not a bad engine in terms of performance, the Gamma 1.6L GDI used in the Hyundai Accent, Veloster, and Kia Rio has been plagued by durability issues in earlier model years.

Owners report problems with piston slap, excessive oil consumption, and even engine knocking. Later models are somewhat improved, but the early ones often need major repairs well before reaching 100K miles.

The 1.6L version of the Gamma engine family includes several variants—G4FA, G4FC, G4FD, G4FG, and G4FJ. The first of Hyundai’s 1.6L Gamma engines was the G4FC, a 1.6-liter four-cylinder gasoline engine with multi-point fuel injection introduced in 2007.

It quickly became a common engine option in Hyundai’s and KIA’s compact sedans and hatchbacks, including models like the Hyundai Accent, Elantra, and KIA Rio and Ceed. The 1.6 MPI G4FC is derived from a smaller 1.4-liter engine in the same family, the G4FA.

The increased 1.6L displacement was achieved by installing a new crankshaft with a longer stroke (increased from 75 mm to 84.5 mm). The 1.6L engine features longer connecting rods and unique pistons, as the compression height differs from that of the 1.4L engine’s pistons. T

he G4FC is entirely aluminum, with an aluminum open-deck cylinder block and a 16-valve, double overhead camshaft (DOHC) aluminum cylinder head. It is equipped with a continuously variable valve timing system, known as CVVT, which adjusts the intake timing only.

The camshafts are chain-driven, and unlike more modern engines, there are no hydraulic cam followers, meaning valve clearance adjustment is necessary every 60,000 miles or 100,000 kilometers. The fixed geometry intake manifold is made of lightweight, cost-effective composite material.

Fuel is delivered via a multi-point fuel injection (MPI) system controlled electronically. As you can see, the G4FC is a straightforward engine by modern standards.

5. Ford 1.6L EcoBoost I4

This turbocharged four-cylinder was used in vehicles like the Escape and Fusion but quickly gained a reputation for cooling system flaws.

Cracked heads, overheating, and coolant intrusion into the cylinders are common complaints.

Despite decent performance numbers, the 1.6L EcoBoost doesn’t age gracefully and has been involved in multiple recalls, making it a cautionary tale in small engine reliability.

The 1.6-liter engine, recognized for its compact design and efficient performance, has firmly established itself as a core component in the Hyundai and KIA vehicle lineup. As a member of the G4CR family, it is praised for offering a well-balanced combination of power and fuel efficiency, making it a highly appealing choice across various models.

Designed with urban mobility and everyday commuting in mind, this engine provides a practical yet engaging driving experience that appeals to a diverse spectrum of drivers.

One of its most notable qualities is the ability to deliver responsive performance while maintaining impressive fuel economy. It incorporates contemporary engineering solutions, including a multi-point fuel injection system, which precisely manages the air-fuel mixture to maximize combustion efficiency.

This results in smoother driving, reduced emissions, and overall better alignment with the growing consumer demand for eco-conscious automotive solutions.

Small engines can be engineering marvels or maintenance nightmares, depending on design, build quality, and usage.

The best ones deliver robust performance and longevity in a compact package proving that size isn’t everything. But others, while promising on paper, fall apart with age, leaving owners with hefty repair bills.

When shopping for a vehicle with a small engine, it pays to do your research not just on horsepower, but on long-term reliability and known weak points.