In regions where winter roads are treated with heavy salt, vehicle owners face a constant battle against corrosion. This challenge is especially serious for those living in the Salt Belt, a term used for areas in the United States where road salt is heavily applied to melt ice during snowy months.

The salt may keep roads safer for drivers, but it comes with a hidden price: it accelerates the process of rusting in metal parts. While most car owners immediately think of body panels and undercarriage components as the main victims, the truth is that some engines also suffer greatly from long-term exposure to road salt and moisture. The constant contact with saltwater mist and spray from the road can lead to corrosion inside and outside of the engine.

This means that two cars driving in the same conditions can have very different lifespans depending on what type of engine is under the hood. Certain engines have been designed with materials and coatings that resist corrosion more effectively, while others have design weaknesses that trap moisture and allow rust to develop.

Even the smallest amount of internal rust can affect oil circulation, cooling passages, and vital components like pistons and valves, eventually leading to reduced performance or complete engine failure.

For drivers in states like Michigan, New York, Pennsylvania, and Ohio, as well as other areas with heavy snowfall, knowing which engines are better suited to handle these conditions can make a significant difference. Choosing an engine that can withstand the Salt Belt environment will save thousands in repairs and replacements.

However, ending up with an engine prone to internal rust could lead to costly breakdowns. Our list features five engines that are known to survive long-term exposure in the Salt Belt and five that have earned a reputation for rust problems when faced with these same conditions.

Engines That Survive the Salt Belt

1. Toyota 2UZ-FE

The Toyota 2UZ-FE V8 engine is well known for its durability and ability to withstand tough environmental conditions, making it a trusted option for drivers in regions where road salt is common.

This engine, which powered vehicles like the Toyota Land Cruiser, Sequoia, and certain Lexus SUVs, was designed with heavy-duty construction and long-lasting materials. Its iron block is one of the reasons it holds up so well, as cast iron is naturally resistant to corrosion when compared to lighter alloys.

The design of the 2UZ-FE also helps keep salt and moisture from causing internal damage. The block and heads are sealed tightly, and the cooling system is efficient in preventing the buildup of corrosive residue. Toyota engineers also incorporated high-quality gaskets and strong internal components that do not wear out quickly, reducing the chances of leaks that could introduce salt-laden water into sensitive areas.

Another reason the 2UZ-FE performs well in the Salt Belt is the quality of its manufacturing process. Toyota used precise machining and coatings on many parts to extend their life in wet and salty environments. Even vehicles that have been driven for more than 15 years in snowy climates often show minimal engine rust when equipped with this V8.

Maintenance plays a role, too. The 2UZ-FE responds well to regular oil changes and cooling system flushes, which further prevent internal corrosion. Its forgiving nature means that even if owners are not overly meticulous with upkeep, the engine still holds up better than many others in similar conditions.

For drivers who want a long-lasting powertrain in an area with severe winters, this engine remains one of the safest choices. It is proof that strong design, quality materials, and solid engineering can make a difference in resisting the damaging effects of road salt.

2. Honda J35 V6

Honda’s J35 V6 engine, used in models such as the Honda Pilot, Odyssey, Ridgeline, and Acura MDX, has earned a strong reputation for reliability in regions where winter road salt is a constant threat. Built with an aluminum block and heads, this engine might seem more vulnerable to corrosion than iron-block engines, but Honda’s design and manufacturing approach give it an advantage.

One of the reasons the J35 survives well in the Salt Belt is its tight sealing and precise gasket placement. These prevent salt-contaminated moisture from entering areas where it can cause damage.

The cooling passages are designed to keep coolant flowing efficiently, which reduces the risk of localized corrosion. The J35 also uses stainless steel components in certain areas, further reducing the effects of rust.

Honda’s attention to manufacturing tolerances means that even small details, such as bolt placements and drainage pathways, are optimized to prevent water accumulation. Many other aluminum-block engines suffer from pitting and corrosion in cold-weather climates, but the J35 has shown an ability to resist these problems for well over 200,000 miles when properly maintained.

Owners in salt-heavy states often report that while the underbody of their vehicles may show rust, the engine remains clean and functional. Regular coolant changes, timely oil changes, and ensuring that the radiator and heater core stay free from leaks help this engine last even longer. Its track record shows that an aluminum engine can still be a great choice for the Salt Belt if it is designed with corrosion prevention in mind.

Also Read: 5 V8 Engines That Refuse to Quit and 5 That Self-Destruct

3. Ford 300 Inline-Six

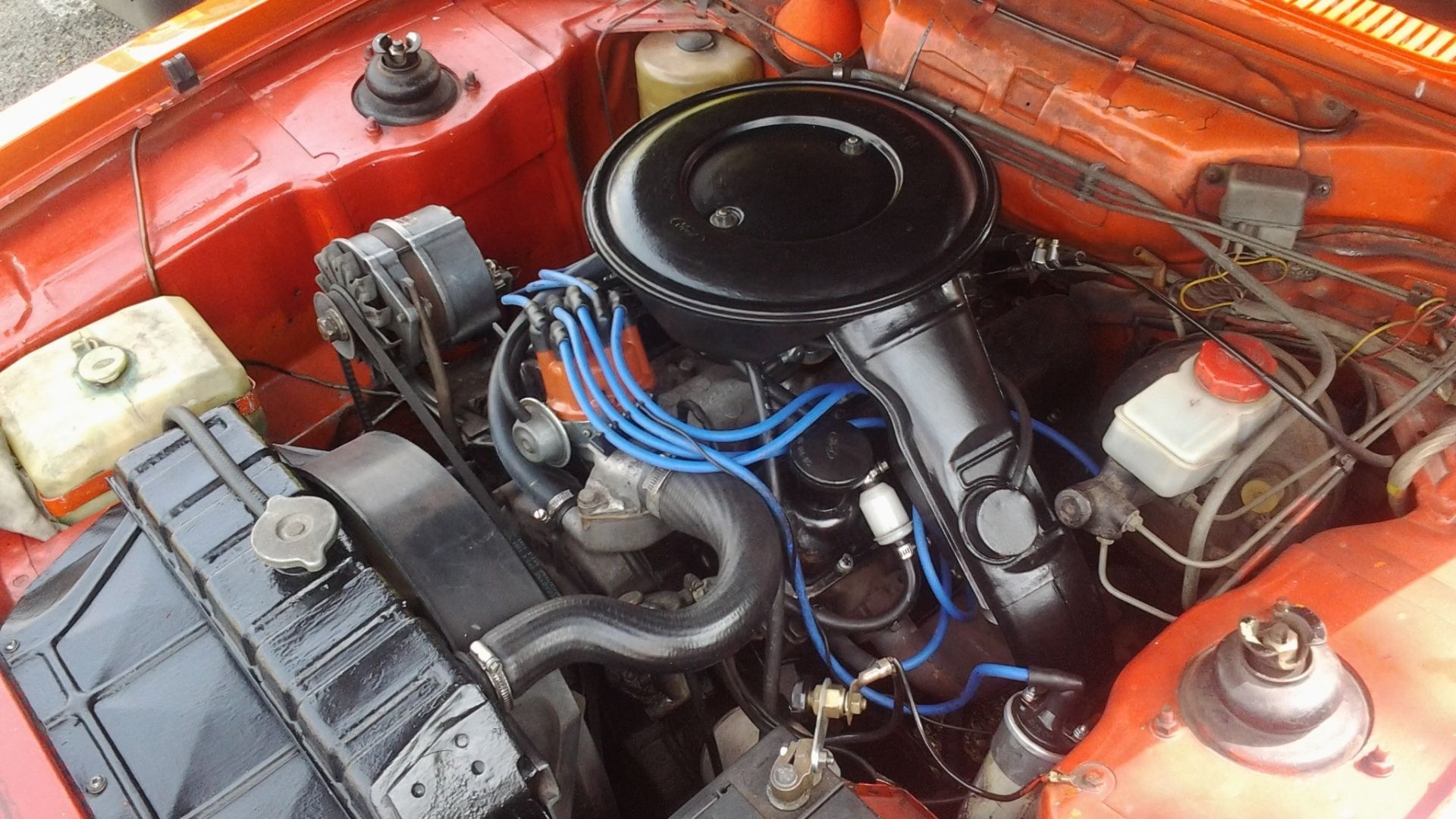

The Ford 300 cubic inch inline-six is one of the most respected, long-lasting truck engines in American automotive history. Produced for decades and used in many Ford trucks, this engine is known for its simplicity and strength. Its cast iron block and head construction make it particularly resistant to the effects of salt and moisture, allowing it to endure many winters without internal rust becoming a problem.

The 300 inline-six was designed with durability in mind, not high performance. Its relatively low compression ratio and robust internal components mean that it runs cooler and has fewer hotspots where corrosion might start. The block design also minimizes areas where water can collect, making it less prone to freeze damage in cold climates.

Owners in the Salt Belt have long trusted the Ford 300 for daily use in snow and ice conditions. Many of these engines have seen over 300,000 miles of service with only basic maintenance. Even when trucks around them are plagued with body rust, the engines often continue to operate with minimal issues. This resilience is part of the reason the Ford 300 became a favorite among commercial users who needed reliable performance in harsh conditions.

Regular oil and coolant service is still essential, but the engine’s tolerance for less-than-perfect care makes it a good match for tough winter use. Its heavy-duty construction, combined with a simple and serviceable design, ensures that it remains one of the engines least affected by Salt Belt driving.

4. Chevrolet 5.3L Vortec V8

The 5.3L Vortec V8 from General Motors has been a common sight in trucks and SUVs for years, and it has earned a strong reputation for standing up to tough winter conditions in salt-heavy regions. Used in Chevrolet Silverado, Tahoe, Suburban, GMC Sierra, and Yukon, this engine blends durability with efficiency in a way that suits the Salt Belt perfectly.

One of the main reasons this engine lasts so well in corrosive environments is its balance of materials. While it uses an aluminum cylinder head in many versions, the block is often cast iron, which resists rust far better than aluminum in certain conditions. The combination provides both strength and heat management without sacrificing longevity.

GM designed the Vortec with internal oil and coolant passages that minimize stagnant areas where corrosion could develop. The cooling system operates efficiently, reducing temperature fluctuations that could lead to condensation inside the engine. This design is important for winter driving, where cold starts and rapid temperature changes can cause moisture buildup internally.

The Vortec 5.3 is also less prone to developing coolant leaks that could introduce salt-contaminated moisture into sensitive areas. Its gaskets are robust, and its sealing surfaces are machined with high precision. When combined with regular maintenance, such as timely oil and coolant changes, the engine can survive decades of harsh winters without internal corrosion becoming a serious issue.

Owners in Michigan, Wisconsin, and New York often report that while the chassis may rust, the Vortec engine itself stays in excellent condition. This makes it a preferred choice for buyers looking for a reliable workhorse in snowy climates. Its track record over millions of vehicles has proven that the Vortec 5.3 is more than capable of surviving long-term exposure to the Salt Belt.

5. Subaru EJ25

Subaru’s EJ25 2.5-litre flat-four engine has powered many of the brand’s vehicles, from the Outback and Forester to the Legacy and Impreza. Subaru is a popular choice in snow-prone states because of its standard all-wheel-drive system, but the EJ25 also stands out for its ability to handle salty winter conditions with minimal internal rust issues.

The engine’s horizontally opposed layout allows for a low center of gravity, but it also has benefits for corrosion resistance. Its design promotes even heat distribution, which reduces condensation inside the engine during cold starts. In addition, Subaru uses high-quality aluminum alloy for the block and heads, combined with stainless steel and coated internal parts, to resist corrosion.

Another factor in the EJ25’s longevity in the Salt Belt is its cooling system design. The radiator, water pump, and thermostat work together to maintain consistent operating temperatures even in freezing weather. This helps prevent coolant stagnation and corrosion within the engine’s passages.

Subaru also applies protective coatings to certain components to reduce the effects of exposure to road spray and salt. When maintained with regular coolant changes and proper oil service, the EJ25 can exceed 200,000 miles without internal rust problems, even when driven year-round in salty conditions.

Owners who live in Vermont, Maine, and upstate New York often keep their Subarus for many years, with the engine still running strong despite visible rust on body panels. This combination of reliability, winter performance, and corrosion resistance is why the EJ25 remains a dependable choice for those living in the Salt Belt.

Engines that Have Struggled in Salt Belt Conditions

1. Chrysler 2.7L V6

The Chrysler 2.7-litre V6 engine, used in vehicles like the Dodge Intrepid, Chrysler Sebring, and Dodge Stratus, has gained a poor reputation for long-term durability, particularly in the Salt Belt. While some of its issues are related to oil sludge buildup, corrosion has also been a problem for many owners.

One of the weaknesses of the 2.7 is its internal design, which tends to trap heat and moisture in certain areas. This makes it easier for condensation to form, especially in cold weather when the engine is frequently warming up from low temperatures. When combined with the salty, moist air of winter driving, this creates ideal conditions for internal rust to develop.

Another issue is the placement of its water pump inside the engine block, driven by the timing chain. If the pump begins to leak, coolant can mix with the oil, accelerating both corrosion and wear on internal components. In a Salt Belt environment, where small leaks can allow salt-contaminated water into the system, this becomes a bigger problem.

The materials used in some versions of 2.7 also contribute to its vulnerability. While aluminum blocks and heads can resist rust to a point, they are more prone to pitting corrosion when exposed to contaminated moisture. If the cooling system is not maintained perfectly, the damage can be permanent.

Many owners have reported premature engine failures well before 150,000 miles, especially in states with heavy road salt use. Those who avoid these problems usually follow extremely strict maintenance schedules, including frequent oil changes and regular cooling system flushes. Unfortunately, even with good care, the engine’s inherent design flaws make it a risky choice for long-term use in salty climates.

For Salt Belt drivers, the Chrysler 2.7 serves as a reminder that engine design, material selection, and cooling system layout all play a major role in how well an engine resists corrosion.

2. Ford 3.8L Essex V6

Ford’s 3.8-litre Essex V6 engine, found in vehicles like the Ford Windstar, Mustang, and Taurus during the 1990s and early 2000s, has a history of problems in regions with heavy road salt use. While it was praised at launch for its torque and smooth performance, long-term durability in the Salt Belt has been questionable, especially when it comes to corrosion and head gasket failures.

One of the biggest challenges with this engine in salty climates is its head gasket design. The gasket material and sealing surfaces tend to deteriorate faster when exposed to coolant contaminated by road salt moisture. Once the gasket begins to leak, coolant can enter the combustion chamber or oil passages, causing rust to form on cylinder walls, piston rings, and internal bearings.

The block and heads are made of cast iron, which is generally good at resisting rust compared to aluminum, but this advantage is offset by design flaws that allow trapped moisture to remain in certain areas. In winter driving, condensation inside the crankcase is common, and when that mixes with small traces of salt from road spray, it speeds up corrosion.

Another factor is that the 3.8 Essex often suffered from coolant leaks around the intake manifold gaskets. This problem, combined with the head gasket vulnerability, made it easier for coolant to mix with oil and start damaging internal parts. In the Salt Belt, where small leaks are more likely to carry corrosive contaminants, the damage happens faster.

Many owners have reported needing complete engine rebuilds or replacements before 150,000 miles, with corrosion playing a major role. Preventing this requires frequent oil changes, coolant flushes, and immediate attention to any leaks. However, even with diligent care, the Essex 3.8 remains one of the less reliable choices for long-term use in heavily salted regions.

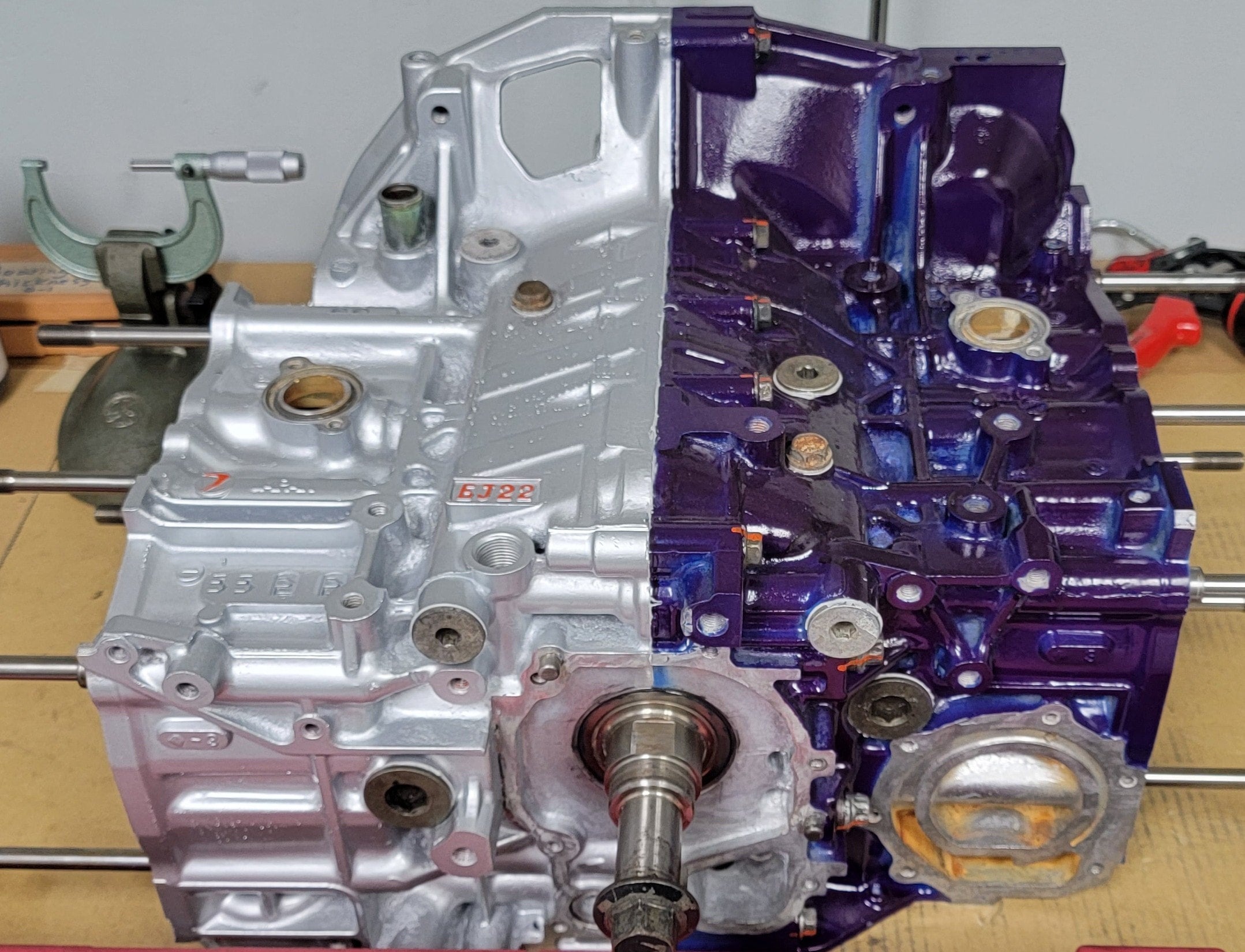

3. Subaru EJ22 (Certain Versions)

While Subaru has produced some engines that survive the Salt Belt well, certain versions of the EJ22 flat-four, especially in older models from the 1990s, were more vulnerable to internal corrosion when used in these conditions. This is not to be confused with the later, more robust EJ25.

The EJ22’s aluminum block and heads offered weight savings, but the alloy used in earlier years was more susceptible to pitting when exposed to contaminated coolant. In areas with road salt, even small cooling system leaks could introduce moisture-carrying salt particles into the engine’s passages. In due course, this caused internal rusting in components like water jackets and oil galleries.

Another concern was the cooling system’s limited capacity in early EJ22 models. During harsh winters, frequent cold starts combined with rapid heating could cause condensation inside the engine. This condensation is sometimes mixed with road spray entering through compromised seals or breathers, which accelerates corrosion.

The boxer engine layout itself did not cause the rust, but the horizontal position of the cylinders meant that any moisture left in the system could sit against cylinder walls for longer periods. This increased the risk of pitting in the bore surfaces, eventually leading to reduced compression and oil burning.

Subaru later improved materials and sealing in their engines, but owners of older EJ22-equipped vehicles in the Salt Belt often had to deal with internal corrosion, especially if maintenance was neglected. Regular coolant changes, using corrosion inhibitors, and promptly fixing leaks were the only ways to extend its life in such regions.

4. General Motors 2.4L Ecotec

The GM 2.4-litre Ecotec engine, used in many Chevrolet, Pontiac, and Saturn models during the 2000s, delivered decent performance and fuel economy, but long-term survival in Salt Belt regions has been less than ideal. Its aluminum block and head construction, while lightweight, is not naturally resistant to certain types of corrosion that occur when road salt is present.

One of the main issues is that the Ecotec’s coolant passages can suffer from corrosion if the coolant is not changed regularly. In salty environments, small leaks or degraded coolant can allow corrosive residue to attack the aluminum surfaces inside the engine. This can lead to overheating, pitting, and reduced flow through the cooling system.

Another problem is the design of its water pump and thermostat housing. If either begins to leak, even slightly, the resulting coolant loss can create hot spots that trap moisture and accelerate rusting in critical areas. In winter, with frequent thaw-freeze cycles, this problem becomes worse.

The Ecotec is also known for timing chain tensioner issues. If corrosion affects the oil supply passages that feed the chain, lubrication can suffer, leading to rapid wear. This is not directly a rust problem, but it is often linked to moisture contamination in the oil caused by winter driving in salted areas.

Many Salt Belt owners have found that unless they follow strict maintenance schedules, including more frequent coolant changes than recommended, the Ecotec can develop corrosion problems before 150,000 miles. While it can last longer with perfect care, its sensitivity to salt-related damage makes it less suitable for drivers who cannot keep up with preventative maintenance.

Also Read: 5 Turbo Engines That Stay Reliable and 5 That Always Break

5. Mazda 2.3L DISI Turbo

The 2.3-litre Direct Injection Spark Ignition (DISI) turbo engine from Mazda, found in the Mazdaspeed3, Mazdaspeed6, and certain CX-7 models, offered exciting performance, but it has not proven to be a long-term survivor in Salt Belt conditions. This engine’s combination of direct injection, turbocharging, and lightweight aluminum construction creates multiple corrosion risks in salty climates.

Direct injection systems are more prone to carbon buildup, which can trap moisture in the intake valves and combustion chamber. In cold, wet environments, this moisture often contains traces of road salt that can accelerate corrosion on valve surfaces and cylinder walls.

The aluminum block and head are not inherently weak, but the cooling system design in the DISI turbo leaves little margin for error. If coolant maintenance is neglected, the internal passages can develop corrosion that reduces heat transfer, which in turn increases engine stress.

Another common issue is the turbocharger’s oil and coolant lines. In Salt Belt driving, these lines are constantly exposed to road spray, which can corrode fittings and lead to small leaks. If that salt-contaminated coolant or oil finds its way back into the engine, it can cause pitting in vital areas.

Owners who keep these engines in good shape often do so by exceeding factory maintenance intervals, flushing the cooling system more often, and protecting exposed fittings from salt exposure. Even so, the Mazda 2.3 DISI turbo remains one of the engines most at risk of internal corrosion in long-term Salt Belt use.