There’s something timeless about the rumble of a classic engine — the raw mechanical soul that modern powertrains just can’t replicate. Whether you’re a die-hard enthusiast wrenching on your ’70s project car or someone who just appreciates old-school engineering, classic car engines are more than just relics of a bygone era.

Some of them have proven to be bulletproof over decades, outlasting trends, tech upgrades, and entire brands. These are the engines that keep firing up with just a twist of the key, reminding us that durability doesn’t have to come with a digital display or drive-by-wire system.

But not every vintage powerplant deserves a second chance. For every mechanical masterpiece, there’s a notorious engine that’s better left in the junkyard — the ones with chronic overheating issues, flawed internals, or design decisions so bad they’ve become cautionary tales in automotive history.

These are the engines that even restoration die-hards hesitate to touch, not because they lack character, but because they lack reliability, parts support, or basic sanity.

In this article, we’re diving into both sides of the coin. First, we’ll celebrate five classic car engines that are still turning over strong, even decades later — engines that have earned their reputation for longevity and dependability.

Then, we’ll take a hard look at five you should avoid at all costs, no matter how good the car looks sitting in your garage. If you’re thinking about buying, restoring, or even starting one of these old beasts, read this first.

Classic Car Engines Still Running Strong

Others, though, are best left untouched plagued by poor engineering, unreliable components, or unforgiving maintenance demands.

Here’s a detailed breakdown of five classic car engines that still run strong and five that are better left dormant.

1. Chevrolet 350 Small Block V8

Introduced in 1967, the Chevy 350 is the gold standard for American small-block engines. Known for its simplicity, reliability, and near-infinite aftermarket support, this engine still powers countless hot rods, pickup trucks, and daily drivers.

Its cast-iron construction and hydraulic lifters help it endure decades of abuse, and it’s not uncommon to find well-maintained examples with over 300,000 miles.

The 350’s parts are cheap and widely available, making it one of the most rebuild-friendly engines ever produced.

The Chevy 350 V8 engine is a legendary powerhouse that has cemented its place in automotive history over several decades. Renowned for its durability, reliability, and robust performance, this engine remains a favorite among car enthusiasts and mechanics alike.

In this article, we’ll explore the in-depth specifications of the Chevy 350 V8 engine, including its configuration, oil requirements, and recommended service intervals.

As part of the Gen I family of engines, the Chevy 350 V8 is classified as a small-block engine with a displacement of 5.7 liters—or 350 cubic inches, which gives it its name.

It features a V8 configuration, meaning it has eight cylinders arranged in a V-shape. Each cylinder is built with a bore of 4.00 inches and a stroke of 3.48 inches. This design is known for delivering excellent power and torque, making it well-suited for a broad range of automotive applications.

Maintaining the Chevy 350 V8 engine in peak condition requires the use of proper engine oil. A high-quality multi-viscosity engine oil is essential. Typically, a viscosity rating of 10W-30 or 10W-40 is recommended for most driving conditions.

However, variations in climate and operating demands may call for adjustments in oil viscosity. To avoid missteps, always refer to the owner’s manual or seek professional guidance for specific oil recommendations.

Oil capacity for the Chevy 350 V8 can vary depending on the particular model and production year. Generally, the engine holds between 5 to 6 quarts of oil, including the oil filter. Regular oil level checks are critical to ensuring it stays within the appropriate range and helps preserve long-term performance.

When performing an oil change, it is equally important to replace the oil filter. The Chevy 350 V8 typically utilizes a standard spin-on oil filter, but it’s essential to select one that aligns with the manufacturer’s specifications to ensure compatibility and effective filtration.

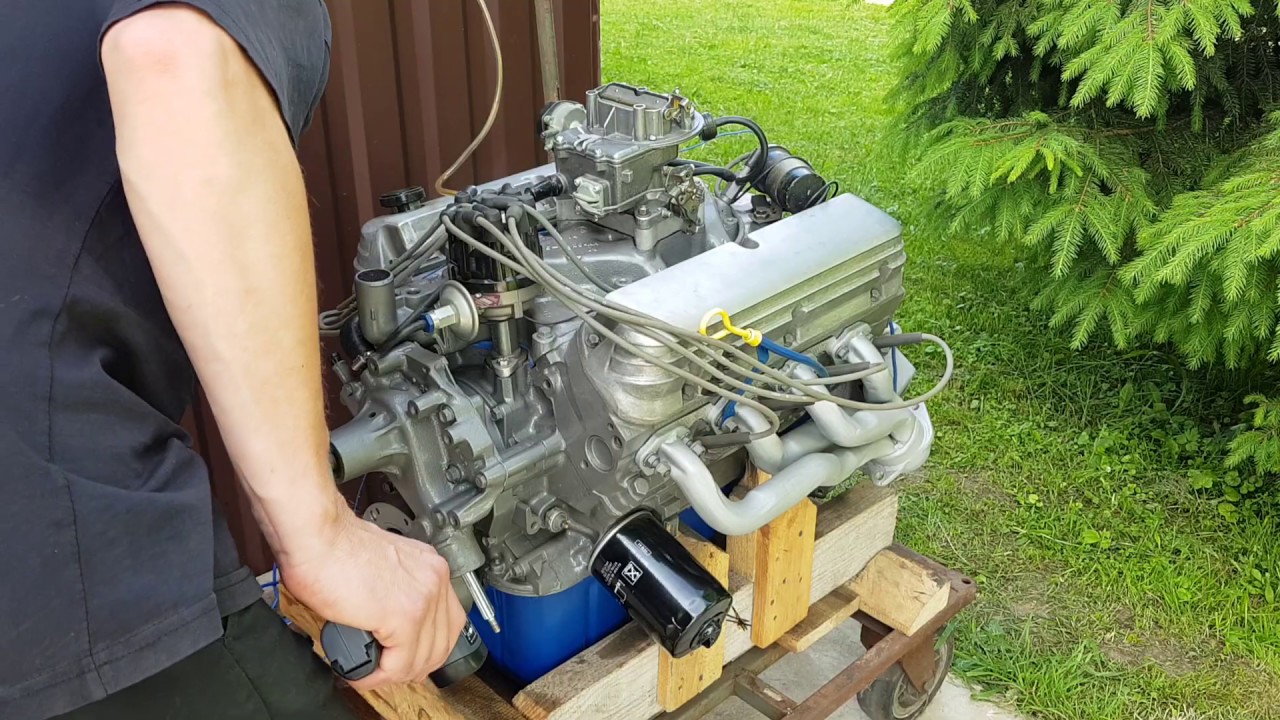

2. Ford 302 Windsor V8

First appearing in 1968, the 302 Windsor V8 became a legend under the hoods of Mustangs, Broncos, and F-Series trucks.

It offered a solid balance between performance and durability, making it ideal for both muscle car enthusiasts and utility drivers.

With proper maintenance, this small-block can last for hundreds of thousands of miles. Its adaptability and easy-to-service nature have made it a staple in the classic car community.

The Ford 302 is known for being compact, lightweight, and adaptable—qualities that make it a go-to choice for both restoration projects and high-performance builds.

Technically, it’s a 90-degree OHV V8 with a displacement of 302 cubic inches (5.0 liters), a bore and stroke of 4.00 inches by 3.00 inches, and a compression ratio that ranges between 8.0:1 and 9.5:1 depending on the year and model.

Weighing in around 460 to 475 lbs with iron heads and intake, it’s relatively manageable, and the firing order differs slightly between versions: early models (pre-HO) used 1-5-4-2-6-3-7-8, while HO versions from 1982–1995 used 1-3-7-2-6-5-4-8.

The valvetrain evolved from flat tappet cams in early models to roller camshafts in the HO variants, and cylinder heads improved over time as well—from small-valve cast iron heads to better-flowing, larger-valve units in the HO versions.

Power output varied by generation. Early versions made between 140 and 200 horsepower, while factory HO models could reach up to 225 horsepower.

Torque output ranged from 240 to 300 lb-ft, making the engine suitable for a variety of driving needs. Fuel delivery systems evolved too, with earlier models using two-barrel (and occasionally four-barrel) carburetors, and later versions receiving electronic fuel injection.

It runs on regular unleaded gasoline. In terms of size, the engine measures approximately 27 inches in length, 29 inches in width, and 27 inches in height, with a dry weight of around 450 pounds.

The ignition system relies on a distributor-based setup, with a spark plug gap of approximately 0.044 inches, though this may vary slightly by year. Cooling is water-based, typically handled by a mechanical fan, although some later models use electric fans.

Oil capacity comes in at roughly 5 quarts with filter change, and the recommended oil type is SAE 10W-30, though this can vary with climate. Additional engine features include an overhead valve (OHV) configuration, two valves per cylinder, a timing chain-driven camshaft, and either a cast iron or forged steel crankshaft depending on the specific version and performance package.

All of these specs make the Ford 302 incredibly versatile. It performs well across various applications, whether for street driving, towing, or competitive use. One of the engine’s greatest strengths is its tuning potential.

Thanks to an enormous aftermarket, the 302 can be transformed into just about anything—from a reliable 350-horsepower daily driver to a high-revving 500+ horsepower monster, depending on how deep you’re willing to go with modifications.

The 302’s broad torque curve makes it ideal for street use, delivering usable power across the RPM range. In heavier vehicles like trucks, that early torque offers great acceleration and towing ability.

Its lightweight construction also preserves handling characteristics, particularly beneficial in lighter cars. Though it’s not known for modern fuel efficiency, the transition to fuel injection in the 1980s made it more reasonable for everyday use compared to its carbureted predecessors.

When deciding between the Ford 302 and its bigger sibling, the 351 Windsor, engine builders often consider the intended purpose of the build. While both belong to the Windsor family, they each offer distinct advantages.

The 302, with its 302 cubic inches of displacement, is favored for its compact size and wide application versatility. It fits easily into most engine bays and is popular for both swaps and restorations. Achieving high horsepower numbers may require more extensive upgrades—such as a stroker kit—but it’s more than capable with the right setup.

On the other hand, the 351 Windsor starts off with 351 cubic inches of displacement, offering more torque and power right out of the box. That extra muscle makes it ideal for those seeking high horsepower with less effort. However, it’s physically larger, and its extra bulk can pose a tight fit in some vehicles.

When it comes to weight, the 302 tips the scales at around 450 lbs, giving it a distinct advantage in terms of handling—particularly in lighter vehicles like Mustangs.

The 351 Windsor, weighing in at approximately 525 lbs, adds more front-end load, which isn’t usually a problem for trucks or bigger cars, but could be a downside for performance-focused street builds. Interestingly, the 351 Windsor shares the same firing order as the HO version of the 302 (1-3-7-2-6-5-4-8), which simplifies tuning and parts compatibility for those upgrading from a 302 HO setup.

Aftermarket support is another area where both engines shine, though the 302 has a slight edge due to its longer production life and massive popularity. Parts are plentiful and often more affordable. The 351 is also well-supported, but some components can be more specialized and expensive due to its lower production volume and fewer vehicle applications.

As for application suitability, the 302 is the better option when weight and space are concerns—ideal for street cars, smaller trucks, and balance-oriented builds.

It strikes a nice equilibrium between power, reliability, and efficiency. Meanwhile, the 351 Windsor is built for big torque and high-horsepower demands, making it better suited for drag racing, off-roading, or heavy-duty applications where pure muscle is the goal.

In conclusion, if you’re building a street machine or restoring a lightweight vehicle where handling and packaging matter, the 302 is often the smarter pick. It’s easier to work with, easier to find parts for, and more than capable of serious performance when built right.

However, if your goal is raw power—especially in a larger vehicle or performance build—the 351 Windsor offers a stronger base with more displacement and torque from the start. Either way, both engines have earned their stripes and remain two of the best small-block V8s ever to come out of Detroit.

3. Chrysler Slant-6 (225 cu in)

The Chrysler Slant-6, especially the 225-cubic-inch version, is one of the toughest straight-six engines ever built.

Launched in 1960, the engine was tilted 30 degrees to the right, lowering the car’s center of gravity and allowing for a longer intake manifold.

It’s not a speed demon, but it’s practically unkillable. Taxi fleets, postal vehicles, and commuters kept these engines running well into the modern era with little more than oil changes and timing adjustments.

The evolution of automotive engine technology is a journey marked by innovation, adaptation, and countless milestones—from the humble beginnings of the single-cylinder gas engine that powered the Patent Motorwagen in the late 19th century, to the cutting-edge 500-plus horsepower electric motor featured in the 2022 Porsche Taycan GTS.

By the 1960s, Chrysler had cemented its place in the American muscle car scene, rolling out legendary street machines like the Plymouth Roadrunner and Barracuda, the Chrysler 300, and the Dodge Challenger—cars built to dominate the pavement with raw power and aggressive styling.

Amid these high-octane offerings, Chrysler also introduced its innovative slant six engine design. In 1960, the 170 cubic inch version debuted in the compact Plymouth Valiant, while a larger 225 cubic inch variant was used in bigger models, bringing dependable, efficient performance to the brand’s more utilitarian lineup.

4. Mercedes-Benz M110 Inline-6

Built from the early ’70s through the mid-1980s, the Mercedes-Benz M110 DOHC inline-6 was ahead of its time. Used in models like the W123 and early S-Class cars, it offered smooth performance and longevity when maintained properly.

These engines are known for easily reaching 300,000+ miles, and their mechanical fuel injection systems (on earlier variants) are highly regarded for their consistency.

The M110 is an excellent example of German overengineering paying off in the long term. The M110 engine family, developed by Mercedes-Benz during the 1970s and 1980s, features a DOHC (double overhead cam) layout with two valves per cylinder in a straight-6 configuration.

This engine line was engineered for both performance and durability, representing a key part of Mercedes-Benz’s powertrain evolution during that era. Within the M110 range, the M110.92x and M110.93x variants were carbureted models, utilizing either Solex or Pierburg carburetors, while the M110.98x and M110.99x versions were equipped with fuel injection systems.

The fuel-injected models initially used Bosch’s D-Jetronic system up to the .983 version, after which the .984 and subsequent engines transitioned to the Bosch K-Jetronic system.

All M110 engines share a common displacement of 2.8 liters (2746 cc or 170.8 cubic inches), with bore and stroke measurements of 86 mm and 78.8 mm respectively. The firing order for these engines is 1-5-3-6-2-4. The cooling system capacity was 11 liters in models produced in the 1970s, which increased slightly to 12 liters in those manufactured from the 1980s onward.

The engines required 6 liters of oil, and lubrication was provided via a pressure circulation lubrication system. Each cylinder was fitted with one intake and one exhaust valve in a V-shaped overhead configuration, operated by two top-mounted camshafts. The camshaft drive relied on a durable duplex roller-type chain.

Eventually, the M110.92x and .93x carbureted engines were phased out and replaced by the single overhead cam (SOHC) 2.6-liter M103 engine. Similarly, the M110.98x and .99x fuel-injected variants were succeeded by the more advanced 3.0-liter M103 engine beginning in 1986.

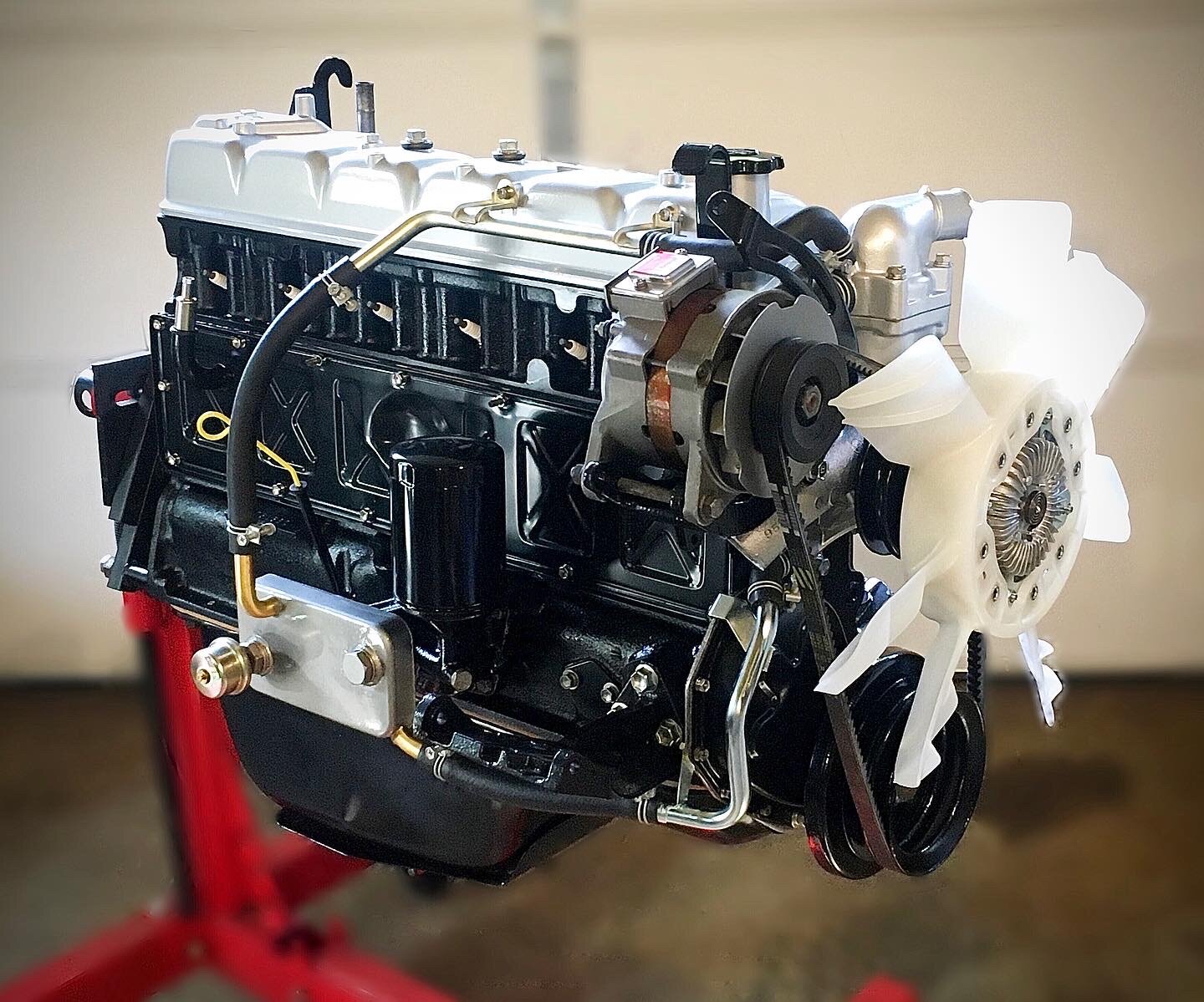

5. Toyota 2F Inline-6

Toyota’s 2F engine, found in the rugged Land Cruiser FJ40 and FJ60 from the mid-’70s to late ’80s, is an absolute tank.

It wasn’t fast, but it was engineered for endurance in some of the harshest environments on Earth. Simple carburetion, thick cast-iron construction, and low compression made it almost immune to failure. Even today, many 2F engines are still powering off-road expeditions and working farms without issue.

Toyota initiated the development of its inline 6-cylinder F Series engine in December 1948, primarily by enlarging the bore of the earlier Type B engine.

Crucially, Toyota applied insights gained from its wartime development of the B Series, and the F engine was notably improved with the inclusion of lightweight alloy pistons and a more effective lubrication system compared to its predecessors.

The F Series engine made its debut in 1949, installed in the Toyota BM Truck chassis destined for export to the Brazilian market, where it was designated as the FM Truck.

By 1950, the FM Truck also became available in the domestic Japanese market. Although the F engine earned widespread recognition for powering the Land Cruiser, its use extended beyond that iconic vehicle. It was also fitted in various large commercial vehicles, including fire trucks and Toyota’s FQ15 trucks.

Classic Car Engines You Should Never Start

There’s a fine line between nostalgia and nightmare when it comes to classic car engines. Sure, vintage rides have undeniable charm — chrome-laced grilles, analog gauges, that unmistakable old-school vibe.

In this article, we’re pulling back the curtain on the worst offenders: classic car engines you should never — and we mean never — start.

Whether you’re shopping for a vintage project car, eyeing that barn find with rose-colored glasses, or just curious about the mechanical black sheep of automotive history, these are the powerplants that are better left untouched, unstarted, and in some cases, completely forgotten.

1. Cadillac V8-6-4 (L62)

On paper, Cadillac’s early attempt at fuel-saving cylinder deactivation in 1981 was innovative. In practice, the L62 V8-6-4 engine was a nightmare.

Its primitive ECU often failed to manage the cylinder switching properly, leading to rough running, poor reliability, and a cascade of drivability issues.

Mechanics at the time didn’t have the tools or experience to work on it, and even today, owners often disable the cylinder-deactivation feature just to keep the car running.

General Motors engineers teamed up with electronics supplier Eaton Corporation to develop a system that could deactivate engine cylinders and fire only as needed. While the concept seems almost routine today, at the time it felt as futuristic as something out of Star Wars.

An engine naturally requires all eight cylinders when you press hard on the throttle—whether merging onto a freeway, climbing a hill, or towing. But during low-demand situations, like highway cruising or slowly navigating a parking lot, running on all eight simply isn’t necessary.

That was the premise: to enable a computer to control whether two or four cylinders could shut down when it detected the engine was under little to no load. Imagine the fuel savings that could result from such a system.

Cadillac began this venture with a standard, off-the-shelf 368 cubic inch V8, internally known by its code name L61. This engine had already powered numerous Cadillac models.

Essentially, it was a smaller-bore version of the 425 ci V8 that had been in service since the mid-1970s. As a result, the engine’s architecture was well-established and had already proven its reliability across hundreds of thousands of vehicles.

2. Triumph Stag 3.0L V8

The British-designed 3.0L V8 in the Triumph Stag should have been a home run. Instead, it turned out to be one of the most temperamental engines of the classic era.

Overheating was constant due to poorly designed cooling systems and aluminum heads that warped easily.

Timing chain failures and oiling issues were also common. Many Stag owners eventually swapped in more reliable engines just to enjoy the car without constant worry.

The Triumph Stag had all the ingredients to be a global success. With its striking design by Michelotti, four-seat convertible layout, and V8 engine under the hood, it seemed destined to win hearts.

This was a car built for stylish family touring—with room for luggage—and it delivered a sonorous soundtrack alongside ample performance, courtesy of its torquey 3.0-liter engine.

However, as history shows, the Stag fell short of its potential. Its downfall stemmed from a combination of poor build quality and lackluster dealership support, which often failed to address the recurring issues that plagued owners during the warranty period.

A major contributor to the Stag’s woes was the inconsistent quality control during the manufacturing of its components. Compounding matters, the V8 engine was introduced without sufficient development, leading to a notoriously high failure rate in the early years.

Fortunately, times have changed. The majority of surviving Stags have undergone restorations that address the shortcomings of the original production. Today’s restorations are typically carried out with a level of care and precision that far exceeds what the factory once offered.

Many of the inherent design flaws have now been corrected through thoughtful engineering solutions. As a result, concerns about reliability are no longer justified. In fact, a properly restored Stag with a few well-chosen upgrades is now considered one of the most usable, affordable, and enjoyable classic cars you can own.

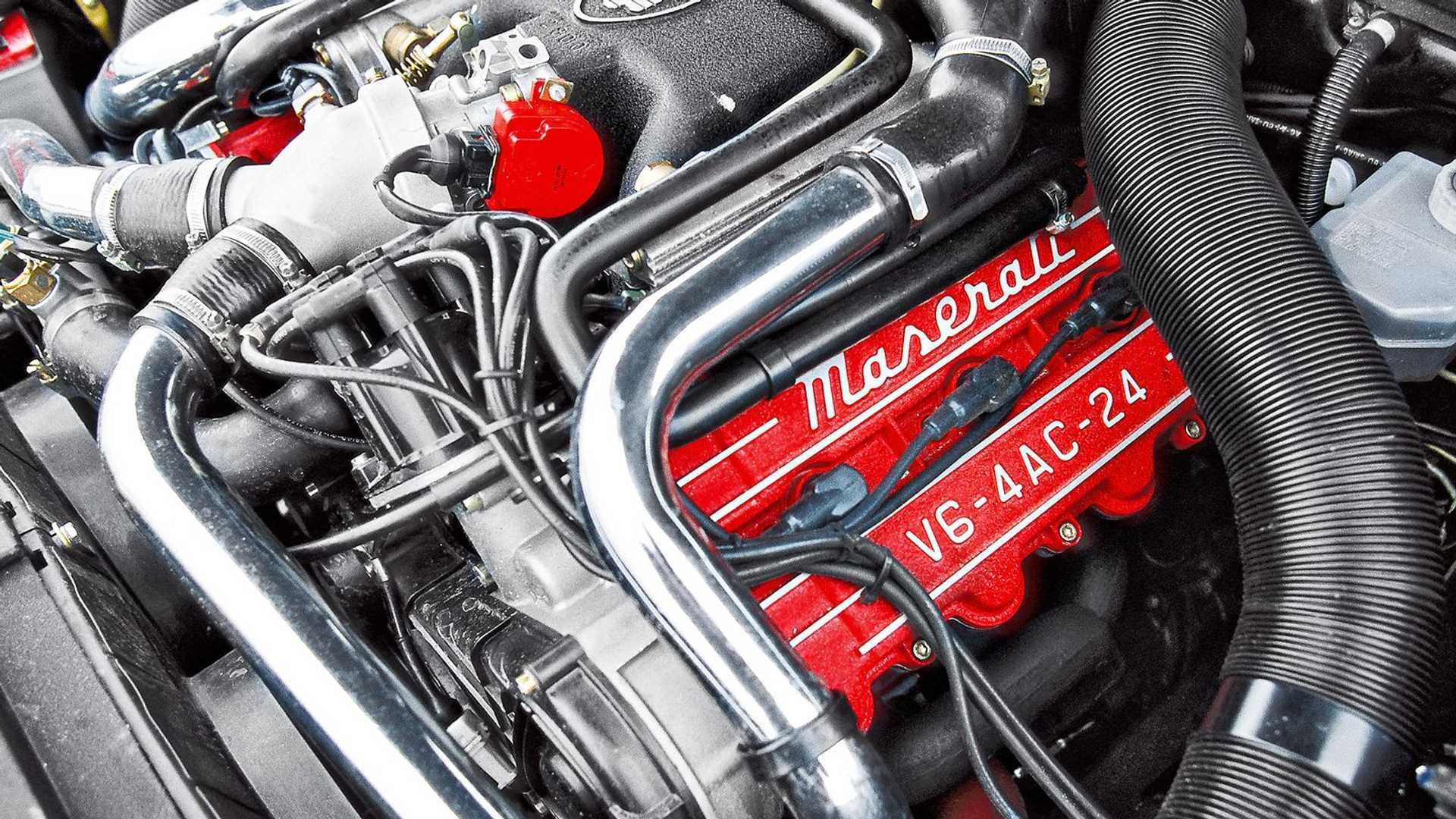

3. Maserati Biturbo V6

Maserati’s Biturbo V6, introduced in the early 1980s, was intended to revive the brand with twin-turbo excitement. Instead, it became infamous for catastrophic reliability.

Turbo lag, weak head gaskets, poor electrical systems, and cheap interior components made the Biturbo a cautionary tale. The engine’s short service life and complex design make it a nonstarter for most classic car buyers and restorers today.

Some cars are simply meant to be four-doors, and the Maserati 425 is one of them. Visually, the two-door Biturbo has always come across as awkwardly short and compressed, almost as if the designer ran out of space on the drafting board.

In contrast, the 425 offers more balanced proportions that look just right. While it might not represent cutting-edge styling in the same vein as the Audi 5000 or Ford Taurus, the 425’s exterior design remains hard to fault.

he bodywork is sharp and refined—think of it like a tailored Italian business suit, devoid of unnecessary embellishment or excess. In a time when much of the automotive world is embracing rounded, organic forms, Maserati is holding firm to its folded-paper aesthetic. As noted, it’s a design that stands apart from the crowd.

The 425’s interior also bucks the prevailing trends. While most manufacturers chase the clean, utilitarian look of German-inspired design, Maserati takes a different route by enveloping the cabin in luxurious hand-stitched leather.

Sitting inside feels more like sinking into a well-worn catcher’s mitt—plush and inviting. The craftsmanship, as well as the fit and finish, are of exceptional quality. Though the seats lack aggressive side bolsters, they offer a high level of comfort.

The driver’s seat features full six-way power adjustment, while the passenger seat comes equipped with power rake adjustment and manual fore-and-aft movement. Those in the rear aren’t left out either, enjoying generous legroom and headroom along with the added convenience of a fold-down center armrest.

4. Vega 2.3L Aluminum I4

Chevrolet’s Vega 2.3L engine was revolutionary for using a sleeveless aluminum block. Unfortunately, it also had a catastrophic tendency to overheat, warp, and seize.

Poor coolant flow and weak cylinder heads plagued the engine, especially when paired with 1970s-era emissions controls. Many Vegas ended up in junkyards well before 100,000 miles, and survivors today are often running completely different powertrains.

The 140-cubic inch Vega engine is a completely original design, purpose-built for Chevrolet’s new compact car. The goals set for the engine from the start were solid performance, respectable fuel economy, strong reliability, and straightforward maintenance.

While the engine’s design stands apart from other American production engines of the time, the aluminum Vega powerplant has earned a warm reception from buyers in the mini car market.

Several innovative engineering choices set this engine apart, most notably the use of a die-cast aluminum cylinder block featuring five main bearing bulkheads, a design that results in impressive structural strength. Complementing the block is a cast-iron overhead camshaft head.

The engine utilizes a long-stroke configuration, with a stroke length of 3.625 inches compared to a bore of 3.5 inches. Both the standard 90-horsepower and the optional 110-horsepower variants run a compression ratio of 8.00:1.

Chevrolet states that the installed engine delivers a net brake horsepower rating of 80 hp at 4400 rpm, and recent dynamometer testing conducted by Speedwin Automotive Engineering of Mineola, New York, has confirmed that this figure is accurate and not overstated.

5. Jaguar V12 (Pre-HE)

Jaguar’s pre-1981 V12 engines, found in the XJ12 and E-Type Series III, delivered smooth power but were plagued by overheating and vacuum line nightmares.

The engine bays were cramped, and the cooling systems simply couldn’t keep up with the heat generated.

Timing chain stretch, leaking gaskets, and hard-to-reach spark plugs made servicing a nightmare. Unless it’s been heavily modernized, this V12 is best admired from afar.

Not all classic engines are created equal. Some have proven they can stand the test of time with little more than regular maintenance, while others are infamous for stranding their owners or bankrupting restorers.

The Jaguar V12 engine was a V12 automobile engine developed and produced by Jaguar Cars. Though it drew partial inspiration from an earlier concept intended for a Le Mans race car—the Jaguar XJ13—it made its production debut in the Series 3 Jaguar E-type in 1971.

This V12 marked only the second engine design from Jaguar to reach production in the company’s history. Featuring an all-alloy engine block, it was equipped with removable wet liners and a single overhead camshaft (SOHC) alloy cylinder head.

The head had a flat mating surface with the block, while the combustion chamber was shaped into a shallow cup in the piston crown. It earned a reputation among some enthusiasts and experts as one of the standout powerplants of the 1970s and 1980s.

Design work on the V12 began as far back as 1954, originally aimed at powering a Le Mans race car. The concept was a 5.0-liter quad-cam engine with a high-revving character, sharing the basic structural design of the XK engine’s cylinder head.

When Jaguar later exited motorsport, the V12 project was shelved until 1963, when Jaguar acquired Coventry Climax. That acquisition brought back Walter Hassan—who had co-developed the XK engine with William Haynes at SS Cars Ltd—into Jaguar’s fold, along with engineers Harry Mundy and Claude Baily.

At that point, the V12 was revisited as a possible engine for Jaguar’s return to Le Mans. The design team thoroughly reworked the engine, resulting in an alloy block, dual overhead camshaft (DOHC) layout with fuel injection, which was then installed in the Jaguar XJ13 in 1966.

However, when plans for racing were suspended in 1967, the team considered adapting the engine for use in a production luxury car. The original quad-cam setup was ultimately deemed too complicated, heavy, and noisy for such an application.

In response, the racing-derived engine underwent significant revisions. The cylinder heads were replaced with a simpler, more conventional two-valve layout using SOHCs, where the camshaft operated vertically inclined valves via bucket tappets.

This redesign shared notable similarities with the contemporary Rover 2000 cylinder head, especially in the use of a flat head and dished “heron” pistons.

These updates simplified the engine, reducing its complexity, size, weight, and acoustic output. While the redesigned cylinder heads featured long and somewhat restrictive intake ports—diminishing high-end performance—they greatly improved mid- and low-range power. That trade-off was intentional, as the engine was intended for a large, heavy luxury sedan.

The change to chain-driven SOHC heads and the use of softer valve springs, intended to limit valvetrain noise, also led to a reduced redline of 6,500 rpm—down from the 8,000 rpm of the original quad-cam concept.

When the planned limousine project was ultimately cancelled, the engine was once again shelved, only to be revived a few years later for production use in the Series 3 E-type starting in 1971.

If you’re diving into the classic car world, knowing which engines can still roar and which should stay quiet can save you time, money, and a lot of frustration.

Whether you crave the rumble of a Chevy 350 or the unkillable pace of a Slant-6, choosing the right engine is the difference between a rolling legend and a driveway ornament.