When truck manufacturers design heavy-duty vehicles, one major concern is how to manage heat within the fuel system. Trucks that handle long hauls, heavy loads, and extreme driving conditions often require well-engineered components that maintain reliability and prevent breakdowns.

One component that plays a very important role in this process is the fuel cooler. It helps regulate the temperature of the fuel to ensure steady performance.

Some trucks come equipped with oversized fuel coolers, which go beyond standard capacity to deliver better thermal control and reduce wear. These trucks maintain fuel efficiency during high-load operation, especially in hot climates or when towing.

On the other side, some trucks are prone to issues due to heat-soaked fuel pumps. These pumps are affected by rising temperatures during long engine operation or after shutdown, leading to vapor lock or erratic performance.

Heat soaking happens when fuel trapped in the pump or lines absorbs residual engine heat after shutdown or under low-speed operation. This can cause hard starts, performance loss, and in worst cases, complete failure of the fuel system. Trucks that suffer from such issues can become unreliable in demanding usage scenarios.

To give a clear view of how this plays out on the road, this article discusses five trucks known for having oversized fuel coolers and compares them with five trucks that are known to have experienced issues due to heat-soaked fuel pumps.

The goal is to provide truck buyers and enthusiasts with useful information about which models perform better under thermal stress, and which ones might require extra attention.

Each truck listed has been described based on real-world use, user experiences, and known engineering characteristics that affect fuel cooling efficiency. While no truck is perfect, some stand out in their ability to manage fuel temperatures efficiently.

Trucks with Oversized Fuel Coolers

1. Ford Super Duty F-350 (2020-Present)

Ford’s Super Duty F-350 remains a preferred choice among professionals who depend on consistent power and reliability. The fuel cooling system used in this truck demonstrates Ford’s effort in ensuring durability, especially under load.

The 6.7-litre Power Stroke turbo diesel engine that powers this truck requires efficient temperature control to function under high demand. This engine can generate up to 1,200 Nm of torque and carries a workload when towing or operating in high-temperature regions.

To manage this, Ford fitted an oversized fuel cooler, which provides extended fuel system life and prevents overheating during long-distance travel or when hauling trailers.

This cooler plays a major role in stabilising fuel temperature and ensuring the engine receives a consistent fuel flow without vapour bubbles. By keeping the diesel at a stable temperature, the Super Duty F-350 avoids performance drops or hesitation that commonly affect trucks with standard-sized coolers.

This truck also benefits from improved reliability during idle-heavy operation, such as on construction sites. Even when the engine is running for hours, the fuel system remains stable, avoiding heat soak problems that plague other models.

Owners of the F-350 often report fewer fuel system issues even when driving under high ambient temperature, making it a preferred vehicle for use in areas with extreme heat like Texas, Arizona or the desert West.

Apart from the oversized fuel cooler, Ford added heavy-duty transmission and engine oil coolers, making the entire thermal management system very effective.

Drivers report fewer shutdown issues or hard starts after extended operation. This system has proven reliable for long-haul towing, commercial work, and utility service across the country.

2. Ram 2500 HD (2020-Present)

Ram 2500 HD has consistently maintained a good reputation among heavy-duty truck users. Equipped with the 6.7-litre Cummins diesel engine, this model brings a combination of strength and thermal control.

Ram engineers fitted a large-capacity fuel cooler located strategically near the tank, which allows for cooler airflow and effective temperature reduction. This ensures that fuel does not overheat even under severe load.

The oversized cooler contributes greatly to reducing vapour lock. Many diesel owners know that long idling, high heat, and turbo backpressure can raise fuel system temperature.

By equipping this truck with a more robust cooling setup, Ram ensures consistent injection pressure, which leads to smooth throttle response and better fuel economy. This type of cooler makes a clear difference when comparing Ram 2500 HD to models from older generations, which often lacked sufficient cooling support.

Towing performance is also improved thanks to this cooling system. Whether pulling a livestock trailer, camper, or a loaded flatbed, the fuel system maintains steady pressure and temperature. It also prevents common diesel-related problems such as injector coking or fuel line vapour bubbles.

This setup is especially helpful in mountainous terrain or during high-altitude operation, where the engine often works harder and heat builds up faster.

For those who use this truck in agriculture or off-grid work, the oversized fuel cooler proves useful in maintaining smooth operation under all weather conditions.

Cold starts are easier, and the fuel system remains stable after hot shutdowns, reducing engine wear. The 2500 HD with the Cummins setup is engineered to meet the demands of serious operators who cannot afford fuel delivery issues due to excess heat.

Also Read: 5 Models Depreciating Due to Reliability Issues vs 5 That Stay Valuable

3. Chevrolet Silverado 3500HD (2020-Present)

Chevrolet’s Silverado 3500HD with the 6.6-litre Duramax diesel engine has long been recognised for its durability and hard-working design.

One of the reasons behind this truck’s high performance is its fuel system design, which includes a large fuel cooler mounted along the frame rail. This cooler plays a major role in keeping fuel temperature under control, especially under stress conditions.

Whether the truck is climbing steep hills or pulling a trailer across hundreds of miles, the fuel remains at a safe operating temperature. This prevents any sort of pressure drop or hard starts that may result from hot fuel.

The system has proven effective for commercial drivers who operate in warmer climates, and it holds up well under repeated heavy towing. By incorporating such a large fuel cooler, GM assures common diesel issues related to thermal expansion and vapor lock.

Owners also report that the fuel system remains quieter and more responsive even after extended operation. The electronic control unit adjusts the injection timing more efficiently when the fuel temperature remains stable, resulting in smoother engine performance. This design also reduces wear on high-pressure fuel pumps, injectors, and filters.

Many Silverado 3500HD units are used in construction and oilfield work, which places huge demands on both the engine and fuel system. Even in such demanding conditions, this truck continues to function well without showing symptoms of overheating or pump fatigue.

Combined with a robust transmission cooling system and intelligent airflow management, the oversized fuel cooler maintains the truck’s performance stability and predictability during heavy operation.

4. Nissan Titan XD (2016-2019)

Nissan Titan XD stands between light-duty and full heavy-duty trucks. The model equipped with the 5.0-litre Cummins V8 diesel engine had several upgrades focused on durability, including an oversized fuel cooling system.

The fuel cooler was placed along the underside of the frame and received direct airflow, allowing fuel to stay cool even under prolonged engine use.

This truck was designed to offer diesel benefits to those who did not want to step up into a full-size heavy-duty truck like the Ram or Silverado.

As a result, Nissan worked with Cummins to build a powertrain that could handle heavy work without heat-related damage. The fuel system was one of the focal points in that design. Its cooler was sized to prevent vapour buildup, especially during towing or uphill driving.

This helped reduce the chances of injector imbalance, starting problems, or poor throttle response. Users found that after long drives or exposure to high ambient heat, the Titan XD continued to deliver consistent fuel pressure and injection timing. Unlike smaller trucks with limited fuel cooling, the Titan XD handled heavy loads without issue.

Its cooler also proved useful for off-road work and slow-speed operation where airflow is usually limited. The system helped avoid heat soak during slow climbs or when idling on job sites.

Though this model is no longer in production, it remains a good example of how oversized fuel cooling can improve diesel truck performance without stepping into full heavy-duty territory.

5. Toyota Tundra i-FORCE MAX (2022-Present)

Toyota’s re-engineered Tundra i-FORCE MAX hybrid offers a modern curve to truck powertrains by combining a twin-turbocharged V6 engine with an electric motor.

While it is not a diesel truck, Toyota addressed the fuel heating issues common in turbocharged systems by equipping the i-FORCE MAX with a large-capacity fuel cooler integrated into the hybrid control module.

The twin-turbo V6 generates higher fuel system temperatures due to increased pressure and combustion demands.

To protect the direct injection system and prevent premature wear, Toyota added a fuel cooling system that exceeds the size used in its earlier models. This helps ensure consistent combustion and smooth throttle under all load levels.

During long-distance drives, users of the Tundra report fewer issues with warm starts and fuel pressure inconsistencies.

Even after engine shutdown, the hybrid power unit continues to manage system temperatures, keeping the fuel at a safe level and reducing vapour formation. This is helpful in stop-and-go traffic where heat buildup normally causes performance issues.

Towing efficiency also benefits from this system. The cooler keeps fuel lines and injectors at proper temperatures during trailer hauls, especially up inclines or under desert conditions. Toyota has carefully engineered airflow paths around the engine bay to support this cooling effort, adding louvers and airflow ducts.

Though the Tundra i-FORCE MAX does not follow the traditional diesel truck path, its fuel cooling performance is among the best in modern trucks. Its oversized system stands out especially because turbocharged petrol hybrids face similar thermal problems that diesel engines do. Toyota’s engineering addresses these concerns well.

Trucks with Heat-Soaked Fuel Pumps

1. Chevrolet Colorado (2015-2022)

The Chevrolet Colorado has attracted many drivers who want a midsize utility vehicle without stepping up to full-size trucks. Despite its popularity, many owners of the 2.8-litre Duramax diesel model reported concerns with heat-related fuel delivery issues, especially in warmer climates or after extended driving.

This particular truck uses a compact fuel system where the lines and pump are positioned near the engine and exhaust components, leading to potential heat soak.

After extended drives followed by short shutdowns, some users noticed difficult restarts, engine hesitation, and slow fuel pressure buildup. These symptoms are often associated with vapour forming in the fuel pump or lines.

When the fuel temperature climbs due to residual engine heat and poor airflow around the pump, it disrupts the ability to deliver a consistent spray pattern to the injectors. In areas where ambient temperatures remain high year-round, such as in Southern California or Arizona, the issue becomes more frequent.

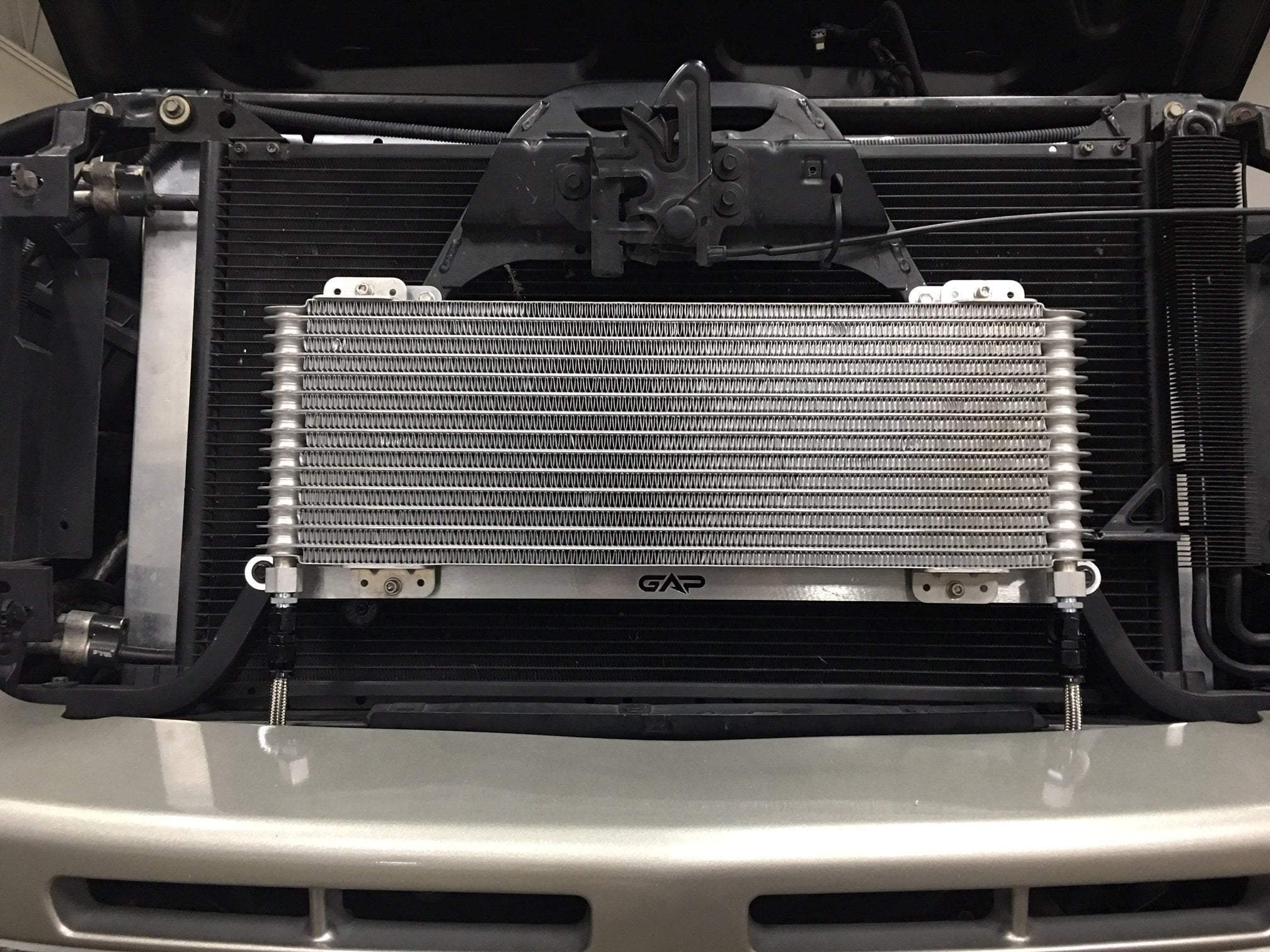

Some mechanics have resorted to installing aftermarket heat shields or adding external fuel coolers, but these modifications do not come with the truck by default. General Motors did not design a very large cooler for this application, as the engine bay was already compact.

Towing with the Colorado further aggravates the issue. The increased load pushes the engine and fuel system harder, raising heat levels and increasing the risk of vapour lock.

Several owners have had to wait several minutes before restarting their trucks after short stops. This makes it inconvenient for delivery drivers or those frequently on and off job sites.

Although not every unit suffers from this issue, enough cases have been reported to make it a point of concern. Without a larger stock fuel cooler or better thermal isolation, the Colorado’s fuel pump remains vulnerable to heat soak, especially under heavy-duty or off-road conditions.

2. Ford Ranger (2019-2022)

Ford’s reintroduction of the Ranger for the North American market brought excitement for those who preferred midsize trucks. However, the 2.3-litre EcoBoost petrol engine version came with a known issue related to fuel temperature control, especially around the high-pressure fuel pump mounted near the engine.

The design placed it close to other heat-generating components, and with no large cooling feature dedicated to the fuel system, some users reported performance issues related to heat soak.

This becomes most obvious after prolonged driving in stop-and-go traffic or under heavy load. When the engine is shut off, temperatures under the hood continue to rise, and with the pump surrounded by hot metal surfaces, heat transfers into the fuel system.

Once restarted, the system sometimes struggles to maintain ideal pressure, and this affects acceleration, idle smoothness, and throttle response. The Ranger does not have an oversized fuel cooler and relies on the standard returnless fuel system common to many turbocharged petrol vehicles.

While this may be sufficient under normal use, extreme heat combined with turbo backpressure and tight under-hood packaging creates a situation where vapour formation becomes a concern. Unlike larger trucks with better ventilation and cooling capacity, the Ranger’s compact setup leaves little room for airflow improvement.

Towing with the Ranger further exposes these weaknesses. Though Ford rated the truck to tow around 7,500 pounds, drivers who use it for frequent hauling have observed reduced performance during hot weather. Once parked, the heat from the turbocharger and engine causes a build-up around the fuel rail and pump area.

While not affecting every owner, this heat-soak tendency is recognised among truck users in hot states or those who do long-distance driving with few breaks. Ford may eventually address this in newer models with better airflow design or a more robust cooling solution, but for now, it remains an area of concern.

3. Jeep Gladiator (2020-2023)

The Jeep Gladiator combined off-road ability with pickup functionality, drawing interest from those who needed both adventure and utility.

Equipped with the 3.6-litre Pentastar V6 or the 3.0-litre EcoDiesel engine, the Gladiator experienced some challenges related to heat soak, especially when used in demanding conditions. Owners driving in off-road scenarios or in traffic-heavy areas found that fuel delivery would sometimes become erratic following hot shutdowns.

The design of the Gladiator’s engine bay is similar to the Wrangler’s, and both suffer from poor heat dissipation when parked. The high-pressure fuel pump, especially on the diesel version, sits in a location that does not receive adequate cooling airflow once the engine stops.

With heat from the turbo and exhaust manifold radiating back, the fuel in the lines begins to boil slightly or forms vapour pockets. This creates hard start conditions or engine stumbling upon restart.

Many Jeep enthusiasts who use their Gladiators for rock crawling or trail duty in high-temperature areas such as Moab, Utah, or the California deserts have reported this behaviour.

They often add aftermarket cooling components or engine bay heat extraction systems to reduce under-hood temperatures. However, these solutions are not factory standard, and the heat-soak tendency remains a common complaint among experienced drivers.

The diesel engine model, which is tuned for torque-heavy use, suffers more from this issue due to tighter fuel delivery tolerances.

When the system is exposed to thermal stress, pressure fluctuations increase, and the engine control module may delay fuel delivery to protect components. This results in hesitation or limp-mode triggers, affecting performance during crucial moments.

Even though the Gladiator remains reliable for off-road tasks, its thermal design does not prioritise long-term heat management. Without a dedicated oversized fuel cooler or better heat shielding, fuel pump heat soak remains a technical weakness that reduces operational efficiency under extreme conditions.

4. GMC Canyon (2015-2022)

The GMC Canyon shares its platform with the Chevrolet Colorado and inherits many of the same features and limitations. The 2.8-litre Duramax diesel variant in particular has shown tendencies for fuel system heat soak under high demand.

Like its Chevrolet counterpart, the Canyon places its high-pressure fuel pump in an area that does not receive optimal airflow, especially once the engine is turned off and residual heat builds up.

Drivers have complained of rough idle, delayed throttle response, and hard starting after driving for extended periods in hot environments.

The absence of a dedicated oversized fuel cooler means that the diesel fuel, which is more susceptible to temperature changes, does not return to a safe temperature fast enough. Heat from the engine block, turbocharger, and exhaust all contribute to raising the fuel system temperature.

The compact size of the truck and the design choices made to keep the fuel system close to the powertrain created challenges in thermal regulation.

Some drivers working in commercial delivery or remote operations have added secondary cooling lines or heat-wrap solutions to the pump and rail system to improve reliability. These modifications often work but are not part of the original equipment.

When pulling light trailers or operating at high altitudes, the Canyon also tends to show reduced fuel pressure performance.

This leads to inconsistent acceleration and sometimes triggers diagnostic trouble codes. Though GM made updates in later models to improve calibration, the physical fuel system layout remained mostly unchanged across this generation.

Many owners continue to praise the Canyon’s torque output and size, but those who operate in high-demand roles must remain aware of its fuel system limitations. Without extra thermal protection or upgraded cooling, the truck may face heat-related fuel pump fatigue in conditions involving heavy loads or prolonged engine use.

Also Read: 5 Manual-Transmission Cars That Hold Value vs 5 That Lose Value with a Stick

5. Toyota Tacoma (2016-2022)

Toyota’s Tacoma has a strong reputation for reliability and off-road strength. Despite this, the 3.5-litre V6 engine used during these model years has shown some vulnerability to heat soak in the fuel system.

The high-pressure fuel pump and related lines sit close to the engine and exhaust components, and during periods of extended idling or after shutting the engine off, the surrounding temperatures can cause fuel vapour formation.

This design setup affects the fuel rail and injector performance. When the engine is restarted after a hot soak, the ECU has to compensate for inconsistent fuel pressure readings.

This leads to temporary hesitation or rough starts. Although the Tacoma is designed to operate in a range of environments, it lacks a robust fuel cooler compared to what is found in heavy-duty or turbocharged vehicles.

Drivers who use the Tacoma for overlanding or trail driving have found that heat can build rapidly in tight spaces, especially when additional equipment like skid plates or bumper upgrades reduces airflow. This causes under-hood temperatures to remain high long after the engine is shut off, affecting the nearby pump and injector components.

Toyota attempted to manage the issue through software updates and fuel system recalibrations, but the hardware design continues to face temperature-related limitations. Without the benefit of a fuel cooler large enough to bring temperatures back down quickly, the system takes longer to recover from heat soak.

Though this issue does not cause long-term engine damage in most cases, it does affect the user experience, especially for those who operate in hot weather conditions or perform frequent short trips.

Hard restarts and brief stumbles can be frustrating and reduce trust in the truck’s readiness for demanding use. For many, adding thermal shielding or improving under-hood airflow remains the most effective solution, though such steps are not offered by Toyota as standard.