Engines are the heart of every vehicle, and their performance often depends on how well they manage revolutions per minute, or RPMs. The ability of an engine to rev high is a major factor in sports cars, motorcycles, and even performance sedans.

High-revving engines are usually built with precision, strong internal components, and designs that can withstand extreme stress. They deliver an exciting driving experience by pushing power delivery to the upper range of the tachometer, creating a sound and sensation that many drivers love.

However, not all engines are made to live comfortably at high RPMs. Some are better suited for low-end torque, meaning they perform best at slower crankshaft speeds. When such engines are pushed too hard, they can overheat, suffer internal wear, or even fail.

The difference often comes down to engineering decisions, material strength, lubrication quality, and how the engine was intended to be used by its manufacturer.

In the performance scene, there are certain engines celebrated for their ability to keep pulling strongly without breaking apart at redline. These are the powerplants that thrive on being revved hard, whether on the track or during spirited driving.

On the opposite side are engines that quickly show their limits when pushed beyond their comfort zone. These motors might perform well under normal conditions, but reveal weaknesses when subjected to constant high RPMs.

First, we will examine five engines famous for their high-rev capabilities, explaining what makes them strong and reliable under those conditions. Then, we will discuss five engines known for their struggles when revved too aggressively, pointing out the engineering reasons for their vulnerability.

Each section will highlight the build quality, performance traits, and potential problems so that enthusiasts and everyday drivers can better understand which engines can handle the thrill of high RPMs and which are better left in a lower range.

5 Engines That Handle High RPMs

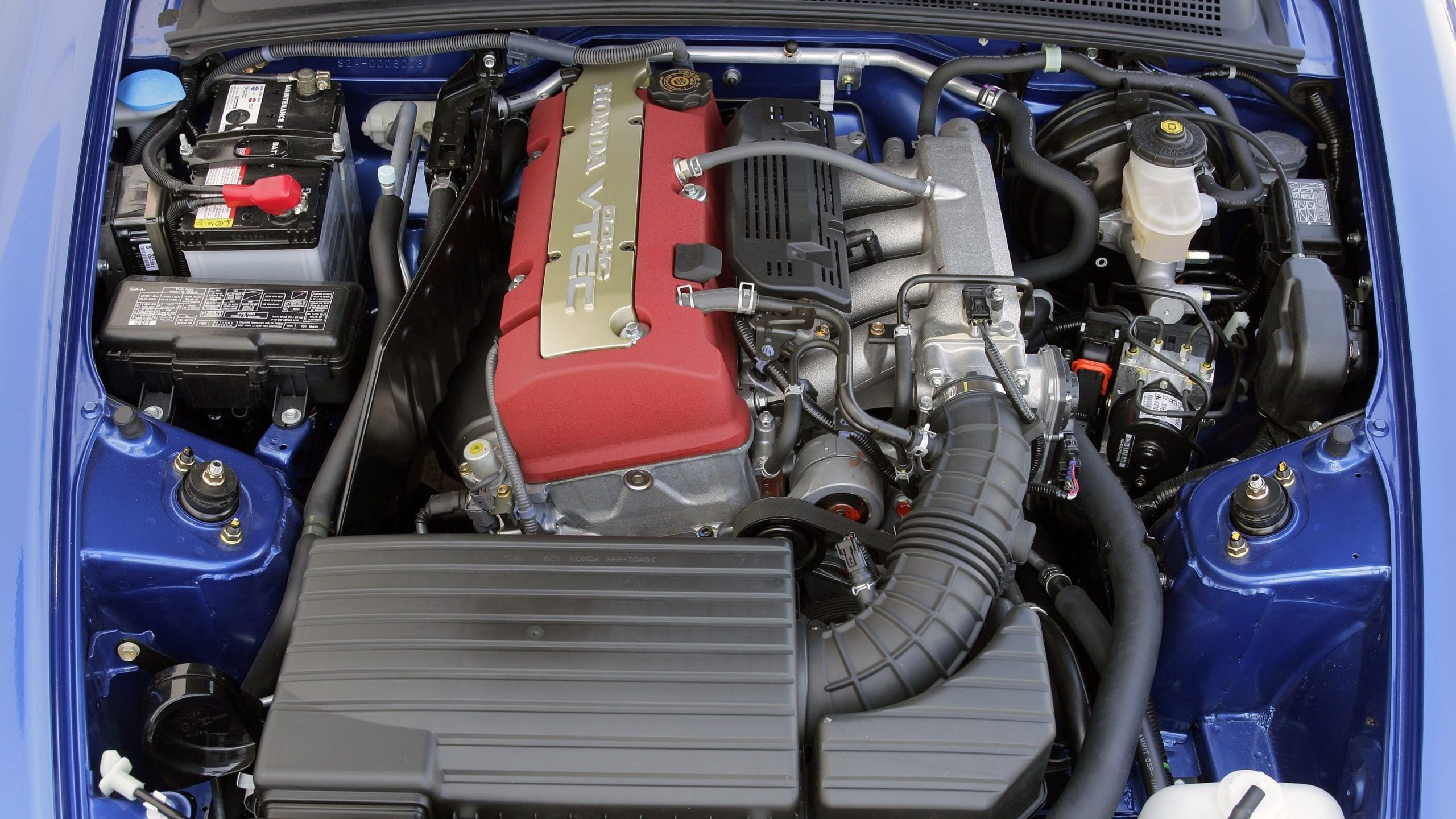

1. Honda F20C

The Honda F20C is widely admired for its incredible ability to sustain high RPM operation without losing reliability. This 2.0-litre naturally aspirated four-cylinder engine, found in the Honda S2000, was designed with track performance in mind. It is famous for its sky-high redline, sitting at 9000 RPM, which is rare for a production car engine of its size and era.

One of the reasons the F20C can handle such high revolutions is its extremely short stroke. A short stroke reduces the piston’s travel distance within the cylinder, allowing it to move faster without creating too much stress on the connecting rods and crankshaft. The engine also uses lightweight forged pistons and strong connecting rods, which help manage the intense forces generated at high speeds.

The cylinder head design is another strength. Honda used a performance-focused VTEC system that adjusts valve timing and lift at specific RPM ranges. At lower RPMs, it provides good efficiency, but once the higher cam profile engages, the engine breathes far better, enabling it to keep pulling strongly toward the top of the rev range.

The aggressive cam profiles, combined with large valves, allow the F20C to produce a remarkable 240 horsepower from just 2.0 litres, which was a record for a naturally aspirated engine in a production car when it launched.

Durability is also supported by a rigid block structure and a high-quality oiling system that ensures lubrication even during extreme driving conditions. The F20C’s oil pump is designed to maintain pressure at high RPM, preventing bearing wear and other lubrication-related failures.

For many owners, the F20C provides a thrilling driving experience. Drivers can push it hard lap after lap on a racetrack without worrying about sudden engine failure. The sound as it screams toward redline is another major attraction for enthusiasts.

This combination of engineering precision, material strength, and smart design choices makes the F20C one of the finest high-revving production engines ever built, proving that Honda’s engineering expertise in the early 2000s was ahead of its time.

2. Toyota 2ZZ-GE

The Toyota 2ZZ-GE is another high-revving gem that has earned respect among performance enthusiasts. Developed in partnership with Yamaha, this 1.8-litre inline-four was fitted into models like the Toyota Celica GT-S, Lotus Elise, and Toyota Corolla T-Sport. Its engineering focus was on delivering power at high RPM, with a redline of around 8,200 RPM.

One of the main strengths of the 2ZZ-GE lies in its advanced valvetrain technology. Toyota’s VVTL-i system, which stands for Variable Valve Timing and Lift with intelligence, changes both valve timing and lift depending on engine speed. At lower speeds, it offers efficient combustion and smooth operation, but at higher RPMs, the aggressive cam profile allows the engine to breathe more freely, unleashing its full performance potential.

The 2ZZ-GE uses a square bore and stroke configuration, meaning the bore and stroke dimensions are nearly equal. This balance helps maintain stability at high piston speeds while still allowing impressive top-end performance.

To keep the engine reliable under these conditions, Toyota included forged connecting rods, a forged crankshaft, and lightweight pistons. The high compression ratio, around 11.5:1, further supports strong high-rev output while maintaining efficiency.

Another advantage of the 2ZZ-GE is its oiling system. High-revving engines often face oil starvation issues, especially during hard cornering or prolonged high RPM driving. Toyota addressed this by designing an oil pump and delivery system capable of maintaining consistent pressure at elevated engine speeds.

Drivers often praise the 2ZZ-GE for its sharp throttle response and the way it comes alive once the high-lift cam engages. The sensation of pushing the rev counter toward the redline is rewarding, with the engine delivering a surge of power right before the switching point. Its lightweight construction and durable components mean it can handle spirited driving on both roads and racetracks without losing reliability.

When maintained properly, the 2ZZ-GE can handle years of aggressive use. It rewards drivers who enjoy keeping an engine in its powerband, proving that with the right engineering, even a small-displacement motor can produce big thrills at high RPM.

Also Read: 5 Affordable Engines That Still Sound Good and 5 That Always Knock

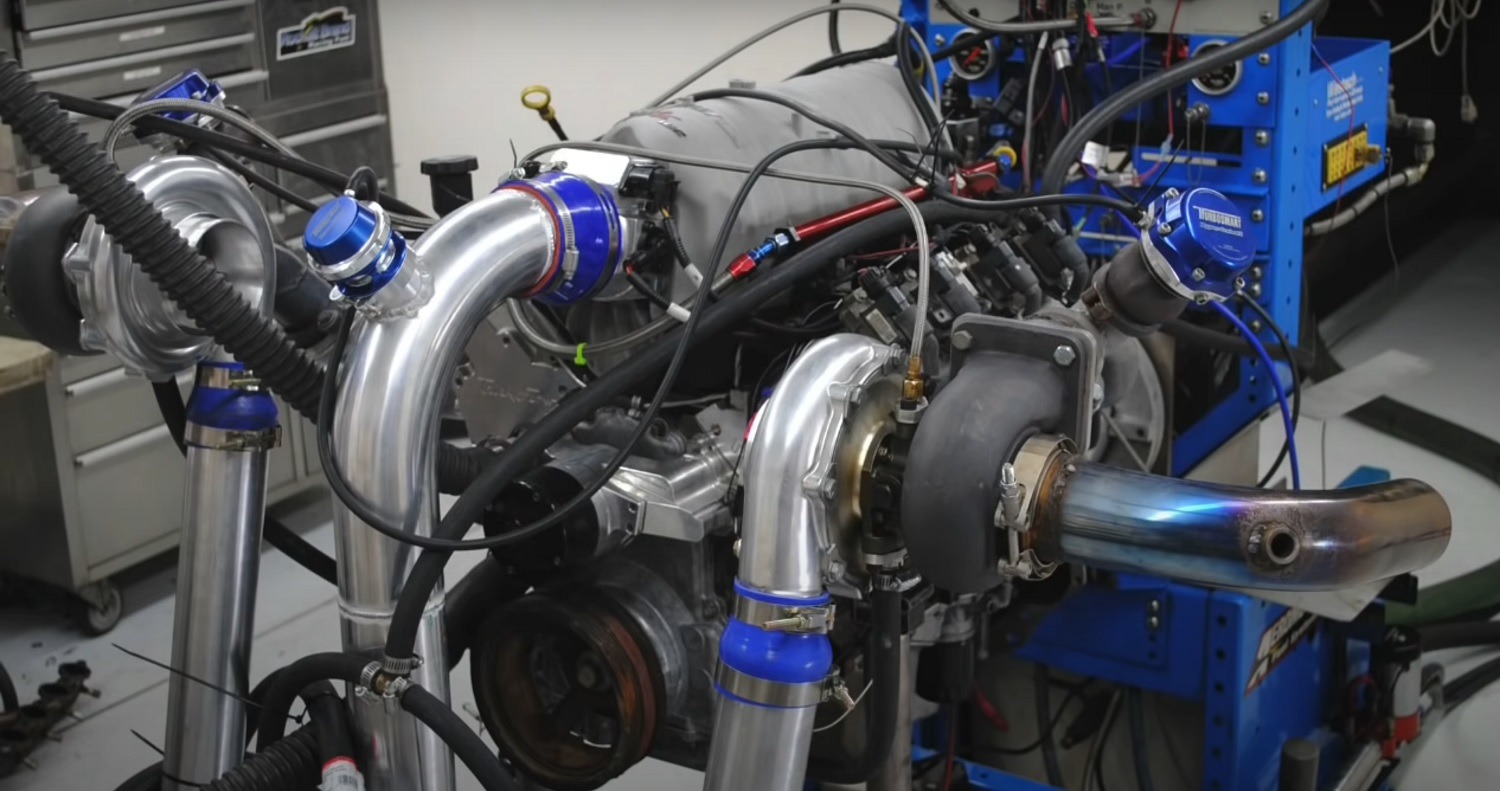

3. BMW S65 V8

The BMW S65 V8, used in the E90 and E92 M3 models from 2007 to 2013, is well known for its ability to sustain high RPM without sacrificing reliability. This 4.0-litre naturally aspirated V8 revs to 8,400 RPM, which is unusually high for an engine of its size and cylinder count.

Derived from BMW’s Formula 1 experience, the S65 uses a short-stroke design that reduces piston travel distance, allowing for quicker revolutions with less stress on internal parts. The lightweight forged crankshaft and forged connecting rods are designed to withstand the extreme forces generated at high speeds.

The valvetrain is another engineering highlight. BMW employed double-VANOS, its variable valve timing system, which optimises valve operation for both low and high RPM performance. Combined with individual throttle bodies for each cylinder, this setup ensures precise air intake control, enhancing throttle response and top-end power delivery.

A sophisticated quasi-dry sump system handles lubrication. This design uses multiple scavenging pumps to maintain oil pressure even under extreme cornering forces, which is crucial for high-revving track use. Many engines fail due to oil starvation at high RPM, but the S65’s system prevents such issues, preserving bearing life and preventing heat damage.

Another reason for its high-rev capability is its lightweight valvetrain components. Lighter valves and followers reduce inertia, allowing the engine to rev faster and higher without valve float. The 12.0:1 compression ratio further enhances performance, delivering 414 horsepower from a naturally aspirated setup.

Drivers often describe the S65 as an engine that encourages you to chase the redline. Its sound transforms from a deep growl to a sharp race-inspired note as it approaches maximum RPM. On track days, it delivers consistent performance lap after lap, provided it is well-maintained.

When treated with proper care, including timely oil changes and bearing inspections, the BMW S65 V8 remains one of the most rewarding high-revving engines available in a production car. It combines motorsport-derived technology with road-going reliability in a manner that few engines can match.

4. Ferrari F136 V8

The Ferrari F136 V8, which also appeared in certain Maserati models, is a naturally aspirated engine designed for high RPM performance. Depending on the variant, this 4.3- to 4.7-litre V8 can rev between 8,000 and 9,000 RPM. Cars like the Ferrari F430 and 458 Italia benefited from its engineering, which delivered both breathtaking performance and a thrilling soundtrack.

The F136 was designed with a flat-plane crankshaft, which is a major contributor to its high-revving nature. A flat-plane crank allows for even firing intervals, reduced rotational mass, and faster engine response compared to a traditional cross-plane crank. This design also gives the engine its distinctive, sharp exhaust note.

Internally, the F136 uses lightweight forged pistons, titanium connecting rods in some versions, and an aluminium block with wet liners. The combination keeps weight down while ensuring strength to handle high piston speeds. The cylinder heads are equipped with large valves and aggressive cam profiles to maximise airflow at high RPM.

Ferrari also invested in advanced lubrication systems for this engine. The dry sump design ensures that oil is always available to critical components, even during intense cornering or prolonged high-speed driving. This prevents oil foaming and starvation, which are common issues in high-performance engines operating at high RPM.

Another highlight is the intake and exhaust tuning. Ferrari engineered the intake manifold and exhaust system to work together, creating a resonance that boosts power in the upper RPM range. The result is an engine that feels alive and eager as it approaches redline, rewarding drivers who keep it in the powerband.

Drivers often praise the F136 for its combination of responsiveness, reliability under demanding conditions, and an exhaust note that many consider among the best in automotive history. While it requires careful maintenance, including regular timing chain checks and fluid changes, it remains one of the finest examples of a high-revving V8 ever fitted to a road car.

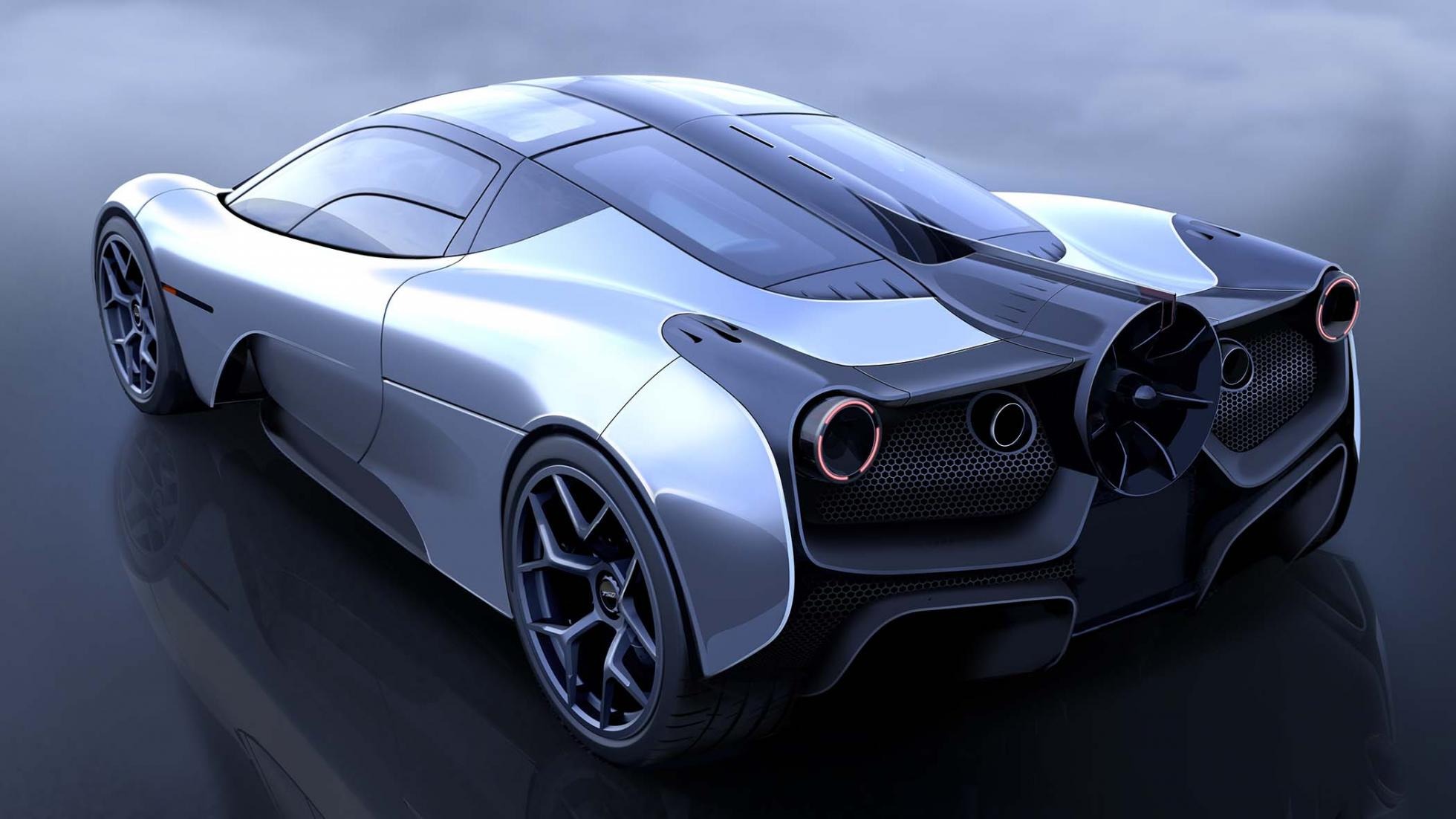

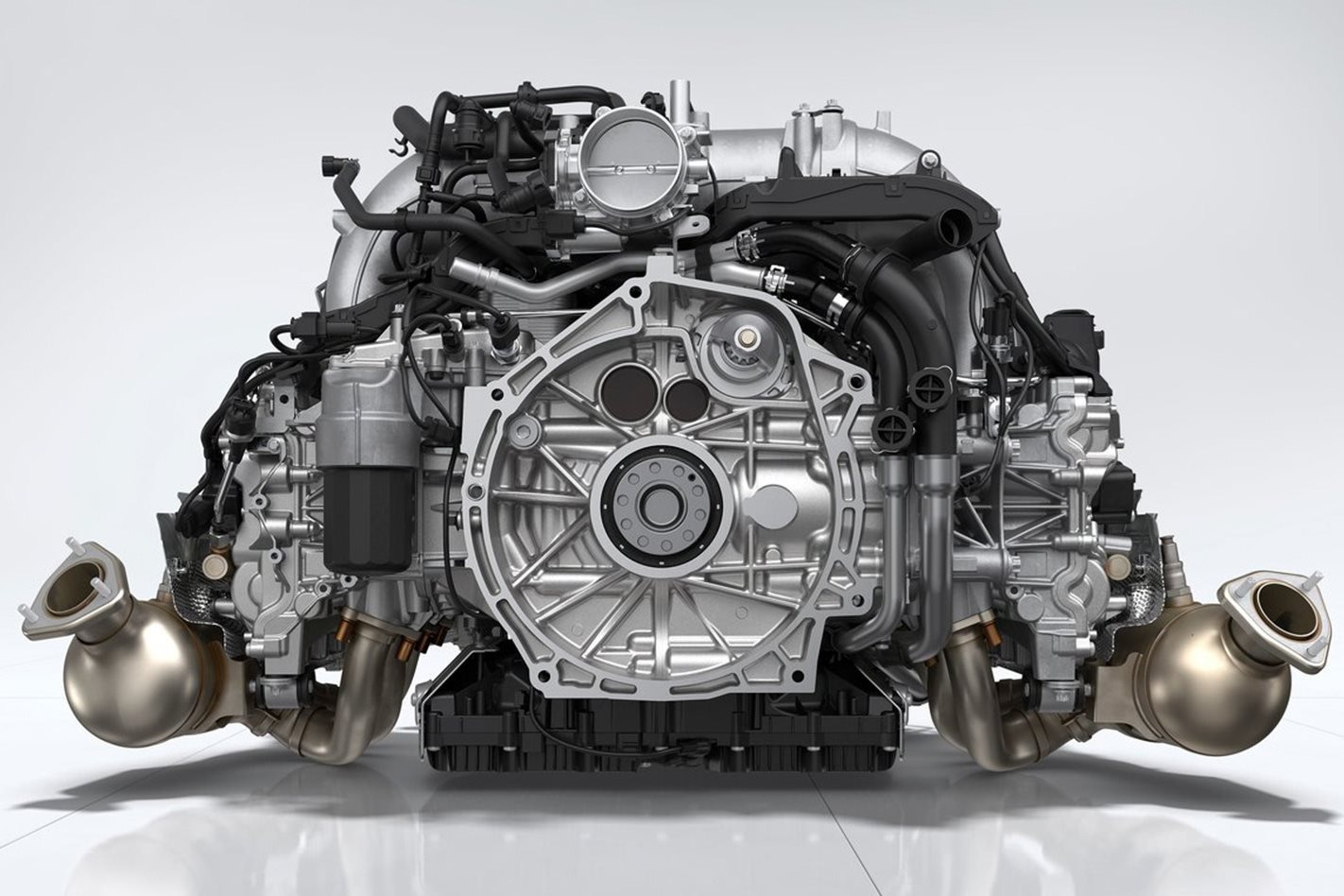

5. Porsche 4.0-litre Flat-Six (GT3)

Porsche’s 4.0-litre naturally aspirated flat-six, found in the 911 GT3 models, is one of the most impressive high-revving engines in modern sports cars. With a redline of around 9,000 RPM, it combines endurance racing technology with road car usability.

This engine’s strength starts with its balanced flat-six layout, which reduces vibration and allows for smoother high-RPM operation. Porsche uses forged pistons, titanium connecting rods, and a lightweight crankshaft to minimise reciprocating mass. These components are critical in allowing the engine to spin freely at such high speeds without excessive wear.

The valvetrain features Porsche’s variable valve timing and lift system, which ensures that airflow is optimised across the rev range. At higher RPM, the cam profiles enable maximum breathing efficiency, allowing the engine to deliver strong power right up to redline.

Porsche also uses a dry sump lubrication system in the GT3’s engine. This ensures a constant oil supply under extreme driving conditions, including high lateral loads on a racetrack. The oil system’s design also helps keep the engine’s centre of gravity low, improving handling.

Another reason this engine thrives at high RPM is its motorsport heritage. Many of its components are derived from Porsche’s endurance racing programmes, where engines must sustain high speeds for hours without failure. This background means the 4.0-litre flat-six is built to last under demanding conditions.

Drivers often comment on the addictive nature of revving this engine to its limit. The sound changes from a mechanical growl to an intense scream as it approaches 9,000 RPM. On a track, it delivers lap after lap of consistent performance without overheating or losing power.

While maintenance costs can be high, especially for components like the valvetrain and lubrication system, the durability and driving pleasure make it worthwhile. For enthusiasts who love high RPM performance, the Porsche 4.0-litre flat-six stands as one of the best examples of modern engineering done right.

5 Engines That Break When Revved

1. Chrysler 2.7-litre V6

The Chrysler 2.7-litre V6, used in models like the Dodge Intrepid, Chrysler Sebring, and Dodge Stratus in the late 1990s and early 2000s, is remembered more for its problems than for any performance achievements. While it was adequate for regular driving, this engine was not designed to handle sustained high RPM use. Drivers who pushed it hard often faced serious reliability issues.

One of the major weaknesses of the 2.7-litre V6 was its oiling system. The narrow oil passages, combined with a tendency for sludge buildup, meant that lubrication could quickly become inadequate when the engine was revved aggressively. At higher RPMs, oil flow demands increase sharply, and if the system cannot keep up, critical components like bearings and camshafts can fail.

The timing chain tensioners and guides were also prone to wear, especially when subjected to frequent high-rev driving. Once these parts began to degrade, timing could become inaccurate, leading to misfires or, in severe cases, catastrophic engine damage.

Cooling system limitations further reduced the 2.7’s tolerance for hard use. Under sustained high RPM operation, the engine could overheat, which would accelerate wear on gaskets, seals, and internal components. Overheating also made the sludge issue worse, as heat would cause oil to break down faster.

Another contributing factor was the relatively heavy internal components. Pistons and connecting rods were not optimised for high-speed movement, and the engine’s stroke length was on the longer side. This meant that at higher RPMs, the stresses on these parts were considerable, increasing the risk of mechanical failure.

Many owners discovered that while the 2.7-litre V6 could rev up when needed for overtaking, doing so frequently or for extended periods drastically shortened its lifespan. Repair costs for a failed 2.7 were often higher than the value of the vehicle, which made this engine’s reputation even worse.

For drivers seeking a motor that can live happily in the high range of the tachometer, the Chrysler 2.7-litre V6 is best avoided. Its design flaws, lubrication challenges, and poor heat tolerance make it a prime example of why some engines should be kept within a modest RPM range.

2. Subaru EJ25

The Subaru EJ25, a 2.5-litre flat-four engine used in many Legacy, Impreza, and Forester models, has its strengths in low-end torque and smooth power delivery. However, it has long been associated with head gasket problems and other issues that become worse when the engine is pushed to high RPMs for long periods.

One of the main reasons the EJ25 struggles with sustained high revs is its cooling system layout. The flat-four design has advantages for handling and balance, but it also creates challenges for coolant flow. Uneven cooling between cylinders can occur, which is less noticeable during normal driving but can cause overheating in high RPM situations.

The EJ25’s open-deck block design is another limitation. While it helps reduce manufacturing costs and weight, it provides less support for the cylinder walls compared to semi-closed or closed deck designs. At high RPM, especially under turbocharged applications, cylinder wall stability can become an issue, leading to long-term durability concerns.

Head gasket failures are a well-known issue with this engine, and high RPM use tends to accelerate the problem. When the engine is revved aggressively, combustion pressures and heat levels rise sharply. As time goes on, this can cause the gaskets to weaken and eventually fail, allowing coolant and oil to mix. This leads to overheating, bearing damage, and other serious problems.

Another point to consider is the valvetrain. The EJ25’s valve springs and timing components were not specifically engineered for extreme high-RPM operation. Prolonged high-speed driving can cause valve float or timing belt stress, increasing the risk of failure.

While enthusiasts have built heavily modified EJ25s capable of withstanding high RPM, these builds require upgraded internals, reinforced head gaskets, and improved cooling systems. In factory form, the EJ25 is best kept within its intended operating range. Drivers who consistently push it toward redline without modifications risk encountering the well-documented reliability issues that have followed this engine’s reputation for decades.

3. GM 3.4-litre V6 (LA1)

The GM 3.4-litre LA1 V6, used in vehicles like the Chevrolet Venture, Pontiac Grand Am, and various mid-size GM sedans in the late 1990s and early 2000s, was built for basic transportation rather than high-performance driving. When forced into frequent high-RPM use, its weaknesses quickly become apparent.

One of the main design limitations is the intake manifold gasket system. This engine was known for premature gasket failures, which could cause coolant leaks into the oil. At higher RPMs, increased vibration and thermal expansion could speed up gasket wear, making failures more likely. Once coolant entered the oil, lubrication suffered, leading to bearing and camshaft wear.

The bottom end of the LA1 V6 also lacks the robust construction seen in engines designed for performance. The crankshaft and connecting rods are built for longevity under moderate loads, not for sustained operation near redline. High RPM increases piston speeds, generating more heat and stress than the materials were meant to handle.

Valve float is another concern. The LA1’s valvetrain components, including springs and retainers, were not engineered to manage extreme speeds. As a result, prolonged high-RPM driving could lead to loss of valve control, misfires, or even piston-to-valve contact in worst-case scenarios.

The oiling system, while adequate for normal driving, can struggle during extended high-rev use. Oil pumps and passages in the LA1 are relatively modest, and they can fail to deliver enough pressure under aggressive conditions. This leads to accelerated wear on cam bearings and other moving parts.

Drivers who attempted to treat the LA1 V6 like a performance motor often faced costly repairs far earlier than expected. Its design philosophy was focused on efficiency and low-cost production, not sustained high-speed operation. While it could handle occasional bursts to higher RPM for overtaking, pushing it hard repeatedly was a quick way to shorten its life.

4. Ford 5.4-litre Triton V8 (2-valve)

The Ford 5.4-litre Triton V8 in its 2-valve configuration, used widely in trucks like the F-150 and Expedition in the late 1990s and early 2000s, was built for towing and hauling rather than racing or high-rev performance. It produces strong torque at low RPM, but when revved aggressively, it shows several weaknesses.

One of the most common issues with this engine is its valvetrain design. The 2-valve Triton uses cam followers and lash adjusters that can wear prematurely under high-speed operation. Prolonged high RPM can cause valve float, reducing performance and increasing the risk of mechanical damage.

Another concern is the oiling system. While it works well for steady, low-to-mid range operation, it is not optimised for rapid oil delivery at high crankshaft speeds. Under aggressive driving, the oil pump may struggle to maintain consistent pressure, leading to accelerated bearing wear.

The long stroke of the 5.4 also means higher piston speeds at any given RPM compared to shorter-stroke engines. This generates more heat and stress, which can quickly wear out rings, bearings, and connecting rod bolts if the engine is pushed too hard for too long.

Cooling can also be a problem during extended high-rev use, especially when the engine is under heavy load. Overheating in such conditions can cause head gasket problems, warped heads, or cracked blocks.

In real-world use, the 2-valve Triton performs best when kept within its designed powerband. Owners who use it for its intended purpose low RPM, high torque work, often enjoy long service life. Those who try to drive it like a performance V8 quickly find that it is not built to handle constant high-rev stress without modifications.

Also Read: 5 Engines with Oversized Radiators vs 5 with Stock Radiators That Boil

5. Mitsubishi 4G64 SOHC

The Mitsubishi 4G64 single overhead cam 2.4-litre engine, found in models like the Mitsubishi Galant, Eclipse, and some trucks, is another example of a motor built for torque and efficiency rather than high-revving performance. While it can provide dependable service in normal use, pushing it hard toward the redline exposes several weaknesses.

The SOHC version of the 4G64 uses a relatively simple valvetrain design. While this helps keep maintenance straightforward, it also means it is more prone to valve float at higher RPM compared to engines with stronger springs or multi-valve setups. When valves cannot keep up with the camshaft at high speeds, performance drops, and engine damage becomes possible.

The rotating assembly is not optimised for high piston speeds. The 4G64 has a relatively long stroke, which increases piston travel distance and speed at higher RPM. This leads to greater stress on connecting rods and crank bearings, making sustained high-speed operation risky.

Oil flow can also become an issue. The pump and passages in this engine were designed for moderate use. During long periods of high RPM driving, oil pressure can drop, especially if the engine is not in perfect condition. This can result in bearing wear, camshaft damage, or even catastrophic failure.

Cooling is another limiting factor. The 4G64’s cooling system is adequate for daily driving but may struggle to keep temperatures in check when the engine is pushed hard for extended periods. Overheating increases the risk of warped heads and blown gaskets.

While enthusiasts have built high-performance versions of the 4G64, these typically involve serious internal upgrades, stronger valve springs, improved oiling, and better cooling. In its stock form, the SOHC 4G64 is best treated as a reliable workhorse for everyday use rather than a high-revving performance engine.