The head gasket may be one of the smallest components in an engine, but when it fails, it spells big trouble. From overheating nightmares to complete engine failure, a blown head gasket is a repair most drivers dread—and for good reason.

Not only is it expensive, but it often means your engine has been compromised far beyond a simple fix. Thankfully, not all engines are plagued by this problem.

Some power plants have gained legendary status for their resilience, even after hundreds of thousands of miles. These engines laugh in the face of warped heads and combustion leaks.

On the flip side, some engines seem engineered to fail. Known for poor cooling system designs, thin gaskets, or aluminum heads mated to iron blocks, these motors are walking time bombs.

For car buyers looking for reliable vehicles or engine swap enthusiasts trying to avoid future headaches, knowing which engines are bulletproof and which are budget-busters is crucial.

In this blog, we dive deep into five engines famous for never blowing a head gasket and five that are infamous for blowing them frequently. If you care about engine reliability, long-term durability, and maintenance costs, read on—you might just save yourself thousands in repairs.

5 Engines Known for Zero Head Gasket Failures

These engines are the very definition of mechanical confidence. Built with solid engineering, durable gaskets, and excellent cooling systems, they’ve earned reputations as rock-solid performers.

Whether under the hood of a daily commuter or a rugged off-roader, these powerplants are known to run for hundreds of thousands of miles without ever needing a head gasket replacement. If you’re looking for a vehicle with an engine that never loses its cool, these five engines are your best bets for bulletproof reliability.

ALSO READ: 5 Engines That Easily Last 300,000 Miles Without Rebuild and 5 That Never Make It

1. Toyota 2UZ-FE 4.7L V8

The Toyota 2UZ-FE is a cast-iron V8 that defines what it means to be overbuilt. Originally found in the Land Cruiser, Sequoia, and Tundra, this engine was built for long-term abuse and off-road durability.

Thanks to its cast-iron block, aluminum heads, and conservative tuning, the 2UZ-FE delivers reliable power without stress. But what really sets it apart is its remarkable resistance to head gasket failure.

Unlike many aluminum engines that suffer from expansion and contraction issues, the 2UZ-FE’s cast iron block keeps everything stable. The head gasket design is simple and robust, mated with exceptional coolant flow.

Even after 300,000 miles, this engine typically shows no signs of gasket wear. The design avoids hotspots in the cylinder head, which are a common trigger for failure in other engines.

For those towing, off-roading, or just commuting, the 2UZ-FE is a loyal companion. Routine maintenance is all it demands. No blown gaskets, no overheating drama—just Toyota-grade toughness. You’ll find these engines still running strong in old Land Cruisers all over the world, from desert dunes to mountain passes.

If head gasket reliability is your top concern, this is a gold-standard V8 that simply doesn’t quit.

2. Honda K24

Honda’s K24 engine is the kind of powerplant that engineers brag about. Found in Accords, CR-Vs, and even the legendary Acura TSX, this four-cylinder is the poster child of daily driver reliability.

Moreover, with its all-aluminum construction and advanced engineering, you’d think it might be susceptible to thermal expansion issues—but that’s where Honda nailed the design.

The K24 features a multilayer steel (MLS) head gasket, which provides excellent sealing even under high-pressure conditions. Combined with a well-designed cooling system, the K24 doesn’t develop the hotspots that lead to head gasket failures in lesser engines.

Even when pushed hard—like in high-mileage delivery cars or modified Civics—these engines remain rock solid.

The gasket itself is thick and sandwiched tightly, with excellent bolt torque retention. That, along with smart ECU tuning and knock sensors, prevents overheating and detonation—two major causes of blown gaskets. If you’re a high-mileage driver or a DIY tuner, the K24 is a perfect blend of power and dependability.

Engines like the K24 remind us that good engineering can beat bad luck. It’s an engine you can trust to go the distance without ever giving you a head gasket headache.

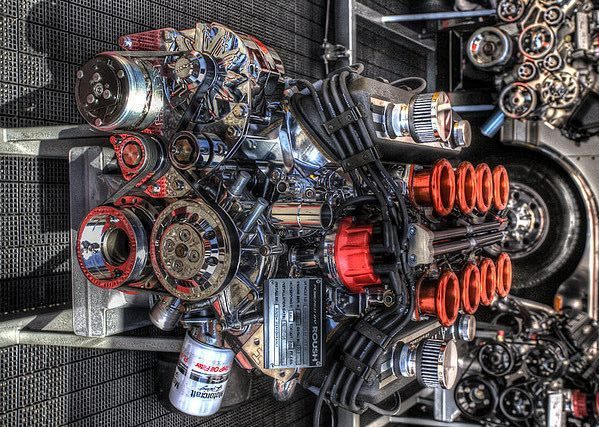

3. GM LS3 6.2L V8

The LS3 is a modern legend in GM’s LS engine lineup, praised for its robust design and high horsepower potential.

Found in the Chevrolet Corvette, Camaro SS, and a handful of other muscle machines, the LS3 is a beast, but it’s also incredibly well-built when it comes to gasket reliability.

This all-aluminum engine features cast heads and an advanced cooling system that keeps temperatures even across the cylinder banks.

The MLS head gaskets are thick, durable, and torqued down with precise clamping force, drastically reducing the chance of combustion leaks. Even with forced induction setups, the LS3 holds strong without blowing its top.

Unlike older GM small-blocks with composite gaskets that degrade over time, the LS3 was designed to handle modern demands.

It uses larger head bolts and improved clamping patterns to ensure proper sealing even after thousands of heat cycles. Many LS3s with over 200,000 miles have never had the heads off—something you rarely hear about performance engines.

Whether you’re running it stock or swapping it into a project car, the LS3 stands tall as one of the most gasket-resilient V8s ever built. If you want big power with small maintenance worries, this engine deserves a spot on your shortlist.

4. Mercedes-Benz OM617 Diesel

Old-school diesels are known for reliability, and none wears that badge prouder than the Mercedes-Benz OM617. Found in the W123 and W126 chassis, this inline-five diesel engine is the epitome of German overengineering.

Built like a tank, it can often run for over half a million miles—and it’s nearly immune to head gasket failures.

The OM617 features a cast-iron block and cast-iron head—an unusual combo in today’s aluminum-heavy engine world.

That material pairing virtually eliminates expansion differential, one of the main culprits in head gasket failure. Its indirect fuel injection also runs cooler than modern direct-injection diesels, reducing thermal stress.

Cooling passages are generous, and oil cooling is integrated, ensuring that heat is well-managed across the entire engine. Combined with thick head gaskets and proper torque specs, this diesel rarely sees top-end trouble. Even abusive neglect rarely fazes it.

It may not be fast or quiet, but the OM617 is a prime choice for those who value durability above all else. If head gasket reliability were a religion, the OM617 would be its prophet.

5. Ford 300 Inline-6

Known as the “Million Mile Motor,” the Ford 300 cubic-inch inline-six is a legend among truck enthusiasts, farmers, and anyone who just needs an engine that will never die.

Produced from the 1960s until the 1990s, this pushrod engine became synonymous with workhorse reliability, and part of that reputation comes from its bulletproof head gasket record.

The 300 I6 features a cast-iron block and head, simplifying thermal management. With only six cylinders spaced far apart in a straight line, the engine avoids the heat-concentrated design flaws of many V-configured engines.

The head gasket is large, thick, and clamped down by a solid row of head bolts—no multi-layer MLS trickery, just good old-fashioned strength.

Cooling is handled by a basic but effective water pump and radiator system. No fancy thermostats or risky designs—just reliable, consistent cooling across every cylinder.

Even under heavy towing loads or constant idle, these engines rarely overheat or warp the head.

Many 300s still run today in older F-Series trucks, proving that when you build something right the first time, you don’t have to fix it later. It may be simple, but this straight-six is nearly immune to the dreaded blown gasket blues.

5 Engines That Blow Head Gaskets Regularly

These engines are known for cooking themselves from the inside out. Weak gasket materials, flawed cooling systems, or poor engineering choices make them infamous for regular head gasket failures. If you own a car with one of these motors, your coolant system better be flawless—or you’ll be shopping for a tow truck. Below are five of the worst offenders when it comes to blown head gaskets, and why you should think twice before buying anything powered by them.

ALSO READ: 5 Vehicles With Legendary Oil Leak Resistance and 5 That Leak Like a Sieve

1. Subaru EJ25

The Subaru EJ25, especially the Phase I and early Phase II variants, is infamous for head gasket issues. While Subaru loyalists appreciate its boxer configuration and smooth power delivery, mechanics know it for one thing: repeated head gasket failures.

Models like the Outback, Forester, and Legacy from the late ’90s to early 2000s all suffered the consequences of poor gasket design and uneven cooling.

The engine’s horizontally opposed layout puts added thermal stress on the head gaskets due to uneven heat distribution between the two cylinder banks. In earlier models, Subaru used a single-layer graphite head gasket that was especially prone to failure.

Combine this with an aluminum block and heads, and you get a recipe for blown gaskets as the materials expand and contract at different rates.

Symptoms like coolant loss, oil mixing, and white exhaust smoke appear as early as 70,000 miles in some cases. Subaru later switched to a multi-layer steel gasket, but by then, the EJ25 had already earned its reputation.

Even with upgrades, overheating and repeat failures are still common if not religiously maintained.

If you’re eyeing a used Subaru from this era, make sure the head gaskets have already been replaced—or be ready to open your wallet. The EJ25 is one of the most notorious gasket-blowers in modern automotive history.

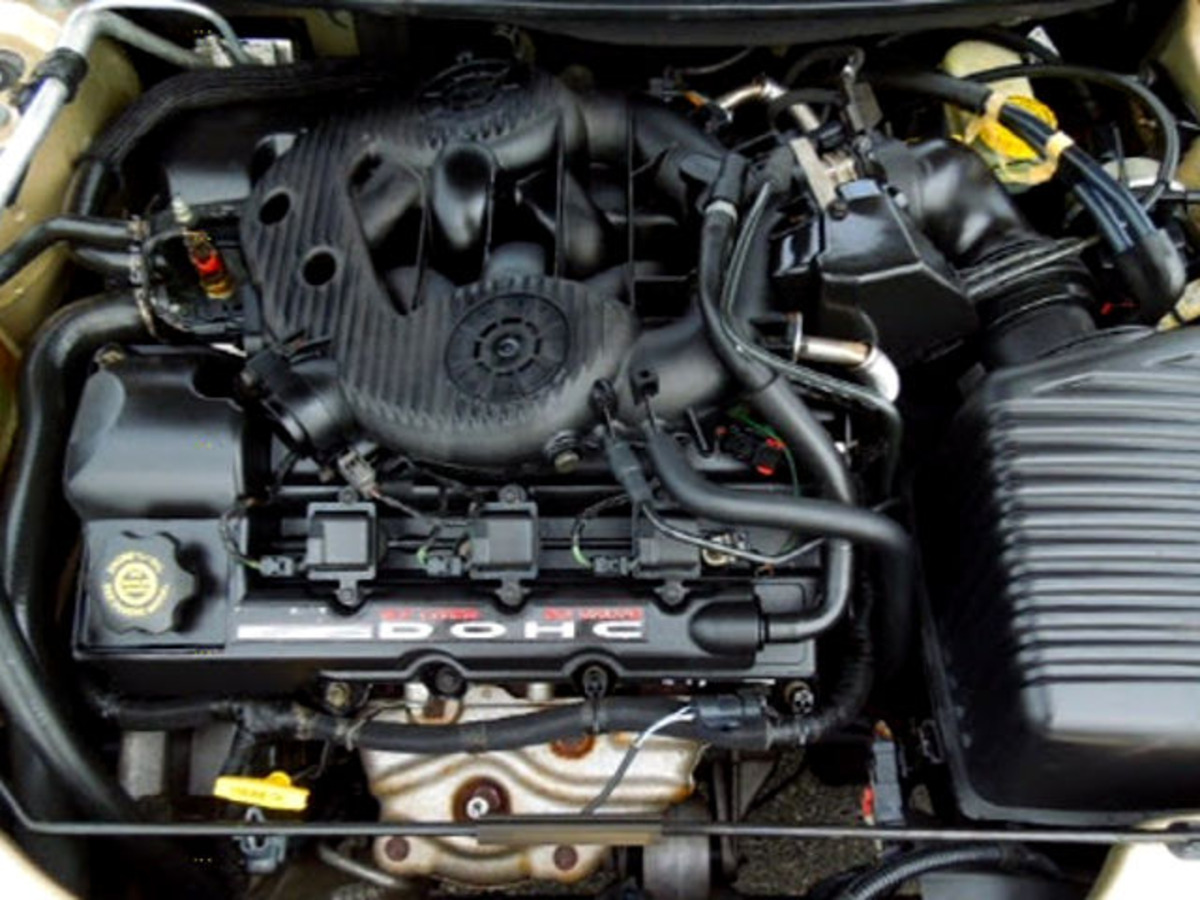

2. Northstar V8 (Cadillac 4.6L)

Cadillac’s Northstar V8 was supposed to be a high-tech marvel—DOHC, aluminum construction, and performance to rival the best.

Instead, it became known for one of the worst design flaws of any American engine: chronic head gasket failure. Used in models like the Cadillac DeVille, Seville, and Eldorado from the mid-1990s through the mid-2000s, this engine’s issues stem from a fatally flawed head bolt design.

Rather than threaded bolts deep into the block, GM opted for aluminum blocks with short-thread head bolts.

Over time, heat cycling and stress would cause these threads to pull out of the soft aluminum, leading to a complete loss of head gasket clamping force. Once that happened, you could expect coolant leaks, overheating, and complete failure to follow shortly.

To fix it correctly, many mechanics install “Time-Serts” to repair the threads—a job that costs thousands.

DIY head gasket swaps are discouraged due to the precision required to prevent repeat failure. Unfortunately, even engines that receive this treatment may not stay cured forever due to other thermal weaknesses in the design.

Despite its initial promise, the Northstar V8 became an expensive headache for owners. If gasket failure doesn’t get you, oil leaks or coolant seepage probably will. It’s a classic case of an ambitious design let down by poor execution.

3. Chrysler 2.7L V6

The Chrysler 2.7L V6, used extensively in early 2000s Dodge Intrepid, Chrysler Concorde, and Sebring models, is an engine that haunts used car buyers to this day.

On paper, it looked good: compact size, decent fuel economy, and reasonable horsepower. But in reality, it was a poorly executed design that combined multiple reliability issues, most notably, head gasket failure.

This engine suffers from poor internal oiling and sludge buildup, which affects cooling and lubrication.

Once internal sludge blocks key oil passages, the engine begins to overheat internally, warping the aluminum heads and compromising the head gasket. From there, coolant loss and cross-contamination are just a few miles away.

To make matters worse, the water pump is located inside the engine, driven by the timing chain.

If the water pump leaks, it dumps coolant into the crankcase, mixing with the oil and accelerating wear. This internal leak can easily lead to a head gasket failure or total engine destruction.

Even low-mileage examples have suffered catastrophic failures if maintenance wasn’t perfect. Chrysler attempted improvements later in the engine’s run, but by then, the 2.7L had developed a reputation as a disposable motor.

If you see this engine in a used car ad, run the other way. It’s a textbook case of what not to buy.

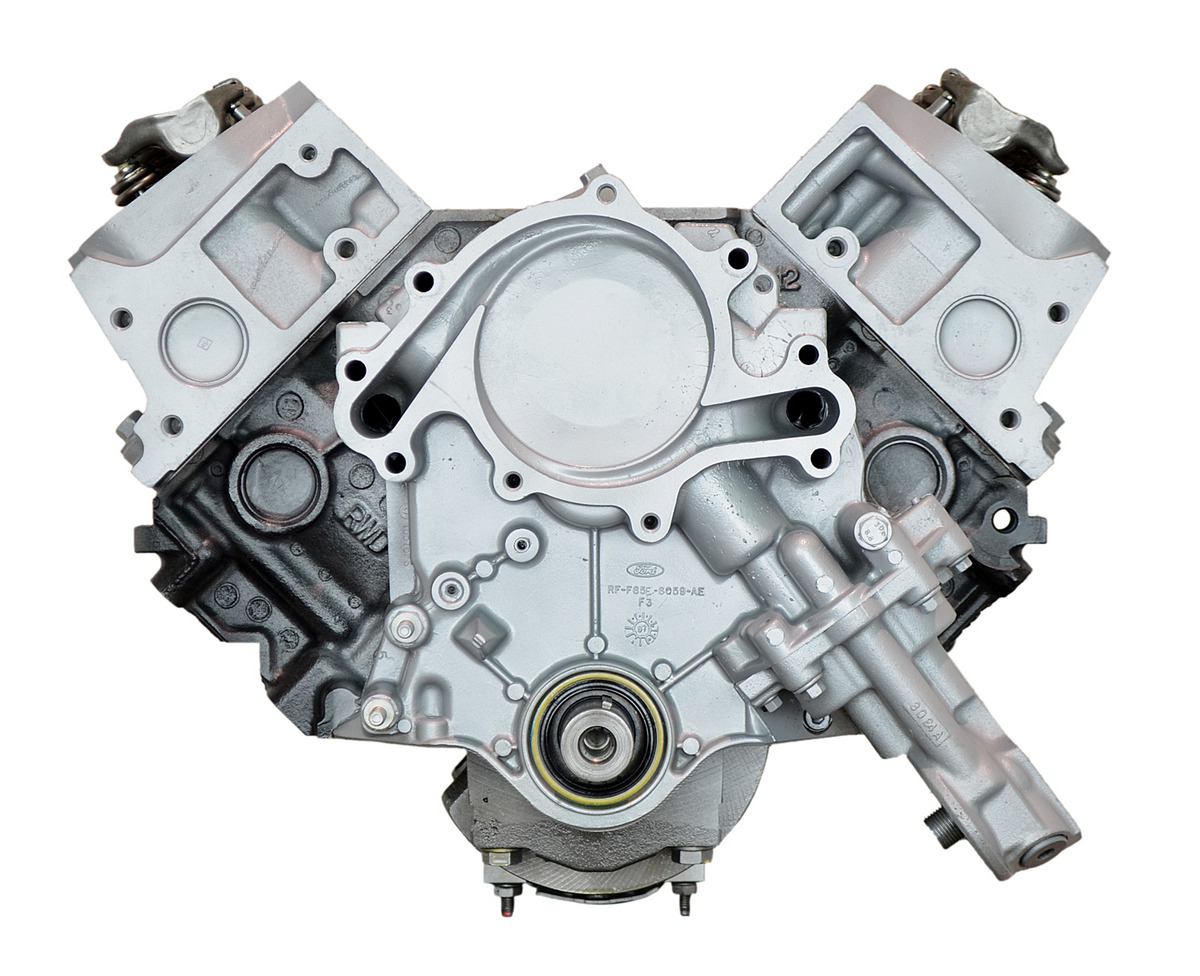

4. Ford 3.8L V6

Ford’s 3.8L V6, especially in vehicles from the late 1980s to the mid-1990s, became infamous for repeated head gasket failures.

Found in models like the Ford Taurus, Thunderbird, Windstar, and even the Mustang, this engine was plagued with overheating and sealing problems right off the assembly line.

One of the biggest issues was the mismatch between the cast iron block and aluminum cylinder heads. The differing expansion rates between the two materials led to repeated stress on the gasket.

As miles added up, the head gaskets would fail prematurely—sometimes as early as 60,000 miles.

Ford even issued recalls and extended warranties for head gasket repairs in some models, an unusual move that acknowledged just how widespread the problem had become.

While the engine itself was decently powerful for its time, its poor thermal management and weak gasket materials made it a ticking time bomb.

Later revisions of the engine were improved slightly, but many mechanics still refuse to touch them due to the engine bay layout and repeated issues. For buyers of older Fords, it’s often not a question of if the head gasket will fail, but when.

If you find one of these on the used market, assume the worst and walk away. There’s no bargain good enough to justify the risk.

5. Pontiac 2.4L Twin Cam

The 2.4L Twin Cam engine, also known as the LD9, was used in many GM compact cars during the late 1990s and early 2000s—including the Pontiac Sunfire, Grand Am, and Chevrolet Cavalier.

While it offered decent performance for its class, it’s most remembered for one thing: frequent and costly head gasket failures.

Unlike other engines, where failure results from aging, the LD9 could blow a gasket at surprisingly low mileage. A combination of poor coolant flow, soft aluminum heads, and thin gasket material created a trifecta of unreliability.

Once the engine overheats—which wasn’t uncommon due to weak thermostats and fragile water pumps—the head can warp and ruin the gasket seal.

To make matters worse, the intake manifold gaskets also had issues, which sometimes mimicked head gasket symptoms or led to further complications. Owners would often sink money into multiple coolant-related repairs before discovering the true culprit.

While some enthusiasts have found ways to bulletproof the engine, it’s far from a plug-and-play solution. For the average daily driver, the risk just isn’t worth it.

This engine is a perfect example of how even a compact, seemingly simple powerplant can lead to major repair bills. Unless it comes with documentation of a full engine rebuild, avoid the 2.4L LD9 if you value reliability.

Head gasket failures are more than just a nuisance—they can be the death knell for an otherwise decent engine. As we’ve seen, engine design, material choices, and cooling system efficiency all play major roles in determining whether a head gasket lasts 300,000 miles or blows up at 60,000.

The engines that earned a reputation for resilience—like the Toyota 2UZ-FE, Honda K24, or Ford 300—are the result of thoughtful engineering, simple designs, and robust gaskets that hold up under pressure.

On the other hand, engines like the Subaru EJ25 and Cadillac Northstar V8 are perfect examples of how poor decisions in metallurgy or bolt design can doom an otherwise promising powerplant.

Once the head gasket goes, the cost of repair often outweighs the car’s value, leaving owners frustrated and broke.

If you’re car shopping, engine swapping, or just curious about the long-term durability of what’s under your hood, make gasket reliability a priority. It’s not glamorous, but it’s the difference between a car that runs forever and one that spends its life in the shop.

So choose wisely—because when a head gasket blows, so might your budget.