Diesel engines sit at the core of numerous industries, shaping the backbone of transport, agriculture, shipping, and power generation.

Two distinct timing systems, pan-drive and belt-drive, carry specific characteristics that significantly impact how these engines function over their operational lives.

Choices made in the design phase ripple through daily usability, maintenance planning, and long-term dependability. Pan-drive setups, easily recognized by their robust metal gears or chains housed in a secure, lubricated casing, favor heavy-duty applications seeking years of trouble-free service.

Alternatively, belt-driven timing systems offer a quieter and lighter alternative, ideal for some modern vehicles but occasionally prone to reliability concerns that can catch owners unaware.

Recent trends point to increasing scrutiny over which timing solution provides the right mix of endurance, cost-effectiveness, and ease of care.

With experience pointing to recurring patterns of success and trouble across brands and models, it has become important to clarify which diesel engines gain an edge from their pan-drive systems and which encounter recurring nuisances with belt-driven timing.

The following discussion covers both advantages and troublesome patterns, guiding readers through critical distinctions that influence long-term satisfaction, mechanical soundness, and overall investment value.

Also Read: 5 Trucks with Sealed Wiring Harness vs 5 with Frayed Electricals

Five Diesel Engines with Pan-Drive Timing

A diesel engine’s core strength is often determined by the way its moving parts are synchronized, making pan-drive timing an especially common feature among powerplants expected to operate under demanding loads and for long durations.

Pan-drive timing leverages the rigidity of carefully engineered chains or robust gear sets, locked inside a metal cover bathed in engine oil.

This configuration is highly valued when manufacturers and owners prioritize survivability in harsh conditions and demand low service frequencies.

The decision to focus on pan-drive timing is no coincidence. Increasing expectations for minimal downtime and a strong resistance to wear drive engine makers to rely on this time-tested approach, especially in industrial, agricultural, and off-highway machinery where end users measure success by the years an engine runs without major intervention.

The engines featured here were chosen due to their longevity and demonstrated resilience, each regarded for excelling in real-world settings where reliability overshadows the desire for absolute quietness or reduced weight.

By observing these engines, readers can better appreciate the substantive gains delivered by pan-drive timing systems and understand why these designs remain favored in crucial sectors where engine failure is simply not an option.

1. Cummins 6BT (5.9L) Diesel Engine

The Cummins 6BT, also referred to as the “12-valve,” has built a stellar reputation among truck drivers, industrial operators, and diesel enthusiasts across decades.

Central to its durability is the use of a pan-drive timing mechanism, in this case a combination of a heavy-duty gear train and timing cover located at the front of the engine.

Unlike belt-driven alternatives that might suffer a snapped belt or gradual stretching, the gear-driven timing assures that valve and fuel injection events remain precisely timed long after other components may begin to tire.

This engine finds widespread use in commercial vehicles, agricultural machinery, and backup power generators, all sectors where reliability often trumps every other consideration.

The focus on Cummins’ 6BT in this context is warranted, not only for its universal presence but also because so many vehicles fitted with this engine still operate reliably after hundreds of thousands of miles some even with minimal attention beyond routine service.

By centering on the 6BT, the discussion emphasizes the practical, long-term value gained from robust timing engineering. Its track record matters for anyone aiming to minimize cost-of-ownership worries while maximizing productive uptime, especially in roles where an unexpected breakdown translates directly into lost revenue and operational headaches.

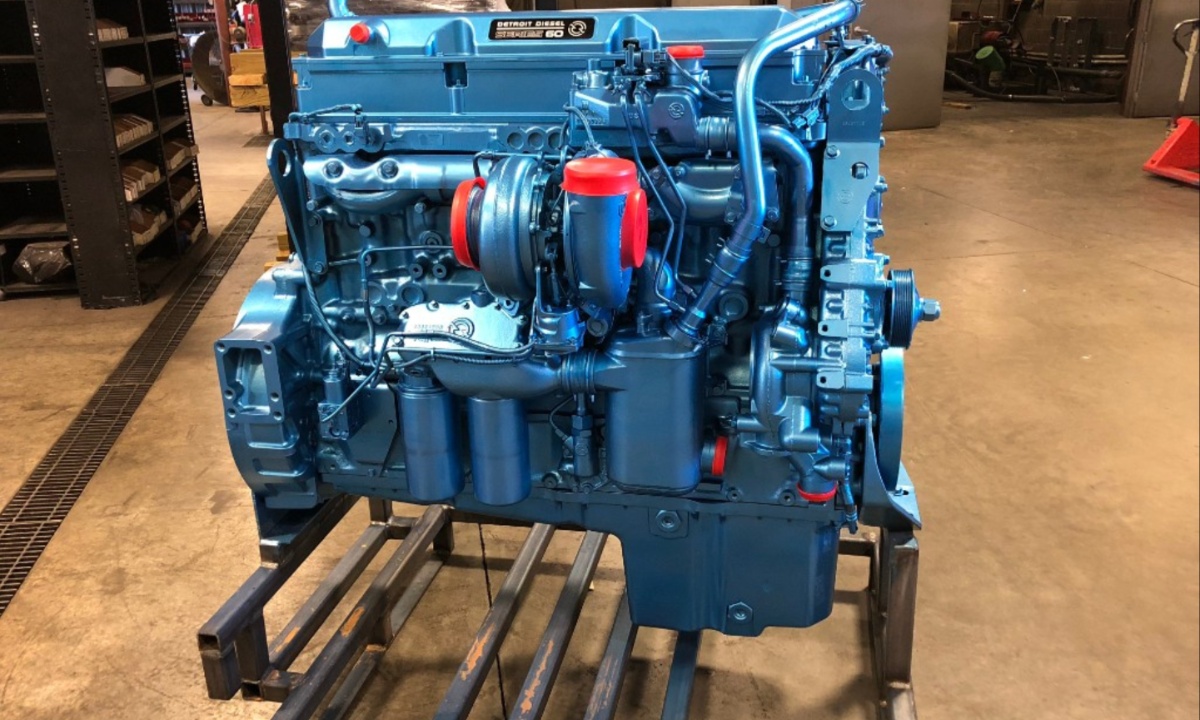

2. Detroit Diesel Series 60

The Detroit Diesel Series 60 engine stands as a prominent example of pan-drive timing done right. Famed among truckers and fleet operators, the Series 60 employs a gear-driven timing system that operates within an oil-bathed metal case.

This configuration effectively shields crucial synchronization components from the sort of degradation associated with belts, such as cracking or fraying.

Operators chose these engines precisely because they wanted trucks to run year after year under heavy loads with minimal intervention or risk of catastrophic failure.

The Series 60’s approach reduces concerns about losing timing, an event that, with belt-driven systems, could easily lead to bent valves or even ruined pistons if the slippage or break occurred at speed.

Highlighting the Series 60 draws attention to how a meticulously designed gear train can support long-haul operations and large industrial installations with limited, predictable maintenance.

The broad adoption of these engines within both freight and bus fleets further underlines how vital this reliability is for organizations running tight schedules and large capital investments.

Centering the conversation on the Series 60 showcases how well-chosen pan-drive timing components contribute to mechanical peace of mind, directly influencing not only repair budgets but also a firm’s reputation for timely delivery and operational continuity.

3. Perkins 1100 Series Diesel

Perkins has built a legacy of resilient engines, and the 1100 Series epitomizes the company’s approach to robust design. Built for tractors, generators, and industrial machinery, the 1100 Series relies on a steel timing gear assembly housed within a sturdy front cover.

Unlike engines that opt for lighter but sometimes less durable belt-driven solutions, the Perkins 1100’s pan-drive timing arrangement provides exceptional resistance to maintenance issues.

Owners of this engine often report going years between timing-related interventions, a testament to the practical advantages lent by this system.

The 1100 Series stands out because its timing gears maintain synchronization despite variable load conditions and fluctuating operating temperatures factors that can sometimes accelerate the decline of rubberised belt-driven mechanisms.

By focusing on the Perkins 1100 Series, this segment illustrates how manufacturers address the real-world demands of end users seeking maximum uptime and a predictable service schedule.

Selection of this engine for discussion stems from its broad applicability and proven record in challenging conditions, making it an accessible example for countless farm and construction equipment operators who can ill afford breakdowns or expensive, time-consuming repairs.

4. Mercedes-Benz OM457 Diesel Engine

The Mercedes-Benz OM457 engine, widely used in heavy commercial trucks and buses, features a robust pan-drive timing system. Specifically, its timing gears are machined to tight tolerances and designed to last for extreme mileage intervals.

This system’s enclosed design protects the moving components from debris and external contaminants, resulting in a clean, consistent oil bath that extends the life of gears and chains.

The OM457’s reliable timing mechanism is a key reason why the engine is trusted in fleet applications where high annual mileage pairs with expectations of minimal downtime.

It offers strong resistance to problems like skipped timing or sudden failures that can occur with less mechanically robust systems.

The focus on the OM457 is relevant due to its standing among European truck manufacturers, many of whom have standardized on this engine family to power long-route haulers and buses.

Discussing the OM457 shows how pan-drive timing not only supports daily operations but also upholds manufacturer reputations for reliability and low cost of ownership.

Owners regularly cite this engine as a prime example of lasting value, where solid design enables trucks to clock up extensive mileage with predictable, straightforward service routines.

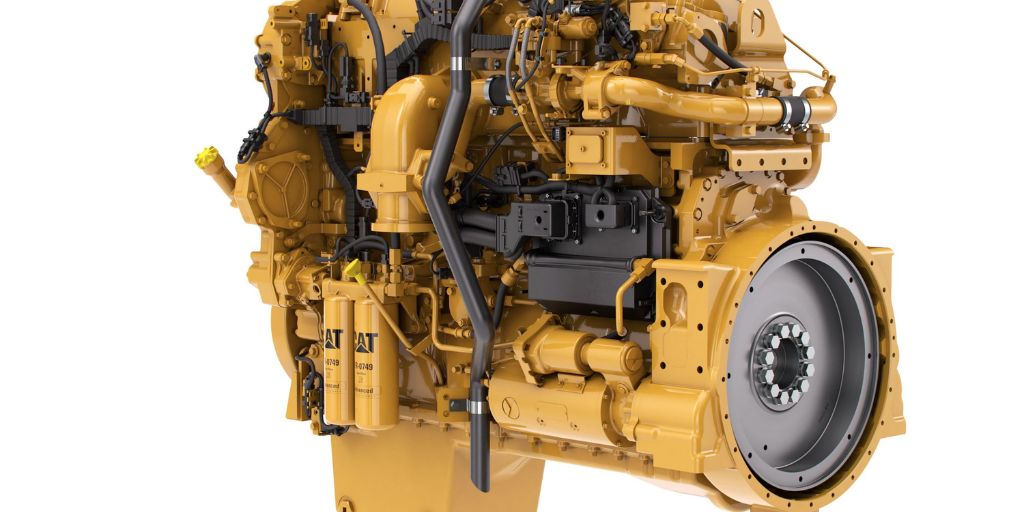

5. Caterpillar C15 Diesel Engine

The Caterpillar C15 diesel engine is a frequent choice for heavy-duty trucking and earth-moving equipment, largely due to its rugged construction and pan-drive timing arrangement. The engine’s timing gear system manages complex valve and injector events with high accuracy across countless operating hours.

The gears are housed in a sturdy casing that isolates them from potential damage and contamination, promoting a long working life without persistent maintenance concerns.

Caterpillar’s commitment to overengineered, robust solutions manifests clearly in the C15, which explains its adoption in applications where engine downtime directly affects profitability think mining operations, interstate freight, and construction projects that cannot afford washed-out schedules.

The inclusion of the Caterpillar C15 in this analysis is justified by its prevalence and the glowing feedback from operators who have experienced years of reliable service without major timing-related failures.

Focusing on this engine helps underline how a commitment to pan-drive timing construction makes a tangible difference in grueling applications, safeguarding operational goals and reinforcing the trust users place in the machinery day after day.

Diesel Engines with Belt-Drive Problems

While belt-driven timing systems offer advantages in noise reduction and engine efficiency, they are not without a set of recurring issues that continue to affect both maintenance practices and long-term vehicle reliability.

These systems typically utilize reinforced rubber or composite belts to synchronize the crankshaft and camshaft, a method that simplifies replacement compared to gear or chain drives.

However, belts are inherently more vulnerable to wear from heat, oil splashes, or simply the stress of long operational periods.

Manufacturers turn to this design primarily where low weight and cost play a significant role, but the frequent need for replacement and susceptibility to unexpected failures can quickly offset these initial gains.

Focusing on engines that have grappled with well-documented timing belt issues emphasizes the real impact of belt-drive architecture.

Real-world complaints from commercial and private vehicle owners after premature belt wear, tensioner failures, or belt-related breakdowns have shaped how future buyers and fleet managers evaluate diesel engine options.

By reviewing engines associated with belt-drive concerns, this section gives practical context to the trade-offs between upfront simplicity and long-term durability, ensuring readers are better equipped to anticipate and address potential challenges when choosing their next diesel-powered vehicle or machine.

1. Volkswagen 1.9 TDI (ALH, ALU, AGR) Diesel Engine

Volkswagen’s 1.9 TDI engines, particularly the ALH, ALU, and AGR variations, gained tremendous popularity in compact cars and light vans for their balance of torque, fuel efficiency, and quality engineering.

However, these engines have been repeatedly noted for issues related to their belt-driven timing systems.

Drivers commonly report that the timing belt requires replacement at relatively short intervals usually every 60,000 to 80,000 miles, to avoid catastrophic engine damage.

Premature failures can occur when a worn or incorrectly tensioned belt skips teeth or snaps altogether, leading to bent valves and, in worst cases, completely ruined cylinder heads.

The significance of listing these engines centers around how real-world maintenance demands and potential for high-stakes breakdowns shape ownership experiences.

Mechanics advise careful adherence to service intervals and warn of accelerated wear if the car is regularly subjected to dusty or humid conditions.

Since these models remain widespread and affordable on the secondhand market, it is essential to recognize that initial lower entry costs often come paired with discipline in service scheduling.

This discussion draws attention to the balance between the well-documented performance strengths and the maintenance headaches that timing belt failures can introduce, providing a full picture for current and future owners.

2. Ford Duratorq TDCi (1.8/2.0/2.2) Diesel Engines

Ford’s Duratorq TDCi engines, seen in models like the Focus, Mondeo, and Transit vans, leverage a belt-driven timing design in several popular configurations.

These engines have a history of timing belt troubles, particularly in commercial fleet use where prolonged or harsh driving conditions increase risks.

Common concerns include early belt degradation due to oil leaks, which accelerate the breakdown of belt material, and tensioner failures that introduce slack and cause the timing to shift unpredictably.

Repairs often prove costly, as a snapped belt on an interference engine typically leads to significant valve or piston damage. The inclusion of the Duratorq TDCi lineup is motivated by its volume of complaints and mechanic advisories.

Real-world experiences highlight how belt-driven systems require not just frequent inspection and disciplined replacement intervals, but also careful checking for any oil contamination a problem often traced back to crankshaft seals or valve cover gaskets.

For many business and private owners, this translates into more rigorous and sometimes expensive maintenance regimes than initially expected.

Understanding the pitfalls associated with these Ford engines clarifies why some fleet operators now opt for alternatives with chain or gear-based timing where available, even at the expense of slightly higher up-front weight or cost, simply to maximize service predictability.

3. Renault 1.5 dCi Diesel Engine

The 1.5 dCi diesel from Renault, commonly fitted to compact and family vehicles, has gained notoriety for recurring timing belt issues that impact reliability and ownership satisfaction. This engine relies on a lightweight belt-driven system to coordinate its internal timing, saving weight and reducing idle noise, but often at the cost of resilience.

A known problem with this engine involves the effect of driving in stop-start traffic or through aggressive climate swings, both of which can lead to premature belt wear or progressive elongation.

Renault’s recommended intervals for belt changes, while lengthy on paper, frequently require adjustment downwards when the engine sees regular urban use or extended idling.

Failures rarely give much warning; in some cases, the belt’s inner cords fray or the outer surface cracks, raising the chance of tooth skipping or complete breakage.

Reasons for focusing on the 1.5 dCi stem from its widespread deployment and the volume of customer experiences reflecting higher-than-anticipated maintenance costs.

For buyers lured by affordable running costs, understanding these recurring problems helps set realistic expectations and encourages owners to budget accordingly for thorough, professional servicing within or before the specified timelines.

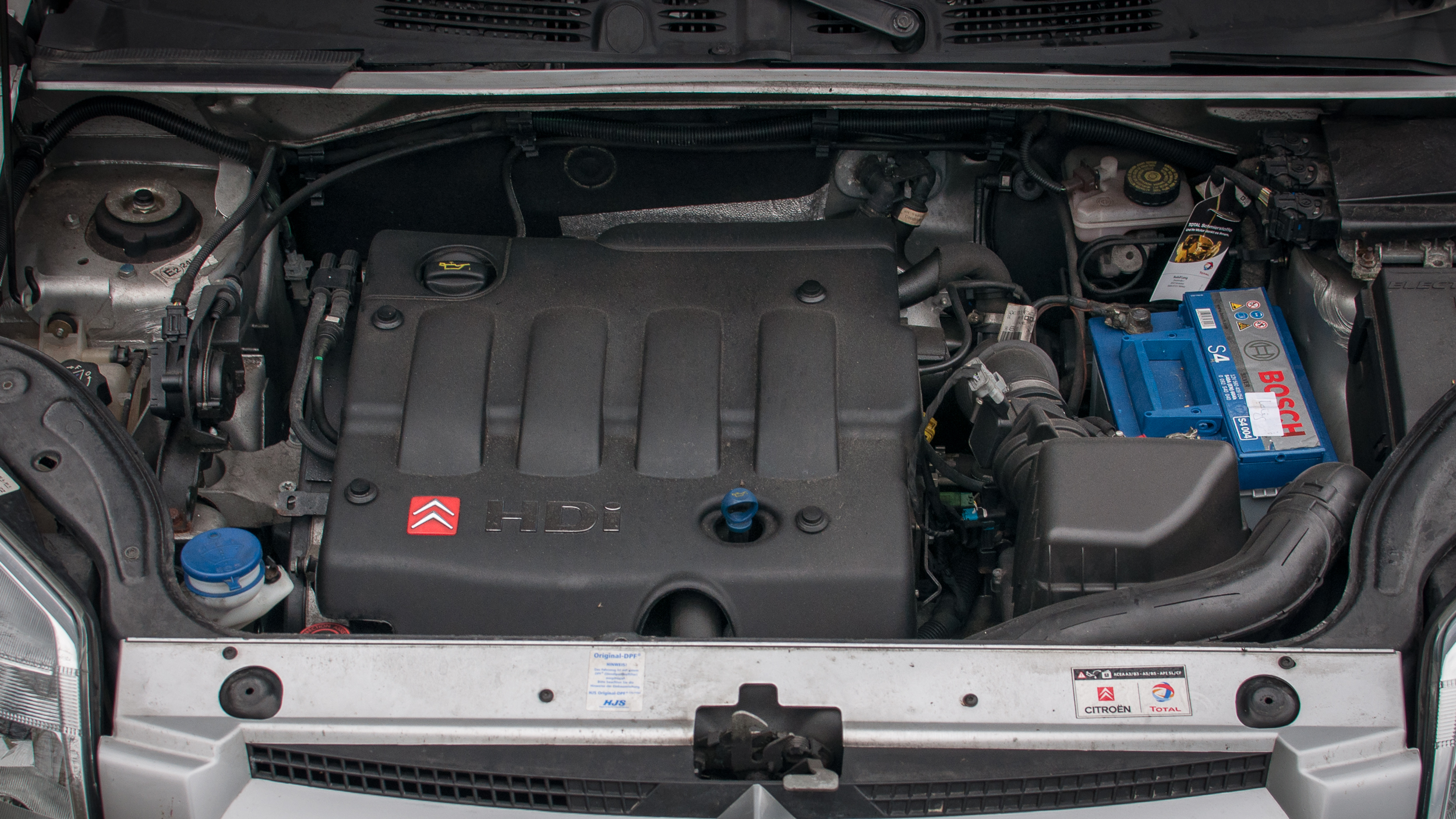

4. Peugeot/Citroën HDi 2.0/2.2 Diesel Engines

Peugeot and Citroën’s HDi diesel engines, especially the 2.0 and 2.2 liter models, are widely used across both family cars and commercial vans. These powerplants rely on belt-driven timing and are known for both emission compliance and fuel efficiency.

Yet they often generate headaches for owners because of timing belt issues that can surface well before the engine’s official service interval arrives.

Specific trouble spots include belt degradation due to exposure to coolant leaks something that can stem from nearby water pumps or failing gaskets.

Once contaminated, the belt rapidly loses integrity, sometimes resulting in skipped teeth or abrupt failures that may cause severe internal damage.

Highlighting the Peugeot/Citroën HDi engines is pertinent due to their prevalence on European roads and the significant number of reported cases where owners faced expensive engine repairs linked directly to timing belt failures.

Mechanics recommend vigilant inspections and fastidious adherence to both belt and water pump servicing.

For many, the issue lies in the need for synchronization between timing belt health and associated components, making seemingly routine repairs more involved and costly than anticipated.

Discussing these engines draws attention to how maintenance realities sometimes outweigh theoretical efficiency gains, urging potential buyers to evaluate long-term ownership needs carefully.

5. Vauxhall/Opel 1.7 DTI/CDTI Diesel Engine

The 1.7 DTI and CDTI diesel engines from Vauxhall and Opel have played a central role in their compact and midsize car lineups for years.

These engines use a belt-driven timing system, a design that brings clear advantages in manufacturing cost and smoothness but not without a proven track record of reliability concerns.

Numerous reports from drivers and independent mechanics point to early timing belt wear, sometimes exacerbated by faulty tensioners or pulleys that fail to retain proper alignment or tension.

When a tensioner or pulley gives way, it can cause the belt to jump, instantly putting valves and pistons at risk. The frequency at which auxiliary components threaten the belt’s health plays a part in why these engines have gained notoriety for timing-related failures.

The reason for examining the 1.7 DTI/CDTI engines arises from widespread customer experience and their popularity on the used car market, where new owners may not know if prior timing belt service was performed on schedule.

This reality makes maintenance planning around timing components a core concern. For both current and prospective owners, these problems underscore the value of professional, regular intervention and a realistic understanding of the risks inherent in belt-driven timing systems in these particular engines.

This article compares two distinct timing systems used in diesel engines pan-drive timing and belt-drive timing highlighting their strengths, weaknesses, and impact on reliability and maintenance across various diesel engine models.

Pan-drive timing systems rely on metal gears or chains housed inside a lubricated, sealed cover, designed for strength and durability.

These systems feature prominently in heavy-duty, industrial, agricultural, and commercial diesel engines that demand long service lives with minimal maintenance.

This method helps reduce the risk of timing failure, which can lead to costly and severe engine damage. The article reviews five notable diesel engines with pan-drive timing:

Cummins 6BT (5.9L): Known for its rugged gear-driven timing system, this engine is popular in trucks and industrial equipment for its longevity and consistent performance over hundreds of thousands of miles.

Detroit Diesel Series 60: This engine emphasizes reliability through its oil-bathed gear timing mechanism, favored in fleet and long-haul trucking applications where minimizing downtime is critical.

Perkins 1100 Series: Widely used in agricultural and industrial machinery, its steel gear assembly offers solid resistance against wear under variable loads and temperatures.

Mercedes-Benz OM457: Featured in European trucks and buses, this engine’s precisely machined timing gears contribute to long service intervals and high dependability.

Caterpillar C15: Common in heavy trucking and construction, this engine utilizes a robust pan-drive timing system to limit maintenance needs and avoid unexpected failures in demanding environments.

In contrast, belt-drive timing systems utilize reinforced rubber or synthetic belts that reduce noise and save weight but are more prone to wear, stretching, or breakage.

Belts require regular replacement, and timing failures can cause significant engine damage due to loss of synchronization between the crankshaft and camshaft. The article details five engines known for belt-drive timing challenges:

Volkswagen 1.9 TDI (ALH, ALU, AGR variants): Requires strict replacement schedules to avoid belt failures, which can lead to extensive valve damage.

Ford Duratorq TDCi (1.8/2.0/2.2): Subject to early wear from oil leaks and tensioner problems, making maintenance essential to prevent costly repairs.

Renault 1.5 dCi: Experiences premature belt wear in urban driving conditions, stressing the importance of timely belt changes.

Peugeot/Citroën HDi 2.0/2.2: Vulnerable to coolant-induced belt degradation, emphasizing synchronized maintenance of belts and water pumps.

Vauxhall/Opel 1.7 DTI/CDTI: Common timing belt and tensioner failures can unexpectedly jeopardize engine timing and reliability.

The comparison illustrates that while pan-drive timing systems are generally more durable and better suited for heavy-duty use, belt-drive systems offer benefits in noise reduction and weight that come with trade-offs in longevity and maintenance demands.

Readers interested in diesel engine reliability and maintenance considerations will find this overview useful when selecting or servicing engines for commercial or private applications.

Also Read: 5 Cars with Lifetime Wheel Bearings vs 5 with Bearings Grinding at 80,000 Miles