In today’s tech-heavy automotive world, engines are under constant surveillance from an army of sensors and control modules. That can be a blessing — catching issues early — but it also means some powerplants are notorious for lighting up your dash like a Christmas tree for the smallest glitch.

Then there are the quiet champions — engines so reliable and well-designed, they seem to run forever without a single warning. This list breaks down five engines that rarely ever throw a code, and five that seem to use the Check Engine Light as a status symbol.

5 Engines That Rarely Throw a Code

These engines are known for their long life, low maintenance demands, and near-zero drama. They’re the ones mechanics nod at respectfully and owners rarely complain about.

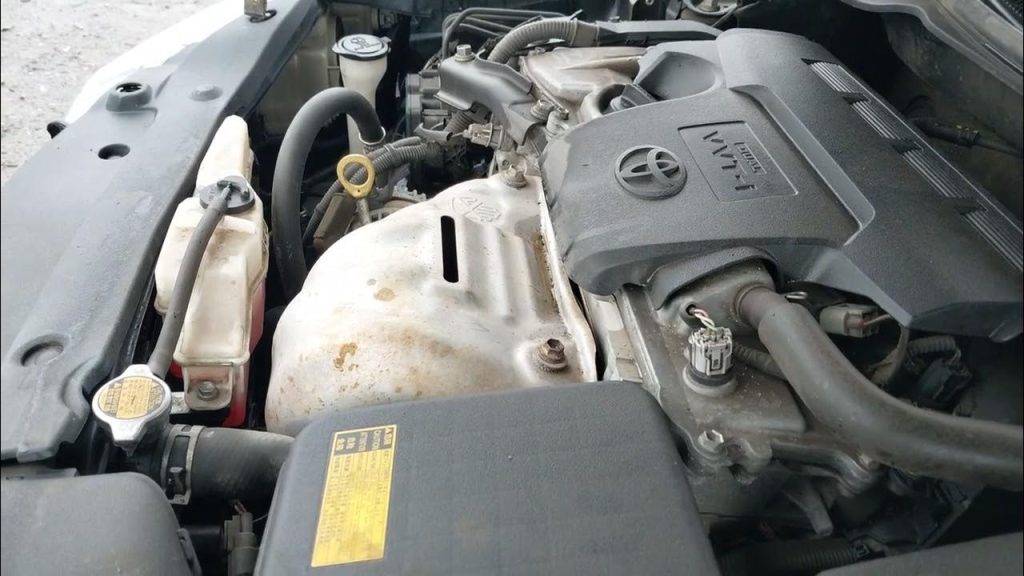

Toyota 2AR-FE (2.5L I4)

Found in the Camry, RAV4, and Highlander, the 2AR-FE is Toyota doing what Toyota does best: keeping it simple and reliable. It’s a naturally aspirated inline-four with no turbos or fancy tech to complicate things. As long as you do the basics — oil, filters, maybe a water pump — this engine will easily clear 200,000 miles without ever flicking on the CEL.

The 2AR-FE engine debuted in 2008 as the successor to the 2.4-liter 2AZ engine. While its power output remains comparable to that of the 2AZ, it improves upon fuel efficiency. This gain in efficiency was made possible through the implementation of modern engine technologies during development. Alongside the 2.5-liter 2AR-FE, Toyota also introduced the 2.7-liter 1AR-FE engine.

Structurally, the 2AR-FE retains the aluminum cylinder block design found in its predecessor, incorporating thin cast iron liners within the bores. However, this block is non-serviceable, as the liners are not replaceable. Internally, the engine features a forged steel crankshaft that is offset by 10 mm toward the exhaust side — a configuration known as an offset crankshaft.

This crankshaft comes with eight counterweights and is fully balanced for smooth operation. In order to reduce vibrations, it also drives a pair of balance shafts via a gear located inside the crankcase.

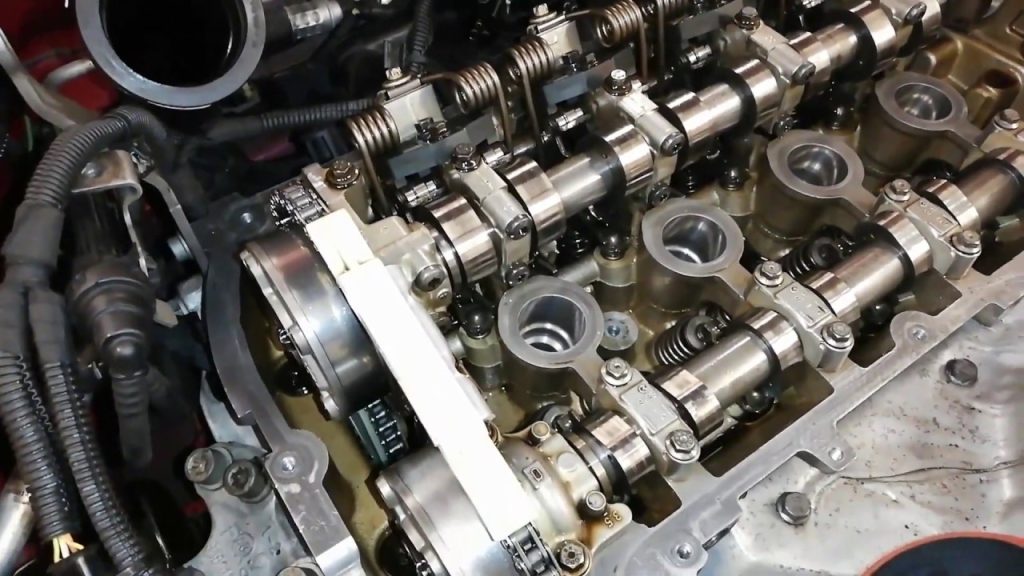

A major redesign was applied to the cylinder head. It is constructed from aluminum alloy and features a DOHC 16-valve layout. Unlike the 2AZ, the 2AR is equipped with hydraulic valve lifters. Each of the two camshafts is fitted with Toyota’s Dual VVT-i system, which enables variable valve timing on both intake and exhaust sides.

The valvetrain also includes roller rocker arms, contributing to overall efficiency. The engine incorporates several low-friction technologies; for instance, the pistons are fitted with reduced-tension rings, and the oil pump is a variable design that operates in three distinct stages.

The intake system, known as the ACIS or Acoustic Control Induction System, features variable geometry. This system adjusts the length of the intake tract in two stages using valves, depending on engine speed and throttle position. The plastic intake manifold works in conjunction with this system to optimize performance.

The fuel injection system utilizes updated 12-hole, long-nozzle injectors to enhance fuel economy and lower emissions. On the intake side, a stainless steel header is integrated along with a catalytic converter to help meet emissions standards.

In 2016, Toyota introduced the successor to the 2AR-FE as part of its new line of “Dynamic Force Engines.” The replacement is a 2.5-liter powerplant designated the A25A-FKS.

Also Read: 5 SUVs That Stop Running When Hotwired and 5 That Are Too Easy to Steal

Honda K24 (2.4L I4)

The K-series has earned its place in the reliability hall of fame, and the K24 might be its MVP. Found in models like the Accord, CR-V, and even the Element, this engine is a perfect mix of efficiency, performance, and durability. It’s practically allergic to throwing codes and shrugs off abuse as long as you keep up with oil changes.

The K24 is a 2.4-liter four-cylinder gasoline engine that belongs to the Honda K engine family. It made its first appearance in the 2001 Honda CR-V, specifically as the K24A1 variant. Its overall design is based on the 2.0-liter K20 engine but features a larger bore and longer stroke, along with several design modifications to accommodate the increased displacement. Honda introduced the K24 as a modern replacement for the older F23A engine.

Like the K20, the K24A engine features an aluminum cylinder block reinforced with cast iron cylinder liners. A new crankshaft was designed for the K24A, extending the stroke by 13 mm compared to the K20, and the bore diameter was increased by 1 mm. These changes resulted in an overall displacement increase of 200cc.

The K24A block stands taller than the K20, with a deck height of 231.5 mm. To accommodate the new dimensions, the K24 received unique pistons (retaining the same height) and revised connecting rods.

However, the design of the cylinder head remained largely the same: it is made from aluminum, includes 16 valves (four per cylinder), and features a dual overhead camshaft configuration. The spark plugs are located centrally and are paired with individual ignition coils (coil-on-plug design).

The engine incorporates Honda’s i-VTEC system. Both the intake and exhaust camshafts are driven by a timing chain and operate the valves through roller rocker arms. This setup does not use hydraulic tappets, so regular valve clearance adjustment is required.

The base model, the K24A1, was produced from 2001 through 2006 and served as the foundation for the entire K24 lineup. In this configuration, the i-VTEC system operated only on the intake camshaft. Valve sizes for the K24A1 include a 35 mm diameter for the intake valves and 30 mm for the exhaust valves, with valve stem diameters of 5.5 mm.

It also came equipped with a variable geometry intake manifold — Honda’s two-stage PPA intake, made from aluminum and composite materials — along with a 60 mm throttle body. Fuel delivery was handled by an electronic multi-port injection system using 270 cc fuel injectors. Among all versions in the K24 series, the K24A1 had the lowest compression ratio at 9.6:1.

Another widely produced variant in the series was the K24A4. This engine featured revised pistons and an increased compression ratio of 9.7:1. It also included reworked intake and exhaust ports within the cylinder head, an aluminum single-stage RAA intake manifold, and modified i-VTEC tuning compared to the K24A1.

In 2006, the K24A4 received further upgrades and was re-designated as the K24A8. This updated version came with an electronic throttle body and an RTB intake manifold, allowing it to meet more stringent emission standards.

In addition to the regular production engines, the K24A series also includes a high-performance version built for Honda’s sportier models — the K24A2, also known as the K24A3 in European and Australian markets.

This engine underwent significant bottom-end improvements, including the addition of dual balance shafts, a forged crankshaft, strengthened connecting rods, and lightweight pistons. Its compression ratio was increased to 10.5:1. The engine was also equipped with the full version of Honda’s i-VTEC system, applied to both the intake and exhaust camshafts.

The camshaft profiles were made more aggressive to enhance performance. Airflow was significantly improved thanks to a high-flow exhaust header and a single-stage RBB intake manifold, which came with a larger 60 mm throttle body.

The engine also featured a drive-by-wire throttle and integrated EGR ports within the intake manifold. With VTEC engaging above 6,000 rpm, this engine delivered an output of 197 horsepower and 171 lb-ft (232 Nm) of torque.

Lexus 1UZ-FE (4.0L V8)

The 1UZ-FE, found in the Lexus LS400 and SC400, is a shining example of overengineering from the ’90s. This smooth, balanced V8 runs so clean and efficiently, it’s not uncommon to see one push past 300,000 miles with only minimal maintenance. It doesn’t just resist trouble — it avoids it like the plague.

The 1UZ-FE was the first engine introduced in Toyota’s UZ family. This 4.0-liter V8 gasoline engine was used in a variety of luxury and sports cars under the Toyota and Lexus brands from 1989 until 2002, at which point it was succeeded by the 3UZ-FE.

Before the 1UZ came into the picture, Toyota relied on the V series engines, which dated all the way back to the 1960s and served through the early 1990s. The 1UZ-FE effectively replaced that aging lineup with a more advanced and modern powerplant.

The 1UZ-FE features an aluminum cylinder block outfitted with thin cast-iron liners. Its V8 layout has a 90-degree bank angle, and the cylinder banks are offset from one another by 21 mm. The engine uses six main bearings and incorporates a forged steel crankshaft with eight counterweights to ensure balanced operation.

To reduce rotational mass, the 1UZ was fitted with lightweight forged steel connecting rods and aluminum pistons, while the connecting rod pins were induction-hardened for added durability. In late 1994, Toyota updated the engine with an even lighter crankshaft and connecting rods, along with shorter, thinner piston pins and redesigned pistons.

Known for its refined and quiet performance, the 1UZ-FE also benefited from liquid-filled compound engine mounts, which played a key role in minimizing vibrations. In 1997, further improvements were made to the engine, including enhancements to the cylinder block’s rigidity, which contributed to even quieter operation.

The engineering philosophy behind the 1UZ-FE leans more toward race engine design than a typical road-going V8. With its expensive eight-counterweight crankshaft, lightweight internals, and nearly square bore-to-stroke ratio, the engine was a technological standout in its class.

But what truly set the 1UZ apart was its DOHC 32-valve aluminum cylinder heads. At a time when most V8s featured a single camshaft and overhead valve (OHV) design with just two valves per cylinder, the 1UZ-FE introduced a more advanced layout.

Each cylinder head had two camshafts — one for intake and one for exhaust — and four valves per cylinder. The intake camshafts are driven by a timing belt, while the exhaust camshafts are gear-driven from the intake cams.

The valvetrain did not use hydraulic lifters. Instead, the engine relied on solid aluminum alloy valve lifters with steel outer shim-type valve adjusters mounted above. Initially, both the intake and exhaust valve stems measured 6.0 mm in diameter. Intake valves were 33.5 mm across, while exhaust valves were 28.0 mm.

However, in late 1997, Toyota revised the valvetrain once again — increasing the intake valve diameter to 34.5 mm and the exhaust valve diameter to 29.0 mm, while reducing the stem diameter to 5.5 mm.

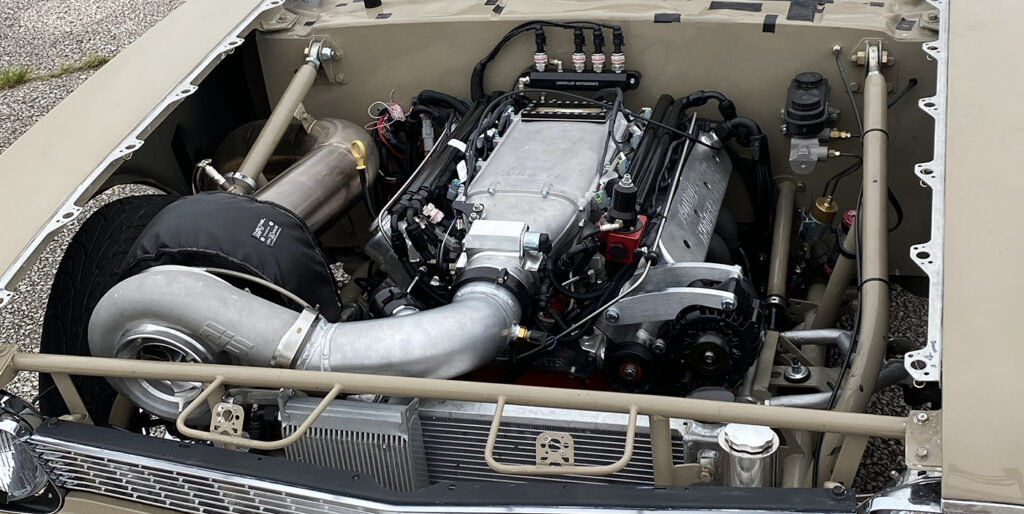

Chevy LS-Series V8 (5.3L, 6.0L, etc.)

Whether it’s in a Silverado, Suburban, Camaro, or Corvette, the LS V8 is one of the most respected engines in America. Its pushrod design is old-school in the best way: simple, tough, and easy to fix. These engines can take a beating — towing, racing, commuting — and keep on humming with barely a hiccup, let alone a CEL.

When discussing performance engines, few names hold as much weight as General Motors’ LS series of V8s. The LS family is widely regarded as one of the finest engine lineups ever produced.

These engines have powered some of the world’s most iconic performance vehicles and, due to their compact dimensions, dependability, and relatively low cost, they’ve also become the go-to choice for engine swaps across countless builds.

Over the course of its 20-year production run, GM developed a wide range of LS engines, beginning with the debut of the 5.7-liter LS1 in the 1997 C5-generation Corvette.

This engine produced 345 horsepower and set the stage for what would become a legendary platform. In addition to performance applications, the LS series extended into GM’s truck lineup, where variants carried designations like LR, LM, LY, LC, and LQ.

In 2005, GM introduced the first of the Generation IV LS blocks. This new generation featured increased use of aluminum construction, an all-new intake manifold design, lighter exhaust manifolds, and added technologies such as displacement on demand, variable valve timing, and an expanded bore diameter.

These changes not only enhanced performance and efficiency but also laid the foundation for even more advanced LS variants.

The following year, Chevrolet took things a step further with the unveiling of the C6-generation Corvette Z06, which introduced the world to the LS7 — a naturally aspirated 7.0-liter V8 generating 505 horsepower.

Not long after, GM released the 6.2-liter LS3, which quickly became one of the most sought-after engines for swaps due to its excellent balance of power, cost, and availability. Later additions to the lineup included the supercharged LS9 and LSA engines, which were featured in high-performance models like the Corvette ZR1 and the Cadillac CTS-V, respectively.

Also Read: 5 Sedans With Top NHTSA Safety Ratings And 5 With Lowest

Mazda BP-Z3 (1.8L I4)

Found in the second-generation Mazda Miata (NB), the BP-Z3 is a simple, durable, rev-happy little engine that matches the car’s lightweight design perfectly. No forced induction, minimal electronics, and easy DIY serviceability mean this engine almost never complains. It’s one of the most carefree motors you’ll ever drive behind.

Mazda’s 1.8L engine, commonly identified by its engine code, has built a strong reputation as a dependable and adaptable powerplant in the automotive industry. First appearing in the early 1990s, this inline-four engine became a cornerstone of several Mazda models, known for striking a solid balance between performance, fuel efficiency, and long-term reliability.

Featuring a DOHC (Dual Overhead Camshaft) layout and constructed with precision using an aluminum alloy, the engine was crafted to offer a lively driving experience without compromising on fuel economy—a combination that continues to resonate with car enthusiasts.

A key highlight of this engine is its capacity to generate a commendable amount of horsepower and torque, which makes it well-suited for both daily driving and more spirited road use.

Drivers often note the 1.8L engine’s smooth power curve and quick throttle response, attributes that significantly boost the driving feel in the vehicles it powers. On top of that, it has earned praise for being relatively inexpensive to maintain, positioning it as a smart choice for drivers who are mindful of upkeep costs.

5 Engines That Light Up the Dash Like Times Square

These engines might offer performance, but it comes at the cost of constant attention. Whether it’s due to poor engineering, overcomplicated systems, or just bad luck, these are the ones known for never staying quiet for long.

BMW N54 (3.0L Twin-Turbo I6)

A powerhouse with a dark side, the N54 was BMW’s first twin-turbo inline-six and found in cars like the 335i and 135i. While it delivers exhilarating power, it’s a nightmare for reliability. Expect issues with high-pressure fuel pumps, VANOS solenoids, turbo wastegates, and more. It doesn’t just throw a code — it throws the whole book at you.

Mazda’s 1.8L engine, commonly identified by its engine code, has built a strong reputation as a dependable and adaptable powerplant in the automotive industry.

First introduced in the early 1990s, this inline-four engine quickly became a cornerstone in many Mazda models, thanks to its consistent blend of performance, fuel efficiency, and long-term reliability.

Its DOHC (Dual Overhead Camshaft) configuration, combined with a thoughtfully engineered aluminum alloy construction, was specifically designed to deliver a spirited driving experience while still keeping fuel consumption in check—a combination that continues to appeal to automotive enthusiasts.

One of the engine’s standout qualities is its ability to produce a respectable amount of horsepower and torque, which makes it a great fit for both everyday commuting and more enthusiastic driving styles.

Drivers often praise the 1.8L engine for its smooth power delivery and responsive throttle, two characteristics that significantly improve the overall driving dynamics of the vehicles it powers. Additionally, it has garnered a reputation for low maintenance costs, which makes it a practical choice for those who want a reliable engine without breaking the bank on upkeep.

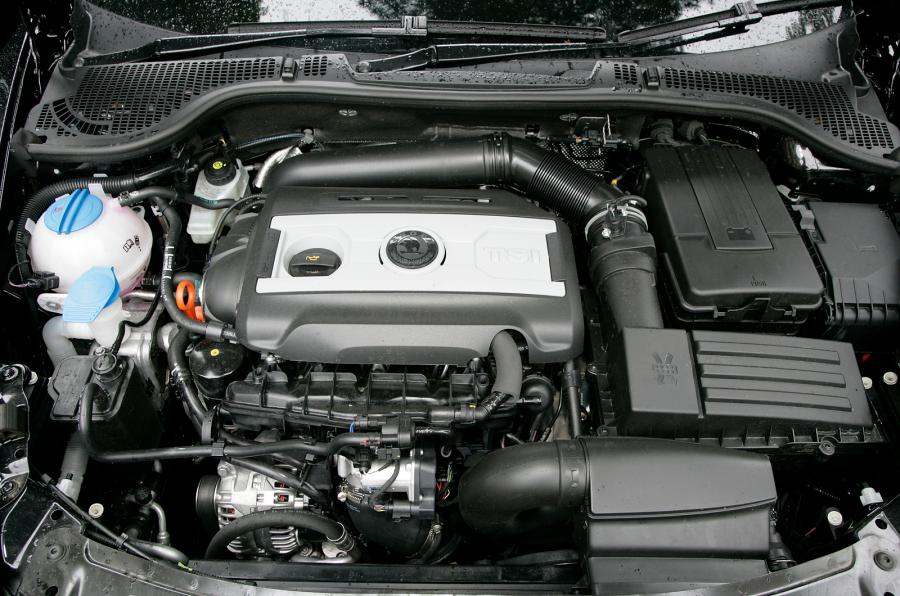

Volkswagen EA888 Gen 2 (2.0T I4)

Used in everything from the GTI to the Audi A4, the Gen 2 EA888 is infamous for its flaws. Timing chain tensioner failures, excessive oil consumption, PCV problems, and carbon build-up are just the start. The CEL might as well be a permanent fixture on the dash of these cars — it’s almost part of the interior design.

The VW 2.0 TSI/TFSI EA888 is a 2.0-liter four-cylinder gasoline turbocharged engine developed as an evolution of the 1.8 TSI/TFSI from the EA888 series.

Production of the 2.0 TSI began in March 2008, introduced to replace the earlier 2.0 TSI engines from the EA113 family. Much like its 1.8-liter counterpart, this two-liter variant underwent multiple revisions over the course of its production. The final 2.0 TSI engine under the EA888 designation consists of three different generations.

The 2.0 TSI EA888 Gen 1, officially identified by engine codes such as CAWA, CAWB, CBFA, CCTA, and CCTB, shares several design elements with the 1.8 TSI.

This version features a cast-iron cylinder block with a cylinder spacing of 88 mm (3.46 in) and an overall block height of 220 mm. The increase in displacement was achieved through the use of a new forged steel crankshaft with a 92.8 mm (3.65 in) stroke, while the bore diameter remained unchanged.

The engine also incorporates shorter 144 mm connecting rods and redesigned pistons, resulting in a reduced compression ratio of 9.6:1. To aid in vibration control, the block is fitted with two chain-driven counter-rotating balance shafts.

The cylinder head, made of aluminum and containing 16 valves, is very similar to the one found on the 1.8 TSI. Each cylinder is equipped with two intake valves and two exhaust valves, measuring 34.0 mm and 28.0 mm in diameter respectively, with a valve stem diameter of 6 mm for both. The valvetrain is designed with low-friction roller finger cam followers and hydraulic tappets that automatically adjust for valve clearance.

Positioned at the top of the head, the intake and exhaust camshafts are driven by a timing chain, with the intake camshaft incorporating a variable valve timing system to enhance performance and efficiency. Fuel delivery is handled through a direct injection system that employs homogeneous mixing.

A low-pressure fuel pump located in the fuel tank sends gasoline to the high-pressure pump, which supplies up to 190 bars (2,760 psi) of pressure to the six-hole injectors. The high-pressure pump itself is actuated by a four-lobe cam mounted on the exhaust camshaft. For ignition, the engine utilizes an electronically controlled system with long-life spark plugs and four individual single spark coils.

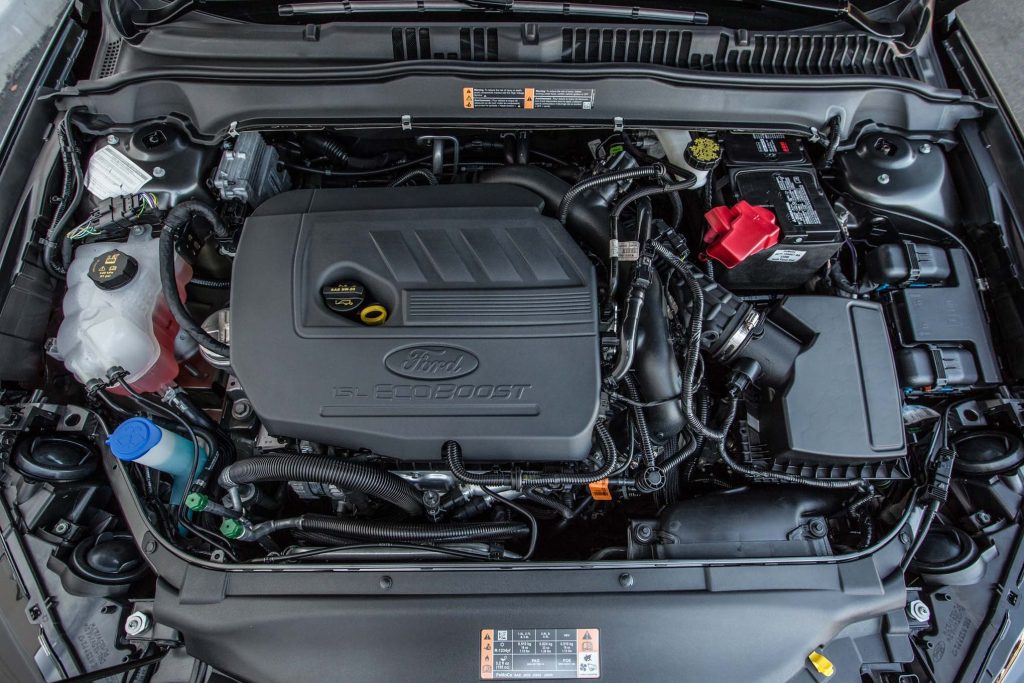

Ford EcoBoost 1.6L I4

This turbocharged engine powered the Escape, Fusion, and Fiesta ST, but early versions were plagued by cooling system failures, overheating, and head gasket leaks. Combine that with turbo issues and a sometimes laggy throttle response, and you’ve got a recipe for constant warning lights and frequent shop visits. Great on paper, but high-maintenance in the real world.

Ford launched the 1.6L EcoBoost engine in 2010, debuting it in the Ford Focus and Ford C-Max. Alongside the 2.0 EcoBoost, it marked one of the first turbocharged engines developed by Ford as part of its Downsizing strategy.

This engine is a 1.6-liter inline four-cylinder gasoline unit equipped with a turbocharger and a direct injection fuel system. Thanks to its advanced engineering, it was capable of replacing larger displacement engines, such as the 2.0L and 1.8L Duratec, without any compromise in performance, while simultaneously achieving better fuel efficiency and reduced emissions.

The engine features a cylinder block with an open-deck design, constructed from high-strength aluminum alloy. This open-deck configuration contributes to reduced overall weight and enhances the cooling balance of the engine.

The block incorporates thin cast iron sleeves (liners) that are cast directly into the aluminum cylinder walls for durability. A cast iron crankshaft with four counterweights and five main bearings anchors the bottom end, complemented by forged connecting rods and aluminum hypereutectic pistons.

These pistons are equipped with low-friction, resin-coated skirts for improved efficiency. The piston pins are treated with a diamond-like coating (DLC) for added wear resistance. Additionally, the aluminum oil pan not only aids in weight reduction but also provides structural reinforcement to the engine block.

MINI N14 / N18 Turbo Engines

Found in MINI Coopers from 2007 to 2014, these engines came packed with personality — and problems. Common issues include timing chain rattle, carbon deposits on intake valves, turbo failures, and oil leaks. They’re fun when they work, but it takes a very committed (and financially prepared) owner to keep them going without constant dashboard drama.

The Mini Cooper S with the N14 engine has gained a reputation for its spirited performance and unique styling. However, like any vehicle, it comes with its share of issues that can leave owners scratching their heads.

This article delves into the common problems associated with the N14 engine, focusing on the symptoms that drivers may encounter. Understanding these symptoms can help owners identify potential issues before they escalate into more serious problems.

One of the first signs that something might be off with the N14 engine is the presence of oil leaks. Owners may notice spots of oil on their driveway or garage floor. This can be caused by several factors, including: worn gaskets, faulty oil seals, and loose oil pan bolts. Ignoring oil leaks can lead to low oil levels, which can cause severe engine damage over time.

Another common symptom is overheating. If the temperature gauge on the dashboard starts creeping into the red zone, it’s a clear indicator that something is wrong. Possible causes include: coolant leaks, a faulty thermostat, and a clogged radiator. Overheating can lead to catastrophic engine failure if not addressed promptly.

Chrysler 2.7L V6

The 2.7L V6 engine, often associated with Chrysler’s LH platform, emerged in the mid-1990s as a response to the growing demand for efficient yet powerful engines in the automotive market.

This powerplant was designed to strike a balance between performance and fuel economy, making it a notable choice for various sedans and minivans produced by Chrysler, Dodge, and Plymouth during its production run. With a design that prioritized smooth operation and reliability, the 2.7L V6 engine featured a DOHC (Dual Overhead Camshaft) configuration and a lightweight aluminum construction.

This combination not only contributed to its overall performance but also helped in maintaining a favorable weight-to-power ratio. The engine was engineered to deliver a respectable horsepower output, making it suitable for both everyday commuting and long-distance travel.

The 2.7L V6 engine found its way into several models across Chrysler’s brand lineup. Here’s a look at some of the key vehicles that utilized this engine: Chrysler 300M – Launched in 1998, this full-size sedan showcased the 2.7L V6 as a standard option, appealing to drivers looking for a blend of luxury and performance.

Overall, the 2.7L V6 was a versatile engine that catered to a wide array of vehicles, from family sedans to sporty roadsters. Its design aimed at delivering a smooth driving experience while also keeping an eye on fuel efficiency, making it a compelling choice during its production years.

The 2.7L V6 engine is a noteworthy component in Chrysler’s lineup, offering a unique blend of performance and efficiency. Below is a detailed breakdown of its specifications, which highlight the engineering that went into creating this powerplant.

The engine type is V6, DOHC (Dual Overhead Camshaft), with a displacement of 2.7 liters, and a compression ratio of 10.5:1. It delivers a maximum horsepower of 200 hp @ 5,600 rpm and a maximum torque of 192 lb-ft @ 4,000 rpm.

The fuel system is Multi-Point Fuel Injection, and it runs on regular unleaded gasoline (87 octane). The ignition system is a Distributor-less Ignition System (DIS), while the valvetrain includes 24 valves (3 per cylinder).

The performance metrics of the 2.7L V6 engine are impressive for its class, making it suitable for a variety of applications. It can go from 0–60 mph in approximately 8.5 seconds, reach a top speed of approximately 130 mph, and achieve fuel economy of approximately 18 mpg in the city and approximately 26 mpg on the highway. These numbers reflect the engine’s balance between everyday usability and respectable on-road capability.

Proper maintenance is crucial for the longevity of any engine, and the 2.7L V6 is no exception. The oil capacity (with filter) is approximately 5 quarts, with a recommended oil type of SAE 5W-30. The oil change interval is suggested at every 5,000 to 7,500 miles.

The specifications of the 2.7L V6 engine not only demonstrate its engineering prowess but also highlight the importance of regular maintenance for optimal performance and longevity. This engine remains a significant part of Chrysler’s history, showcasing their commitment to creating reliable and efficient powertrains.

Engines are like people — some are dependable and low-maintenance, while others are high-strung and always in need of attention. If you value peace of mind, go with one of the proven legends from Toyota, Honda, Lexus, GM, or Mazda.

They’ll reward you with years of drama-free driving. But if you’re tempted by high-output turbocharged thrills from BMW, VW, Ford, MINI, or Chrysler, just know what you’re signing up for — frequent dashboard alerts, expensive fixes, and the occasional tow truck.

Reliability isn’t just about luck — it’s about engineering. And in a world full of flashy tech and fragile components, sometimes the most boring engine is the one that lets you sleep at night.