Engine longevity relies on more than just consistent maintenance and good-quality fuel. A primary part of engine health comes down to proper oil management, and that begins with the oil pan.

This part of an engine may seem ordinary at first, but the size and strength of the oil pan play a major role in how well an engine handles heat, pressure, and long driving conditions.

Some engines are equipped with oversized oil pans, designed to carry more oil and reduce the likelihood of overheating or starvation during spirited driving or off-road adventures.

These larger oil pans offer better cooling properties and help engines maintain performance for longer stretches without breaking down. Whether for track use or high-torque applications, oversized pans help keep temperatures under control and oil pressure consistent.

On the other side are engines that come with smaller, standard oil pans. While these may serve average drivers well, certain designs have earned reputations for cracking under stress or as time goes on.

Poor material selection, lack of reinforcement, and poor positioning near road hazards can make these pans vulnerable. Once the oil pan cracks, oil leaks, engine wear increases, and serious mechanical problems may follow.

This comparison focuses on five engines known for using oversized oil pans that improve reliability and five others that have faced criticism due to their stock oil pans being prone to cracking. Each engine will be examined for how its oil pan affects performance, long-term durability, and the entire cost of maintenance.

Whether you are a car enthusiast or someone who wants to understand why engine failures happen, this breakdown will provide clear insight. It can also help guide decisions when buying used vehicles, modifying engines, or maintaining performance cars that see high use or demanding conditions.

Engines with Oversized Oil Pans

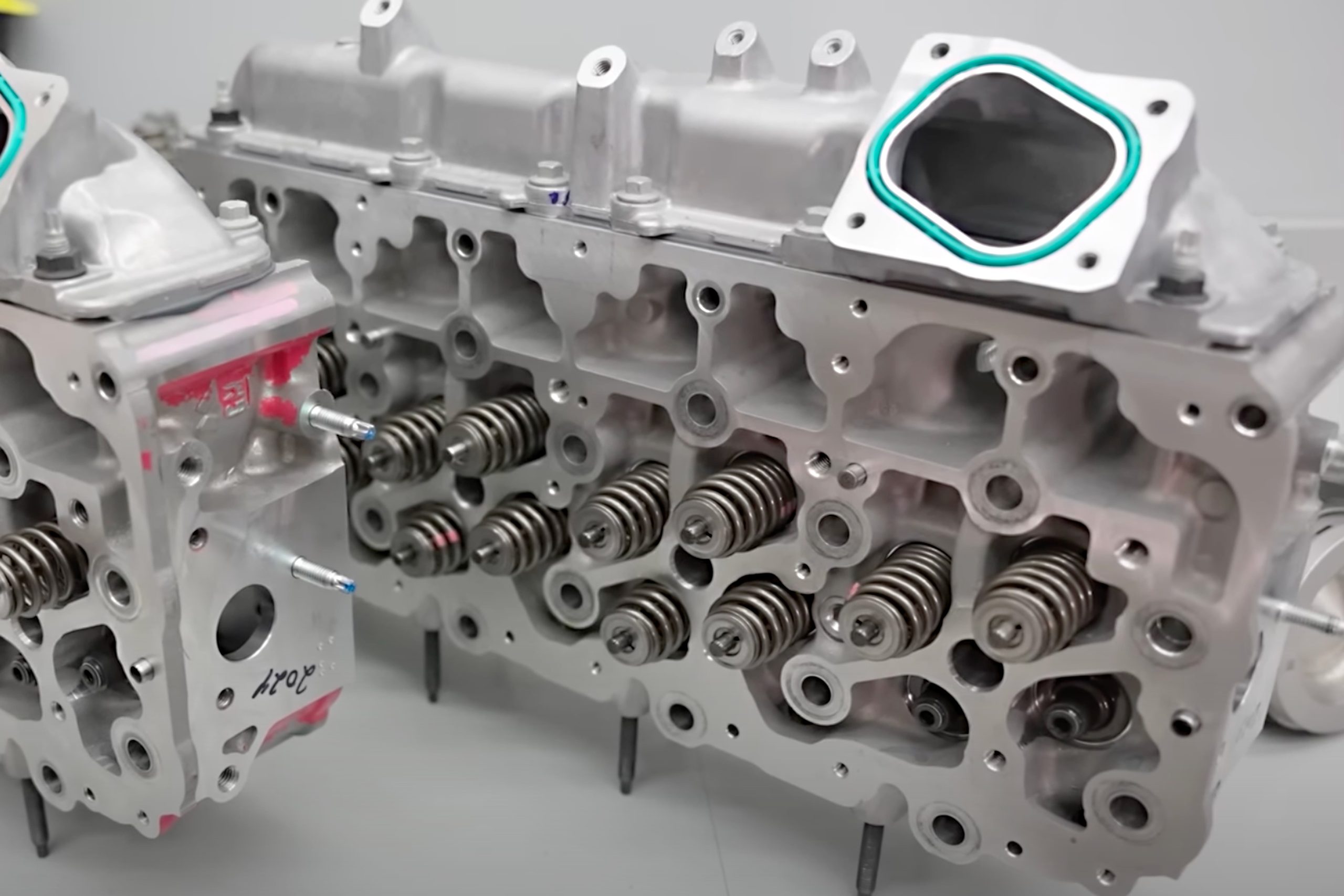

1. Chevrolet LS7

The Chevrolet LS7 engine, famously used in the Corvette Z06, is a high-performance powerplant that benefits greatly from its oversized dry sump oil system. This V8 was built for speed and endurance, delivering more than 500 horsepower.

To handle such output, General Motors designed it with a race-inspired oil system that includes a larger oil pan and an external reservoir. This setup supports extended high-rpm use without the engine suffering from oil starvation.

The oversized oil pan allows for more oil volume, which means better thermal control and sustained lubrication across all engine parts. During aggressive acceleration or high-G cornering, the oil inside a traditional wet sump pan can slosh away from the pickup, causing a momentary pressure drop.

With the LS7’s setup, oil is kept available at all times, even when the car is pushed to its limits on a track. This design reduces the chances of wear or catastrophic damage during spirited use.

The design is not only about volume but also about shape and structure. It is made from cast aluminum with integrated windage trays and baffles.

These internal features help reduce foaming, stabilize oil flow, and support the lubrication system’s reliability. Because of this, the LS7 can maintain steady oil pressure even during hard braking or acceleration.

Drivers who take their cars to the racetrack appreciate how this engine resists overheating and oil pressure drop, problems that would damage a less prepared engine. The oversized oil pan setup also plays a role in the LS7’s extended service intervals compared to other high-output V8s.

Whether it’s for road course racing or long highway pulls, this engine’s oiling system proves it was engineered for durability under stress. That makes the LS7 a strong example of how oversized oil pans can support high-performance demands without sacrificing engine life.

2. Toyota 2JZ-GTE

The Toyota 2JZ-GTE engine, known for its legendary strength and tuning potential, features an oversized oil pan that has become one of its defining characteristics.

This straight-six turbocharged engine, used famously in the Toyota Supra MKIV, was built to handle extreme conditions and high power outputs. Part of its durability comes from how its oiling system is engineered.

Toyota designed the 2JZ-GTE with a deep, cast aluminum oil pan that offers ample volume for oil storage. This is especially beneficial when the engine is pushed to higher horsepower levels through aftermarket tuning.

The oversized nature of the oil pan means oil starvation is less likely during aggressive driving or high-speed cornering. It also provides room for baffling, which helps direct oil where it is needed during acceleration or deceleration.

The pan’s strong construction adds another layer of protection. Unlike thinner stamped steel designs, the 2JZ’s oil pan can withstand road debris and vibration without cracking.

It serves not just as a reservoir but as a structural piece that helps keep oil pressure reliable under different driving conditions. Whether in drag racing, drift competitions, or long dyno pulls, the oiling system in this engine remains stable thanks in part to the generous oil capacity.

Many tuners and mechanics have observed that even when these engines are modified to produce over 800 horsepower, they maintain good oil pressure as long as the oil pan and pump are in proper condition. The 2JZ-GTE’s oversized oil pan is part of the reason why this engine has become a favorite among enthusiasts worldwide.

Toyota understood that serious performance requires a serious approach to lubrication, and the results show in how long these engines last and how consistently they perform under stress.

Also Read: 5 Cars With Generous Legroom vs 5 With Tight Rear Seats

3. Dodge Hellcat 6.2L HEMI

The supercharged 6.2L HEMI engine powering Dodge’s Hellcat models is engineered for extreme horsepower and equally extreme durability. This V8 delivers more than 700 horsepower from the factory, and to support such intense performance, Dodge fitted it with an oversized oil pan as part of a reinforced lubrication system.

The oil pan is not simply larger than average; it is shaped to hold high oil volume and features baffles and windage trays that maintain pressure and prevent aeration.

The Hellcat’s oil pan supports long sessions of hard driving by keeping oil available where it is needed the most. Rapid acceleration and tight cornering can move oil away from the pickup in standard pans, but the design of the Hellcat engine solves this.

It uses deep sump construction to allow greater storage, and with the aid of internal channels, oil movement is controlled during violent directional changes. This means that whether on a drag strip or a long highway pull, oil pressure remains stable.

The material used is cast aluminum, which helps with heat dissipation and adds strength to resist damage from underneath. The pan is also reinforced with additional bolts and structural ribs, making it less vulnerable to cracking or deformation.

Drivers often push Hellcat engines to their limits through tuning, but even when producing over 900 horsepower, the oil system maintains reliability if properly maintained. The oversized oil pan is one reason these engines remain dependable in both stock and modified form.

Dodge did not cut corners in designing this engine, and the lubrication setup shows attention to long-term durability. It is not just a performance solution but a measure that helps reduce premature wear.

By using a large and well-structured oil pan, Dodge ensured that this supercharged engine could withstand repeated stress without compromising reliability or engine life. The Hellcat oil pan proves that durability and performance can go hand-in-hand when thoughtful engineering is applied.

4. GM Duramax L5P

The Duramax L5P diesel engine from General Motors is used in heavy-duty trucks like the Silverado HD and Sierra HD. This engine is designed for hauling, towing, and long-distance use under load.

To support the intense requirements of commercial and off-road use, it features an oversized oil pan that holds more oil than a standard gas engine, ensuring stable lubrication even under prolonged strain.

The oil pan is made from cast aluminum, which adds both durability and effective heat dissipation. Its deep design allows the engine to store over 10 quarts of oil, which helps in keeping temperatures down during continuous operation.

The shape of the pan includes integrated baffles that prevent oil from sloshing around during heavy acceleration or steep climbs. This keeps oil pressure steady and prevents dry starts, especially after the vehicle has been parked on an incline or run for long periods.

Diesel engines generate higher torque and experience different thermal loads compared to petrol engines. The oversized oil pan in the L5P plays a critical role in managing these conditions. It supports longer intervals between oil changes and helps reduce engine wear after some time.

Drivers who use their trucks for towing benefit from this, as the engine maintains consistent oil pressure even when under extreme pulling forces or loaded uphill drives.

Many fleet operators and diesel mechanics praise the L5P for its strong design and long lifespan. The oversized oil pan is part of what gives this engine a reputation for dependability in commercial applications.

It is one reason why trucks equipped with the Duramax engine are often seen with high mileage and minimal issues related to lubrication. This large oil pan design helps reduce stress on the internal components and allows the engine to remain operational and efficient even after years of heavy-duty use.

5. Mercedes-AMG M156

The M156 engine developed by Mercedes-AMG stands out as one of the brand’s first independently built engines. Found in vehicles like the E63 AMG, S63 AMG, and CLK63 AMG, this naturally aspirated 6.2-litre V8 is both powerful and durable.

A critical part of its design is the use of an oversized oil pan that ensures lubrication remains consistent during high-performance driving. With its capacity of around 10.5 quarts, the oil system is built to cope with both daily driving and extreme track sessions.

The oil pan in the M156 is deep and wide, allowing it to hold more oil than a standard V8. It is made from cast aluminum, which provides both strength and excellent thermal conductivity. This helps the engine shed heat faster and maintain a steady oil temperature.

The shape of the pan is optimised with internal baffles and channels that prevent oil from shifting during aggressive turns, acceleration, or braking. As a result, oil pressure remains constant and prevents the risk of starvation.

Engineers at AMG understood that an engine producing over 500 horsepower needed an oiling system capable of withstanding stress.

The oversized oil pan is paired with an advanced oil pump system that supports high flow and keeps up with the demands of the engine even at high RPMs. This combination ensures that the valvetrain, pistons, and bearings are always lubricated under heavy loads.

For owners who drive these cars on the autobahn, racetracks, or through mountain roads, the oversized oil pan contributes to a sense of reliability. Even in warm climates or during long-distance driving, the M156 performs consistently.

The larger pan reduces the rate of oil breakdown, leading to longer service intervals and fewer issues with overheating. It also provides an extra buffer during emergencies, where temporary oil loss would otherwise cause severe damage.

Mercedes-AMG’s decision to use an oversized oil pan on the M156 reflects the engine’s purpose-built nature and enhances its long-term durability for those who push it to the limit.

Engine with Stock Pans That Crack

1. Ford Coyote 5.0

The Ford Coyote 5.0 engine is widely respected for its performance and adaptability, particularly in the Mustang GT. While the engine delivers impressive power and has a loyal following, one area where it faces scrutiny is the design of its stock oil pan, especially in earlier models. Built using plastic composites in some versions, the pan has drawn complaints for cracking under certain conditions.

The stock oil pan in the earlier Coyote versions was part of an effort to reduce weight and improve efficiency. However, plastic pans tend to expand and contract at a different rate from the metal engine block.

In due course, this mismatch can cause stress on the sealing surfaces, which may result in leaks. Cracks may also form if the pan is struck from below or exposed to frequent heat cycling without proper care. These issues are more common in vehicles that are driven hard or lowered without extra undercarriage protection.

While Ford improved the design in later model years by moving to stamped steel or aluminum in higher trims, many vehicles with the older plastic pans remain on the road.

Owners often report oil seepage, oil pressure fluctuations, or full cracks that require the entire pan to be replaced. For those who modify their cars for track use or drag racing, upgrading to an aftermarket aluminum or steel pan becomes a necessity to prevent future engine damage.

The issue does not render the engine unreliable, but it introduces a maintenance concern that buyers and enthusiasts should consider. An engine can have excellent power delivery and sound tuning, but if it cannot maintain oil pressure due to a cracked pan, the long-term cost rises.

The Coyote 5.0 remains popular, but its stock oil pan design in earlier variants serves as a warning that even strong engines can be undermined by cost-saving design choices.

2. BMW N20

BMW’s N20 engine was introduced as a turbocharged four-cylinder alternative to their earlier inline-six options. Found in vehicles like the 3 Series and X3, the N20 was designed with efficiency in mind. However, one design feature that has drawn criticism is its oil pan, which has been known to develop cracks, especially under long-term use or heavy stress.

The N20 uses an aluminum oil pan that, while light and well-matched to the engine’s performance goals, is vulnerable to cracking if subjected to strong impact or if over-torqued during service.

The thin walls of the pan save weight but offer less protection against road debris or high levels of vibration. Many owners have reported oil leaks that eventually lead back to pan cracks. In colder climates where thermal expansion and contraction happen more often, the issue becomes worse.

The location of the oil pan also increases risk. Positioned low in the engine bay, it is one of the first components exposed to speed bumps, potholes, or poorly installed skid plates.

Since the oil pan plays a direct role in the engine’s lubrication system, even a hairline crack can allow oil to escape, reducing pressure and raising engine wear. Repairs are costly, especially considering BMW labor rates and the need to reseal or replace the part entirely.

Even routine service can contribute to the problem. Overtightening bolts or using the wrong gasket material during oil changes may cause stress on the corners of the pan, making it more likely to fracture.

Though the N20 engine can deliver smooth performance and respectable fuel efficiency, the vulnerability of its oil pan creates a long-term issue for maintenance-conscious drivers.

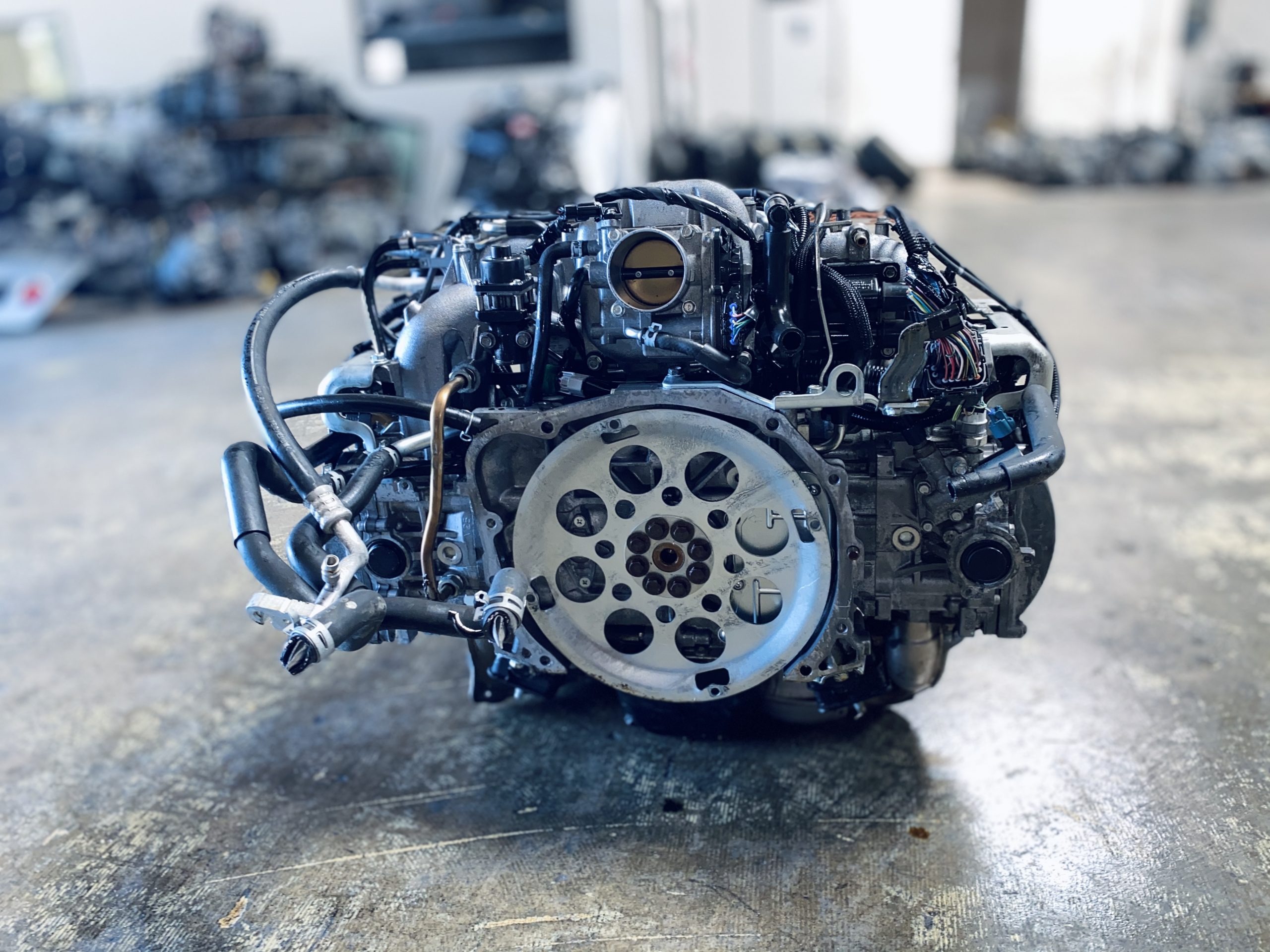

3. Subaru EJ25

The EJ25 engine from Subaru has powered a wide range of models, including the WRX and Forester, but it has had persistent issues with its stock oil pan in certain versions.

The pan, constructed from stamped steel in many models, is known to develop cracks or leaks after some time. These issues arise more frequently in cars that are used in spirited driving or are lowered without sufficient protection underneath.

The design of the pan places it in a vulnerable position just beneath the front crossmember. Its relatively thin material means that even a small strike from a rock or speed bump can dent or crack the surface.

As time goes on, road vibrations and heat cycles worsen the condition, and stress cracks can form near the welds or the drain plug. Oil seepage may not be noticed immediately, but low oil levels or pressure warnings often follow, leading to engine damage if ignored.

Subaru owners who upgrade their vehicles for performance often replace the stock oil pan with an aftermarket alternative made from thicker aluminum or steel.

These upgraded options also feature trap doors or baffles to improve oil control during hard cornering or acceleration. Subaru did attempt to improve the situation in later versions by redesigning some aspects of the oil system, but many older models remain on the road with pans that are prone to damage.

Even routine maintenance must be done carefully. Over-tightening the drain plug can distort the pan and cause a crack. Mechanics familiar with Subaru engines often recommend replacing the pan preemptively if the vehicle will see any track time or rough roads.

While the EJ25 can be a reliable engine when cared for, its stock oil pan represents a weak spot that can turn costly if not addressed. Replacing it with a more durable version is one of the most common upgrades among long-term Subaru owners and tuners.

4. Honda K24

Honda’s K24 engine is widely regarded for its reliability and high-revving nature. Found in vehicles like the Honda Accord, CR-V, and Acura TSX, the engine has a loyal base among both everyday drivers and performance tuners.

However, one issue that has surfaced in specific applications is the vulnerability of the stock oil pan to cracking, especially when driven aggressively or under modified setups.

The K24’s oil pan, made from aluminum, is prone to cracking if it encounters heavy impact or thermal stress. The design is relatively shallow, which works well for ground clearance but puts it at greater risk when vehicles are lowered or exposed to uneven road surfaces.

Even a small collision with road debris can lead to a hairline fracture, which may cause oil leakage without immediate signs. As time goes on, this leads to low oil levels and reduced lubrication to vital components.

In vehicles modified for racing or track use, oil sloshing during hard cornering can reveal the limits of the stock oil pan. Some drivers report that under extreme conditions, the K24 experiences brief drops in oil pressure, especially without internal baffles or trap doors in the pan.

These conditions can lead to premature engine wear if left unaddressed. This concern is especially relevant in older vehicles that have already accumulated considerable mileage.

Many enthusiasts have responded by upgrading to aftermarket oil pans with more volume and better construction. These replacements often include baffles and reinforced flanges that help maintain pressure and prevent cracks

Honda’s engine design remains solid, but the stock oil pan introduces a maintenance point that should not be ignored. For those who value engine life and performance, replacing the factory oil pan becomes a smart step, especially before subjecting the car to high loads or competitive driving conditions.

Also Read: 5 Cars You Can Maintain at Home and 5 That Require Dealer Visits for Everything

5. Chrysler 3.6L Pentastar

Chrysler’s 3.6L Pentastar V6 engine has been widely used across various Dodge, Jeep, and Chrysler vehicles. While it has earned praise for efficiency and smooth power delivery, the earlier versions of the Pentastar engine came with a stock oil pan made from plastic composite.

This material, while lightweight and cost-effective, has caused problems due to cracking and oil leaks, particularly in vehicles with higher mileage or those driven in harsh conditions.

The use of a plastic oil pan may have reduced manufacturing costs, but it introduced durability concerns. Temperature changes, vibrations, and even mild impacts from debris can cause cracks or warping in the pan.

As the engine heats up during driving and then cools down, the plastic can become brittle after a while. Some drivers have also reported problems with oil seepage near the drain plug, especially after repeated oil changes where the plug has been overtightened.

Another concern is the location and shape of the oil pan. It sits relatively low on the engine, making it more likely to be damaged by road hazards or debris. Even hitting a high curb can cause enough impact to weaken or fracture the pan.

Once a crack forms, oil leaks slowly and reduces pressure, increasing the risk of engine damage if the issue goes unnoticed. This has led many mechanics to recommend replacing the factory pan with a steel or aluminum aftermarket unit, particularly for drivers who use their vehicles for off-roading or heavy-duty work.

Chrysler eventually improved the design in newer iterations by switching to more durable materials and modifying the mounting surfaces. However, many vehicles still operate with the original plastic pans and continue to experience these problems.

Owners who want to avoid major engine trouble should inspect the oil pan regularly and consider a replacement during scheduled maintenance. While the Pentastar engine can be reliable under proper conditions, its stock oil pan has created long-term reliability issues that are worth addressing before they escalate.

Engines designed with oversized oil pans like the LS7, 2JZ-GTE, or M156 show how thoughtful oil management can preserve performance and reduce wear. These setups not only carry more oil but also prevent starvation, support heat control, and offer extra durability in demanding conditions.

Also, engines like the Coyote 5.0, BMW N20, and Pentastar V6 remind us that poorly designed or vulnerable stock oil pans can become a major liability. Cracks, leaks, and low oil pressure become common issues in such setups, affecting long-term maintenance costs and increasing the chance of engine damage.

Whether you drive a high-performance machine or a reliable daily commuter, paying attention to the design and material of your engine’s oil pan is worthwhile.

It could be the difference between a dependable engine that runs for years and one that suffers repeated failures due to something as simple as a cracked oil pan. Careful inspection, timely upgrades, and smart modifications can make all the difference.