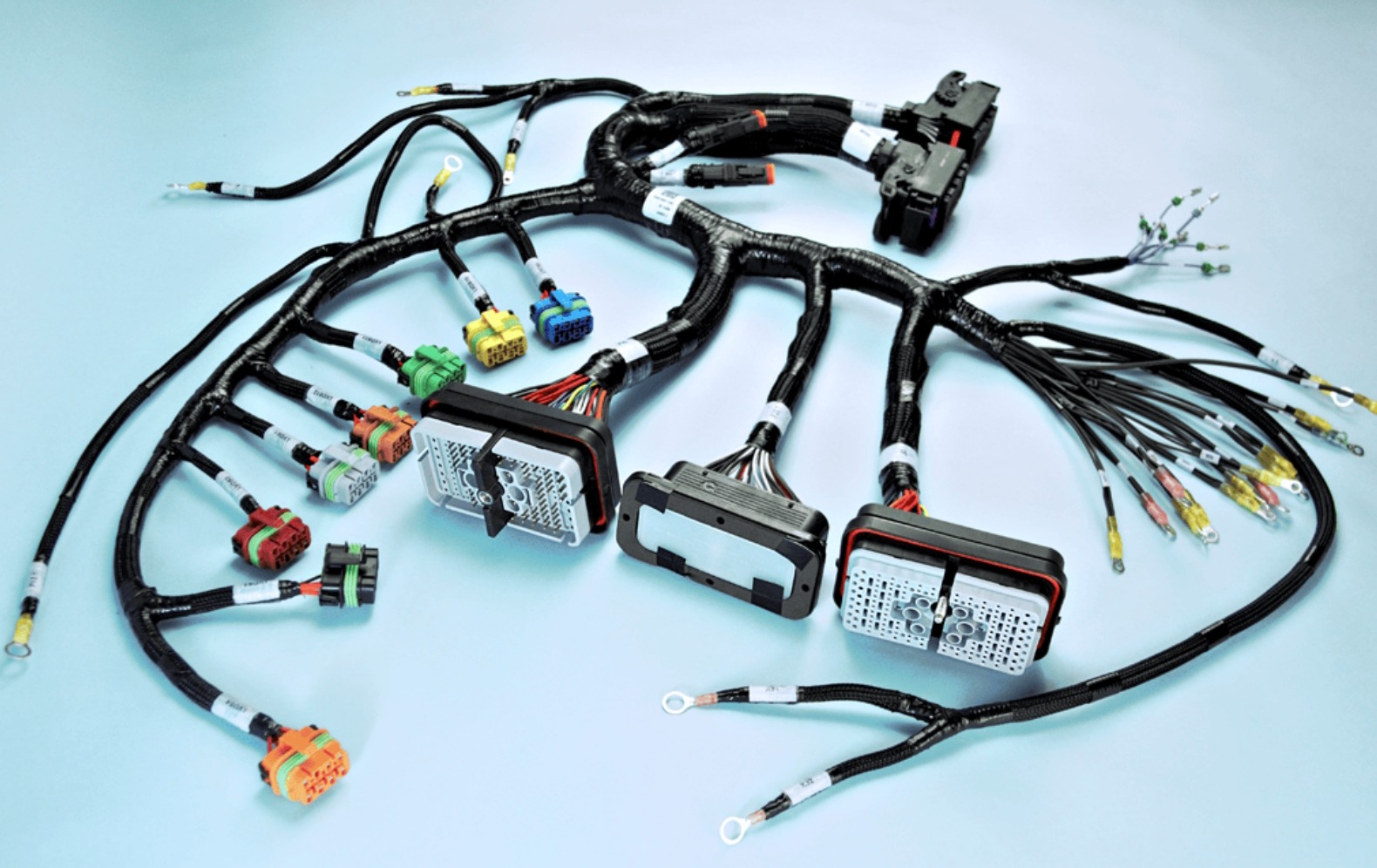

When you look at how truck performance can be affected by small internal components, the electrical wiring system plays a major role that many people often ignore. A truck that works smoothly on the road usually depends on a strong and secure electrical connection that carries signals and power to various parts of the vehicle.

The type of wiring harness used in the truck contributes to either better performance or constant faults that frustrate both drivers and fleet managers. Wiring that is properly sealed helps prevent unnecessary exposure to moisture, dirt, and heat.

On the other side, frayed electricals can introduce multiple problems like short circuits, poor fuel efficiency, frequent battery drainage, or even fire hazards in extreme cases.

Sealed wiring harnesses are built to protect internal wires from harsh external conditions, especially for trucks that work in rugged or demanding environments. These trucks often pass through construction sites, off-road terrain, and wet or dusty roads, making them prone to wear and tear.

Trucks with sealed harnesses can operate with fewer maintenance needs because they are more resistant to corrosion, oil spills, and physical damage. The sealants used around the wires keep water out and reduce the chances of electrical failure.

Apart from safety, this also helps the trucks last longer, improving their resale value and making them more reliable for long-distance haulage or commercial delivery jobs. On the other side, trucks with exposed or frayed wiring often battle electrical faults that interrupt daily operation.

These wiring systems are usually affected by weather, vibration from the engine, road debris, or animals that chew on wires. As time goes by, frayed wires start to show signs like flickering lights, power loss in certain components, or complete engine shutdown.

While these may sound like small troubles, the cumulative cost of repairing such issues can build up fast. Also, frayed wiring can make it difficult for mechanics to trace and fix faults quickly. That delay can lead to missed delivery schedules or business losses.

As we look at five trucks with sealed wiring harnesses and compare them with five trucks that come with frayed electrical systems, the aim is to present how wiring quality affects performance, safety, efficiency, and long-term reliability.

Trucks with Sealed Wiring Harness

1. 2023 Ford F-150

The 2023 model of the Ford F-150 has made strong improvements in its electrical structure by using sealed wiring harnesses across most of its trims.

This choice was influenced by Ford’s interest in improving durability while reducing maintenance stress for drivers who take their trucks through heavy tasks. Whether it is hauling, towing, or carrying tools and goods through rural roads, this truck can maintain solid electrical connections throughout.

Ford placed its sealed wiring harnesses in protective routing channels that guard against engine heat, rain splash, and physical rubbing. The connectors are weatherproof, and they are often double-locked to avoid detachment during rough driving conditions.

This is particularly helpful for people who live in places where snow, mud, or rain affect their daily transport routines. Once moisture gets into electrical components, it becomes easy for rust to form. Ford prevents this by wrapping each harness in thick insulation sleeves that also serve as a thermal barrier.

Another thing that makes the Ford F-150 stand out is how easily technicians can access and work on the wiring without damaging the protection.

Unlike trucks with exposed electrical systems, this model reduces the rate of electrical faults by keeping its circuits isolated from outside threats. As a result, the headlights, air conditioning, starter system, sensors, and safety tools all continue to work efficiently.

For those who use the F-150 for commercial or off-road activities, this wiring style brings peace of mind. It reduces downtime, saves repair costs, and allows the truck to maintain strong resale value.

The solid wiring system also adds to the comfort of driving because the driver does not need to worry about sudden warning lights or power loss on the road. These sealed wiring harnesses are not just about protection; they are part of what makes the truck perform consistently in tough conditions.

2. 2023 RAM 2500

RAM has always focused on making its heavy-duty trucks withstand rough workloads, and the 2023 RAM 2500 reflects that same focus in how its electrical systems are designed.

This truck benefits from a factory-installed sealed wiring harness that was introduced as part of its advanced electrical management. The harness is fitted with waterproof connectors that stop mud, dust, and water from damaging the electrical flow between main components.

Under the hood, this RAM model protects each major cable with an extra layer of insulation that handles both heat and abrasion. One area that shows this effort well is around the alternator and the fuse box.

These areas carry high-voltage energy and, if left exposed, can easily suffer from melted cables or poor current flow. RAM avoids this by using thick rubber-like sleeves that wrap around each group of wires, preventing contact with engine heat or foreign objects.

The truck also shines when it comes to sensor protection. Since modern trucks depend on sensors for automatic driving features, blind spot detection, and trailer controls, RAM made sure those connections remain stable through weather-resistant wiring.

No matter how wet or dusty the working environment is, the system does not cut off or give false warnings. This gives truck operators better control and increases trust in automated systems during trips.

For business owners who rely on fleet trucks to move goods across the country, the sealed wiring harness helps extend the time between servicing. Less interruption means better business flow and fewer emergency garage visits. In the long run, it saves a lot of money on replacements and labor.

This truck represents how modern electrical protection adds to mechanical strength. The wiring does not wear out fast, which means fewer electrical faults and a longer life for all powered accessories inside the truck.

Also Read: 5 Cars with Reinforced Control Arms vs 5 with Bent Arms Under Stress

3. 2022 Toyota Tundra

Toyota redesigned the 2022 Tundra with one thing in mind: strength and resilience. The new version does not just bring changes in appearance or engine, it also introduces a refined wiring setup that improves electrical safety and reliability.

Every major harness in this truck is sealed from moisture and dust. From the front grille to the tail lamps, all electrical channels are wrapped in layers of insulation and tight clips to prevent loosening.

Toyota uses a special method that involves coating the internal wires with heat-resistant tape before wrapping them in waterproof jackets. This double-layer method gives added safety where other trucks may fail.

The design also includes custom routing that follows the body curves of the truck, reducing the chances of wire bending or snapping from engine vibration. This also makes repairs easier because technicians can follow a clean layout when inspecting parts.

The Tundra’s cabin systems, such as the touchscreen display, seat adjusters, and climate controls, benefit from this wiring method because power is delivered steadily.

Also, the trailer hook-up points at the rear have sealed connectors, making towing safer and more reliable in all seasons. Snow or rain does not interfere with electric brake signals or camera feeds.

Because of this protection, the Tundra has fewer complaints when it comes to battery issues or blown fuses. The wiring does not wear down quickly, which helps drivers spend less time checking for faults.

This makes it a good choice for those who use trucks daily for long-distance travel or rural site work. The sealed harness makes it easier for the Tundra to maintain high performance, no matter the weather or terrain.

4. 2023 Chevrolet Silverado 2500HD

The Silverado 2500HD from Chevrolet has built its name on strength and dependability, and the 2023 edition takes it further by reinforcing its wiring system with sealed harnesses.

In this truck, the electrical protection starts from the engine bay and stretches to the back of the vehicle, ensuring that all major components are shielded from water, heat, and corrosion. It was built with drivers in mind who work in places where rough terrain, temperature swings, and long road hours are normal.

One major strength of this Silverado is how each connector is designed to lock firmly and resist accidental loosening. When driving over potholes, gravel roads, or construction zones, this feature becomes extremely helpful.

The sealed wiring layout avoids the usual disconnection issues that can affect lights, ignition switches, or dashboard displays. Chevrolet uses heat-shrinking sleeves and rubber grommets to add more tightness around the joints where wiring enters the cabin or touches metallic parts.

Another area that Chevrolet has improved is the fuse box area, which now comes with a built-in drainage channel and cover insulation. This prevents water from seeping into sensitive zones. Trucks often face electrical shorts because of fuse box leaks, but this version of the Silverado greatly reduces that risk.

In cold climates, where salt and chemicals are used on roads, wiring is more likely to decay fast if not protected. Chevrolet designed its sealed harness to resist chemical exposure, which helps the truck last longer.

The comfort features like heated seats, smart trailer technology, and camera support all run on a reliable electrical system. Thanks to the sealed harness, these systems remain stable in the course of time without glitches.

The less time spent in the workshop fixing electrical problems, the more efficient this truck becomes. For business owners or construction supervisors, the Silverado stands out as a strong performer with dependable electrical protection built into its design.

5. 2023 Nissan Titan XD

The Titan XD is Nissan’s heavy-duty truck that was developed to meet the expectations of drivers who want power, comfort, and reliability in one machine. This 2023 version features sealed wiring harnesses that are well-built to match the rough use that this truck often experiences.

Whether it is pulling a trailer, working on a construction site, or driving through muddy paths, the Titan XD keeps its electrical connections safe and working.

Nissan used moisture-blocking gel in the connector pins, which helps prevent short circuits even when exposed to rain or mud. This is especially useful in the underbody, where wires are exposed to dirt and stones.

The harness is built with corrosion-resistant materials that stop rust from affecting current flow. Each group of wires is separated into layers and routed with clips that absorb shock from road vibration.

Inside the cabin, everything from the infotainment screen to the charging ports and digital dashboard functions well without delay or flicker. That kind of consistency is made possible by a wiring system that is sealed and isolated from outside damage.

Even when the engine bay gets hot, the wires remain cool and stable. Nissan also included a special wiring loop for towing signals that are separately shielded, so any towing problems do not affect the truck’s main system.

Because many people use the Titan XD for long travel or transport work, this added protection reduces emergency stops. It avoids many common issues like sudden warning lights or engine cut-offs.

The truck stays available and productive for more hours, making it a solid investment for both private owners and fleet managers. Nissan’s focus on strong wiring protection reflects its understanding of how electrical faults can ruin a truck’s day-to-day service.

Trucks with Frayed Electricals

1. 2018 GMC Sierra 1500

The 2018 Sierra 1500 from GMC is well-known for its strong engine performance, but its electrical system has given many users a reason to complain.

In the course of time, this model has shown a tendency to suffer from frayed wiring, especially in areas where wires are routed close to hot engine components or tight corners. Without proper sealing, these wires rub against sharp edges and start to wear out.

One major problem area in this truck is under the driver’s side dashboard, where the harness lacks full insulation. Vibration from driving on uneven roads makes the wires shake continuously, and over months of use, small tears start to show.

These tiny cuts in the wiring insulation allow moisture to enter and cause corrosion. That corrosion then spreads and interferes with the signal path, leading to random faults like blinking lights or non-functional buttons.

Many Sierra drivers have reported issues with the trailer brake system, reverse camera, and power seats, all traced back to damaged wiring. Also, during cold seasons, the wires become stiff and crack more easily when flexed.

Some users even experienced battery drainage because frayed wires created invisible power leaks. The engine sometimes struggles to start due to poor connections caused by damaged ground wires.

One of the biggest frustrations with this truck’s wiring is the time it takes to find the fault. Since the wires are not well-protected or color-coded, mechanics spend extra hours tracing where the break happened.

In urgent cases, this leads to missed appointments or extra rental charges. Fixing the frayed harnesses is often expensive because replacing the full wire section becomes the only safe option.

This model shows how weak wiring can affect even a mechanically strong truck. Without sealed protection, electrical parts become vulnerable to wear, damage, and poor performance. While the Sierra still delivers on engine strength, its electrical flaws pull it down in terms of reliability.

2. 2017 Dodge Ram 1500

The 2017 Dodge Ram 1500 was widely accepted for its smooth ride and towing power, but the electrical system on this model has brought frustration to several owners.

Unlike the newer RAM models that use sealed wiring harnesses, this version has multiple areas where the wires are either exposed, poorly routed, or poorly secured. Because of this, the wires rub against other parts and eventually start to wear out, leaving the vehicle open to unexpected faults.

One frequent complaint among users is with the taillight wiring. The harness in that section has little to no insulation protection, and the routing puts it close to moving suspension components. After some time, as the vehicle vibrates or hits bumps on the road, the wires start chafing and the insulation peels off.

When that happens, short circuits or complete failures in tail lights, turn signals, or reverse lights begin to show up. Some owners have even received fines because their lights stopped working without them knowing.

Another sensitive area is under the front hood, where the battery cables and sensor wires run very close to the engine block. Since there is no strong thermal protection, the heat gradually melts the wire coating.

This has led to several engine stalling issues, false warnings on the dashboard, and sometimes the complete failure of the power control module. These electrical problems make driving risky, especially for long-distance users or fleet operators who depend on the truck daily.

The power window system, door locks, and dashboard controls are also common trouble spots. Users have reported flickering displays, slow window response, or doors refusing to lock properly.

Tracing and fixing these problems is not only difficult but also costly. Since the truck has no clear sealing or wiring shields, mechanics usually recommend full rewiring or complete harness replacement after a few years of use.

Although the 2017 Ram 1500 holds its ground when it comes to comfort and load-carrying strength, the poor state of the wiring system leaves it weak on long-term reliability.

Electrical faults from frayed wiring can quickly cancel out all the benefits of its physical strength, especially when repairs start to pile up in cost and time.

3. 2016 Ford Super Duty F-250

This Super Duty F-250 model from 2016 remains popular among construction workers and heavy-haul drivers because of its strong towing ability. But one common headache for many owners is the condition of the electrical wiring, especially as the truck begins to age.

The wires under the hood and beneath the truck are prone to early wear, leading to fraying that brings electrical issues that are hard to fix. A major weakness is found in the wiring near the battery terminals. Without strong sealing or shielding, the wires are exposed to both water and heat. After continuous use, rust builds up on the terminals, and the wire covering becomes brittle.

This leads to a slow power response, weak engine starts, and sometimes total disconnection in cold or wet conditions. The alternator also becomes stressed because it is forced to push more voltage through weak wires.

Ford used plastic clips to hold some of the wiring against the body, but after some time, these clips loosen or break off. When this happens, the wires swing freely and get scraped by metal edges or engine parts.

This damage usually affects fuel injectors, ignition coils, and even the truck’s control modules. Once these systems are compromised, the vehicle begins to act unpredictably.

The trailer connection in the 2016 Super Duty is another common problem area. Users pulling trailers have faced situations where the trailer lights or brake signals cut off without warning.

This can lead to safety risks on highways, especially during night driving or poor weather. Often, the root cause is frayed wiring close to the rear hitch, where salt and road debris are likely to damage exposed cables.

Fixing these problems can be stressful because many of the wires run deep through the engine bay or along the chassis. Mechanics usually have to remove panels or disconnect parts to find the affected spots.

Since the wiring was not sealed from the factory, replacements are more frequent. These faults have pushed many users to consider rewiring or upgrading to newer models.

Even though the 2016 Super Duty still delivers excellent horsepower, its vulnerability to electrical wear reduces its value with time. Unsealed and fraying wires mean more visits to the workshop and less time being productive on the job.

4. 2015 Chevrolet Colorado

The 2015 Colorado is a mid-size pickup that gives users a good balance between utility and daily comfort. But its electrical system has not held up well for long-term users.

Many units from this model year developed frayed wiring problems that affected core features like ignition, lighting, and dashboard functions. Unlike later versions with improved sealing, this model has exposed wires in sensitive locations.

One of the areas that suffered most was the wiring beneath the front seats. Chevrolet ran wires for airbag sensors and seat warmers in that area without strong protection.

When passengers moved seats or spilled drinks, those wires got twisted or wet. After some time, the insulation peeled off, exposing bare copper wires. This caused warning lights to stay on and, in some cases, airbags stopped working altogether. That’s a major safety concern.

The headlights and fog light systems also suffered because of weak connections in the wiring harness at the front bumper. The cables were not shielded well from road debris or temperature changes.

As a result, many users complained of flickering headlights or total lighting failure. These failures usually happened while driving, which made night trips unsafe and stressful.

Battery issues were also common with this model. Frayed ground wires near the chassis weakened the battery’s ability to stay charged, especially during colder seasons.

The truck would sometimes go completely silent without warning, and jump-starting it became a routine for some owners. These issues forced many to replace wires manually or upgrade to thicker harnesses made from aftermarket brands.

Electric window systems and entertainment units were not left out. Some users experienced frozen touchscreens or slow window movement, all due to poor current delivery from worn wires. Since many of the truck’s wires were bundled without sealing, one frayed cable often affected others nearby.

Repair costs added up fast because each fault required deep inspection. Unlike sealed systems, these faults are not easy to trace. The 2015 Colorado might still be attractive due to size and fuel economy, but the electrical issues that come from frayed wiring reduce its dependability as it ages.

Also Read: 5 Cars with Lifetime Turbochargers vs 5 with Failed CHRA Assemblies

5. 2014 Toyota Tacoma

The 2014 Toyota Tacoma made a good name for itself through its durability and off-road capabilities, but the wiring setup on this model has shown weak points as time goes by.

One major issue is the level of exposure found across several wiring sections under the chassis and in the engine bay. While this model was strong mechanically, its lack of sealed electrical harnesses led to early wear in many units still on the road today.

A common area where fraying occurs is behind the taillights. The rubber coating on the wires does not hold up well against water and road salt. Trucks used in snowy regions usually suffer the most, as the rear wires corrode faster.

This results in brake lights going out or reverse lights failing without any warning. For drivers who often haul trailers or work on job sites, this becomes a serious issue that interrupts daily routines.

Inside the cabin, frayed wiring has affected power windows, door locks, and dashboard controls. When moisture finds its way through cracks in the insulation, it disrupts electrical flow and causes features to lag or stop working entirely.

Since these systems were not designed with weatherproof shielding, even regular rainwater or washing can create long-term damage. Once the damage spreads to control modules, repairs become expensive.

Another area of concern is the wiring for off-road equipment. Many Tacoma owners install custom lights, winches, or GPS trackers, but the stock wiring is often not strong enough to handle the added load. Frayed wires make the truck vulnerable to shorts and voltage drops.

This can damage both factory electronics and any aftermarket accessories added later on. Users often find themselves rewiring or adding protective tubes just to keep their systems working.

Repairing the wiring takes more time because Toyota did not include organized wire labels or easy access ports in this version. Mechanics have to remove interior panels or climb under the truck to find the issue.

In many cases, entire sections of the harness need replacing. Although the Tacoma holds strong in terms of engine life and body strength, the frayed electronics make it less dependable when it comes to comfort and day-to-day performance.