Engines are the beating hearts of vehicles, and their longevity can vary widely based on design, materials, and how they are maintained. While some engines can serve drivers faithfully for decades without major repairs, others begin to show serious wear surprisingly early. The difference is often found in engineering quality, the way components are matched, and whether the manufacturer prioritized durability or cost savings during production.

A well-built engine is like a trusted companion on long journeys. It can keep running with consistent performance for hundreds of thousands of miles, provided it is given the right care. Such engines are built with robust materials, precise tolerances, and designs that allow them to handle stress without developing major faults.

Few engines are made with weaker components or suffer from engineering flaws that make early rebuilds almost inevitable. These engines may perform well at first, but hidden weaknesses begin to show much sooner than drivers expect.

Drivers and car buyers often want to know which engines have earned a reputation for lasting a lifetime and which ones struggle to make it past 60,000 miles before requiring serious work. Making an informed choice can save both money and frustration. It can also determine whether a vehicle becomes a long-term asset or a short-term headache.

We will look at five engines that have proven their strength and can serve for many years without needing a rebuild. We will also review five engines that are known for developing serious problems early, sometimes needing major work before reaching the 60,000-mile mark.

Each engine will be examined in detail, focusing on why it lasts or fails, the engineering behind it, and what owners can expect after some time.

Engines That Can Serve a Lifetime Without a Rebuild

1. Toyota 22R/22RE

The Toyota 22R and 22RE engines have earned a respected place among mechanics and drivers for their remarkable durability. Produced from the late 1970s through the mid-1990s, these engines powered vehicles like the Toyota Hilux, pickup trucks, and the 4Runner. The 22R was carbureted, while the 22RE came with fuel injection, but both shared the same basic architecture.

One major reason for their long life is their simple design. The engines are four-cylinder units with a cast iron block and an aluminium cylinder head, offering a balanced combination of strength and heat dissipation.

The robust construction allows them to endure high mileage without developing serious internal wear. The timing chain system, when maintained properly, is also long-lasting and less prone to catastrophic failure compared to timing belts in other engines.

Another factor that contributes to the 22R/22RE’s reputation is how forgiving they are to maintenance lapses. While neglecting oil changes or running low on coolant is never advisable, these engines can sometimes survive conditions that would destroy more delicate designs. Their relatively low compression ratio helps reduce stress on internal components, and the conservative power output means the parts are never pushed to their limit.

Owners who maintain them well often report surpassing 300,000 miles without a rebuild. Even in commercial or off-road use, the engines hold up under demanding conditions. Parts availability is still strong, and many aftermarket suppliers produce high-quality replacements, making them economical to repair if minor issues occur.

These engines also have a wide knowledge base among mechanics, which means repairs and adjustments can be handled easily. While modern engines may be more powerful or efficient, few can match the 22R/22RE’s ability to keep running decade after decade. For anyone looking for an engine that can serve faithfully for a lifetime, it remains an outstanding choice.

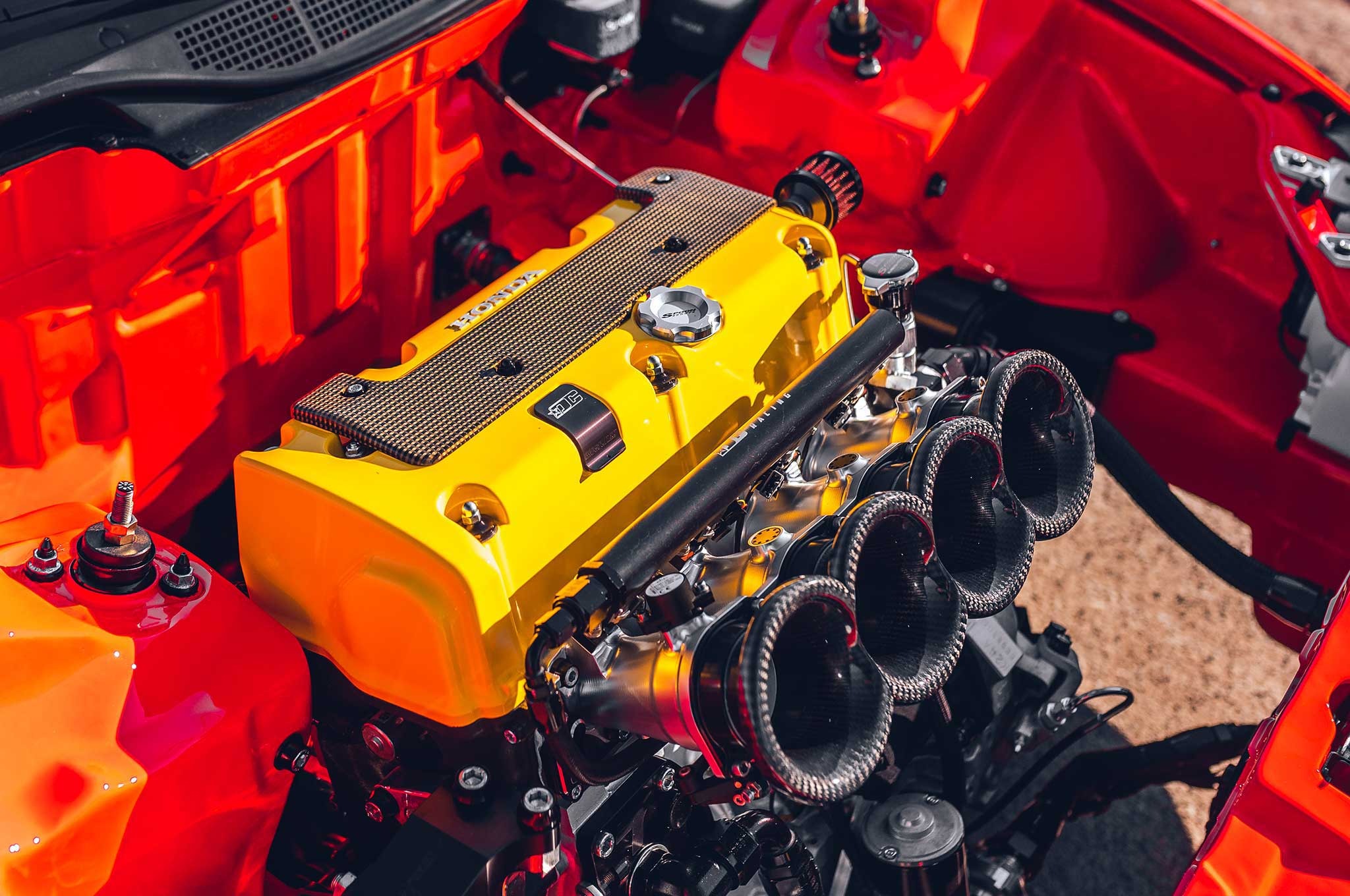

2. Honda K-Series (K20/K24)

Honda’s K-Series engines, especially the K20 and K24 variants, have built a solid reputation for reliability, longevity, and performance. Introduced in the early 2000s, these engines have been used in models like the Honda Civic Si, Accord, CR-V, and Acura TSX. They combine modern engineering with Honda’s proven quality control, resulting in an engine that can run for hundreds of thousands of miles without major work.

The K-Series engines feature aluminium blocks and heads, with forged steel crankshafts in certain versions. This mix of lightweight materials and strong internals ensures both efficiency and strength. One of their most valued characteristics is the i-VTEC variable valve timing system, which allows the engine to balance fuel economy with performance, while still maintaining durability.

High-quality components such as the timing chain system, oil pump, and valvetrain are designed for extended service life. These engines also manage heat effectively, reducing the risk of overheating and the damage it can cause. Regular oil changes with the correct grade of oil keep the internal parts well-lubricated, allowing for smoother operation even at high mileage.

Many K-Series owners report surpassing 250,000 to 300,000 miles without any major repairs. Even when driven hard, the engines often show minimal wear. Their ability to handle aftermarket modifications without drastically reducing reliability has made them favourites among car enthusiasts as well.

The simplicity of routine maintenance, combined with excellent parts availability, means these engines can be kept in service for decades. They offer a blend of modern efficiency and old-school Honda toughness, making them an outstanding choice for drivers who want both reliability and performance in the same package.

Also Read: 5 Engines With Legendary Lifespans and 5 That Barely Make It

3. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 diesel engine stands as one of the most enduring powerplants ever built by the brand. Produced from the mid-1970s to the mid-1980s, it was found in models like the 240D, 300D, and 300SD. Known for its five-cylinder layout and indirect fuel injection system, the OM617 was designed with longevity as its primary goal.

This engine features a cast iron block and head, making it extremely resistant to wear and heat distortion. The robust bottom end can withstand sustained high loads without developing bearing damage, and the crankshaft design allows smooth operation even after hundreds of thousands of miles. Its low power output is relative to displacement reduces internal stress, which helps extend its operational life.

A major reason the OM617 is so reliable lies in its simplicity. It uses mechanical fuel injection, which does not rely on electronics that can fail after some time. While it may not offer the fuel economy or emissions performance of modern diesels, it can run in harsh conditions that would stop other engines. Owners in different climates have reported these engines starting and running even in extreme cold or heat.

Routine maintenance, such as regular oil and filter changes, is important, but the engine is remarkably forgiving if intervals are occasionally stretched. With proper care, it is not unusual to see these engines last 500,000 miles or more without a rebuild. Many are still in service decades after leaving the factory.

Parts availability remains good due to the engine’s popularity and the fact that it shares many components with other Mercedes types of diesel models of the era. The OM617’s slow but steady performance, combined with its incredible resilience, has made it a favourite among those who value longevity above all else. It is an example of how overengineering can result in an engine that seems almost impossible to wear out.

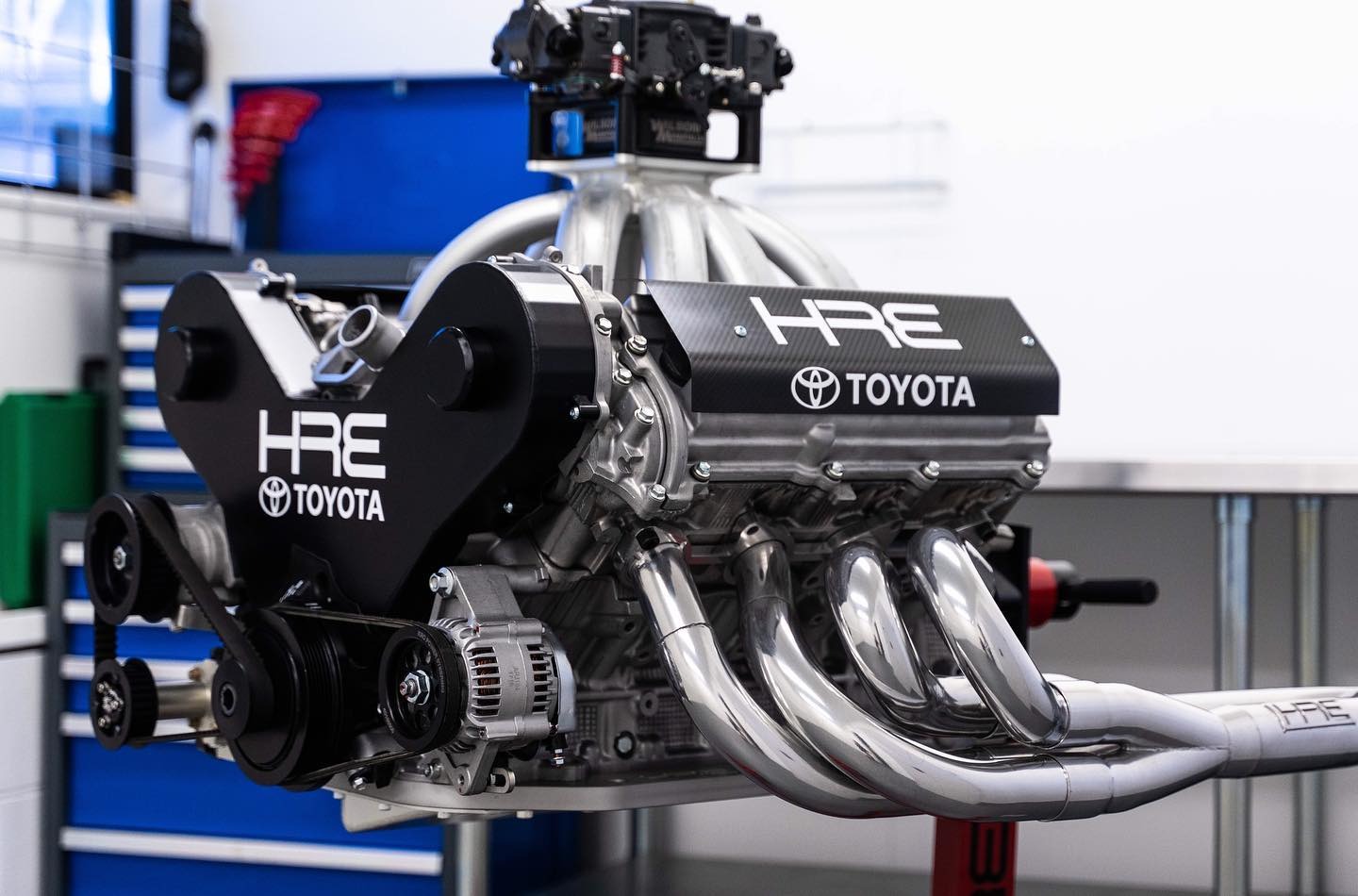

4. Toyota 1UZ-FE V8

The Toyota 1UZ-FE V8 was introduced in 1989, initially powering the Lexus LS400 luxury sedan. It was a bold move by Toyota to challenge established European luxury brands, and they invested heavily in engineering to ensure it would impress both in performance and durability. The 1UZ-FE has since become known as one of the most dependable V8 engines ever made.

It uses an aluminum block with cast iron cylinder liners, coupled with aluminum heads and dual overhead camshafts. This combination offers strength with reduced weight, allowing for smooth and balanced operation. The engine’s forged steel crankshaft and high-quality connecting rods provide excellent resistance to wear, even under heavy use.

Precision manufacturing is a major reason for its longevity. The 1UZ-FE was built with tight tolerances and subjected to rigorous quality control. Its timing belt system, when changed at the recommended intervals, ensures consistent performance without valve damage. The cooling system is also robust, preventing overheating that could lead to engine failure.

Owners often report these engines surpassing 400,000 miles without a rebuild, provided they are maintained with high-quality fluids and filters. Even when neglected, the 1UZ-FE can continue running without major issues, although fuel efficiency and smoothness may decline.

Its adaptability has made it popular for engine swaps into sports cars, off-road vehicles, and even boats. Despite being designed for luxury vehicles, it can handle demanding conditions without complaint. Parts are still widely available, and the large community of enthusiasts ensures support for repairs and modifications.

The 1UZ-FE’s blend of refined performance, bulletproof construction, and extended service life proves that a V8 can be both powerful and incredibly durable. For anyone seeking a lifetime engine, it remains an outstanding candidate.

5. Chevrolet Small-Block V8 (Gen I)

Chevrolet’s first-generation small-block V8, produced from 1955 until 2003 in various forms, is one of the most enduring and widely used engines in automotive history. It powered everything from family sedans to high-performance sports cars and trucks, earning a reputation for reliability and ease of maintenance.

The engine’s cast-iron block and heads give it excellent strength, while its straightforward pushrod design keeps moving parts to a minimum. Fewer parts mean fewer potential points of failure, and the design has proven capable of withstanding high mileage without wear. Many small-blocks have crossed the 300,000-mile mark without ever being rebuilt.

Another reason for its durability is its simplicity in maintenance. Oil changes, timing adjustments, and component replacements are easy to perform, making it accessible for both professional mechanics and home repair enthusiasts. The vast aftermarket support ensures that replacement parts are readily available at affordable prices.

These engines also tolerate a wide range of operating conditions. Whether used in a daily commuter, a work truck, or a race car, the small-block has shown an ability to keep running reliably with minimal fuss. Its ability to handle modifications without sacrificing much reliability is another reason it has been so beloved.

Even decades after production began, the small-block V8 remains a benchmark for a long-lasting gasoline engine. It is a testament to the idea that careful engineering and a straightforward design can produce a power plant that serves for a lifetime.

Engines That May Need a Rebuild by 60,000 Miles

1. Subaru EJ25

The Subaru EJ25 engine, used in models like the Outback, Forester, and Legacy, has gained attention for its performance and all-wheel-drive compatibility. However, it also has a history of developing problems relatively early in its life, with many owners facing major repairs before reaching 60,000 miles.

One of the most common issues is head gasket failure. The EJ25’s design places stress on the head gaskets due to the horizontally opposed cylinder arrangement and the way heat is managed. Coolant leaks and oil seepage can result, leading to overheating and engine damage if not addressed quickly.

Another issue is piston ring wear, which can lead to excessive oil consumption. This problem can become severe enough to cause low compression and loss of power long before the expected lifespan of the engine. While some engines avoid these problems with meticulous maintenance, many do not.

Repairing these issues can be expensive, often requiring the engine to be removed from the vehicle. This leads some owners to opt for a full rebuild or replacement rather than attempting piecemeal repairs. The combination of high labour costs and recurring problems has given the EJ25 a reputation for shorter-than-average longevity.

While the engine can perform well when new, its tendency to develop serious issues relatively early makes it a risky choice for those seeking a vehicle they can keep for many years without major work.

2. BMW N54 Twin-Turbo Inline-Six

The BMW N54 engine, produced from 2006 to 2016, is known for its impressive power and smooth delivery. Found in models like the 335i, 135i, and early versions of the 740i, it uses twin turbochargers to deliver strong acceleration. While praised for performance, the N54 has developed a reputation for costly repairs well before many drivers expect them.

One major concern is the high-pressure fuel pump (HPFP) failures, which can occur with less than 60,000 miles on the odometer. Symptoms include long cranking times, loss of power, and engine stalling. BMW issued extended warranties for these pumps, but many owners still experienced failures outside of warranty coverage.

Another issue is turbocharger wastegate rattle, which is not just an annoyance but also a sign of worn components that may require expensive replacement. The turbo system is under high stress, and after some time, the components can degrade faster than those in naturally aspirated engines.

Carbon buildup on the intake valves is another problem linked to the N54’s direct fuel injection system. Since fuel does not wash over the valves, deposits can accumulate quickly, leading to rough idling, reduced performance, and poor fuel economy. Walnut blasting or other cleaning methods are often required long before 100,000 miles.

While enthusiasts appreciate the tuning potential of the N54, those modifications can accelerate wear on already stressed components. For drivers seeking long-term reliability without frequent repairs, this engine can be an expensive choice. Its design offers thrilling performance, but the maintenance demands and high cost of parts mean it often needs major work far earlier than more conservatively engineered engines.

3. Chrysler 2.7L V6

The Chrysler 2.7L V6 engine, used in models like the Dodge Intrepid, Chrysler Sebring, and Dodge Stratus during the late 1990s and 2000s, has become known for premature failures that can occur well before reaching 60,000 miles. While it delivered decent performance and fuel economy for its time, its design introduced weaknesses that often led to costly repairs.

One of the most common problems is oil sludge buildup. The narrow oil passages and high operating temperatures of the 2.7L make it prone to sludge formation, especially if oil changes are not performed on schedule with high-quality oil. Once sludge begins to develop, it can restrict lubrication to critical components, leading to bearing damage and eventual engine seizure.

The water pump design is another weak point. Positioned inside the engine, a leaking water pump can allow coolant to mix with engine oil, causing severe damage. This failure can happen suddenly and often without early warning signs, making it a serious risk for owners.

Timing chain tensioner issues have also been reported, and when the tensioner fails, it can cause the chain to jump teeth, resulting in valve and piston contact. Such an event almost always requires a full rebuild or replacement.

Even with meticulous maintenance, the Chrysler 2.7L V6 has a higher-than-average rate of early failures compared to similar engines from other manufacturers. While some examples have lasted longer, the odds are not in the owner’s favor, making it a risky engine for anyone seeking dependable service over many years.

4. Ford 6.0L Power Stroke Diesel

The Ford 6.0L Power Stroke diesel engine, used in F-Series Super Duty trucks from 2003 to 2007, promised high towing capacity and modern features. Unfortunately, it became one of the most controversial diesel engines Ford has ever produced, with many owners facing serious repairs well before 60,000 miles.

One major issue involves the EGR (Exhaust Gas Recirculation) cooler, which is prone to clogging or cracking. When the EGR cooler fails, it can lead to coolant loss, white exhaust smoke, and eventually head gasket failure. The head bolts used in the 6.0L are another weak point, as they can stretch under high pressure, allowing the head gaskets to leak.

The turbocharger variable vane mechanism is also vulnerable to sticking due to soot buildup, leading to poor acceleration and reduced power. Additionally, the high-pressure oil system, which powers the fuel injectors, is complicated and sensitive to leaks, causing hard starts or no-start conditions.

While aftermarket solutions exist to address many of these weaknesses, such as upgraded head studs, EGR deletes, and improved oil coolers, these fixes are expensive. For owners who cannot afford these upgrades, the likelihood of facing a major failure early in the engine’s life remains high.

Despite its strong towing capabilities when in good condition, the Ford 6.0L Power Stroke’s combination of design flaws and costly repairs has given it a lasting reputation for being unreliable in stock form.

Also Read: 5 Affordable Engines That Survive Neglect and 5 That Don’t

5. Mini Cooper 1.6L (Prince Engine)

The 1.6L “Prince” engine, developed jointly by BMW and PSA Peugeot Citroën, powered many Mini Cooper models from 2006 onward. While it offered peppy performance and good fuel economy, it is well known for needing expensive repairs long before reaching 60,000 miles.

Timing chain tensioner problems are among the most common issues. A failing tensioner can cause a rattling noise at startup and, if ignored, can lead to the chain skipping teeth and causing severe internal damage. In some cases, complete engine replacement has been necessary.

Oil consumption is another recurring complaint. The engine’s piston rings can wear prematurely, leading to low compression and the need for a rebuild. High oil usage can also damage the catalytic converter and other exhaust components.

Carbon buildup on intake valves, similar to what happens in BMW’s N54, can cause misfires, reduced performance, and rough idling. Cleaning the valves is a labor-intensive process that often becomes necessary before the engine has seen extensive mileage.

The turbocharged versions of this engine face additional stress, with turbocharger failures occurring more often than in better-engineered rivals. Repair costs are high, and parts availability can be an issue in some markets.

While the Mini Cooper offers a fun driving experience, the reality is that its 1.6L Prince engine requires careful attention and frequent maintenance to avoid early failure. Many owners have found that even with good care, the engine may still require work well before its competitors would.

Engines that can serve a lifetime without a rebuild are the product of careful engineering, strong materials, and designs that prioritize durability. Examples like the Toyota 22R/22RE, Honda K-Series, Mercedes OM617, Toyota 1UZ-FE, and Chevrolet’s first-generation small-block V8 have shown that with proper care, a powerplant can last for decades.

On the other side, engines like the Subaru EJ25, BMW N54, Chrysler 2.7L V6, Ford 6.0L Power Stroke, and Mini’s 1.6L Prince demonstrate how design flaws, material weaknesses, or maintenance sensitivities can shorten an engine’s life dramatically.

For anyone buying a vehicle, knowing these histories can help in choosing a model that will deliver many years of reliable service instead of one that demands costly attention early in its life.