Engines that remain dependable after years of use often have one thing in common: they were built to handle stress from the beginning. One of the most critical areas of engine strength lies in the cylinder wall. When the engine is running, the pistons move up and down at very high speeds inside the cylinder walls.

This constant motion creates heat, friction, and pressure. If the walls are weak or not properly treated, they can wear out fast, especially after passing high mileage. Once the cylinder wall starts scuffing, the engine will begin losing compression, burning oil, and eventually failing if left unchecked.

Car makers have dealt with this issue by either making the cylinder walls thicker, adding special coatings like Nikasil or plasma spray, or switching to stronger metals like iron sleeves in aluminum blocks. Engines built with this kind of thinking tend to hold up much better in the long run.

You can often find them still performing strongly after crossing 200,000 miles, especially when maintenance has been done regularly. Reinforced cylinder walls reduce the chances of scuffing, oil consumption, and overheating during long use.

While some engines seem to give up early, mostly because of poor design or cheap materials used in their construction. Some manufacturers made engines with thin walls or low-quality coatings, and while they might have been lightweight or efficient when new, they often struggled to handle aging and heavy use.

When such engines clock 100,000 miles or more, they start showing major issues. Problems like oil burning, compression loss, and cylinder scoring become very common. Once scuffing starts, the only fix is a costly rebuild or full replacement.

Let’s compare five engines known for having durable, reinforced cylinder walls against five engines that tend to scuff under high mileage. Each section explains why certain engines perform better or worse after years of use. It looks at how design choices, materials, and maintenance affect long-term durability.

Whether you’re planning to buy a used vehicle, rebuild your engine, or just want to understand how things work inside, this breakdown will guide you with useful details and examples from real-world experience.

5 Engines with Reinforced Cylinder Walls

1. Toyota 2JZ-GTE

The 2JZ-GTE engine is one of the most respected engines ever made, especially by those who love turbocharged performance. Toyota built this 3.0-liter inline-six with an iron block that gave it an advantage over most aluminum-based engines.

That choice to go with cast iron instead of aluminum helped the engine handle extreme stress and temperature over the years. Iron blocks can manage heat expansion better and resist cylinder wear even under repeated hard use.

Inside the 2JZ-GTE, the cylinder walls are thick and uniform. This construction reduces distortion, allowing the pistons to move smoothly no matter the engine load.

Whether the car is being driven gently or pushed to the limit, the walls do not lose shape. Toyota also included oil squirters that help keep the pistons and cylinder walls cool. This reduces the heat-related breakdown that many engines face after long miles.

People who have owned vehicles with this engine, such as the Toyota Supra, often report hitting 250,000 miles or more without major problems. Even tuners who increase the engine’s horsepower beyond factory limits still find the block reliable.

That speaks to the smart engineering behind it. Another reason it lasts long is that the forged internals and smooth bore finishing inside the cylinders make it harder for scoring to begin. The engine’s design keeps friction low and oil distribution balanced, which helps reduce scuffing risks.

This is why even heavily modified versions still run smoothly. You don’t need to rebuild the bottom end unless you’re targeting very extreme horsepower. That makes the 2JZ-GTE a solid example of how reinforced cylinder walls contribute to engine durability across decades.

2. Chevrolet LS1

The LS1 engine from General Motors was launched in the late 1990s and quickly became a favorite due to its mix of strength, power, and weight. Built with an aluminum block, it might seem weaker than iron-based engines.

However, GM added cast iron liners within the cylinder bores to give the LS1 added protection and durability. This hybrid design allowed the engine to stay light while still managing heavy loads and mileage.

The iron cylinder sleeves are pressed into the aluminum block, offering the best of both materials. While the aluminum helps with weight reduction and heat dissipation, the iron sleeves protect the cylinder walls from scuffing under high pressure. These sleeves do not wear down easily, even with repeated piston movement over long distances.

Many owners have taken their LS1 engines well past 200,000 miles without major cylinder wear, especially those who kept up with oil changes. Even when used in performance cars like the Corvette or Camaro, this engine keeps its smooth operation across the years.

The tight fit of the piston rings inside the iron bores helps the LS1 hold compression longer. This contributes to better fuel economy and lower emissions even after many years on the road.

GM also used cross-bolted main caps and a strong crankcase design to ensure the engine remains stable under high RPMs. When the lower structure of the engine stays firm, the cylinder walls are less likely to flex. That stability adds to the durability of the cylinder walls, especially in high-performance or high-mileage situations.

Also Read: 5 Forgotten GM Cars That Run vs 5 Recent GM Models With Major Issues

3. Mercedes-Benz OM617

The OM617 engine is one of the most dependable diesel engines ever created. Built by Mercedes-Benz in the 1970s and 1980s, it powered models like the 300D and 300SD. With a cast iron block and cylinder head, this engine was designed for longevity. Even though diesel engines already last longer than gasoline ones, the OM617 raised the standard.

Its cast iron block comes with very thick cylinder walls that were designed to resist wear from repeated combustion events. Diesel combustion produces higher pressure compared to gasoline, so the walls must stay strong for the engine to last. Mercedes engineers made the walls heavy and wide, meaning there was plenty of metal to withstand friction and heat.

These engines are known to cross 500,000 miles with basic maintenance. Some taxis in Africa and the Middle East still use this engine today. What helps is that the engine runs at lower RPMs and doesn’t stress the cylinder walls too much, even after decades. The strong structure of the OM617 helps reduce distortion and scoring inside the cylinders.

The engine also comes with a high oil capacity and a solid cooling system. Both features help manage heat and keep the internal parts from overheating. Scuffing happens when heat breaks down the oil film between the piston and wall, but in this engine, that rarely occurs. That’s one reason it still remains respected even after many years of production ended.

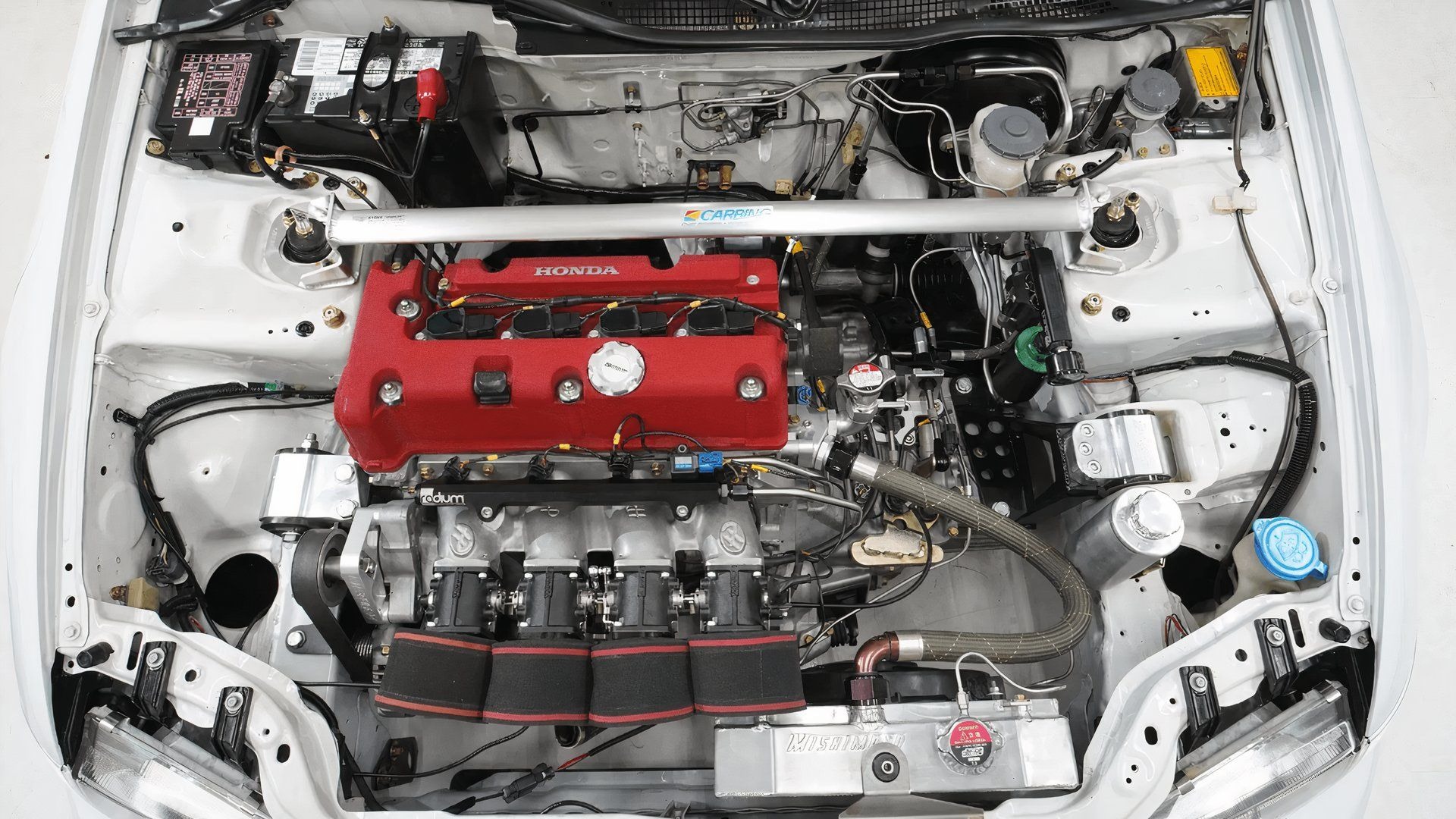

4. Honda K20

The K20 engine from Honda has proven to be one of the most dependable four-cylinder options available. It powers vehicles like the Honda Civic Type R and Acura RSX. Built with an aluminum block, the K20 could have been vulnerable to cylinder wear, but Honda addressed that risk with iron cylinder sleeves embedded within the aluminum.

These iron sleeves help prevent scoring and scuffing, especially in engines that rev high like the K20. Because it can spin over 8000 RPM, the internal forces inside this engine are very intense. Without proper reinforcement, the cylinder walls could warp or wear down quickly. The sleeves maintain a firm and smooth surface for the piston rings to move against.

Another strong feature is Honda’s VTEC system, which allows the engine to adjust valve timing. This flexibility helps manage the engine load during different driving conditions, keeping internal pressure balanced. That balance reduces stress on the cylinder walls, especially under long-distance use.

Many K20 engines remain strong after 200,000 miles, especially when maintained properly. Their long lifespan is also supported by good oil flow, high-quality piston ring design, and thermal management inside the engine block. These features help delay wear on the sleeves and keep the combustion chamber sealed tightly.

5. BMW M54

The M54 engine from BMW is a 3.0-liter inline-six that was common in many models during the early 2000s. It came with an aluminum block but included iron cylinder liners for reinforcement. This combination provided strength without adding unnecessary weight.

The M54’s smooth power delivery and balanced design reduce vibration, which helps the cylinder walls remain in good shape as time goes on. Since vibration can lead to cylinder movement and damage, a well-balanced engine like the M54 naturally lasts longer. The iron liners also handle high compression without allowing ring scoring to start easily.

This engine has shown the ability to go beyond 250,000 miles, especially in cars where regular oil changes and cooling system checks are done. The M54 does have issues with oil leaks and plastic cooling parts, but the internal cylinder condition remains strong in most cases. The liners resist wear even when the piston rings start aging.

One reason the cylinder walls stay clean is that the M54 runs smoothly across all RPM ranges. The combustion pressure remains stable, and the cooling system spreads heat evenly across the block. When internal temperature stays even, the cylinder bores are less likely to distort or crack.

Engines that Scuff Under High Miles

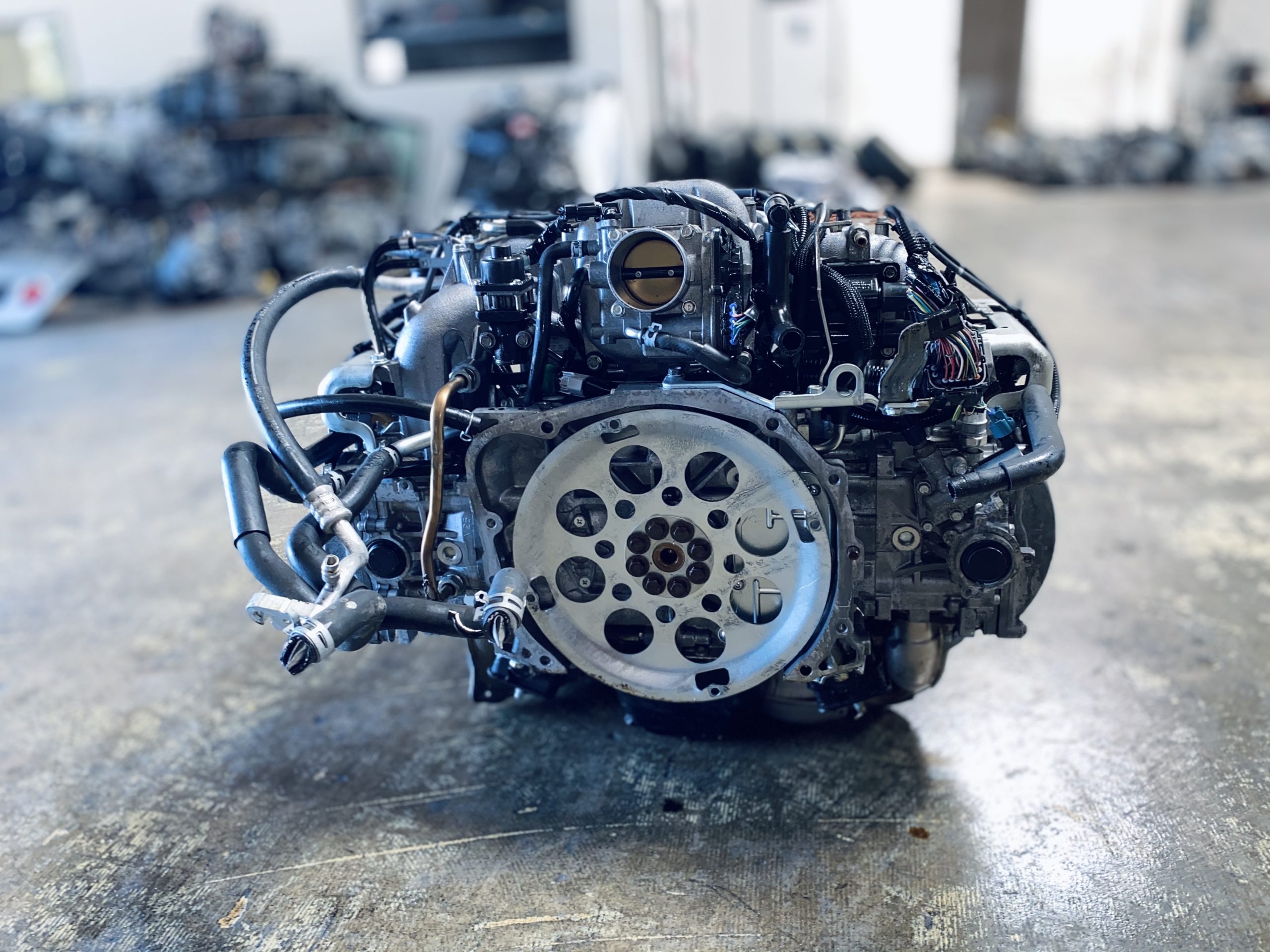

1. Subaru EJ25

The EJ25 engine is well known among Subaru owners, especially those who’ve driven models like the Outback, Forester, and Impreza. Although it delivers decent power and reliability when new, this engine tends to suffer from multiple wear issues as mileage increases.

One of the most common complaints includes scuffing and wear inside the cylinder walls, especially once the engine crosses 100,000 miles. The EJ25 uses an aluminum block with an open-deck design. This structure provides less support around the cylinder walls compared to semi-closed or closed-deck blocks.

As a result, during high-load conditions or when temperatures get too high, the cylinder walls can flex. That movement causes uneven piston travel, which scrapes the cylinder wall and gradually wears down the surface.

Another weak point in this engine is its head gasket design. When head gaskets fail, coolant may leak into the combustion chamber or oil system. Once coolant mixes with oil or enters the cylinders, it weakens the protective layer inside the bore, allowing scuffing to begin.

As time goes on, the cylinder loses its smooth surface, compression begins to drop, and oil consumption rises. Drivers also report piston slap during cold starts, a sign that cylinder clearance has widened from wear.

The combination of aluminum’s natural softness, poor support around the bores, and frequent overheating makes this engine vulnerable. Some mechanics try to solve the problem by replacing the head gaskets or switching to forged pistons, but those fixes don’t fully address the root problem of wall flex and wear.

The EJ25 can still last long if treated gently and serviced early, but it doesn’t respond well to hard driving, turbo upgrades, or poor maintenance.

The scuffing usually becomes more visible after the first 120,000 miles, and by 150,000 miles, rebuilds become common. That places it among engines that struggle under high mileage due to weak bore support and long-term heat damage.

2. Mazda 2.3L DISI Turbo (L3-VDT)

Mazda’s 2.3L DISI Turbo engine, found in vehicles like the Mazdaspeed3 and Mazdaspeed6, was developed to give strong turbocharged performance. At launch, it seemed like a winner.

The engine provided high output for a four-cylinder and responded well to tuning. But with time, many owners began noticing that the engine didn’t hold up well after years of driving. One of the main issues was premature cylinder wall wear.

This engine uses an aluminum block with iron liners, which should offer enough protection. However, the wall thickness and engine layout create a situation where scuffing becomes more likely, especially under high pressure. The direct injection system adds heat and pressure into the combustion chamber, which increases the chance of cylinder scoring if oil breaks down.

Once the car passes 100,000 miles, some users report that compression starts falling in one or more cylinders. This usually comes from scuffing or ring-land failure, where piston rings can no longer seal properly due to worn walls. The combination of high-boost pressure, frequent knock, and poor cooling around cylinder four leads to long-term damage.

Another common issue is blow-by, where combustion gases escape past the piston rings into the crankcase. This problem worsens as scuffing begins. Oil starts burning faster, leading to low oil levels, which only makes the internal damage happen faster. Even light tuning or regular spirited driving can speed up the wear process in this engine.

Drivers who keep the engine stock and follow strict oil schedules can delay the damage, but once wear sets in, performance drops quickly. The repairs are not cheap because the engine often needs a full rebuild with new pistons and re-machined cylinders. These issues have placed the L3-VDT among those engines that show weakness once the miles start to build up.

3. Chrysler 2.7L V6

Chrysler’s 2.7L V6 engine, used in models like the Dodge Intrepid, Chrysler Sebring, and Dodge Stratus, developed a bad reputation as time went on. At first glance, it appears like a modern, fuel-efficient engine, but in actual use, it has proven to be one of the least durable options, particularly when it comes to cylinder wall wear after 100,000 miles.

This engine features an aluminum block and heads, but without the kind of reinforcement needed to handle long-term use. It also has narrow cylinder walls that make the engine more compact but increase the chances of wall scuffing as the metal wears down. The situation becomes worse with the engine’s poor oil circulation design.

The 2.7L has small oil passages and a weak oil pump, making it very easy for sludge to build up. Once the oil thickens or the flow reduces, lubrication inside the cylinders drops. Without a good oil film between the piston rings and the wall, scoring begins. This engine also runs hot under regular conditions, which adds stress to the thin aluminum walls.

Owners report that once the engine hits between 90,000 and 110,000 miles, it starts burning oil and losing compression. This is often caused by the cylinder walls wearing unevenly. The fix usually requires either a full engine swap or an expensive rebuild. Many drivers simply junk their car because of how expensive the repair can be.

Even with good maintenance, this engine rarely reaches the long mileage marks seen in better designs. Its weak cylinder wall structure and poor oil management make it more likely to scuff and fail once it starts aging. Because of this history, the Chrysler 2.7L V6 is often used as a cautionary example in car ownership forums.

4. BMW N54

The BMW N54 engine is a twin-turbocharged inline-six that powered cars like the 335i and 135i during the late 2000s. It was praised for smooth power and strong acceleration, but it has also become known for long-term durability problems, especially involving cylinder wall wear and internal stress.

The N54 features an aluminum block with cast-in iron liners, which should offer some level of strength. But what causes early wear in this engine is how much heat and pressure it generates during regular driving.

Twin turbos create extra strain on the combustion chamber, and as time goes on, this leads to increased wear inside the cylinder walls, especially when the engine is tuned.

The piston rings in the N54 are also known to weaken early, especially if oil is not changed regularly. Once the rings stop sealing properly, they allow blow-by gases to enter the crankcase, which accelerates wear. The iron liners begin to wear unevenly, and that creates scuff marks inside the bore.

Drivers often report seeing high oil consumption and misfires once the car reaches around 120,000 miles. These signs often point to poor sealing in one or more cylinders. Even though some owners try to fix this with carbon cleaning or valve replacements, the root cause is often inside the cylinder itself.

The N54 is an engine that performs very well when new, but starts breaking down faster than expected. That’s especially true for cars that have been tuned or driven hard.

Rebuilding the engine can be expensive, and without reinforcement, the problem may return. These patterns show why the N54 has earned a reputation for giving issues once it reaches high mileage.

Also Read: 5 Forgotten GM Cars That Run vs 5 Recent GM Models With Major Issues

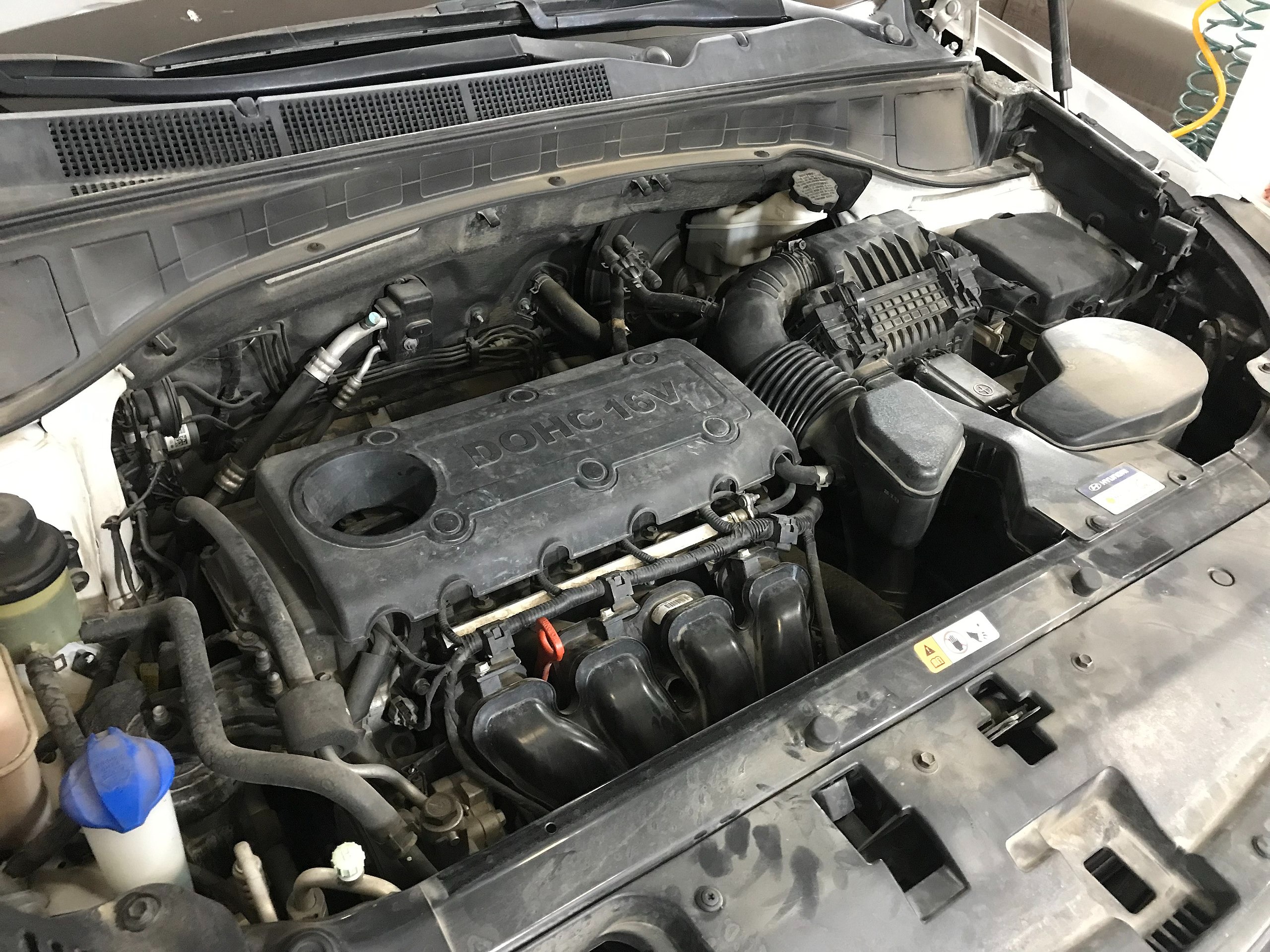

5. Hyundai 2.4L Theta II

The 2.4L Theta II engine from Hyundai and Kia has powered many popular cars like the Sonata, Optima, and Tucson. While it aimed to be fuel-efficient and affordable, many of these engines began failing long before reaching 150,000 miles. One of the most common problems comes from premature cylinder wall wear.

The engine uses an aluminum block without iron sleeves in many versions. That means the cylinder wall is made of aluminum treated with a coating. As time goes on, this surface wears down faster than iron-lined engines. Drivers began reporting engine knock and tapping noises from the bottom end, which usually indicates internal scuffing.

Hyundai later admitted that metal debris left over from the factory process may have caused early damage inside the engine. These tiny particles scrape the cylinder wall and speed up wear, especially when oil circulation is not perfect. Once the cylinder surface gets scratched, the piston rings cannot seal tightly anymore.

Drivers often experience sudden engine failure or loud knocking before hitting 120,000 miles. The company extended warranties and issued recalls for some models, but many engines still failed before reaching a point considered normal for modern cars. Even with proper maintenance, the cylinder walls just could not hold up as expected.

The aluminum construction may have helped save weight and improved fuel economy, but without strong liners or thicker walls, the engine became vulnerable.

Many of these vehicles now suffer from engine replacements or early trade-ins due to scuffing-related failure. This history has placed the Theta II among the engines that do not age well under regular driving use.