When examining high-performance and mainstream internal combustion engines, the question of piston material is crucial to both reliability and output.

Pistons are subjected to immense pressure, heat, and mechanical stress as they travel thousands of times per minute inside engine cylinders.

Two primary types of pistons are used across a broad spectrum of engines: forged and cast. The distinction between the two lies not only in manufacturing, but also in their behavior under extreme conditions.

Forged pistons are made by compressing and shaping high-strength alloy under tremendous pressure, resulting in a denser, more uniform structure that excels under demanding environments like turbocharged or high-revving applications.

On the other hand, cast pistons are produced by pouring molten alloy into molds, allowing for intricate shaping at lower cost but resulting in a microstructure that is more susceptible to cracking and shattering when pushed beyond design limits.

This divergence makes forged pistons a favorite in motorsports and modified engines, while cast pistons are still widely found in production vehicles prioritizing affordability and efficiency.

Understanding how these two piston types behave provides crucial insight into engine reliability and performance potential, as well as why catastrophic failures occur more frequently in certain engines.

This discussion first highlights engines featuring forged pistons, followed by engines known for cast pistons that have earned a reputation for outright failure under high stress.

Also Read: 5 Cars with Lifetime Hatch Hinges vs 5 with Sagging Tailgates

Engines with Forged Pistons

Engines featuring forged pistons have set standards in durability, performance, and adaptability for enthusiasts and professionals alike.

The unique strength properties of forged pistons make them a common feature in road and racing engines that are expected to operate at higher cylinder pressures, temperatures, and engine speeds.

Forged pistons accommodate extreme power adders like superchargers, turbochargers, and nitrous oxide configurations that would rapidly overwhelm the integrity of conventional cast pistons.

Their resistance to deformation and cracking means that they can support increased horsepower levels without the risk of internal meltdown, thus powering many of the world’s most celebrated performance cars, sport bikes, and motorsport machines.

This approach comes at a price, both literally and figuratively: forged pistons are more expensive to produce, and their relatively greater expansion under heat makes engine design and assembly more challenging.

These factors mean manufacturers reserve them for engines where durability and longevity take precedence over cost, most often in vehicles that are pushed far beyond the stock configuration, or that must withstand race-level abuse.

Highlighting five engines equipped with forged pistons illustrates how manufacturers balance cost, performance, and peace of mind for those seeking relentless power without compromise.

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE engine is synonymous with robustness and power potential. Built for the legendary Toyota Supra, this inline-six features factory-forged pistons that have become vital to its reputation for handling extreme power upgrades reliably, even at levels surpassing 1,000 horsepower with the right supporting modifications.

The decision to include forged pistons in the 2JZ-GTE design was driven by Japanese automotive engineers’ desire to create an engine that wasn’t just fast, but also bulletproof under duress.

Forced induction in the form of sequential twin-turbochargers meant the internals needed to be ready for higher-than-average cylinder pressures.

Forged pistons in the 2JZ-GTE provide the structural integrity required to withstand detonation, keep their shape at elevated temperatures, and resist fatigue from repeated high-boost readings.

Owners and tuners gravitate toward this engine because it sets a benchmark in outlasting its rivals in hard-driving scenarios.

Decades after its debut, machine shops, race teams, and private enthusiasts continue to push the 2JZ-GTE further, routinely advertising builds delivering power output unheard of in most production cars.

Its longevity, even when subjected to aggressive racing and substantial power modifications, sets a standard which other production turbocharged engines struggle to match.

Including the 2JZ-GTE serves to underline how factory-forged pistons help certain engines walk the fine line between reliable daily performance and motorsport’s demand for power at any cost.

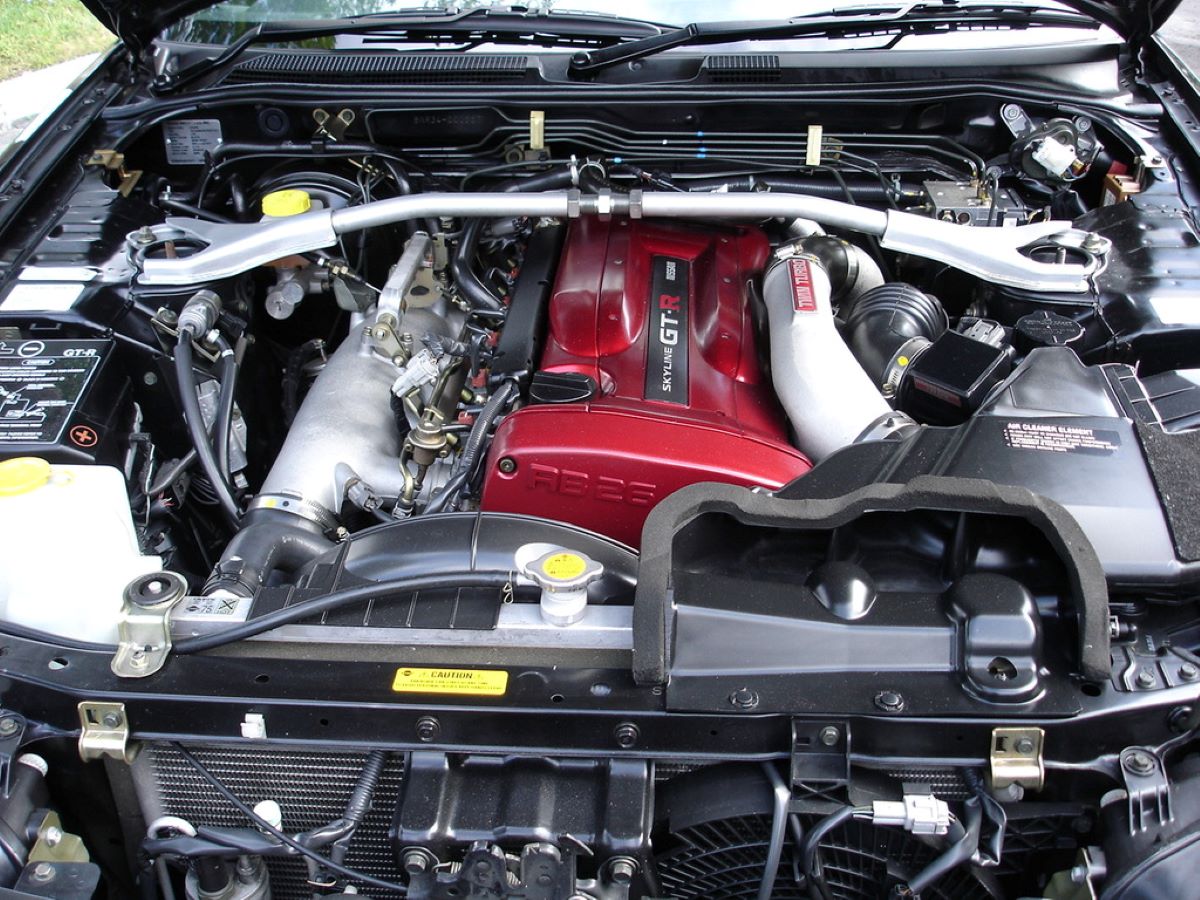

2. Nissan RB26DETT

The RB26DETT, found in the Nissan Skyline GT-R models from the R32 through R34 generations, is another icon in the performance world celebrated for its high-strength internals, including factory-forged pistons.

Like Toyota’s 2JZ-GTE, Nissan designed the RB26DETT to perform exceptionally under turbocharged stress, making it a darling among those who expect a daily driver engine to withstand track abuse.

Engineered during an era of intense technological rivalry among Japanese automakers, the RB26DETT’s forged pistons are fundamental to its ability to safely accept upgrades.

Owners often double or even triple the engine’s stock power output without needing to replace the original pistons an attribute rare among production engines.

Factory forging endows the pistons with grain structures that resist cracking and deformation at both moderate and extreme boost levels.

The motor’s widespread popularity in everything from drift cars to time attack monsters further demonstrates the added value forged pistons provide.

Whether subjected to rapid changes in temperature, repeated high horsepower passes, or the stress of prolonged circuit running, the RB26DETT’s forged pistons rarely fail before other supporting components.

Including the RB26DETT in this discussion shows how Nissan’s engineering foresight resulted in an enduring and bombproof powerplant that supports both stock reliability and the upper echelons of aftermarket tuning potential.

3. Chevrolet LS9

The Chevrolet LS9 V8, the supercharged heart of the Corvette ZR1 (C6 generation), is a modern American example where forged pistons are essential.

This 6.2-liter engine was engineered from the ground up for supercar-level performance, with an eye toward not just raw output but also sustained reliability under conditions that can quickly destroy lesser powerplants.

With a roots-type supercharger force-feeding the V8, internal pressures skyrocket putting significant demands on the reciprocating assembly.

Chevrolet responded with factory-installed forged pistons, capable of handling over 20psi of boost and the spikes of cylinder pressure that accompany aggressive acceleration and high-speed endurance runs.

The LS9’s forged pistons contribute substantially to its ability to reliably deliver more than 630hp directly from the showroom floor, with considerable overbuilt margin for those who later increase boost or make other modifications.

Beyond horsepower, the LS9 is a testament to GM’s commitment to durability in its most extreme applications.

The inclusion of forged pistons ensures the engine can handle not just the power advertised, but also the additional stress brought on by track events, drag racing, and even standing mile runs where engines are held at full-throttle for extended periods.

Purposefully highlighting the LS9 underlines how factory-forged pistons support cutting-edge performance and reliability in high-output American supercars.

4. Mitsubishi 4G63T

Few four-cylinder engines have achieved the cult status of Mitsubishi’s 4G63T, the powerhouse behind the earliest generations of the Lancer Evolution.

It is revered for its turbocharged agility and extraordinary strength, much of which comes down to smart engineering choices like the use of factory-forged pistons in select high-performance variants.

When Mitsubishi set one eye on world rally competition and the other on enthusiast street markets, they recognized the necessity for an engine that could handle both the violent shocks of rough rallying and power-hungry modification culture.

Forged pistons in the 4G63T give it a foundation for running high levels of boost with minimal risk of catastrophic failure. This choice helps the 4G63T achieve a reputation for reliably supporting 400-600hp on stock internals when maintained correctly and tuned well.

Rally teams, professional drivers, and street tuners continue to rely on the 4G63T for setups that push the engine to its mechanical limits something that would simply be impossible with cast pistons.

Its presence in this discussion is critical, as it demonstrates how forged pistons turn an otherwise ordinary four-cylinder into a legend of motorsports and grassroots racing, balancing factory reliability with the hunger for ever-increasing performance.

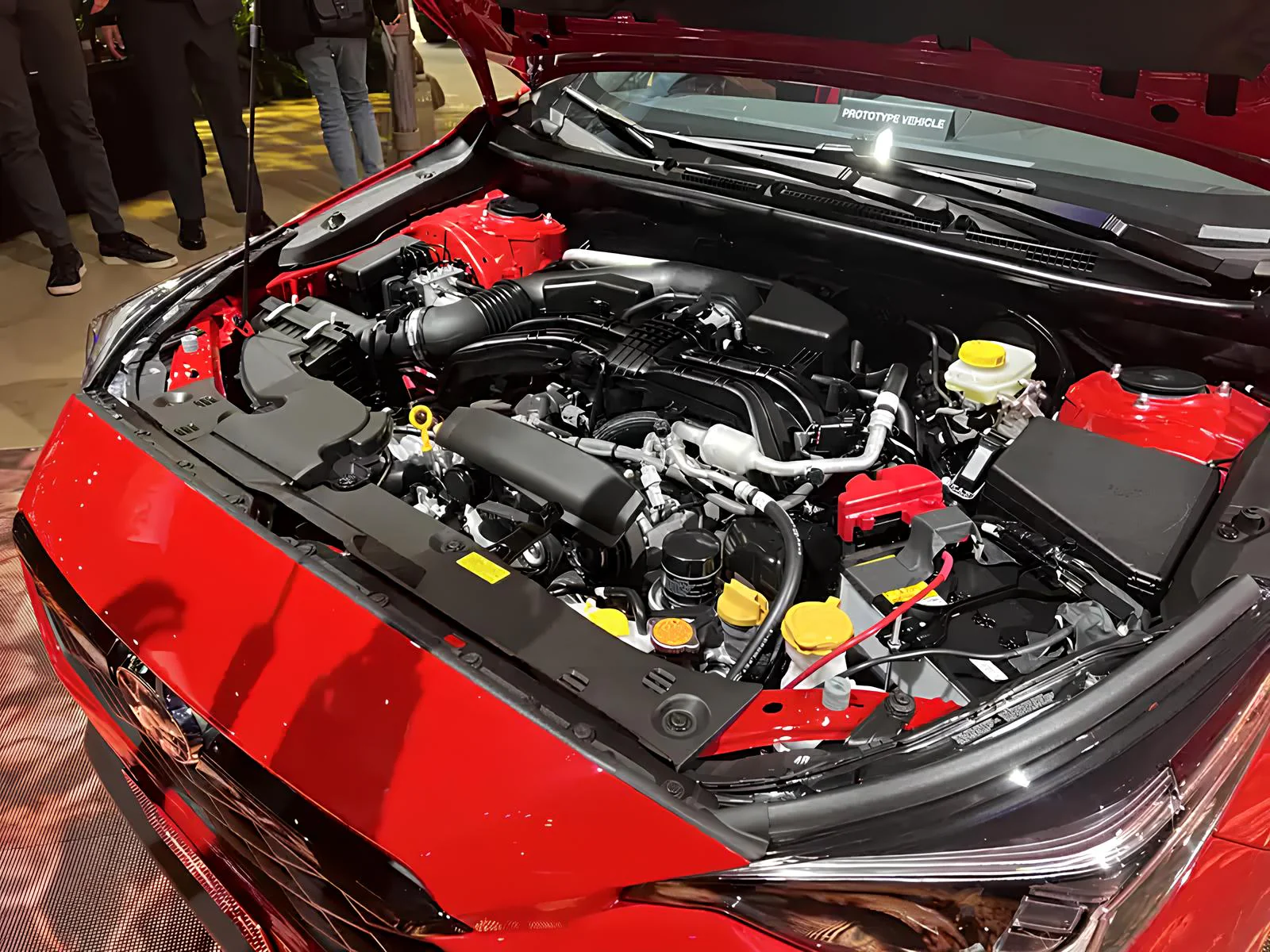

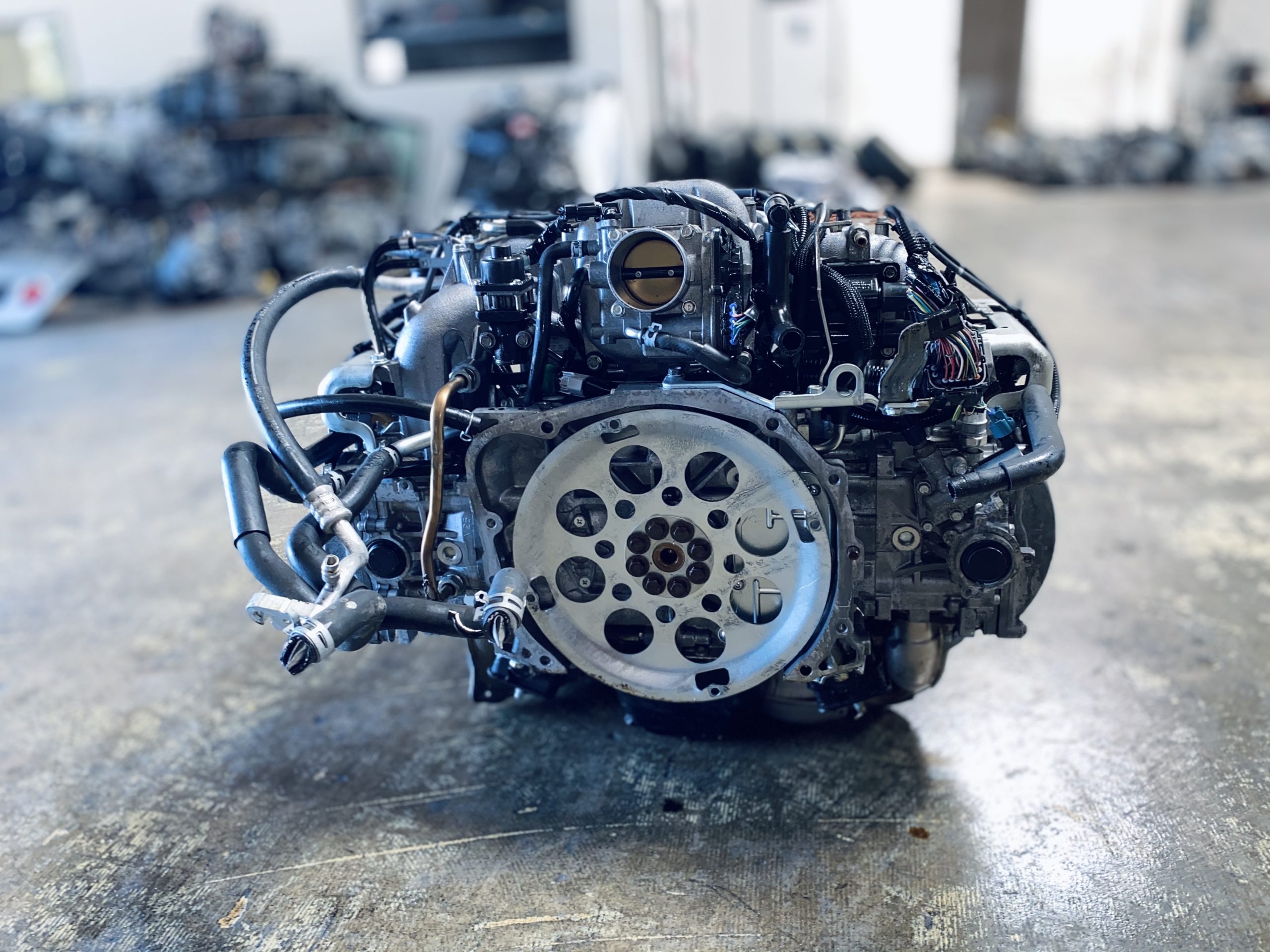

5. Subaru EJ257

The Subaru EJ257, a turbocharged flat-four used in later versions of the Impreza WRX STI, stands as one of the modern-day flag bearers of factory-forged pistons.

Designed to withstand the unique stresses of Subaru’s rally-inspired all-wheel-drive turbo platforms, the EJ257 was engineered with high-strength pistons from the outset, specifically because Subaru anticipated widespread tuning and motorsport use.

Compared to earlier versions with cast pistons, the EJ257’s forged variety has given the engine much greater tolerance for boost and aggressive ignition timing, both common in aftermarket tuning.

These pistons maintain their shape and strength under the specific side-loading conditions created by a flat-four engine layout, as well as the added load of launching the car from a standstill repeatedly in rally-cross and drag-race scenarios.

Many WRX STI enthusiasts appreciate that, with proper tuning, the EJ257 holds up to sustained engines speeds, high boost, and punishing use off-road or on track.

While the engine as a whole has its weak points, piston failure is not a primary concern when forged units are present.

The EJ257’s forged pistons show just how much Subaru learned from years of motorsport success, providing a platform that can absorb abuse beyond what most road cars encounter, making it a solid example in this category for discussing the advantages of a forged approach.

Cast Pistons That Shatter

While forged pistons often grab the spotlight for their strength, cast pistons are far more common in mass-produced engines due to their lower production cost and manufacturing simplicity.

However, this approach comes with a clear compromise when subjected to conditions beyond what the factory originally intended.

Cast pistons, formed by pouring molten alloy into molds, yield intricate shapes suitable for modern engine efficiency and emissions goals.

Unfortunately, the inherent porosity and brittleness of cast pistons mean that, when engines are pushed past design limits be it through forced induction, aggressive tuning, or neglect, failure can occur suddenly and catastrophically, with the piston potentially shattering under stress.

Some engines have become notorious for their susceptibility to piston failure, especially among performance enthusiasts who attempt to extract additional horsepower without first reinforcing the bottom end.

This has led to a reputation for specific engines associated with cracked or shattered cast pistons, contributing to stories of expensive rebuilds and frustrated owners.

Showcasing five engines frequently cited for cast piston failures provides a cautionary perspective on the limits of this manufacturing method.

By examining these cases, it becomes clear why certain upgrades demand a change in hardware, and that, inevitably, cost savings up front can lead to higher expenses down the line if an engine’s limitations are overlooked.

1. Mazda RX-8 RENESIS

The Mazda RX-8’s RENESIS rotary engine is famous for its unique design, high-revving character, and unfortunately, a reputation for fragile internal components, particularly its cast pistons, although strictly speaking, it uses cast rotor apex seals and rotor housings rather than pistons in the conventional sense.

The RX-8 represents a cautionary tale in the balance between affordable manufacturing and real-world durability.

Mazda’s choice to use cast aluminum apex seals and rotors was influenced by cost constraints and a desire for lightweight spinning assemblies to support fast engine speeds.

While these cast elements function adequately for most street driving, issues begin to surface when tuners or owners increase boost, experiment with forced induction, or neglect proper maintenance.

Under such abuse, the cast apex seals are prone to chipping or cracking, and the aluminum rotor housings can fail, leading to catastrophic rotary engine failure. The problems often present after hard runs or with detonation, resulting in loss of compression and expensive rebuilds.

This example is discussed because it highlights how cost-saving measures can haunt engines celebrated for performance potential. Many RX-8 owners who sought additional power or subjected their cars to track conditions have faced blown rotors and apex seal failures.

The notoriety of these failures demonstrates the clear limits of cast components in a high-stress, performance-oriented powerplant, underlining the critical difference that stronger aftermarket forged parts can make for those determined to push the boundaries of Mazda’s legendary rotary.

2. Volkswagen 1.8T 20V (AEB, AWP, AWD codes)

Volkswagen’s 1.8T 20-valve turbocharged engine, utilized broadly across late-1990s and early-2000s Audi and VW models, showcases both robust performance potential and a notorious weak spot its factory cast pistons.

This four-cylinder became a mainstay for enthusiasts due to its turbocharged flexibility and ease of modification. However, many owners pursuing higher power quickly discovered the shortcomings of the original piston design.

These cast pistons are adequate for factory boost levels and conservative power, but their relative brittleness creates a point of weakness when performance tuning begins.

Increasing boost pressure for additional horsepower, a routine upgrade in the 1.8T community, often leads to piston ringland failure or full piston breakage.

The cast design cannot adequately dissipate the added thermal and mechanical stresses, leading to piston fracture under severe detonation or high cylinder pressures.

This engine is an important inclusion because it serves as a common case where cast piston limitations have repeatedly transformed affordable builds into costly engine rebuilds. Aftermarket support offers robust forged piston replacements, which enthusiasts universally recommend once power targets rise above stock levels.

The repetitiveness of catastrophic piston failures in the 1.8T has made the engine a favorite lesson in the risks of pushing cast internals too far, prompting both caution and greater appreciation for more durable forged solutions for anyone planning substantial performance upgrades.

3. Honda K24A2

Honda’s K24A2 engine, a member of the much-celebrated K-series family, offers an excellent package for tuners seeking both reliability and high-revving performance.

However, one consistent area of concern for those applying significant forced induction is the cast piston construction found in these engines.

Honda intended the K24A2 for naturally aspirated use, prioritizing cost-effective manufacturing and lightweight rotating assemblies for efficiency.

Within the stock configuration, the cast pistons perform satisfactorily, supporting strong power output matched to Honda’s VTEC variable valve timing.

Yet, when owners bolt on turbochargers or superchargers or attempt aggressive tuning common practices due to the engine’s otherwise excellent design the cast pistons begin to expose their limitations.

Detonation, increased cylinder pressure, or even minor misfires can cause the top ringland to crack or sections of the piston crown to shatter. Engine builders and track-day enthusiasts quickly learn that, without a switch to stronger pistons, severe internal damage is a very real risk, often leading to total engine failure.

The K24A2’s spot on this list highlights how widespread tuning ambitions can clash with factory material choices. While Honda’s engine can withstand plenty of abuse in factory form, enthusiasts who ignore the limitations of cast pistons frequently face expensive repairs.

This serves to emphasize the importance of aligning piston choice with anticipated use, especially in communities where power upgrades are the norm rather than the exception.

4. Subaru EJ205

Subaru’s EJ205, a turbocharged flat-four found in early-2000s WRX models, acts as a warning for performance enthusiasts underestimating the weaknesses of cast pistons.

While the broader EJ family includes several variants with improved designs, the EJ205 is singled out for its tendency toward piston failure during modifications.

The decision to utilize cast pistons in the EJ205 was motivated by cost efficiency for a mainstream sports sedan, targeting buyers who were unlikely to double the engine’s horsepower.

However, the WRX became an instant favorite in performance circles, with owners routinely opting for higher boost, aggressive ignition timing, and track usage.

Cast pistons in this engine display a notable weakness at the ringlands and crown, with frequent reports of fractures under high thermal and mechanical load, often exacerbated by detonation from poor-quality fuel, inadequate engine management, or excessive boost.

The importance of the EJ205’s inclusion is found in its cautionary value. As tuners flocked to the WRX for its rally pedigree and affordability, hard-learned lessons about cast piston reliability began to accumulate.

Many experienced expensive engine failures, leading to a near-consensus that forged pistons are a required upgrade for reliably supporting anything above stock power, particularly in high-stress or motorsport settings.

The experiences with the EJ205 reinforce the critical role piston material plays in engine survival when ambitions exceed OEM expectations.

5. Ford Focus ST (2.0L EcoBoost – 2013–2018)

The Ford Focus ST equipped with the 2.0L EcoBoost engine is loved for its blend of turbocharged excitement and practical daily usability.

Nevertheless, among tuning circles, the factory cast pistons have garnered a reputation for being the weak link in an otherwise solid engine design.

Ford used cast pistons in the 2.0L EcoBoost to keep manufacturing costs down and ensure decent efficiency for a broad market. Out of the box, these pistons withstand regular driving and moderate spirited usage well.

Problems arise when owners install simple performance upgrades such as higher-flow intercoolers, custom tunes, or larger turbos.

The cast pistons struggle to cope with elevated combustion temperatures and pressures, especially when aggressive tuning leads to detonation or pre-ignition. It is not uncommon to find fractured ringlands or melted pistons in EcoBoost engines subjected to repeated high boost or improper tuning.

Including the Focus ST’s 2.0L EcoBoost highlights the modern manifestation of an old problem: the intersection of mass production economics with the persistent demands of performance enthusiasts.

As these engines age and move into the hands of second or third owners, the frequency of “grenaded” pistons in enthusiast forums illustrates that cast components are rarely up to sustained abuse.

For those aiming for substantial power gains, upgrading to aftermarket forged pistons has become virtually mandatory a lesson driven home by countless costly failures that trace back to the limitations of cast construction.

This article compares engines with forged pistons to those with cast pistons prone to failure. Forged pistons, made by compressing alloys under high pressure, offer superior strength and durability, supporting high power levels and extreme conditions, showcased by engines like the Toyota 2JZ-GTE and Chevrolet LS9.

In contrast, cast pistons, made by pouring molten metal into molds for cost efficiency, are more susceptible to cracking and shattering when pushed beyond limits, as seen in engines such as the Volkswagen 1.8T and Subaru EJ205.

Understanding these differences highlights why forged pistons suit high-performance applications while cast pistons often require upgrades for reliability.

Also Read: 5 SUVs with Integrated Skid Plates vs 5 that Rust Beneath