Car enthusiasts are often drawn to the promise of more horsepower, better acceleration, and an aggressive exhaust note.

The allure of customizing a vehicle’s powerplant fuels a thriving aftermarket performance industry, where adding forced induction, reworked internals, and advanced fuel systems seems like a shortcut to speed.

However, not all engines are created with the same level of robustness or flexibility. While some engines have earned a reputation for easily handling modifications and producing reliable gains, others are notorious for faltering under even mild enhancements, leading to mechanical failures and costly repairs.

Recognizing which engines welcome increased power and which are better left relatively stock is crucial for anyone considering modifications.

Reliable high-performance platforms often feature overengineered internals, forged components, and strong aftermarket support.

In contrast, those with less headroom quickly reach the limits of their design, with weak connecting rods, fragile pistons, or limited cooling capacity.

This contrast is not just about performance but about longevity and safety. Knowing the difference can save both financial and emotional investment.

This article identifies five engines that enthusiasts widely respect for their ability to handle high-performance modifications and contrasts them with five powerplants that tend to resist substantial aftermarket enhancement. Each example is chosen to demonstrate how engineering choices affect modification potential.

Also Read: 5 Engines with Oversized Oil Pans vs 5 with Stock Pans That Crack

5 Engines That Handle High-Performance Mods

Car culture thrives on individuality and the pursuit of personal expression through machinery. Among the most celebrated aspects are the engines renowned for their ability to shrug off higher boost pressures, aggressive cam profiles, and radical fueling changes, all while maintaining or even surpassing factory reliability.

These are the canvases upon which tuners paint their ambitions, attracting both professionals seeking record-breaking times and weekend hobbyists hoping to sharpen their daily drivers. These engines are not simply legends for their factory specifications but for how they respond to upgrades.

Their strength lies in thoughtful engineering: robust iron or alloy blocks, stout forged internals, overbuilt oiling systems, and heads that love to breathe. Manufacturers sometimes anticipate future racing or tuning demands, building in extra margin.

Aftermarket support follows, with an ecosystem of tuning solutions, bolt-on upgrades, and bulletproof replacement parts.

The following five engines are spotlighted because they have consistently earned the loyalty of the performance community, not just for their prowess out of the box, but for their proven track record in the face of ambitious modifications. Each profile explores why it stands out and what makes it a favorite for those seeking more power.

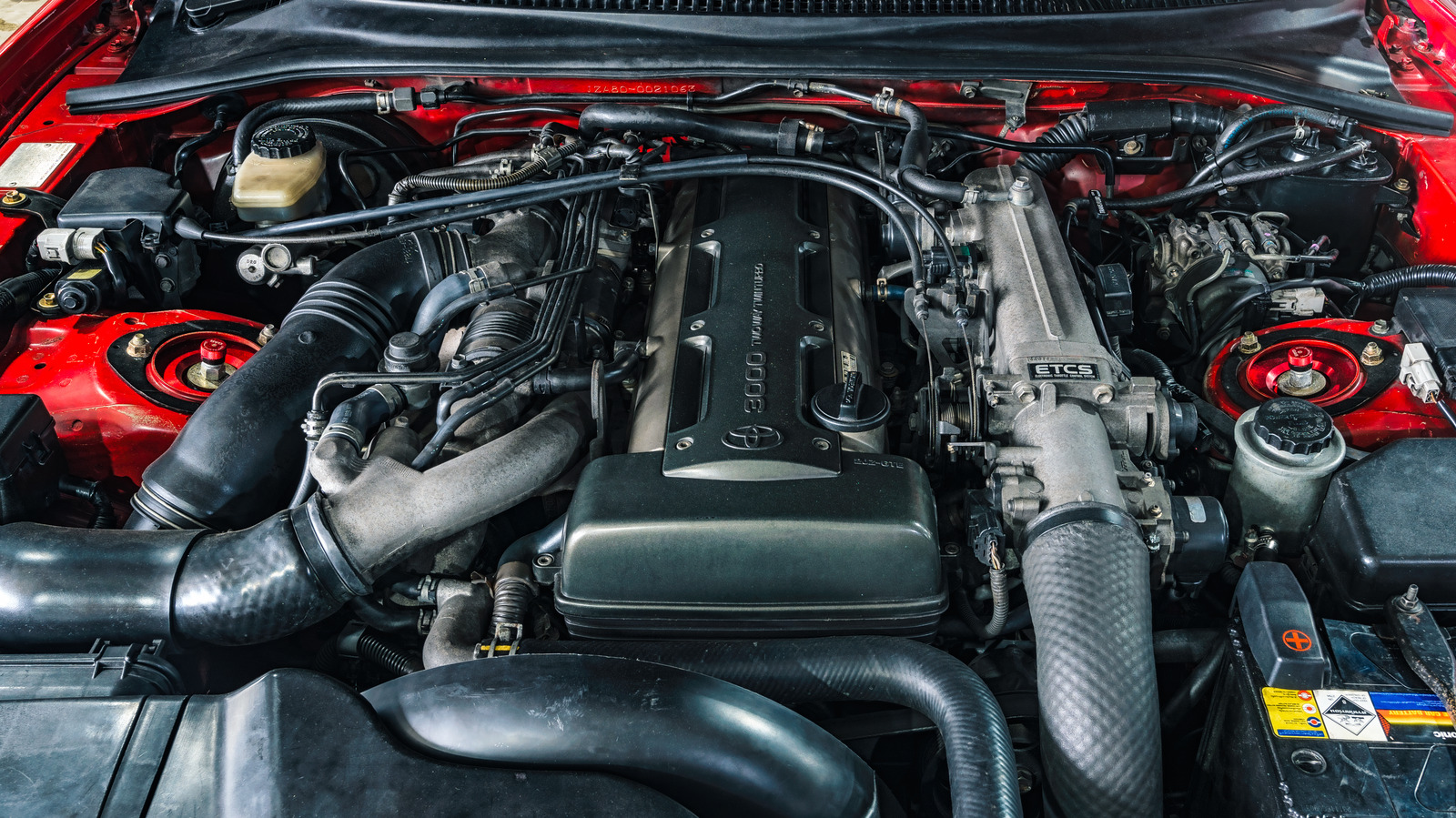

1. Toyota 2JZ-GTE: The Icon of Reliability and Power

The Toyota 2JZ-GTE, a twin-turbocharged 3.0-liter inline-six found in the legendary Toyota Supra Mk4, has become almost synonymous with the pursuit of extreme horsepower.

When Toyota designed this engine in the early 1990s, they seemed to anticipate a level of abuse well beyond what the average consumer would ever deliver.

The 2JZ-GTE was fitted with a cast-iron block, forged steel crank, stout connecting rods, and sequential turbochargers, all packaged to withstand substantial boost.

This attention to robustness set it apart. Street tuners and drag racers quickly realized this engine could double or even triple its factory 276hp output with little more than upgraded turbochargers, fuel management, and basic supporting modifications.

Builds surpassing 1,000hp are not fairy tales told on internet forums the 2JZ-GTE supports these numbers reliably, often with stock internals, proving the original engineers left significant headroom.

Why highlight the 2JZ-GTE in discussions of mod-friendly powerplants? Its reputation is not just built on sheer power, but on a history of taking punishment.

The global aftermarket has developed countless bolt-on and internal upgrades, from standalone engine management systems to billet main caps, ensuring that even the wildest ambitions are covered.

Whether in drag racing, time attack, or street builds, it has achieved a rare cult status, and the shared knowledge among enthusiasts makes tuning relatively accessible. Toyota’s dedication to overengineering ensured the 2JZ-GTE’s place as a reliable foundation for performance dreams.

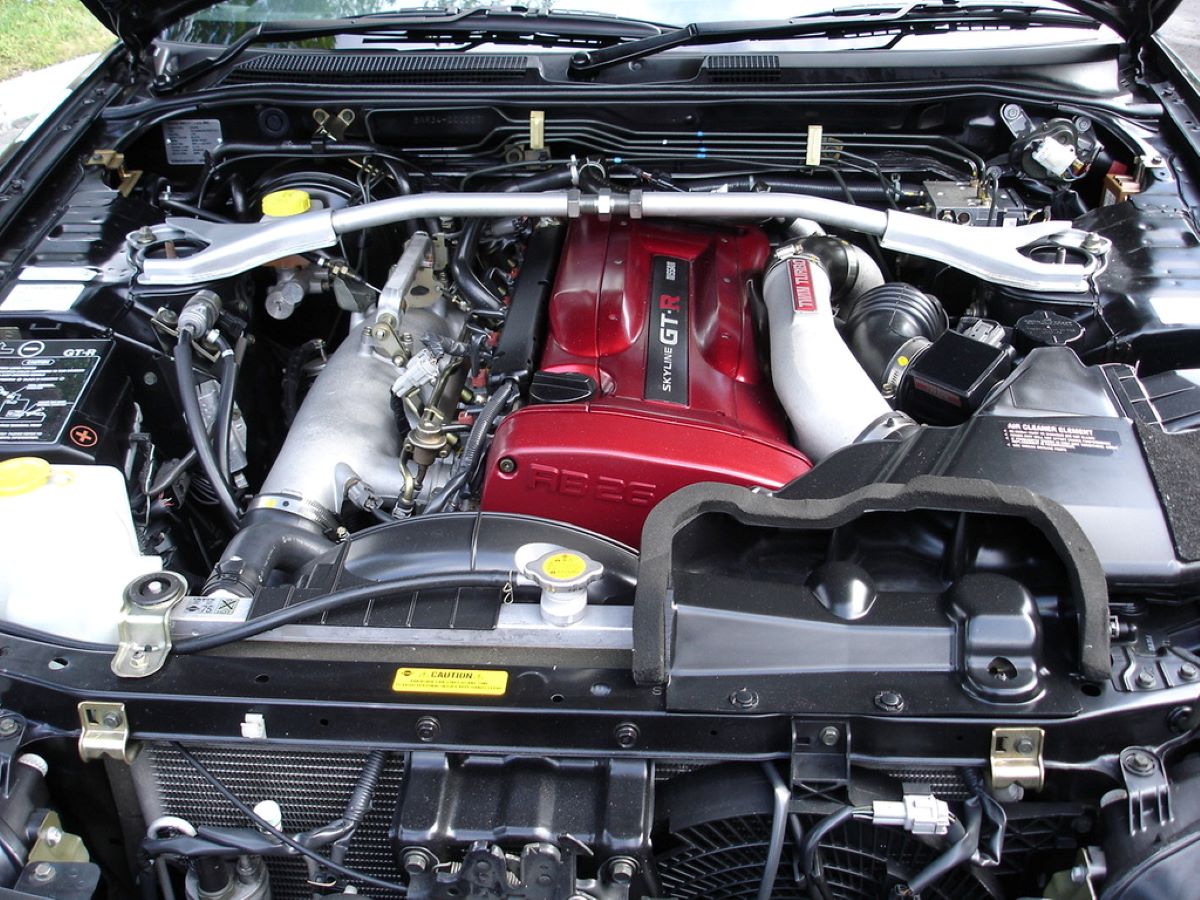

2. Nissan RB26DETT: The Legend from the Skyline

Nissan’s RB26DETT, best known for powering the R32-R34 Skyline GT-R models, commands an almost mythical reputation for performance tuning.

The 2.6-liter, twin-turbo inline-six is instantly recognizable in both Japanese tuning culture and international motorsports.

Its celebrated success stems from its distinctive characteristics, starting with an iron block that provides inherent strength and a forged bottom end capable of enduring high-RPM abuse.

What sets the RB26DETT apart is its motorsport heritage; the engine was designed with Group A racing in mind, where reliability and adaptability to extreme tuning were crucial.

The engine comes equipped with a beefy crankshaft, strong connecting rods, and a DOHC 24-valve cylinder head that breathes exceptionally well. The stock bottom end safely tolerates power well above the original 276hp rating, with many tuners regularly achieving 600–800hp on mainly factory internals.

Highlighting the RB26DETT is essential because its engineering depth continues to influence engine design and modification approaches worldwide.

The aftermarket ecosystem is vast, with components ranging from reinforced head gaskets and oversize turbos to complete stroker kits. The RB26’s flexibility lets tuners pursue drastic horsepower increases for drag racing, time attack, or even daily driving.

Its technical sophistication and historical achievement encourage ambitious projects, making the RB26DETT a gold standard for mod-friendly engines.

3. Chevrolet LS-Series (LS1/LS3/LS7): The Backbone of American V8 Tuning

No conversation about tunable engines is complete without addressing the Chevrolet LS family, especially the LS1, LS3, and LS7 engines.

These aluminum V8s have revolutionized not just domestic performance, but global tuning cultures, thanks to their compact dimensions, lightweight construction, and unrivaled affordability.

Designed for everything from Camaros and Corvettes to trucks, the LS engines combine old-school displacement with modern efficiency.

A remarkable feature is their ability to handle forced induction or naturally aspirated mods with grace. The bottom end is robust, featuring a strong crankshaft and main bearing support; high-flow heads make breathing easy.

Many widely available upgrades superchargers, cam kits, improved valve trains, help LS engines push from an already stout 350–500hp range into four-figure horsepower territory on built internals.

Countless grassroots racers, swap enthusiasts, and professional builders flock to the LS engine because it accepts enormous gains without frequent catastrophic failure.

The LS series is chosen for its accessibility, forgiving design, and the sheer scale of its modification community. Aftermarket parts are reasonably priced and widely available, and technical forums provide a trove of real-world data and tuning support.

The LS engines symbolize democratized performance, making them essential in any discussion of mod-friendly powerplants.

4. Ford 2.3L EcoBoost: Modern Four-Cylinder Modding Powerhouse

Ford’s 2.3-liter EcoBoost, found in vehicles like the Mustang and Focus RS, is a contemporary example of a small-displacement engine built with modification in mind.

Utilizing direct injection, turbocharging, and an all-aluminum construction, the EcoBoost brings new-era technology to enthusiastic tuners who want efficiency and performance in equal measure.

What justifies its inclusion among engines that handle aftermarket power? Ford engineered the EcoBoost with a forged steel crankshaft, high-quality pistons, and advanced cooling channels.

Owners and tuners quickly discovered that factory components can reliably sustain significant increases in boost and horsepower with supporting modifications.

Reliable 400–500hp builds are achievable on stock internals through improved tuning, larger turbochargers, and fueling upgrades, which is an impressive leap from the original output.

The aftermarket has responded in force, providing intakes, intercoolers, turbo kits, and computer reflashes to extract every ounce of capability.

Unlike previous generations of four-cylinders known for fragility under stress, the 2.3 EcoBoost demonstrates that modern engineering can co-exist with modding ambitions.

Its growing popularity in both street and motorsports builds, combined with Ford’s attention to durability, cements its place as a modern hero among tunable engines.

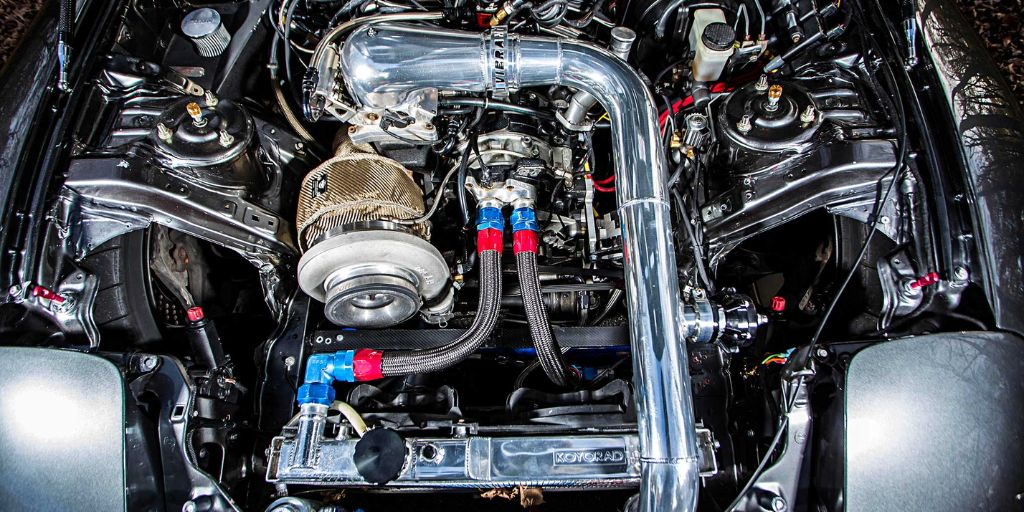

5. Mitsubishi 4G63T: Rally Roots Meet Rugged Durability

For nearly two decades, the Mitsubishi 4G63T has delivered thrills in platforms like the Lancer Evolution, carving a niche among turbo four-cylinder enthusiasts.

Originally designed for rally competition, the 2.0-liter turbocharged engine features a cast-iron block, robust forged internals, and high-flow heads, ingredients that combine to ensure both strength and flexibility.

Much like the 2JZ or RB26, the 4G63T’s design left substantial headroom between the factory power limits and the true mechanical threshold.

The block handles higher boost pressures with ease, and the crank/rod/piston assembly is known to survive 400–600hp regularly with only moderate upgrades.

Stock rotating assemblies in earlier generations, in particular, were famous for forged rods and strong pistons, which withstand aggressive launch control at rallycross events.

Why focus on the 4G63T here? It provides a textbook demonstration of how motorsport-driven engineering translates into street legend status.

Beyond its rallying achievements, a deep aftermarket ensures the availability of everything from head gasket upgrades to gigantic turbochargers.

The knowledge base surrounding the engine simplifies the tuning process, and parts sharing across different years and models broadens possibilities.

For those looking to extract maximum performance from a modest displacement, the 4G63T stands as one of the most trusted engines in the modification community.

5 Engines That Can’t Take Aftermarket Power

While some engines gain legendary status for their resilience, others build a reputation for failure when subjected to significant increases in performance.

These powerplants might perform admirably in standard form, but their materials, assembly methods, or fundamental design limitations mean they simply cannot tolerate persistent high loads or increased cylinder pressures. For unsuspecting enthusiasts, attempts to chase bigger numbers often end in frustration and expense.

Identifying these engines is not about dismissing their achievements at stock specifications but about understanding where factory engineering draws the line.

Weak rods or pistons, poorly supported bottom ends, restricted cooling, or even flimsy head gaskets can spell disaster after relatively modest upgrades.

Some manufacturers, driven by cost, packaging, or emissions regulations, prioritize lightness or efficiency above outright strength, leaving little margin for error.

This section highlights five engines that are not suited to heavy modifications, not to disparage them, but to offer essential guidance.

Knowing these weaknesses helps enthusiasts avoid expensive mistakes and encourages a healthy respect for factory limitations.

By recognizing these engines and understanding their constraints, tuners are better prepared to focus time and resources on platforms that support their ambitions, or to maintain stock power for long-term reliability.

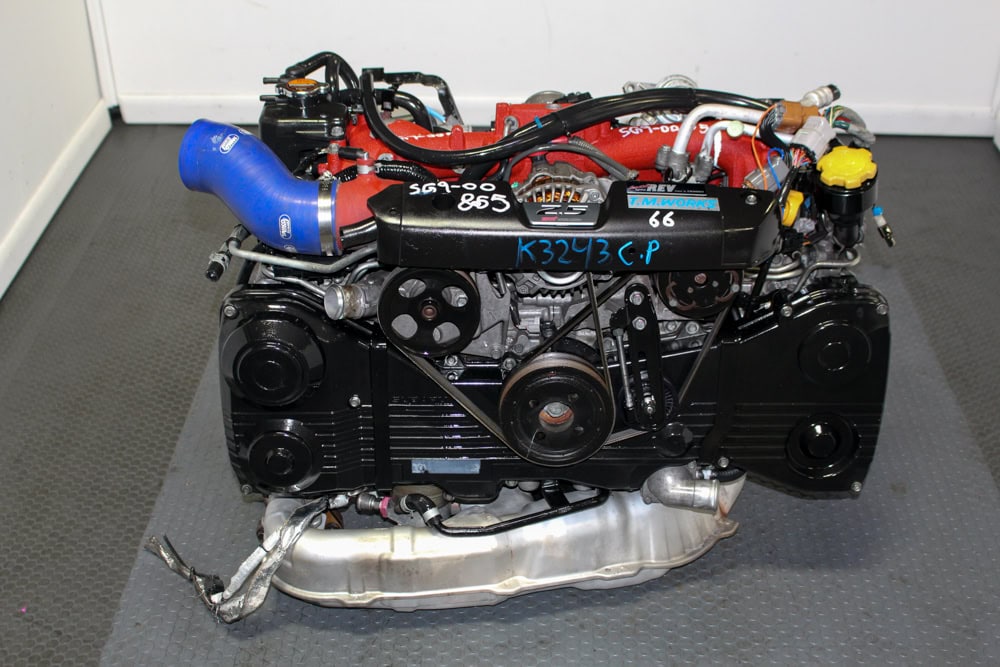

1. Subaru EJ25: Prone to Head Gasket and Bearing Issues

Subaru’s EJ25, a 2.5-liter flat-four found in various WRX and Forester models, is beloved by many for its accessible torque and distinctive boxer rumble.

Unfortunately, its design is just not conducive to reliably supporting substantial power increases beyond the factory setup. While the engine is routinely modified by enthusiasts, ongoing reports of persistent reliability issues surface as output climbs.

The engine’s primary weakness is the well-documented vulnerability to head gasket failure, a consequence of the engine’s open-deck design and relatively thin head gaskets.

As boost pressure and cylinder pressures grow, maintaining proper sealing becomes an uphill struggle. The oiling system’s design further complicates matters; rod bearing failures can occur as performance demands increase, especially when aggressive driving is coupled with a lack of supporting modifications.

The stock pistons and rods, while adequate for factory output, typically lack the strength needed for long-term reliability at higher power levels.

Highlighting the EJ25 in this context serves as a caution to those considering ambitious horsepower upgrades. The romance of Subaru turbo culture is often offset by the cost and hassle of frequent rebuilds.

While moderate modifications with professional tuning and supportive upgrades can yield reliable gains, the ceiling is low compared to platforms engineered for high-output endurance. A careful balance between desire and engineering reality is essential for anyone working with the EJ25.

2. Mazda Rotary 13B-REW: Fragile by Nature, Not by Intent

The Mazda 13B-REW rotary, most famously installed in the FD RX-7, offers a unique driving experience renowned for high-revving elasticity and a compact footprint.

Still, rotary engines are fundamentally different from piston engines, and their inherent limitations become clear as tuners add more boost or chase higher outputs.

Rotary construction brings with it apex seals small metal strips at the corners of each rotor, which are notoriously sensitive to detonation and inadequate fueling. Pushing more air and fuel into the chamber risks catastrophic failure if tuning is not perfect.

Heat management is another Achilles’ heel, as increased power further stresses cooling and oiling. The standard rotors and bearings, designed for efficiency and relatively low thermal loads, quickly reach their limit as performance upgrades mount.

Discussing the 13B-REW in this segment is important because its appeal tempts many to push the envelope without appreciating the risks.

While some dedicated tuners have found ways to tease out more reliable power with extensive modifications and increased maintenance, the reality is that the rotary engine typically resists significant horsepower gains in stock form.

Those considering jumping into the deep end of RX-7 ownership are wise to approach upgrades with caution, a willingness to overbuild, and a realistic expectation about costs and reliability.

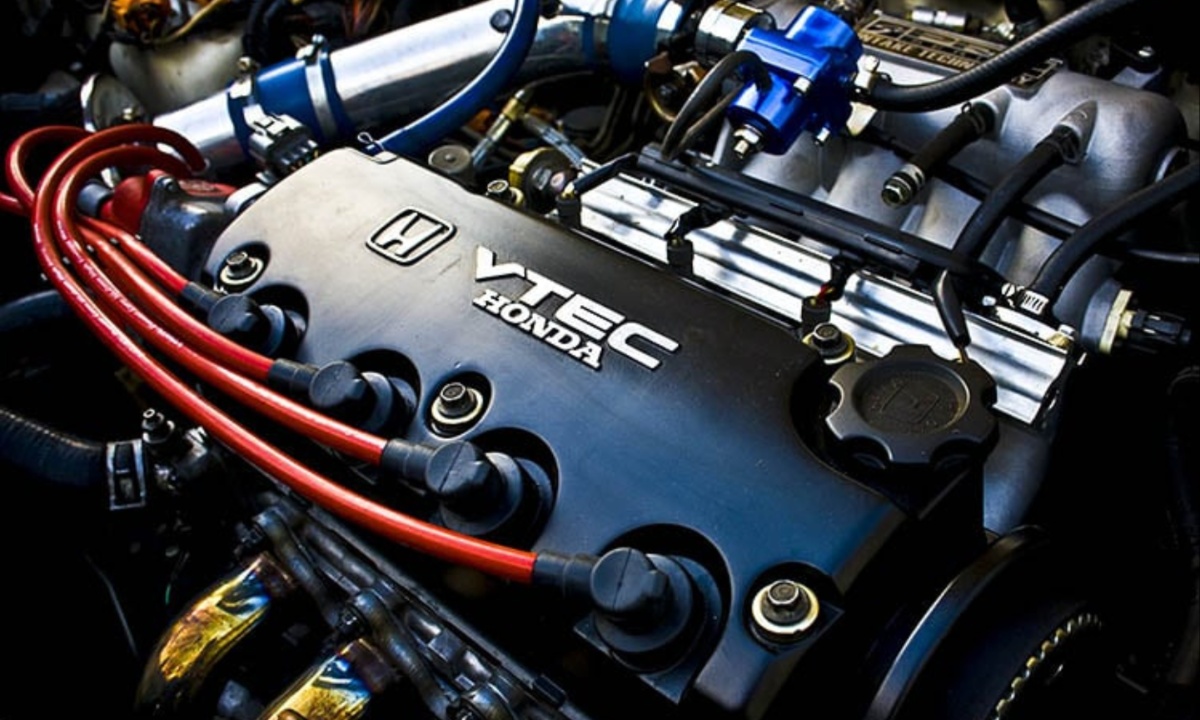

3. Honda D16 Series: Budget Simplicity Means Limited Strength

Honda’s D16 series, found in a host of Civics throughout the 1990s and early 2000s, is admired for its simplicity and frugality.

The Single Overhead Cam (SOHC), 1.6-liter architecture is light, economical, and easy to service characteristics that made it one of the world’s most popular commuter engines. However, those same attributes are what limit its capacity for handling meaningful power increases.

The block and rotating assembly were never intended to tolerate turbocharging or high-revving stresses over long periods. Rods and pistons are lightweight but lack the reinforcement needed for substantial power or high-RPM abuse.

The cylinder head design, geared for fuel efficiency, places limitations on flow and combustion dynamics. Exceeding factory power outputs by even a moderate margin leads to decreased reliability, frequent head gasket failures, and in some cases, catastrophic rod failure.

The Honda D16 series is an important reminder that economy-focused engineering cannot be expected to deliver high-performance results without extensive upgrading.

Its place here isn’t to deter modest improvements a carefully tuned D16 with light, bolt-on mods is both fun and reliable.

The caution applies mainly to those eyeing turbo kits or substantial horsepower hikes; the D16 simply wasn’t engineered for the abuse associated with serious performance tuning.

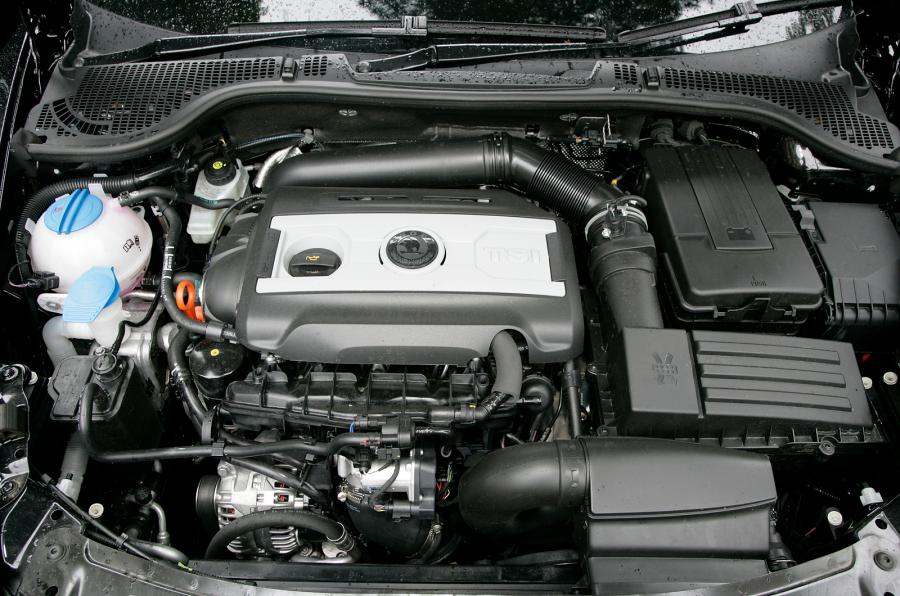

4. Volkswagen/Audi 1.8T (EA113/EA888 Early Series): Temperamental Under Pressure

Volkswagen’s and Audi’s 1.8T engines (especially early EA113 and EA888 versions) have had widespread use across the Golf, Jetta, Audi A4, and TT platforms.

These engines initially won praise for turbocharged innovation and versatile tuning possibilities. Yet, beneath the surface, several design choices restrict the engine’s reliability as power increases beyond factory intent.

Weaknesses include piston rings that are prone to wear, causing oil consumption; a delicate turbocharger that rarely survives increased boost beyond manufacturer allowances; and timing belt systems that, if not meticulously maintained, can lead to costly failures.

The fragile coil packs and a sensitive electronic management system present even more hurdles for tuners. As horsepower rises, the engine struggles with higher cylinder pressures, and stock internals only tolerate modest enhancements before breakdowns become frequent.

This example is instructive for anyone considering modifying a VAG 1.8T. The platform is not inherently flawed for daily driving or moderate mods; problems scale sharply as ambitions grow.

Aftermarket solutions exist, but they require comprehensive investment—neither cheap nor simple. For those on tighter budgets or seeking worry-free gains, these engines are best enjoyed close to their design limits.

5. BMW N54: High Potential Meets Notorious Reliability Headaches

BMW’s twin-turbocharged N54 inline-six, found in the 335i and 135i, quickly earned acclaim for its willingness to respond to tuning. Out of the box, the N54 takes to bolt-ons, upgraded turbos, and flashed ECUs, with impressive power returns.

However, beyond a certain threshold, the N54’s weaknesses begin to overwhelm the positives, and its spot on this portion of the article is a caution born of hard-earned experience within the performance community.

The N54’s Achilles’ heel is its tendency toward high-pressure fuel pump failures, injector issues, problematic turbo seals, and cooling system woes.

The stock internals, while initially robust, start to fail when subjected to sustained, high-boost operation typical of more aggressive builds. Cylinder wall scoring and rod bearing failures are commonly reported among high-mileage, heavily tuned examples.

Even with ample aftermarket support, costs to retain reliability escalate rapidly, sometimes negating the attraction of the original platform.

This engine’s reputation is a lesson in the risks of chasing power without adequately weighing the supporting investment.

While moderate, professionally tuned upgrades can provide impressive and enjoyable performance, major horsepower jumps court a parade of potential breakdowns.

For enthusiasts without a substantial maintenance budget, the N54 is best left closer to stock than its tempting aftermarket suggests.

This article compares two categories of automotive engines based on their ability to handle high-performance modifications.

The first portion highlights five engines celebrated for their robustness and tuning potential, while the second portion addresses five engines known to struggle when subjected to aftermarket power increases.

Among the engines well-suited to modifications are the Toyota 2JZ-GTE, Nissan RB26DETT, Chevrolet LS series, Ford 2.3L EcoBoost, and Mitsubishi 4G63T.

These engines feature qualities such as strong iron or alloy blocks, forged internals, and excellent cooling systems. Their engineering foundations allow them to reliably sustain significant power boosts.

For example, the 2JZ-GTE is famous for exceeding 1,000 horsepower with stock internals, while the RB26DETT benefits from its motorsport-born durability.

The Chevrolet LS series is widely praised for its affordability and massive aftermarket support. The modern Ford 2.3 EcoBoost impresses with its advanced design allowing nearly double its stock power, and the rally-proven Mitsubishi 4G63T remains a trusted platform for turbocharged builds.

In contrast, the article identifies the Subaru EJ25, Mazda 13B-REW rotary, Honda D16 series, early Volkswagen/Audi 1.8T engines, and BMW N54 as examples that face limitations under heavy modification.

These powerplants suffer from weaknesses like fragile internals, cooling challenges, and sealing issues. Attempts to significantly increase horsepower often lead to reliability problems such as head gasket failures, bearing wear, or turbocharger damage.

While some moderate upgrades are possible, these engines generally cannot support aggressive tuning without substantial rebuilds or risk of failure.

Understanding these differences helps enthusiasts make informed decisions, balancing performance goals with reliability and investment considerations.

Also Read: 5 Trucks with Dual Alternators vs 5 with Single Weak Units