Engines are the beating heart of any vehicle. Whether you’re a gearhead who obsesses over every valve and camshaft or just someone who wants their car to start every morning without a fuss, engine reliability is non-negotiable.

Some powerplants have earned legendary status for their bulletproof engineering and long-haul dependability, while others have become cautionary tales—plagued by misfires, blown head gaskets, oil consumption issues, or worse.

In today’s automotive landscape, where performance, fuel economy, and emissions standards are constantly clashing, building a reliable engine is harder than ever.

Yet, some manufacturers get it right—so right that their engines are known to rack up 200,000 miles with minimal maintenance. On the flip side, there are engines that leave drivers stranded, drain bank accounts, and haunt mechanics’ garages like recurring nightmares.

Engines That Never Misfire

This article breaks down the split: five engines that have proven themselves time and time again, and five that are notorious for letting their owners down. Whether you’re shopping for a used car, curious about what makes an engine trustworthy, or just here to see if your ride made the list (for better or worse), we’ve got you covered.

1. Toyota 2AR-FE (2.5L I4)

Used in: Toyota Camry, RAV4, Scion tC, Lexus ES 250

Why It Never Misfires:

This engine is a symbol of Toyota’s bulletproof engineering. The 2AR-FE uses a timing chain instead of a belt, has low compression stress, and is designed for durability.

Owners rarely report coil, plug, or injector failures typical culprits for misfires. Regular oil changes are often all it needs to last 250,000+ miles misfire-free.

The 2AR-FE engine was introduced in 2008 as the successor to the 2.4-liter 2AZ engine. While it delivers similar output to its predecessor, it does so with improved fuel efficiency. This balance was achieved through the use of advanced technologies during the engine’s development. Alongside the 2.5-liter variant, the manufacturer also produces the 2.7-liter 1AR-FE engine.

Much like the engine it replaced, the 2AR-FE features an aluminum cylinder block lined with thin cast iron sleeves. However, the block is non-serviceable—meaning the liners cannot be replaced or repaired.

Housed within the block is a forged steel crankshaft that is offset by 10 mm toward the exhaust side, a design known as an offset crankshaft. This crankshaft, featuring eight counterweights for complete balance, drives two balancer shafts through an internal gear mechanism, effectively reducing engine vibrations.

The most notable improvements are found in the cylinder head. Constructed from aluminum alloy, the DOHC 16-valve head now includes hydraulic lifters, which were absent in the 2AZ engine.

It uses two camshafts, each equipped with Dual-VVTi for variable valve timing. The valve train utilizes roller rockers to further improve efficiency. A variety of low-friction technologies were incorporated into the design, including reduced-tension piston rings and a three-stage variable oil pump.

Another key feature is the ACIS (Acoustic Control Induction System), a variable intake geometry system. This system uses a plastic intake manifold with valves that adjust the intake tract length in two stages, depending on engine speed and throttle position.

The fuel system was also upgraded with 12-hole long-nozzle fuel injectors to enhance fuel efficiency and reduce emissions. The intake assembly includes a stainless steel header and an integrated catalytic converter.

Also Read: Top 10 Most Reliable Used Cars You Can Buy for Under $10,000 in 2025

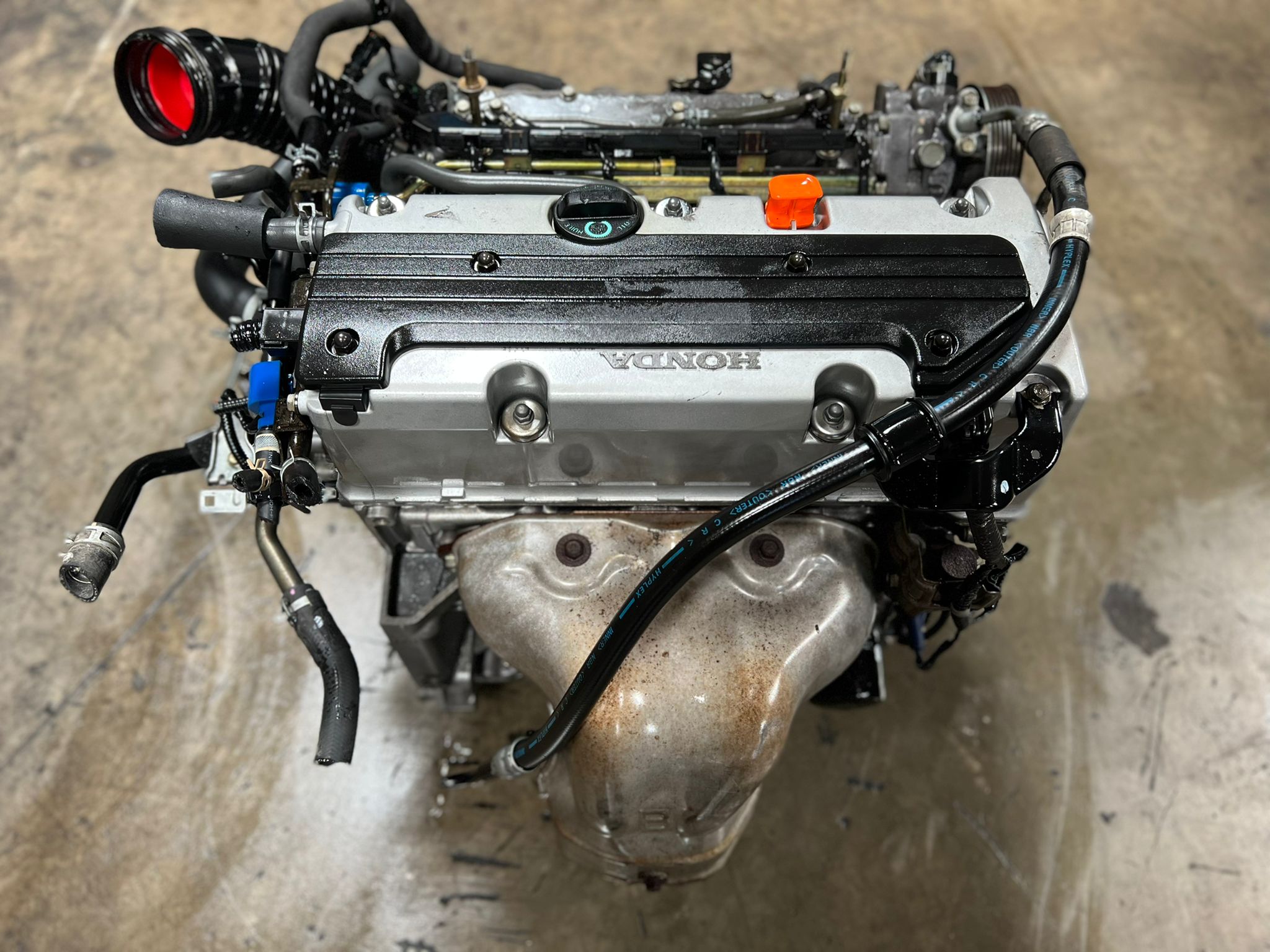

2. Honda K24 (2.4L I4)

Used in: Honda Accord, CR-V, Element, Acura TSX

Why It Never Misfires:

The K24 is lauded for its robust valvetrain, durable coil packs, and balanced combustion design. It handles high miles without losing compression or burning oil.

Its straightforward layout makes spark plug access and maintenance easy, reducing chances of buildup-related misfires.

The K24 is another notable engine in Honda’s K-series family. This 2.4-liter, four-cylinder gasoline engine made its debut in 2001 in the Honda CR-V as the K24A1 variant.

Its overall design mirrors that of the 2.0-liter K20, but with an increased bore and stroke, along with several modifications to accommodate the larger displacement. Honda introduced the K24 as a modern replacement for the older F23A engine.

Like its K-series sibling, the K24A features an aluminum cylinder block with cast iron cylinder liners. A redesigned crankshaft extended the stroke by 13 mm, while the bore diameter increased by 1 mm, resulting in a 200cc increase in total displacement.

The block height for the K24A measures 231.5 mm. To handle the added displacement, the engine uses different pistons and connecting rods, though the piston height remained unchanged.

The cylinder head design stayed largely the same—constructed from aluminum, it includes 16 valves (four per cylinder), dual overhead camshafts, centrally located spark plugs with coil-on-plug ignition, and the i-VTEC variable valve timing system.

The chain-driven intake and exhaust camshafts operate the valves via roller rocker arms, and there are no hydraulic tappets, which means regular valve clearance adjustments are required.

The base K24A1 version was manufactured from 2001 to 2006 and served as the foundation for the entire K24 series. This version featured i-VTEC on the intake camshaft only. The intake valve measured 35 mm in diameter, the exhaust valve 30 mm, and both had a valve stem diameter of 5.5 mm.

It utilized Honda’s 2-stage PPA intake manifold, made of aluminum and composite materials, along with a 60 mm throttle body. Fuel delivery came from an electronic multi-port injection system with 270 cc fuel injectors. Among all versions in the series, the K24A1 had the lowest compression ratio at 9.6:1.

Another mainstream variant in this engine lineup was the K24A4. This engine used different pistons and raised the compression ratio slightly to 9.7:1. Additional upgrades included revised intake and exhaust ports in the cylinder head, an aluminum 1-stage RAA intake manifold, and new i-VTEC calibration compared to the K24A1.

In 2006, the K24A4 received a minor refresh and was redesignated as the K24A8. This updated version came equipped with an electronic throttle body and an RTB intake manifold. Thanks to these changes, the engine was able to comply with more stringent emissions regulations.

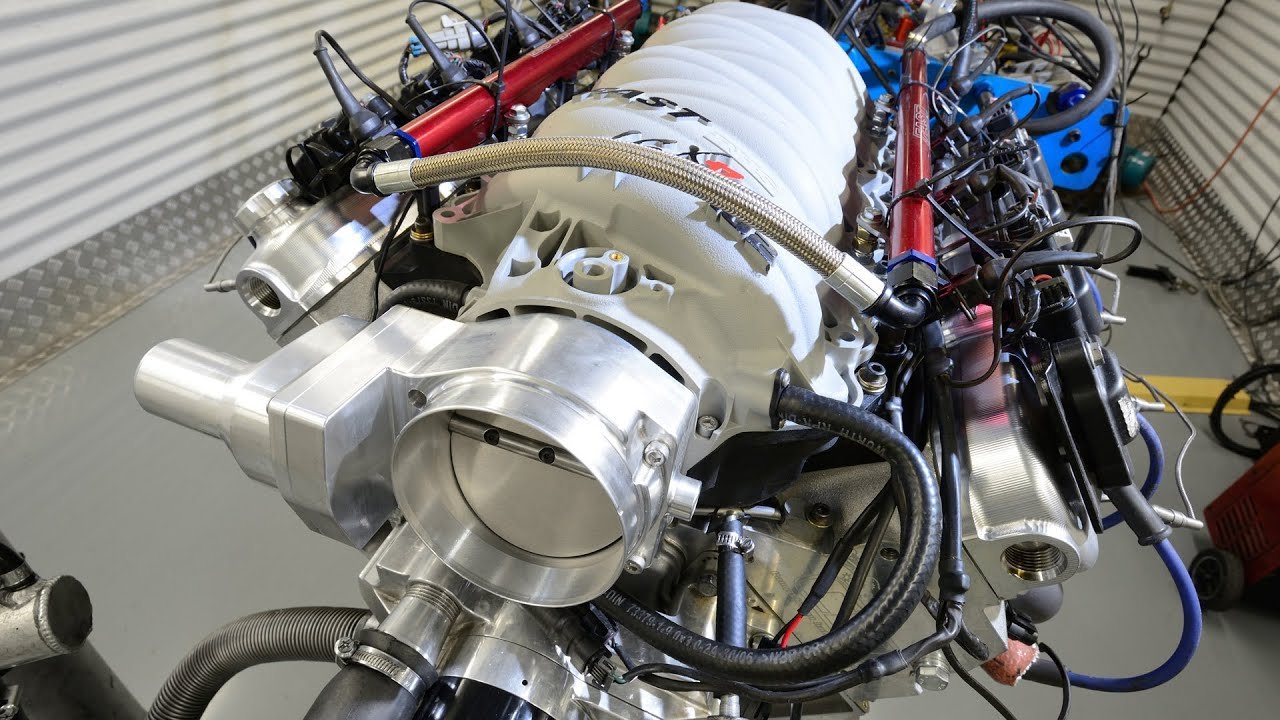

3. GM LS3 (6.2L V8)

Used in: Chevrolet Corvette, Camaro SS, Pontiac G8 GXP

Why It Never Misfires:

The LS3 combines performance with simplicity. Its pushrod design and strong ignition components hold up even under track use.

LS engines in general are known for reliability, but the LS3 stands out by rarely showing ignition issues even after years of abuse.

Chevrolet’s LS-series (short for “luxury sport”) stands as one of the most iconic and widely-used V8 engine families in automotive history, with a vast array of variants to choose from. Among them, the LS3 holds a particularly high status in terms of desirability, especially for enthusiasts seeking a capable daily driver.

It delivers an ideal mix of strength, longevity, and user-friendliness. With a displacement of 6.2 liters, the LS3 is slightly larger than the classic 5.7-liter (350-cubic inch) small block that served as a staple in GM’s lineup for more than 30 years.

Originally launched for the 2008 model year Corvette, the LS3 was rated at 430 horsepower and 424 pound-feet of torque. Buyers who opted for the available sport exhaust system gained an extra six horsepower, bringing the total to 436. T

hese figures were extremely impressive at the time and remain respectable today. The LS3-powered Corvette could sprint from 0 to 60 mph in just 4.0 seconds, completing the quarter-mile in 12.4 seconds.

To put that in perspective, this was faster than a 2008 Porsche 911, despite the Corvette costing nearly 50% less at the time. Beyond its Corvette application (2008–2013), the LS3 also found its way into other GM performance models, including the 2009–2015 Camaro SS and the 2015–2017 Holden-based SS Sedan.

The LS3 utilizes an aluminum engine block, which shaves off approximately 100 pounds when compared to the iron block versions found in earlier LS engines.

This weight reduction improves both acceleration and vehicle handling. While aluminum blocks are often thought to be less robust than iron ones, GM engineers addressed this by reinforcing the LS3’s block based on input gathered from racing teams.

The cylinder heads are also made from aluminum, and they feature rectangular intake and exhaust ports. These ports provide better airflow compared to the cathedral-shaped ports used in previous designs, contributing to the LS3’s enhanced performance capabilities.

Also Read: 5 SUVs With the Best Headlight Throw and 5 With Dark Spots

4. Ford 4.6L Modular V8 (2V version)

Used in: Ford Crown Victoria, Mustang GT (early 2000s), Lincoln Town Car

Why It Never Misfires:

Despite being a dated design, this engine is famously dependable. The 2-valve version avoids the spark plug ejection problems of the 3-valve models and boasts coil packs and plugs that can easily go 100k miles without incident.

Police and taxi fleets ran these engines for years with minimal ignition drama.

The Ford Windsor small-block V8 is widely regarded as one of the greatest V8 engine series of all time. Spanning a remarkable 40-year legacy, it found a home in some of the most iconic vehicles in Ford’s lineup — including the Mustang, Mercury Cougar, and even the legendary GT40.

Yet despite its proven performance and versatility, the Windsor was becoming outdated by the time the 1990s approached. Recognizing this, Ford developed an all-new V8 platform to supplement the aging design: the Modular engine series.

The Modular engine family derived its name from the innovative manufacturing process Ford implemented — one that used simplified, flexible tooling.

This allowed for multiple engine variants, differing in displacement and cylinder count, to be assembled on the same production lines with minimal reconfiguration. The result was a family of V8 and V10 engines ranging in size from 4.6 to 6.8 liters.

The first modular engine made its debut in 1991 under the hood of the Lincoln Town Car, sporting a 4.6-liter displacement. Departing from the Windsor’s traditional pushrod design, this new engine featured a single overhead camshaft and was introduced in its two-valve-per-cylinder format — commonly referred to as the 4.6L 2V.

As Ford refined the modular platform, it realized the key to unlocking more performance: increasing the number of valves per cylinder. In 1993, a four-valve version of the 4.6L V8 arrived, with two intake valves and two exhaust valves per cylinder.

Then in 2005, Ford introduced a three-valve 4.6L variant, which debuted in the S197 Mustang GT and remained in service across multiple vehicles through 2010. Over the course of its production run, the various iterations of the 4.6L modular V8 powered 13 different Ford models between 1991 and 2014.

5. Subaru EJ22 (2.2L H4 Non-Turbo)

Used in: Subaru Legacy, Impreza (1990s)

Why It Never Misfires:

While Subaru’s EJ25 had head gasket and misfire issues, the EJ22 was a rock-solid exception.

Its closed-deck design and conservative tuning meant consistent combustion and minimal plug fouling. With proper timing belt maintenance, misfires were practically nonexistent.

Subaru launched the EJ22 engine as a successor to its aging EA engine platform. Offered in both naturally aspirated and turbocharged versions, the EJ22 was featured in several models including the Subaru Impreza (1995–2001), Subaru Legacy (1990–1999), and Subaru Outback (1995–1996).

The EJ22E was developed by building on the experience gained from the EJ18 and EJ20 engines. This 2.2-liter Subaru engine brought with it modest improvements in both power output and long-term durability. Over the years, Subaru rolled out a series of updates to this engine, aiming to improve fuel efficiency and keep it compliant with evolving emissions regulations.

This article focuses specifically on one of its turbocharged variants: the EJ22T. Below, we’ll dive into the engine’s technical specifications, discuss its reliability, maintenance costs, and explore what it takes to swap this engine into another vehicle.

The EJ22E debuted as an open deck engine with an output of 130 horsepower and 137 lb-ft of torque. Constructed primarily from aluminum — including both the block and the heads — the EJ22 made use of cast-iron cylinder sleeves, SOHC aluminum heads, and belt-driven camshafts. It ran at a 9.5:1 compression ratio, which was fairly advanced for its time.

As Subaru refined the platform, they introduced new iterations of the EJ22E. The EJ221, EJ222, and EJ223 were Phase 2 variants released beginning in 1997. These upgrades raised power output to 142 horsepower and improved fuel economy by approximately 3%.

These improvements stemmed largely from reduced internal friction. Lighter Molybdenum-coated pistons, weighing 100 grams less, helped the EJ22 deliver a 10% boost in power while also improving longevity. The compression ratio was also nudged up to 9.7:1 for added efficiency and responsiveness.

That said, these were all naturally aspirated variants. Now imagine that same rugged EJ22E platform but with forced induction — that’s the EJ22T.

Nearly all of the internal components were retained in the turbocharged version, with one key difference: the pistons. To handle boost, the EJ22T used low-compression dished pistons, reducing the compression ratio to 8.1:1, compared to the EJ22E’s 9.5:1.

Engines That Can’t Go a Month Without Trouble

This article dives into the most infamous culprits: engines with a reputation for breakdowns, recalls, and relentless repairs. If you’re shopping used or wondering why your check engine light refuses to quit, this is the list you’ll want to study closely.

Let’s get into the worst offenders under the hood—engines that can’t go a month without causing trouble.

1. Chrysler 2.7L V6

Used in: Chrysler Sebring, Dodge Intrepid, Chrysler Concorde

Why It Misfires Constantly:

This engine is infamous for sludge buildup, oil starvation, and valvetrain failures. Misfires are often the first sign of catastrophic failure.

Coil pack issues, internal oil leaks, and cylinder washdown mean misfires can become a monthly if not weekly occurrence.

The Chrysler 2.7-liter engine has sparked plenty of debate among both car enthusiasts and everyday drivers, largely because of its well-documented reliability problems.

Found in a range of Chrysler vehicles including the Sebring and 300M, this engine comes with a reputation for developing issues that can cause serious frustration for owners. Having a solid understanding of the symptoms tied to these problems is essential for anyone operating a vehicle powered by this engine.

When dealing with the 2.7-liter engine, several red flags can signal that trouble is brewing. Spotting these symptoms early on can help you avoid more severe damage and reduce the potential repair bill.

Oil leaks are often one of the earliest indicators that the engine may be in trouble. This particular engine is well-known for oil leakage, especially around the timing chain cover and oil pan. If you’re noticing oil collecting where your vehicle is parked or if the oil level keeps dropping, you’ll want to investigate the source as soon as possible.

Overheating is another recurring issue with the 2.7-liter engine. Its cooling system is often inadequate, which can lead to higher-than-normal engine temperatures. If your temperature gauge is regularly creeping toward the red, or if you see steam coming from under the hood, it could indicate a failing water pump, clogged radiator, or another cooling system fault.

Misfires are yet another issue that owners of the 2.7-liter engine frequently report. When this happens, you may feel the vehicle hesitate, shake, or stutter during acceleration. This problem could be rooted in several causes, such as worn-out spark plugs, faulty ignition coils, or fuel delivery issues.

2. Ford 5.4L Triton V8 (3V version)

Used in: Ford F-150, Expedition, Lincoln Navigator

Why It Misfires Constantly:

Between the fragile spark plugs that break during removal, poor coil-on-plug reliability, and cam phaser issues, this engine is a misfire machine.

Owners frequently report cylinder-specific ignition problems, especially after 100,000 miles.

The Ford 5.4L V8 Triton engine is a gasoline-powered unit that was introduced in 1997 and remained in production until 2010. It was engineered for use in a variety of Ford vehicles, including full-size pickup trucks, vans, and SUVs.

As part of Ford’s modular engine family, the Triton was built with versatility and performance in mind. It features a cast-iron engine block paired with aluminum cylinder heads, and it utilizes a dual overhead camshaft (DOHC) design with four valves per cylinder.

One of the key advancements introduced with this engine was the coil-on-plug ignition system, which offered better spark control and reliability over traditional ignition setups.

Throughout its production run, the 5.4L Triton underwent several refinements aimed at enhancing performance and addressing known reliability issues. In 2004, Ford introduced a three-valve-per-cylinder configuration, which helped boost power output and reduce emissions.

This update marked a significant improvement in the engine’s design. However, despite its wide adoption and use in flagship models such as the F-Series trucks and the Expedition, the Triton was not without its problems.

Early versions of the engine developed a reputation for issues related to spark plug blowouts, timing chain tensioner failures, and excessive oil consumption. Ford tackled many of these problems through updates, service bulletins, and revised components over time.

Even with its flaws, the 5.4L Triton remains a popular choice among Ford truck and SUV enthusiasts. It offers a strong torque curve and respectable horsepower across a broad RPM range, making it well-suited for towing and heavy-duty applications. Its durability—especially in later model years—has earned it a place among Ford’s most recognized engines.

The engine was compatible with a variety of automatic transmissions, including 4-speed, 5-speed, and 6-speed units, and it supported a range of emissions control systems such as catalytic converters, positive crankcase ventilation, and exhaust gas recirculation.

Depending on the specific year and application, the engine produced between 260 to 365 horsepower at 4,500 to 5,500 rpm and delivered torque figures ranging from 350 to 460 lb-ft at 2,500 to 4,500 rpm. The compression ratio sat at 9.8:1, and it featured a bore and stroke of 3.55 inches by 4.16 inches.

The engine’s firing order is 1-3-7-2-6-5-4-8, and it operates with a hydraulic roller camshaft with 220 degrees of duration at 0.050″ lift and a lift of 0.500 inches on both intake and exhaust. The intake manifold was composite, and the engine used a 75mm throttle body and 24.5 lb/hr fuel injectors.

It had an oil capacity of 7 quarts, a coolant capacity of 21.2 quarts, and a maximum engine speed of 6,000 rpm. It ran on regular unleaded fuel and typically used 5W-20 or 5W-30 synthetic oil.

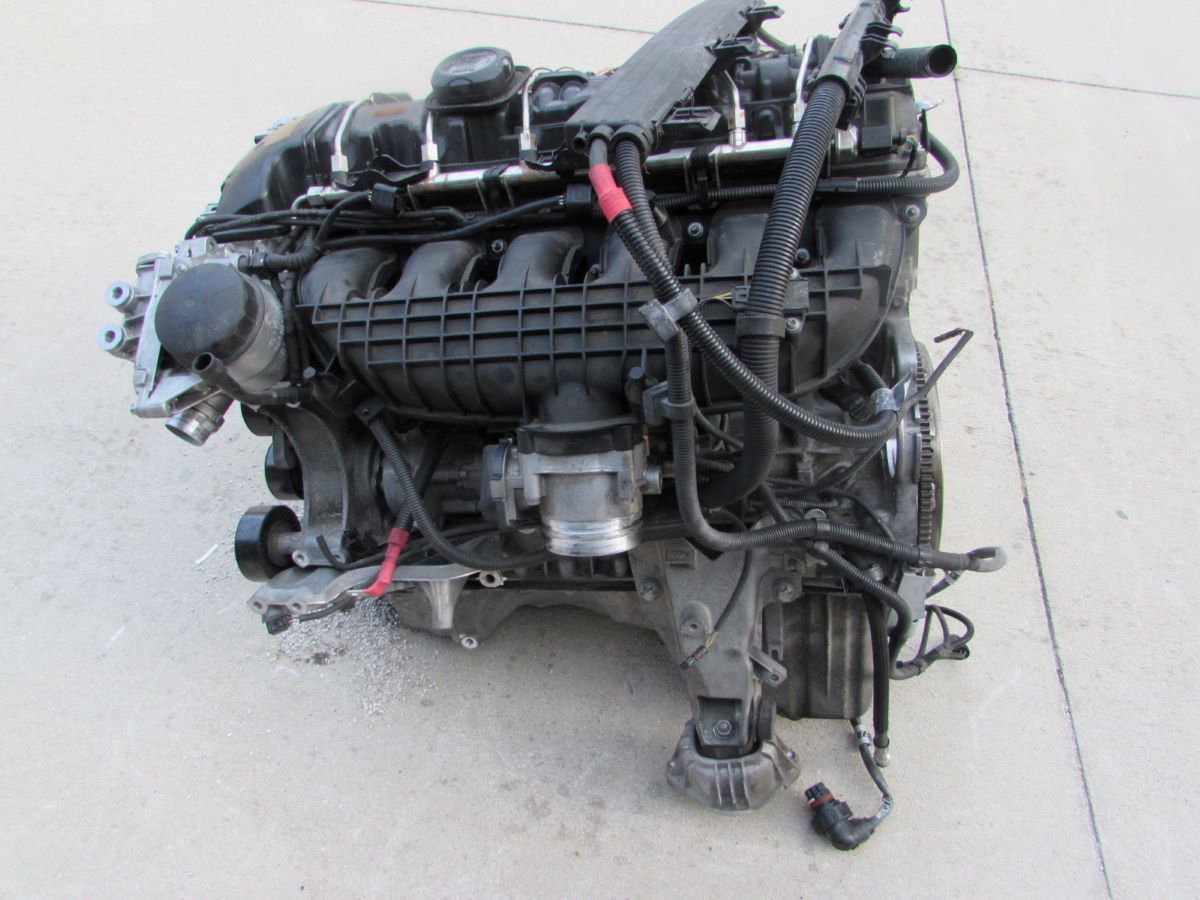

3. BMW N54 (3.0L Twin-Turbo I6)

Used in: BMW 335i, 135i, 535i (2007–2010)

Why It Misfires Constantly:

Though a performance legend, the N54 is notorious for ignition coil failures, carbon buildup on valves (thanks to direct injection), and injector problems.

These issues lead to chronic misfires that many owners accept as part of the ownership experience. The BMW N54 engine is a 3.0-liter inline-6 equipped with twin turbochargers and direct gasoline injection. Produced between 2006 and 2016, it marked BMW’s first mass-produced turbocharged gasoline engine with direct injection technology.

While this represented a major technological leap forward for the brand, it also exposed the engine to a host of problems and growing pains due to its complexity and the fact that it was a first-of-its-kind effort for BMW.

Making its debut in 2006, the N54 was initially introduced in the 2007 E90/E92 335i, setting a new benchmark for performance in BMW’s lineup.

Although it began to be phased out after 2010 in favor of its successor, the single-turbo BMW N55, the N54 continued to power select high-performance models. These included enthusiast favorites like the 2011 BMW 1M and the 2011–2013 335is, both of which showcased the N54’s capability at the top of its game.

Even though the engine is often criticized for its design shortcomings and reliability concerns—such as issues with high-pressure fuel pumps, turbo wastegates, and carbon buildup—it nonetheless earned significant recognition.

The N54 claimed six International Engine of the Year awards and was included three times in Ward’s 10 Best Engines list, cementing its status as a performance icon in spite of its flaws.

Thanks to the pairing of its small twin turbochargers, direct injection, and BMW’s double VANOS variable valve timing system, the N54 delivers a driving experience that minimizes turbo lag. The result is an engine that behaves with the smooth, linear power delivery more akin to a small naturally aspirated V8, making it a favorite among tuners and driving enthusiasts alike.

4. Volkswagen 1.8T EA888 Gen 2

Used in: VW Passat, Jetta, Audi A4 (2008–2013)

Why It Misfires Constantly:

Oil consumption, carbon buildup, failing coil packs, and timing chain tensioner issues plague this engine.

Misfires often arise due to fouled spark plugs and intake valve buildup. Even with dealer maintenance, misfires are common after 60,000 miles.

The Volkswagen EA888 engine was introduced in two displacement sizes: 1.8 and 2.0 liters. The 1.8T TSI/AUDI AG designed and developed the EA888 family’s 1.8 TSI / TFSI engine, which made its debut in 2007.

This engine features a 1.8-liter four-cylinder turbocharged gasoline configuration with direct fuel injection. Over time, the EA888 engine evolved through three distinct generations: the 1.8 TSI EA888 Gen-1, Gen-2, and Gen-3.

All variants of the 1.8-liter engine utilized a 1.8-liter, four-cylinder K03 turbocharged setup, except for the Gen-3 version, which employed an IS12 turbocharger that remains in production and is still undergoing upgrades. Shortly after the 1.8-liter’s release, Volkswagen introduced the 2.0 TSI/TFSI engine in March 2008. Like the 1.8, the 2.0 engine came in three versions known as 2.0 TSI EA888 Gen-1, Gen-2, and Gen-3.

Both the EA888 1.8 TSI and 2.0 TSI engines were created to replace their counterparts from the previous EA113 series, which included 1.8-liter and 2.0-liter powerplants. The 1.8 TSI EA888 continues to receive ongoing development and has seen three generations to date, as mentioned earlier.

As for the engine’s specifications and design, the EA888 has been in production from 2007 to the present. The cylinder head is made of aluminum, while the block is composed of grey cast iron. It features an inline 4-cylinder configuration, with a bore of 82.5 mm and a stroke of 84.1 mm.

The valvetrain consists of dual overhead cams (DOHC) with four valves per cylinder. The engine displaces 1.8 liters (1798 cc) and has a compression ratio of 9.6:1. It weighs approximately 318 lbs and produces a maximum of 170 horsepower between 4,000 and 6,200 RPM, along with 240 lb-ft of torque available from 1,500 to 4,850 RPM.

The first-generation 1.8 TSI EA888, known by engine codes BYT and BZB, was introduced as a replacement for the older 2.0 TSI EA113 engine. The only technical carryover from its predecessor was the 88 mm (3.46 in) cylinder spacing.

At the heart of the Gen-1 1.8 TSI is a grey cast iron cylinder block and crankcase, a durable and stable material known for its acoustic dampening properties, which contributes to longevity and reduced vibration. The crankcase incorporates two chain-driven counter-rotating balancing shafts specifically designed to minimize engine vibrations, and the block stands at a height of 220 mm.

5. Mazda 2.3L DISI Turbo (MZR)

Used in: Mazdaspeed3, Mazdaspeed6, CX-7

Why It Misfires Constantly:

This engine combined direct injection and turbocharging before Mazda ironed out the bugs.

High oil consumption, weak ignition coils, and fuel delivery inconsistencies cause frequent misfires. CX-7 owners in particular saw CELs appear monthly due to persistent ignition issues.

The Mazda 2.3 turbo engine, a member of Mazda’s MZR engine family, has earned recognition for combining strong performance with respectable efficiency. First introduced in the early 2000s, this engine was developed in response to rising demand for compact cars that could deliver an engaging driving experience while remaining practical for everyday use.

The turbocharged version, in particular, drew attention from enthusiasts who wanted a powertrain that struck a compelling balance between output and fuel economy.

Mazda’s goal was to engineer a lightweight and compact engine that would offer solid performance without compromising reliability. The 2.3 turbo was fitted into several models across Mazda’s lineup, most notably the Mazda 3 and Mazda 6. Due to Mazda’s collaboration with Ford, this engine also made its way into select Ford vehicles.

The MZR engine family was built with a forward-thinking approach, incorporating features like variable valve timing and a turbocharger. These enhancements enabled the engine to deliver impressive horsepower and torque numbers relative to its size and class.

That said, the Mazda 2.3 turbo engine has also faced its share of criticisms, particularly when it comes to long-term reliability and common mechanical issues. As is often the case with performance-oriented engines, some compromises and challenges emerge over time. Owners, technicians, and tuners have flagged a variety of problems that can influence engine health and drivability.

For both current owners and prospective buyers—especially those considering performance upgrades—being informed about these potential pitfalls is essential. This article explores the known issues surrounding the Mazda 2.3 turbo engine, offering a clear and detailed look into what drivers should keep in mind to preserve performance and avoid costly repairs.

Misfires can stem from poor design, cheap parts, or just bad luck with maintenance history. Engines like the Toyota 2AR-FE and Honda K24 offer peace of mind and go years without a hiccup.

On the flip side, problematic motors like the Chrysler 2.7L or BMW’s N54 can cause endless frustration and expense.

When shopping for a used vehicle or planning your next build it pays to know which engines are ticking time bombs and which ones will never skip a beat.