When people purchase vehicles, one of the first things on their mind is how long the engine can keep running without constant breakdowns. The motor is the beating heart of any car, and its strength determines whether the ride will endure difficult usage or fail when pushed too hard.

Many car owners, especially those who depend on their vehicles daily, want engines that can go through heavy mileage, poor roads, harsh weather, and even neglect, yet still deliver reliable service. Others have found themselves with cars that perform well when new but begin to show weakness once real stress comes.

Different car manufacturers have produced engines that gained respect for standing firm under pressure. These are the motors that can be driven roughly, taken through long highway trips, or even used in harsh environments without constant visits to the mechanic.

At the same time, some engines might appear advanced but disappoint when put under strain. They either wear out fast, develop repeated mechanical issues, or require expensive parts that frustrate owners.

Knowing which engines can withstand abuse and which ones cannot helps people make informed decisions when buying a vehicle, especially when long-term durability is a priority. Motors that survive stress usually combine simple design, quality materials, and proven reliability.

Those that do not last often struggle with poor engineering choices, excessive complication, or weak components. In this article, we shall look at five engines that have built reputations for being tough survivors and five that often give up too quickly when stress becomes too much.

5 Motors That Survive Abuse

1. Toyota 2JZ-GTE

When people discuss durable engines, the Toyota 2JZ-GTE always comes up as one of the best examples. Produced during the 1990s, it gained worldwide respect because of its strong construction and ability to handle serious abuse. It was originally fitted in the Toyota Supra, a sports car that became an icon. What sets this engine apart is the way it was built to tolerate high stress without failing easily.

The 2JZ-GTE has a cast-iron block, which is far stronger than aluminum blocks found in many modern engines. That solid foundation means it can handle high temperatures and pressure for long periods.

Tuners around the world discovered that this engine could deliver far more power than Toyota originally intended. With proper modifications, it can produce more than 1,000 horsepower and still remain reliable. Many motors break down quickly when power levels are pushed too high, but the 2JZ-GTE thrives under such conditions.

Another reason the 2JZ-GTE is considered nearly indestructible is its design simplicity. Toyota did not try to make it unnecessarily complicated. The twin-turbo setup provides both efficiency and performance without overloading the engine with fragile parts.

Its fuel system and cooling system are also built in a way that allows it to run smoothly even when pushed for long distances. Mechanics appreciate it because parts are accessible and easier to service compared to many modern motors.

Owners who drove this engine hard often report that it can withstand repeated redline runs, aggressive driving, and long hours of use without showing major damage. Even after hundreds of thousands of miles, the motor continues to perform.

For many car enthusiasts, it is a perfect example of how strong engineering can produce an engine that outlives expectations. Toyota built the 2JZ-GTE with durability in mind, and that is why it is still respected today as one of the toughest motors ever produced.

2. Honda K20

Honda’s K20 engine has earned its place among motors that survive stress because of its ability to handle high revolutions without giving up. Introduced in the early 2000s, this engine powered several Honda models, including the Civic Type R and the Integra. It quickly gained popularity because of its blend of performance, efficiency, and durability.

One major strength of the K20 is its high-revving nature. While many engines struggle when pushed close to their redline, the K20 was built to thrive there. It can comfortably spin to over 8,000 RPM without showing signs of weakness.

This makes it a favourite among drivers who enjoy spirited driving. The engine’s design includes a strong aluminum block, forged crankshaft, and Honda’s reliable VTEC system that adjusts valve timing for both power and efficiency.

Even when subjected to hard driving on race tracks, the K20 proves itself capable of lasting long. Honda engineered it with quality internal components that can resist wear under stress. Many owners have taken the K20 past 200,000 miles with little more than routine maintenance. Its ability to balance daily usability with motorsport-level stress is what makes it stand out.

Tuners also respect the K20 because it responds well to modifications. Whether turbocharged or supercharged, it can handle added power without quickly breaking down. This flexibility makes it one of the most trusted motors among performance car enthusiasts. At the same time, its fuel economy in normal driving is respectable, which adds to its appeal.

Drivers who abuse the K20 often share stories of the motor refusing to give up even after years of hard treatment. Whether used for commuting or racing, it maintains its strength. That balance of high performance and long-term resilience shows why it belongs on the list of motors that survive abuse.

Also Read: 5 Cars That Rarely Need Warranty Claims and 5 That Max Them Out

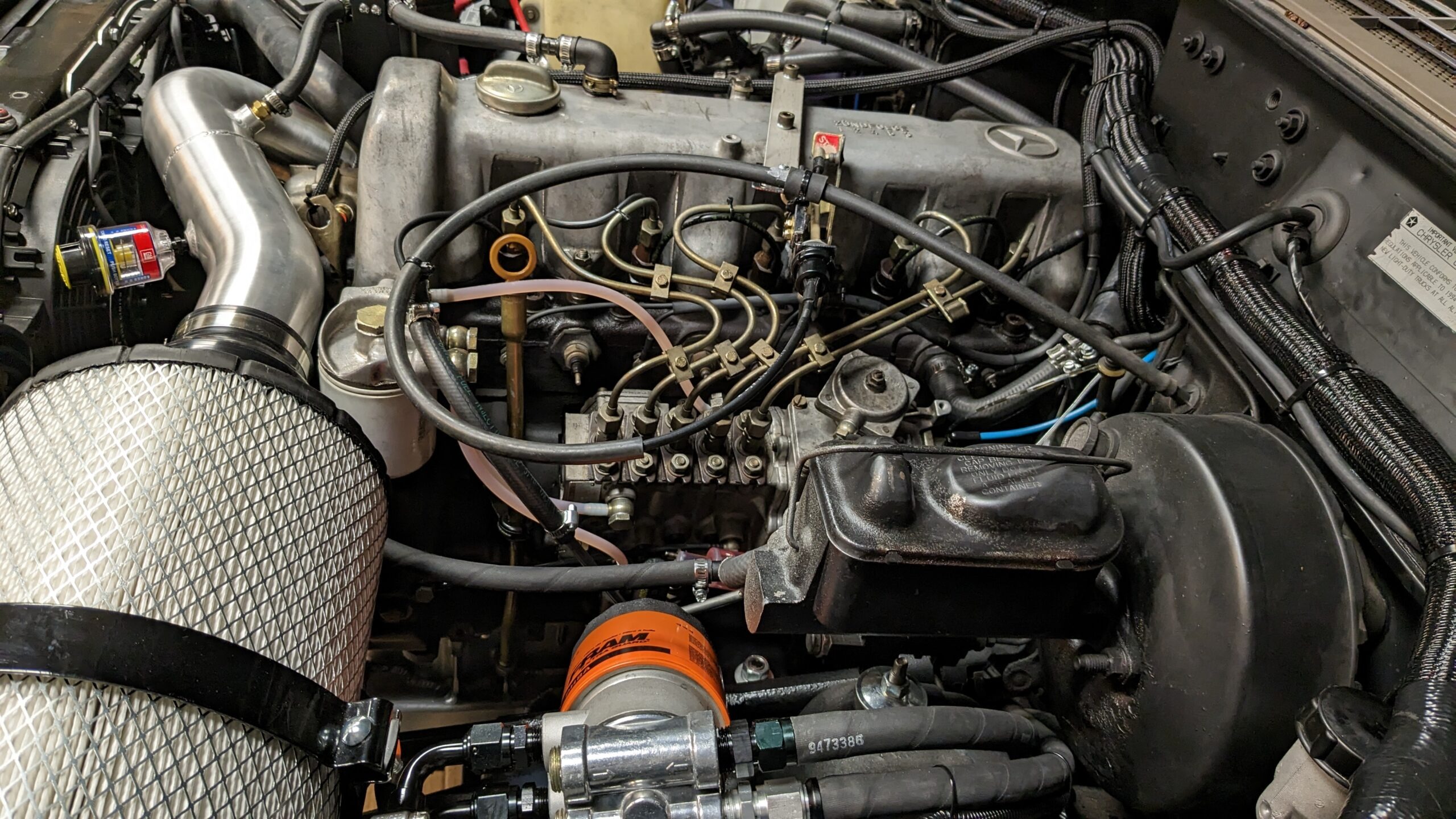

3. Mercedes-Benz OM617

Among diesel engines, the Mercedes-Benz OM617 is often mentioned as a true survivor. Produced from the 1970s into the 1980s, this motor was fitted in models like the 240D and 300D. While not a high-performance engine, its reputation for being extremely tough and long-lasting makes it one of the most dependable engines ever created.

The OM617 was designed with durability as the top priority. It has a cast-iron block and head, making it nearly indestructible. Owners have pushed these engines to cover over 500,000 miles without major repairs.

Many examples are still running today, decades after leaving the factory. The motor is slow compared to modern standards, but its strength lies in the fact that it can endure constant abuse, poor maintenance, and even contaminated fuel while still functioning.

Because it is a diesel engine, it was made to deliver strong torque at low RPM. This means it does not need to be revved hard to perform its duties. That helps it last longer under stress.

Its mechanical fuel injection system is also very simple and less prone to failure compared to electronic systems that came later. Owners in regions with poor fuel quality especially loved the OM617 because it could run even on less refined diesel without breaking down.

Another reason it is considered almost unbreakable is the ease of maintenance. Many parts are accessible and can be serviced without expensive tools. Mechanics praise it for being straightforward and reliable. While it may not deliver speed or excitement, it delivers peace of mind, which is something many drivers value more than performance.

The OM617 remains a legend because it shows how strong engineering focused on durability can produce an engine that outlasts generations of vehicles. It is slow but dependable, making it one of the toughest motors to survive stress.

4. Ford 300 Inline-Six

For decades, Ford’s 300 cubic inch inline-six engine has been known as one of the most durable American engines ever built. First introduced in the 1960s, it powered a wide range of Ford trucks and vans. It gained respect because of its ability to take abuse and continue running without serious problems.

The Ford 300 was built with simplicity in mind. It had a cast-iron block and head, with very few complicated systems that could fail. Its long-stroke design gave it excellent low-end torque, making it perfect for hauling heavy loads. Many owners used it in work trucks that were constantly pushed to their limits, yet the engine would still run strong after decades.

One of its strengths is that it can run under poor maintenance conditions. Even when oil changes were skipped or coolant systems were neglected, the Ford 300 often kept going. Stories exist of these engines running even when abused daily on farms, construction sites, and delivery routes. Some owners claim they clocked more than 400,000 miles without rebuilding the engine.

Another reason the Ford 300 is loved is its repair-friendly nature. The design is straightforward, so mechanics can work on it without stress. Parts are also widely available, which keeps repair costs low. This made it a favourite among businesses that needed reliable vehicles with minimal downtime.

Although it is not a high-performance motor, its strength lies in endurance. The Ford 300 is the type of engine that can be pushed hard for years and still provide dependable service. It remains one of America’s most trusted engines because it was designed to prioritize toughness above all else.

5. Chevrolet Small Block V8

When discussing motors that can withstand abuse, it is impossible to ignore the Chevrolet Small Block V8. First introduced in 1955, it became one of the most produced and widely used engines in history. Its success lies in its ability to handle stress while delivering both performance and dependability.

The Small Block V8 was designed with a strong cast iron block and a simple pushrod valvetrain. This made it durable and easy to maintain. Its compact size also made it flexible enough to fit into different vehicles, from family sedans to muscle cars and pickup trucks. The motor earned respect because it could run for years under heavy use without failing.

Hot rodders and tuners love the Small Block because it can handle modifications with ease. Whether turbocharged, supercharged, or built for racing, it remains reliable when properly maintained. At the same time, stock versions used in daily drivers have proven themselves capable of lasting hundreds of thousands of miles.

One of the strongest qualities of the Small Block V8 is parts availability. Because so many were produced, replacement parts are cheap and easy to find. This has kept the motor alive across generations, making it one of the most dependable engines for enthusiasts and everyday drivers alike.

Chevrolet’s Small Block remains a symbol of American automotive engineering because it combines power and toughness. It can handle stress, modifications, and high mileage without quickly giving up. This is why it remains one of the longest-lasting and most respected motors to this day.

5 Motors That Don’t Last Under Stress

1. Chrysler 2.7L V6

When Chrysler launched the 2.7L V6 in the late 1990s, it was advertised as a modern engine that would deliver smooth performance and efficiency. At first glance, it looked like a solid option, especially since it was used in vehicles such as the Dodge Intrepid, Chrysler Concorde, and Sebring. However, with time, the engine developed a reputation for poor reliability.

One of the major issues with the Chrysler 2.7L V6 is its oiling system. The passages inside the motor are narrow, which causes sludge buildup when regular oil changes are skipped. Even when owners keep up with service, the design still makes the motor prone to sludge.

Once this buildup begins, it leads to blocked passages, poor lubrication, and eventually catastrophic engine failure. Many owners reported problems before reaching even 100,000 miles, which is far below expectations for a modern motor.

Another weakness is the water pump design. The pump is located inside the engine, and when it fails, coolant mixes with the oil. This contamination destroys bearings and other internal parts. Repairing such damage is expensive, often costing more than the value of the car itself.

Mechanics often advise avoiding vehicles with this engine because the chances of facing major repair bills are high. Even if owners try to maintain it carefully, the poor engineering makes it a risky motor. Some Chrysler vehicles equipped with this engine lost resale value because buyers were aware of the problems.

While Chrysler attempted to improve the design in later years, the 2.7L V6 still left a bad impression. Many drivers considered it one of the least reliable motors of its generation. For those who need an engine that survives stress, this motor is a clear example of what not to choose.

2. Volkswagen 1.8T (Early Versions)

Volkswagen’s 1.8T turbocharged engine, produced in the late 1990s and early 2000s, was once praised for its smooth power delivery and efficiency. It was fitted in popular models such as the VW Passat, Jetta, and Audi A4. While performance was impressive for its size, this motor quickly became infamous for its weakness under heavy use.

The biggest problem came from oil sludge buildup. Similar to Chrysler’s 2.7L V6, the 1.8T suffered from a poor lubrication system. Narrow oil passages, combined with the heat from the turbocharger, often caused sludge to form inside the engine.

Once the sludge accumulated, the motor lost proper lubrication and eventually failed. Many owners reported engine failure before 80,000 miles, which is far too early for a modern motor.

Turbocharger issues also made the 1.8T less reliable. Under stress, the turbo often wore out quickly, leading to loss of power and expensive repairs. Some drivers also complained about ignition coil failures, which caused misfires and poor performance. While these issues could be repaired, they often occurred repeatedly, leaving owners frustrated.

Volkswagen attempted to address the sludge issue by extending warranties and advising more frequent oil changes with synthetic oil. However, the damage to its reputation was already done. Mechanics often warned customers about the risks of buying cars equipped with this motor, especially when the maintenance history was unclear.

For drivers who wanted a reliable daily vehicle, the 1.8T proved disappointing. Even though it offered strong performance for its size, the weaknesses made it unsuitable for long-term durability under stress. Owners who abused it or neglected maintenance found themselves facing costly breakdowns far sooner than expected.

3. Subaru EJ25

Subaru has long been respected for producing engines with unique boxer layouts, giving cars like the Impreza and Outback their distinct character. However, the EJ25 engine, used widely from the 1990s into the 2000s, gained a poor reputation because of its repeated head gasket problems.

This motor serves as an example of how design flaws can make an otherwise promising engine unreliable under stress. The boxer design itself offers advantages, such as a lower center of gravity for better handling. But with the EJ25, Subaru used a head gasket material that often failed earlier than expected.

Many owners experienced coolant leaks, oil leaks, and overheating. These problems usually showed up between 80,000 and 120,000 miles, forcing costly repairs. In many cases, even after replacing the gasket, the issue returned.

The problem became so widespread that mechanics almost expected to see EJ25-powered cars in their shops for gasket replacements. For owners who pushed their cars hard or used them for long trips, the engine often failed sooner. Overheating could lead to warped cylinder heads, which would increase repair bills further.

Another issue with the EJ25 is that repairs are labor-intensive. Because of the boxer layout, mechanics must remove most parts of the car to access the engine. This makes fixing even basic problems more expensive compared to inline or V-type engines. Many owners complained that repair costs were too high relative to the vehicle’s value.

While Subaru later improved its gasket materials in newer engines, the EJ25’s reputation for poor durability remains. For buyers looking for a motor that can survive abuse, this engine does not meet expectations. Its repeated head gasket failures made it one of the least trusted motors of its time.

4. BMW N63 V8

BMW is known for building engines that deliver both performance and refinement. However, the N63 V8, introduced in the late 2000s, became a nightmare for many owners. Used in models like the 7 Series, 5 Series, and X5, it was one of BMW’s first twin-turbocharged V8 engines. While it promised high power and smooth delivery, its reliability under stress was extremely poor.

The N63 suffered from a long list of problems. One of the biggest issues was excessive oil consumption. Many owners reported having to top up oil frequently between services. Valve stem seals and other components wore out quickly, causing smoke and performance issues.

Another major weakness was the timing chain system. It was prone to stretching and failure, often requiring expensive repairs long before expected. Some engines needed complete rebuilds under 100,000 miles, which frustrated owners who had paid premium prices for BMW luxury cars.

Heat management was another challenge. With turbochargers placed inside the “hot-vee” of the engine, temperatures often soared, leading to premature wear of various parts. This design decision made the engine prone to repeated failures when stressed.

BMW was forced to issue multiple service campaigns to address these problems, including extended warranties for affected owners. However, the damage to its reputation could not be undone. Mechanics often caution buyers against owning BMW models with the N63 unless they are prepared for frequent and expensive maintenance.

For a motor that was meant to represent BMW’s technological progress, the N63 instead became an example of overengineering without long-term dependability. It may deliver strong performance, but when stressed, it struggles to remain reliable.

Also Read: 5 Cars That Handle Potholes Without Drama and 5 That Shatter Wheels

5. Ford 5.4L Triton V8

Ford’s 5.4L Triton V8, used in F-Series trucks and other vehicles during the 1990s and 2000s, was expected to be a strong workhorse. While some versions performed reasonably, many owners experienced recurring issues that made it unreliable under stress.

One of the main problems was the design of the spark plug threads in the cylinder heads. In early versions, the threads were too short, causing spark plugs to blow out of the engine. This not only damaged the motor but also created safety concerns. Repairing the issue often required replacing the cylinder heads, which was very expensive.

Another weakness was related to timing chain tensioners and cam phasers. These parts wore out quickly, leading to rattling noises, poor performance, and eventual failure. Many owners complained of high repair bills before even reaching 150,000 miles.

Oil consumption was another recurring complaint. Some engines burned excessive oil, leading to low levels that damaged internal components. This was especially common when vehicles were used for towing or heavy hauling.

While Ford trucks remain popular for their entire toughness, the 5.4L Triton motor left a poor mark because of these design flaws. Mechanics often warn buyers to carefully check maintenance records before considering vehicles with this engine.

For drivers who depend on their trucks to handle stress and heavy workloads, the Triton 5.4L often fell short of expectations. Instead of being remembered as a reliable powerplant, it became one of Ford’s most criticized engines.