Engines are the heartbeat of any vehicle, and how well they endure stress often determines the reputation of the brand that produces them. Car buyers across different regions pay close attention to how engines behave under long use, heavy driving conditions, and the pressure of carrying weight or speeding on highways.

Some engines build a record of toughness, lasting for hundreds of thousands of miles without losing efficiency, while others struggle when subjected to heavy driving or intense work.

The distinction between engines that keep performing and those that fail when placed under demand is one of the factors that guide purchasing choices for many people.

Different manufacturers have approached engine building with varying philosophies. Some emphasise strength and long-lasting parts, while others prioritise speed, lightweight design, or cutting-edge features, even if that comes at the expense of long-term reliability.

Drivers know that an engine may look powerful on paper, but it is only when tested on busy roads, long-distance travel, or heavy towing that its actual endurance is revealed. This is why many enthusiasts and technicians separate vehicles with trusted powerplants from those that quickly wear out.

Engines that stay strong under load often share certain qualities. They tend to have simple yet effective engineering, durable internal components, and cooling systems that keep them safe from overheating.

Engines that collapse under strain usually have weaknesses in design, or they rely on advanced features that fail once pressure builds up. We will look at five engines that have built a name for strength and five that often disappoint once pushed to their limits.

5 Engines That Stay Strong

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE has been celebrated for decades as an engine that can withstand high levels of demand. Produced in the 1990s and early 2000s, this inline-six turbocharged engine gained recognition both in stock form and in tuned setups.

Many owners have pushed it to produce double or even triple its factory horsepower without sacrificing its ability to continue running smoothly.

One of the factors that helps the 2JZ-GTE maintain such a reputation is the robust construction of its internal parts. The iron block is extremely strong and capable of handling stress far beyond what most daily drivers will ever require.

Pistons, rods, and crankshaft components were designed to take punishment without giving in quickly, which is why this engine became the choice for tuners who wanted extreme performance. Beyond tuning, even when left in its original state, it can run well for hundreds of thousands of miles if maintained properly.

The cooling system of the 2JZ-GTE is another reason it performs under pressure. Engines that overheat tend to lose strength, but Toyota engineers built a design that keeps temperatures stable even when the car is running hard. This makes it not just a legend in racing communities but also a reliable partner for regular driving.

Its reputation goes beyond technical figures. Owners who rely on it daily confirm that the engine rarely breaks down, and even when problems occur, parts are easy to source and repairs are straightforward.

This combination of durability, performance, and reliability ensures the 2JZ-GTE is remembered as one of the strongest engines that can handle heavy stress without collapsing.

2. Honda K20

The Honda K20 engine, introduced in the early 2000s, stands as another example of an engine that does not give way when placed under strain.

Known for its high-revving nature and reliability, the K20 has been fitted in several popular Honda models, including the Civic Type R and Integra. Its design allows it to maintain efficiency while also delivering strong performance.

At the heart of its reliability is a well-balanced engineering approach. The aluminium block is designed with rigidity in mind, and the internal parts are made to withstand high RPM levels.

While many engines struggle when pushed to their limits, the K20 thrives in conditions where the driver keeps revs high. Honda engineers created a strong valvetrain and an efficient oiling system, which prevents failures that normally affect other engines under heavy loads.

Another factor is how adaptable the engine is. Tuners often take the K20 and push it beyond its standard performance figures, yet it continues to deliver without developing constant breakdowns. This adaptability shows that its core engineering was done with strength in mind.

For ordinary users who simply want a reliable daily driver, the same qualities make the K20 dependable even after years of regular use. Owners often highlight that the K20 is easy to maintain and less prone to overheating compared to many rivals.

Its ability to stay strong, whether used for daily driving, track events, or long-distance trips, demonstrates why it is remembered among engines that do not collapse under load.

The balance between performance and durability keeps the K20 as a trusted option in the minds of car enthusiasts and everyday drivers alike.

Also Read: 5 Engines That Handle High RPMs and 5 That Break When Revved

3. Cummins 6BT

Diesel engines are usually valued for their toughness, and the Cummins 6BT stands as a clear example of a powerplant that can take heavy punishment. Introduced in trucks and industrial machines, this 5.9-liter inline-six diesel is widely regarded as one of the most dependable engines ever made. Its design focuses less on speed and more on strength, which is why it became a favourite in heavy-duty work.

The cast-iron block and cylinder head provide unmatched durability. Many drivers report that the 6BT can cross half a million miles without requiring major internal repairs if maintained properly. Unlike engines that wear down under constant strain, the 6BT can pull weight, handle rough terrain, and remain stable during long working hours.

One of the biggest advantages is its mechanical simplicity. The 6BT does not rely on complicated electronic systems that can fail under stress.

Instead, its mechanical fuel injection system ensures reliable performance, even in environments where advanced electronics might break down. For industries such as farming, construction, and trucking, this simplicity made it invaluable.

Fuel efficiency under heavy load is another quality that sets it apart. The engine manages to provide strong pulling power without burning excessive amounts of fuel, making it both dependable and economical.

Owners also appreciate that parts are widely available, and repair costs are reasonable, which extends their life further.

Because of these strengths, the Cummins 6BT is often described as a machine that simply refuses to quit. While many modern engines collapse under heavy stress, this diesel continues working long after others fail, making it one of the most respected names among strong engines.

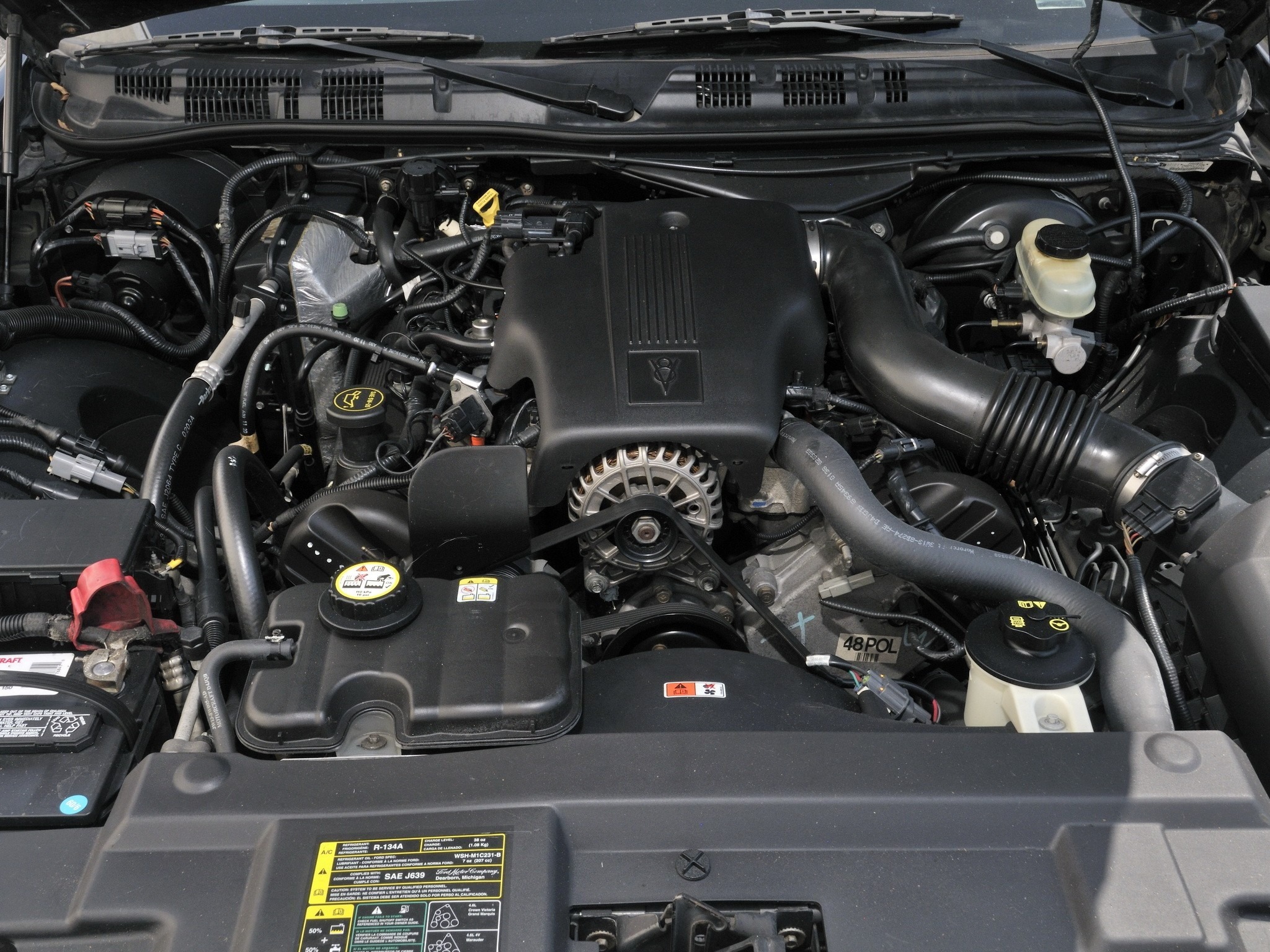

4. Ford Modular 4.6L V8

Ford introduced the Modular 4.6L V8 in the early 1990s, and it quickly became known as a dependable engine across various models.

Found in vehicles such as the Ford Mustang, F-150, and Crown Victoria, it proved to be versatile and resilient under different driving conditions. Its longevity helped build a strong reputation, especially among drivers who required consistent power delivery.

The engine’s durability is tied to its balanced construction. With an aluminium or cast-iron block, depending on the version, it offers both strength and flexibility.

The modular design allows it to be used in several vehicles, but what remains constant is its ability to perform under heavy strain. Taxi drivers, police fleets, and ordinary families all found it trustworthy for long service life.

The 4.6L V8 was not the most powerful engine of its time, but its reliability more than made up for that. Drivers regularly achieved high mileage without major breakdowns.

Its ability to run smoothly under long-distance driving and heavy workloads was clear evidence of strong engineering. Many engines with more advanced designs broke down faster, but this V8 kept running.

Its wide availability of parts also plays a role in its continued relevance. Maintenance costs are manageable, and mechanics across different regions are familiar with its workings. This ensures that even when issues occur, they are easily fixed without extended downtime.

For an engine that served across sports cars, trucks, and utility vehicles, the Modular 4.6L V8 shows that consistent performance is sometimes more valuable than peak power. Its legacy as an engine that stays strong under pressure remains intact decades after its first introduction.

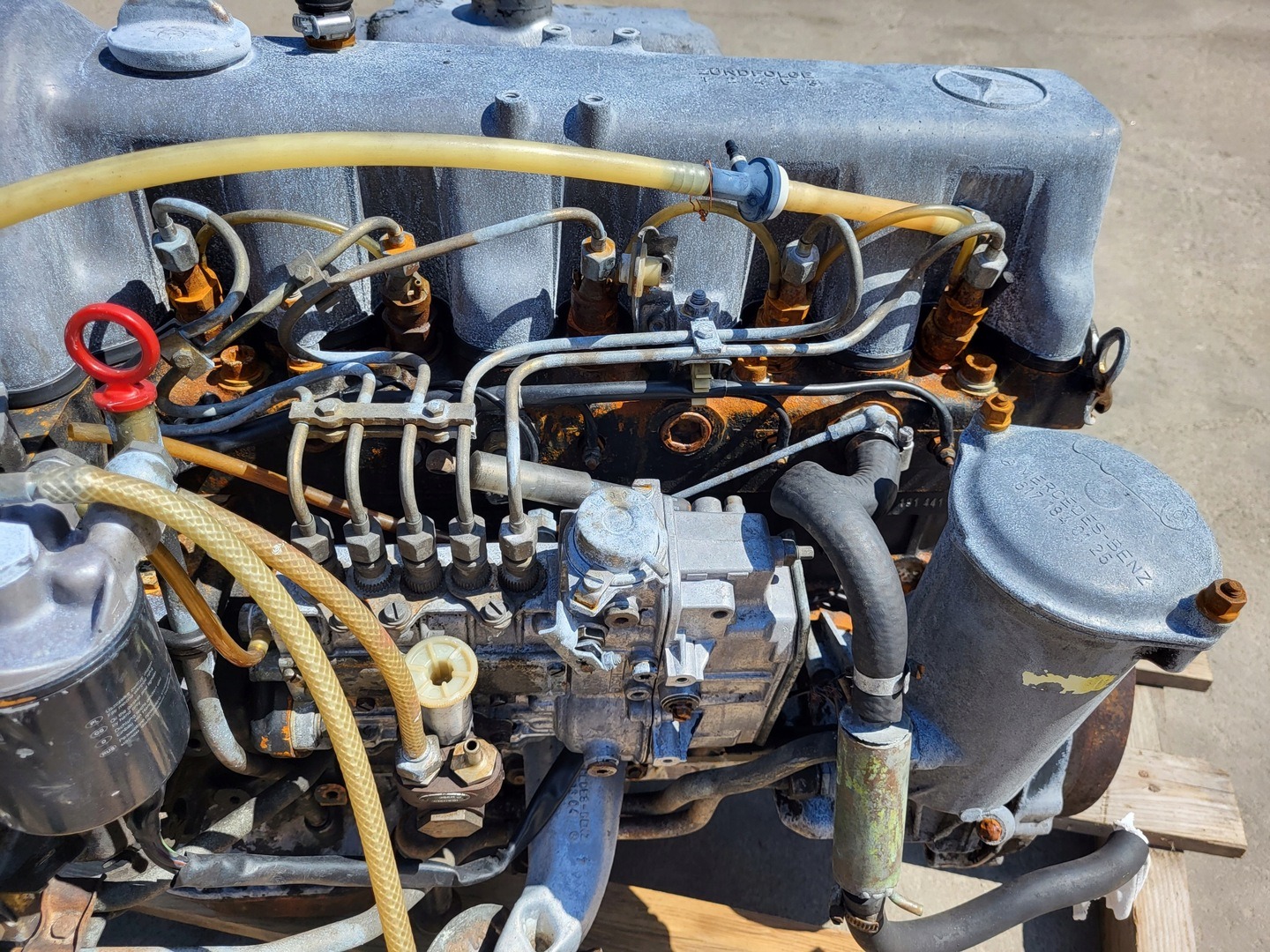

5. Mercedes-Benz OM617

The Mercedes-Benz OM617 diesel engine is widely respected for its ability to keep running under harsh conditions. Produced from the 1970s through the 1980s, this inline-five diesel became one of the most durable engines ever built by the brand. Many vehicles equipped with it still operate today, decades after leaving the factory.

Part of its strength lies in the cast-iron block and head design, which was built to withstand high stress. This makes it less prone to cracks or warping even under extreme conditions. The mechanical fuel injection system adds another layer of dependability, since it functions effectively without reliance on sensitive electronics.

Owners often share stories of their OM617-powered vehicles covering several hundred thousand miles without major overhauls.

For many, it became a symbol of durability because it could handle poor fuel quality, long-distance journeys, and heavy use without breaking down. Even when performance is not as strong as modern engines, its staying power compensates for any lack of speed.

Maintenance is also straightforward, with parts available and repair methods well-known among mechanics. This simplicity ensures that vehicles with OM617 engines can continue serving for decades.

The engine’s ability to endure long-term use with minimal problems made it extremely valuable for both personal cars and commercial use.

This combination of durability, simplicity, and endurance explains why the Mercedes OM617 stands as one of the strongest engines that never gives way easily under load.

5 Engines That Collapse Under Load

1. Chrysler 2.7L V6

The Chrysler 2.7L V6 engine was introduced in the late 1990s with promises of strong performance in a compact design.

However, its history among car owners tells a different story, as it gained a reputation for breaking down when subjected to heavy use. While it looked efficient on paper, its durability often fell short once real-life driving placed it under stress.

One of the biggest issues with the 2.7L V6 lies in its oiling system. The narrow passages often led to sludge buildup, which restricted lubrication to important internal parts. Without sufficient lubrication, friction and heat would increase, causing wear that quickly reduces the life of the engine.

Drivers who maintained strict oil change schedules sometimes managed to delay problems; however, once sludge started forming, failures became common. Another challenge was the cooling system.

The design did not handle heat effectively, and when an engine cannot stay within safe temperature levels, breakdowns are unavoidable, overheating damaged gaskets and warped internal surfaces, which meant expensive repairs or complete replacement.

Engines that are unable to maintain consistent cooling tend to fail under heavy driving conditions, and this is exactly what happened with the Chrysler 2.7L.

The placement of the water pump inside the engine block added more risk. When the water pump failed, coolant would leak into the oil system, contaminating it and creating more sludge.

This combination of poor design choices made the 2.7L V6 one of the least trusted powerplants for anyone who needed a reliable vehicle.

Owners often complained that even normal highway driving could trigger issues, and once repairs started, the costs usually added up quickly. Engines that collapse under load usually show weaknesses in either strength or design, and in the case of the Chrysler 2.7L V6, it was a mixture of both.

While some engines are remembered for lasting hundreds of thousands of miles, this one is remembered for failing too early, especially when pushed beyond light use.

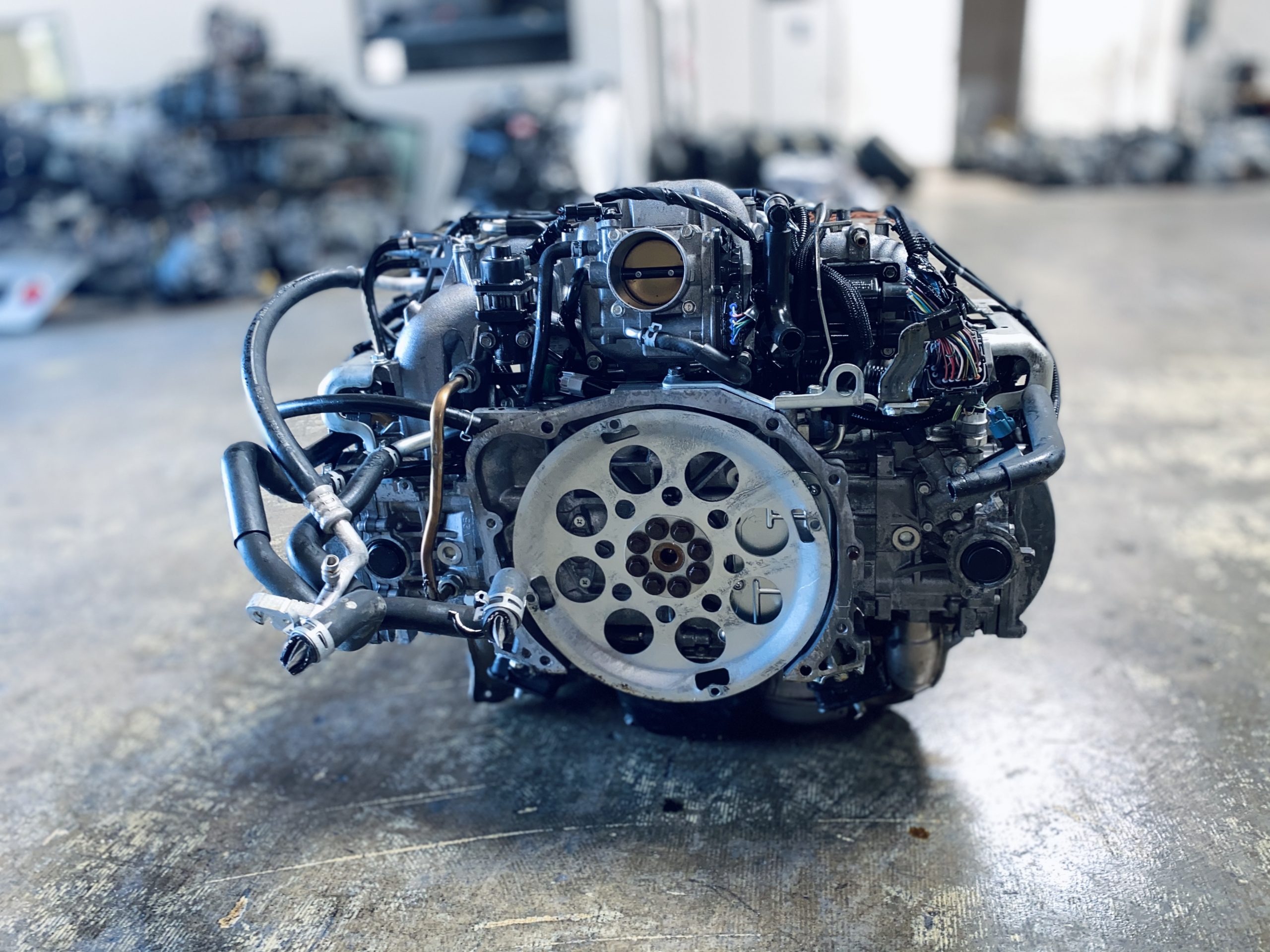

2. Subaru EJ25

The Subaru EJ25 engine has been fitted in several well-loved Subaru models, from the Impreza to the Forester. At first, it looked like a reliable flat-four engine that could handle both daily driving and off-road use. However, with time, weaknesses in its design became obvious, especially when it was pushed hard.

Many owners discovered that what seemed like a dependable engine often collapsed under the pressure of long-term use.

The most common issue tied to the EJ25 is its recurring head gasket failure. The design of the gasket and the cooling passages made it highly prone to leaks. Once coolant and oil began mixing, engine health dropped rapidly.

For drivers who placed extra load on their vehicles by towing, off-roading, or driving long distances, these gasket failures happened earlier and more frequently. Repairs were expensive, and in many cases, the problem returned even after replacement.

Another weakness was the tendency to overheat. Because the EJ25 has a flat-four layout, the cooling system must work harder to maintain even temperatures across all cylinders. When the system struggled, overheating damaged internal parts, which made the engine less capable of handling stress. While some engines can keep running even after years of heat exposure, the EJ25 often reached a breaking point faster.

Oil consumption also became a worry. Many owners reported that the engine burned oil excessively, and once oil levels dropped, internal damage followed. Engines that rely heavily on drivers constantly checking and topping up fluids often collapse under heavier loads since they are less forgiving when neglected even slightly.

While Subaru has strong loyalty from many drivers, the EJ25 reminds us that popularity does not always equal reliability. An engine that regularly suffers from gasket leaks, overheating, and oil problems cannot stay strong when subjected to heavy pressure. That is why the EJ25 sits among engines that often disappoint once demands increase.

3. Cadillac Northstar V8

When Cadillac introduced the Northstar V8 in the 1990s, it was advertised as a technological leap that would bring smooth performance and high output to luxury cars.

On paper, it delivered power and refinement, but once tested under extended pressure, weaknesses started to appear. Instead of becoming a benchmark for strength, it gained a reputation for being fragile when pushed.

The biggest problem with the Northstar was its recurring head gasket failure. The aluminium block and heads expanded at different rates when heated, which often caused the gaskets to fail.

Once coolant began leaking into combustion chambers or oil passages, the engine’s reliability collapsed. Repairing this issue was not only expensive but also time-consuming, making ownership difficult for many people.

Another weakness was the tendency for oil leaks. Engines that leak oil consistently lose lubrication and are more likely to suffer major internal failures. In the case of the Northstar, the leaks were common and difficult to permanently fix. Owners who drove under heavy loads or at high speeds often discovered that their engines developed these issues faster.

The cooling system also added to the troubles. For an engine designed to power luxury sedans, overheating should not have been a common problem, yet it was. Drivers found that under heavy driving or in hot climates, the Northstar could not always manage temperatures effectively, which worsened gasket problems and reduced the life of the engine.

What made matters worse was the high cost of repairs. Since the engine was not simple in design, fixing even minor issues required labour and money. While some drivers enjoyed smooth performance when the Northstar was working well, many experienced major breakdowns once stress levels increased.

This shows that even engines marketed for premium cars can collapse under load if their engineering does not support long-term durability. The Cadillac Northstar became a lesson in how power and technology cannot replace strong foundational design.

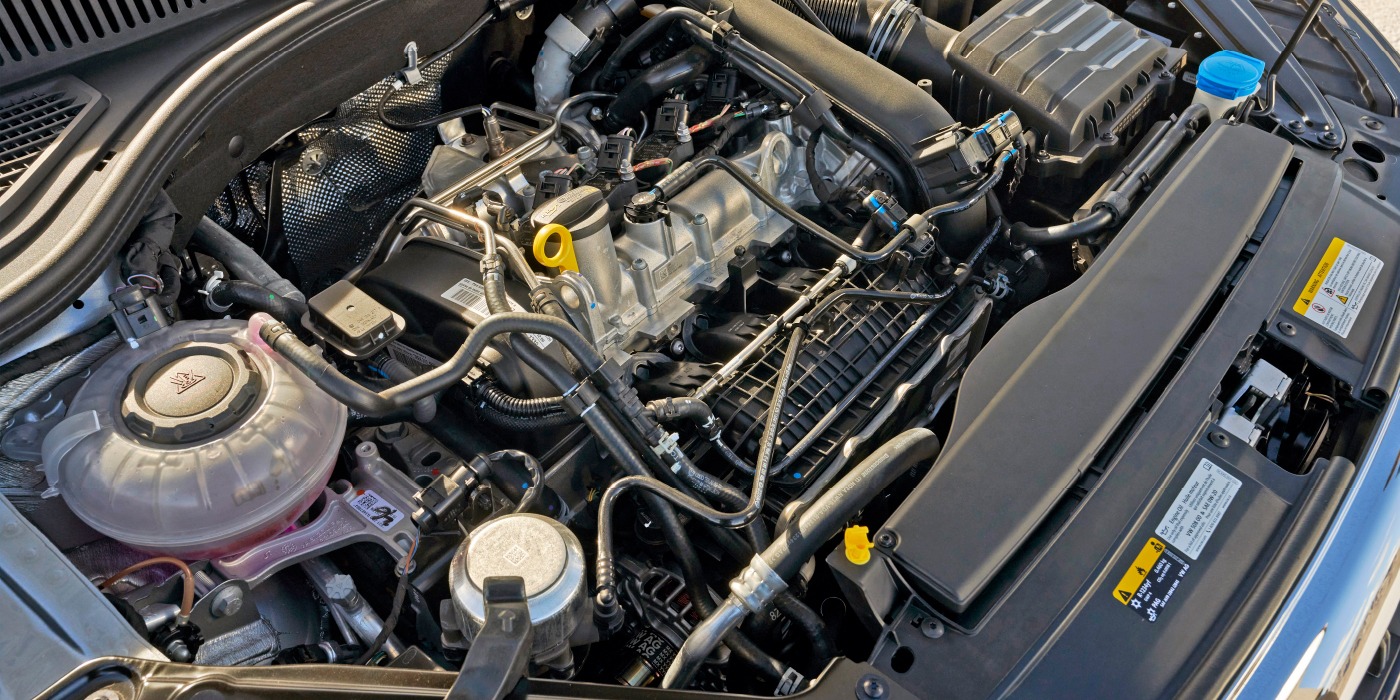

4. Volkswagen 1.4 TSI

Volkswagen’s 1.4 TSI engine was developed to balance fuel efficiency with performance through turbocharging. While it delivered smooth acceleration and good numbers for its size, its long-term reliability suffered when placed under heavy driving conditions.

Many drivers discovered that this small turbocharged unit was unable to handle stress as effectively as larger, naturally aspirated engines.

A major weakness came from the timing chain system. Stretching chains and tensioner failures became a common complaint. When timing issues appear in an engine, it quickly leads to severe damage, and under load, these problems emerge even faster. For a power plant designed to perform well under turbo boost, timing failures limited its reliability.

The turbocharger itself was another weak point. Turbos operate under high heat and pressure, and in the 1.4 TSI, failures were not rare.

Once the turbo failed, the engine lost performance and often required expensive repairs. Drivers who regularly pushed their cars with spirited driving or highway speeds found these issues surfacing earlier than expected.

Oil consumption also reduced its dependability. Like some other modern small turbo engines, the 1.4 TSI burned oil faster than normal, which meant that drivers needed to monitor levels constantly.

If neglected even slightly, damage to pistons and cylinders followed. For engines that collapse under load, high oil consumption is usually a consistent theme, since stress increases wear on already fragile parts.

While the engine provided efficiency and performance when new, its ability to stay strong over long use was limited. Owners who expected it to handle heavy loads, long-distance travel, or years of hard driving were often disappointed. This made the Volkswagen 1.4 TSI a clear example of an engine that promises more than it can sustain.

Also Read: 5 Engines With Legendary Lifespans and 5 That Barely Make It

5. BMW N63 V8

BMW’s N63 twin-turbo V8 engine, introduced in 2008, was designed to provide high performance in luxury vehicles. It delivered strong acceleration and smoothness, but its durability came into question once owners started experiencing repeated failures under pressure. While it was technologically advanced, it struggled to survive heavy use.

One of the main problems was excessive heat. The hot-vee turbo placement, where the turbos sit inside the V of the engine, created intense temperatures that affected surrounding parts.

High heat damaged seals, gaskets, and electronics, leading to frequent failures. Engines that cannot control heat usually collapse quickly under stress, and this was true for the N63.

Another issue was oil consumption. Many owners reported that their engines burned oil at alarming rates. Once oil levels dropped, lubrication suffered, and internal damage followed. Drivers who pushed their cars at high speeds or used them for long journeys discovered that topping up oil became a constant need.

The timing chain system also faced durability problems. Stretching chains meant that reliability decreased with time, and under heavy loads, failure was more likely. Combined with the heat problems and oil consumption, the N63 became an expensive engine to keep alive.

BMW attempted several technical service campaigns to address the issues, but the reputation was already damaged.

Luxury buyers expect engines that remain strong even under demanding conditions, but the N63 showed the opposite. Its collapse under load was not only mechanical but also financial, as owners faced high repair costs.

This engine remains an example of how advanced engineering does not always translate to lasting durability. While it produced impressive power, its weaknesses under heavy stress made it one of the most criticised modern luxury engines.