When mechanics talk about engines, their opinions are shaped by years of experience under the hood, countless repairs, and endless frustrations with parts that either cooperate or fight back. For every power plant that makes them proud to turn a wrench, there is another that drives them to anger with its poor design or constant failures.

An engine is not just metal, pistons, valves, and gaskets. It represents the mind of its designers and the patience or stress of the technicians who must service it. Some engines are praised because they are reliable, straightforward to repair, and keep running for hundreds of thousands of miles with basic maintenance.

Others are cursed because they were built with little consideration for ease of servicing or because they fail too often in critical areas. Every mechanic has stories about engines that were a joy to work on.

These engines tend to combine durability with simplicity. They do not hide important parts behind unnecessary covers, they allow easy access to belts and filters, and they do not rely on fragile electronics that break down with age. They reward proper maintenance with long service life.

On the opposite side of it, some engines make mechanics lose patience. They may require removing the whole front end of a vehicle just to replace a belt. They may place spark plugs in impossible positions that need special tools.

Sometimes the materials used are weak, causing repeated failures in areas like head gaskets or timing components. These are the designs that leave technicians shaking their heads and owners paying high repair bills.

5 Engines Mechanics Respect

1. Toyota 2JZ-GTE

When mechanics mention engines that hardly give trouble, the Toyota 2JZ-GTE always comes up. Produced in the 1990s and early 2000s, this straight-six turbocharged engine gained fame in performance circles, but mechanics appreciate it for other reasons.

Its construction is extremely tough, with an iron block that can take plenty of abuse without cracking. Even when pushed with aftermarket modifications, it maintains its durability. This quality alone wins the respect of technicians who value engines that do not easily fail.

Serviceability is another factor that makes the 2JZ stand out. Unlike some modern designs that hide everything behind plastic covers, this engine is straightforward in its layout.

Belts, pulleys, and common service items are placed where mechanics can reach them without frustration. A well-maintained 2JZ can cross 300,000 miles with little more than routine oil changes and timing belt replacements. That kind of dependability means fewer headaches in workshops and more trust from vehicle owners.

Mechanics also appreciate how predictable this engine is. Problems that do occur are well-documented, and parts are widely available. This saves time during repairs and prevents unnecessary delays.

Many engines force technicians to fight against obscure faults that waste hours, but the 2JZ rarely hides surprises. Even when power modifications are added, the engine takes it well, proving the solid engineering that went into its design.

For technicians, the respect comes not only from durability but from the confidence it gives them. When a car comes in with a 2JZ, they know they are dealing with something built to last. It will not surprise them with fragile gaskets or inaccessible bolts. In workshops across America, it has earned a reputation as one of the most trustworthy engines ever made.

2. Honda K-Series

Honda has always been known for well-engineered engines, but the K-Series deserves special mention. Introduced in the early 2000s, this four-cylinder engine is respected by mechanics for blending power, efficiency, and long-lasting performance. Many cars equipped with it easily pass 200,000 miles with regular servicing, and some go far beyond that without needing major repairs.

One reason mechanics hold it in high regard is its clever design. The K-Series uses Honda’s VTEC system, which adjusts valve timing to balance fuel economy with performance. While advanced, it remains reliable and does not cause frequent breakdowns.

Mechanics like systems that provide benefits without introducing constant repair issues. Unlike some engines where advanced technology translates to expensive failures, the K-Series manages to be both modern and dependable.

Another point of respect is the ease of maintenance. Spark plugs, filters, and belts are accessible without unnecessary disassembly. Timing chain-driven versions reduce the need for costly timing belt replacements, adding another level of convenience for both mechanics and owners.

Even when deeper repairs are required, the layout is logical, and service manuals provide clear guidance. This reduces wasted time in the workshop and allows technicians to work efficiently.

Parts availability is another advantage. Because Honda produced so many of these engines, replacement parts are plentiful and reasonably priced. Mechanics prefer engines where they do not need to wait weeks for a single gasket or sensor. This accessibility makes the K-Series even more attractive to work on.

For mechanics, the K-Series stands out as a powerplant that combines innovative technology with long-term reliability. It delivers strong performance without becoming a maintenance burden, and that balance has made it a favorite in service bays across the country.

Also Read: 5 Engines That Rarely Fail Smog and 5 That Always Fail Tests

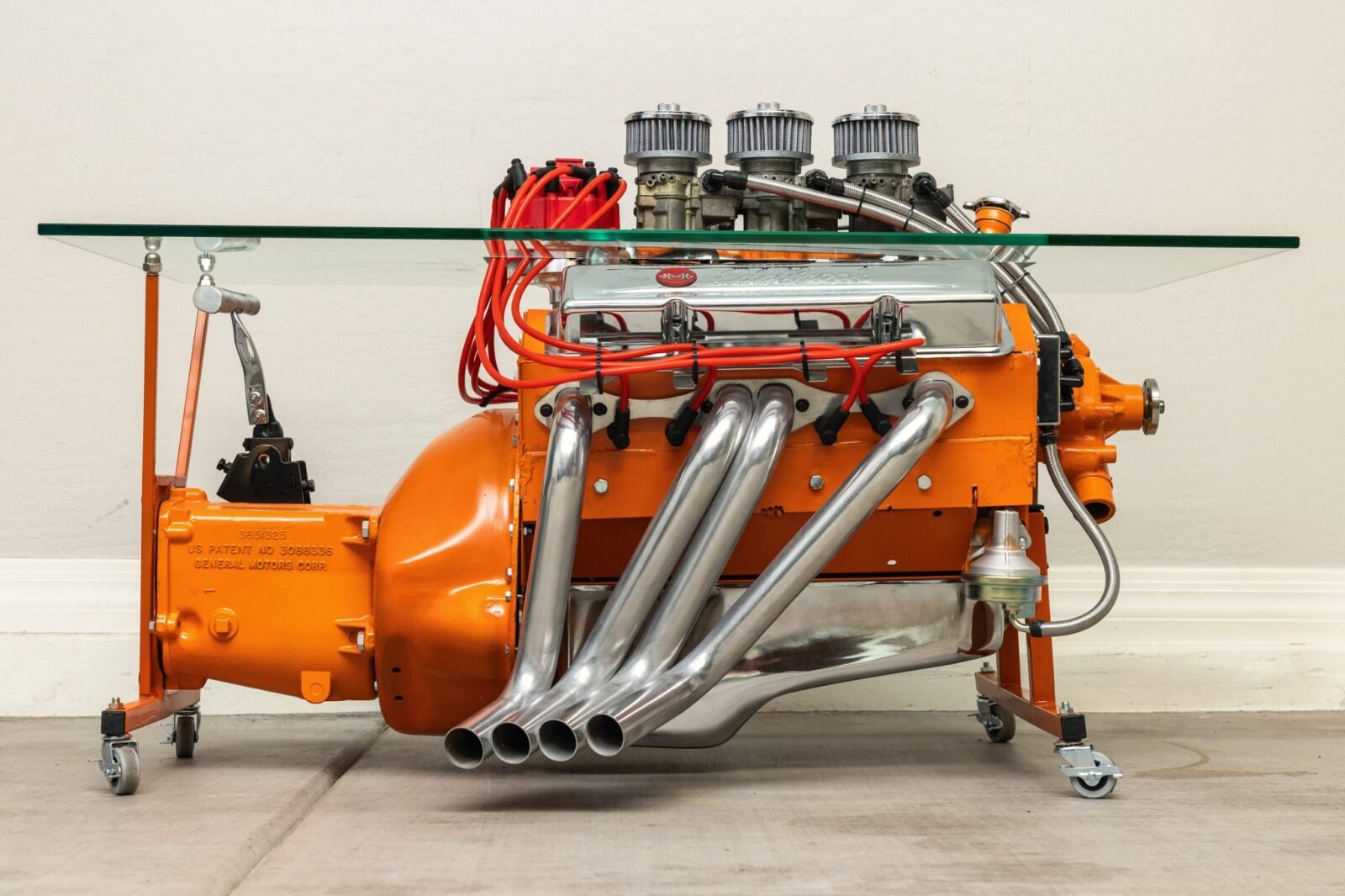

3. Chevrolet Small-Block V8

Few engines carry as much history as the Chevrolet Small-Block V8. First introduced in the mid-1950s, it has remained a staple of American automotive culture for decades. Mechanics respect it not only for its performance but for its incredible simplicity and toughness. Generations of technicians have cut their teeth working on this engine, and many still regard it as one of the best ever made.

The small-block earned its place because of how easy it is to repair. Its design is straightforward, with plenty of room in the engine bay for access. Spark plugs, distributors, and carburetors are within reach, and rebuilds can often be done without specialized tools.

For mechanics, this means jobs that might take hours on other engines can be completed much faster. The result is a power plant that never feels like it is fighting against the person repairing it.

Durability also plays a huge role in its reputation. Properly maintained, these engines can run for hundreds of thousands of miles. Even when abused in performance settings like drag racing or street modifications, they continue to deliver.

The aftermarket support for small-blocks is massive, with every imaginable replacement or upgrade part available. Mechanics know they will never struggle to find what they need.

Another point of respect is the knowledge base surrounding this engine. Because it has been around for decades, nearly every problem and solution has been documented. This makes diagnosis faster and prevents wasted time. A mechanic who understands small-blocks has a strong foundation in engine work.

For many technicians, the Chevrolet Small-Block represents the best of traditional American engineering. It is tough, simple, and rewarding to work on. Even today, long after its introduction, it continues to earn admiration in workshops across the United States.

4. Ford 300 Inline-Six

The Ford 300 inline-six is one of those engines that seems almost impossible to kill. Produced for trucks and vans from the 1960s into the 1990s, it has built a reputation as one of the toughest workhorse engines ever. Mechanics who encounter it respect its sheer resilience and the ease with which it can be maintained.

The design is straightforward. A large displacement six-cylinder with a simple carburetor or basic fuel injection in later versions, it was built with durability as the first priority. Many examples run well beyond 300,000 miles without ever needing a rebuild. For mechanics, this means fewer catastrophic failures and more predictable servicing.

Another factor is the accessibility of components. Spark plugs, belts, and even cylinder heads can be serviced without the frustration common with tightly packed modern engines. It gives technicians room to work, which saves time and reduces the chances of mistakes. An engine that is easy to service is always appreciated in workshops.

This engine also forgives neglect. Even when oil changes were skipped or cooling systems were not perfectly maintained, the Ford 300 often kept running. For mechanics, this speaks to engineering that valued toughness above all. Many truck owners who relied on their vehicles for heavy work trusted this engine because it never let them down.

The Ford 300 is a reminder of when engines were built with long life and serviceability in mind. Mechanics respect it not just because it is easy to repair, but because it rarely needs repair in the first place. Its reputation for toughness is well-earned, and it remains one of the most admired engines ever built for heavy-duty use.

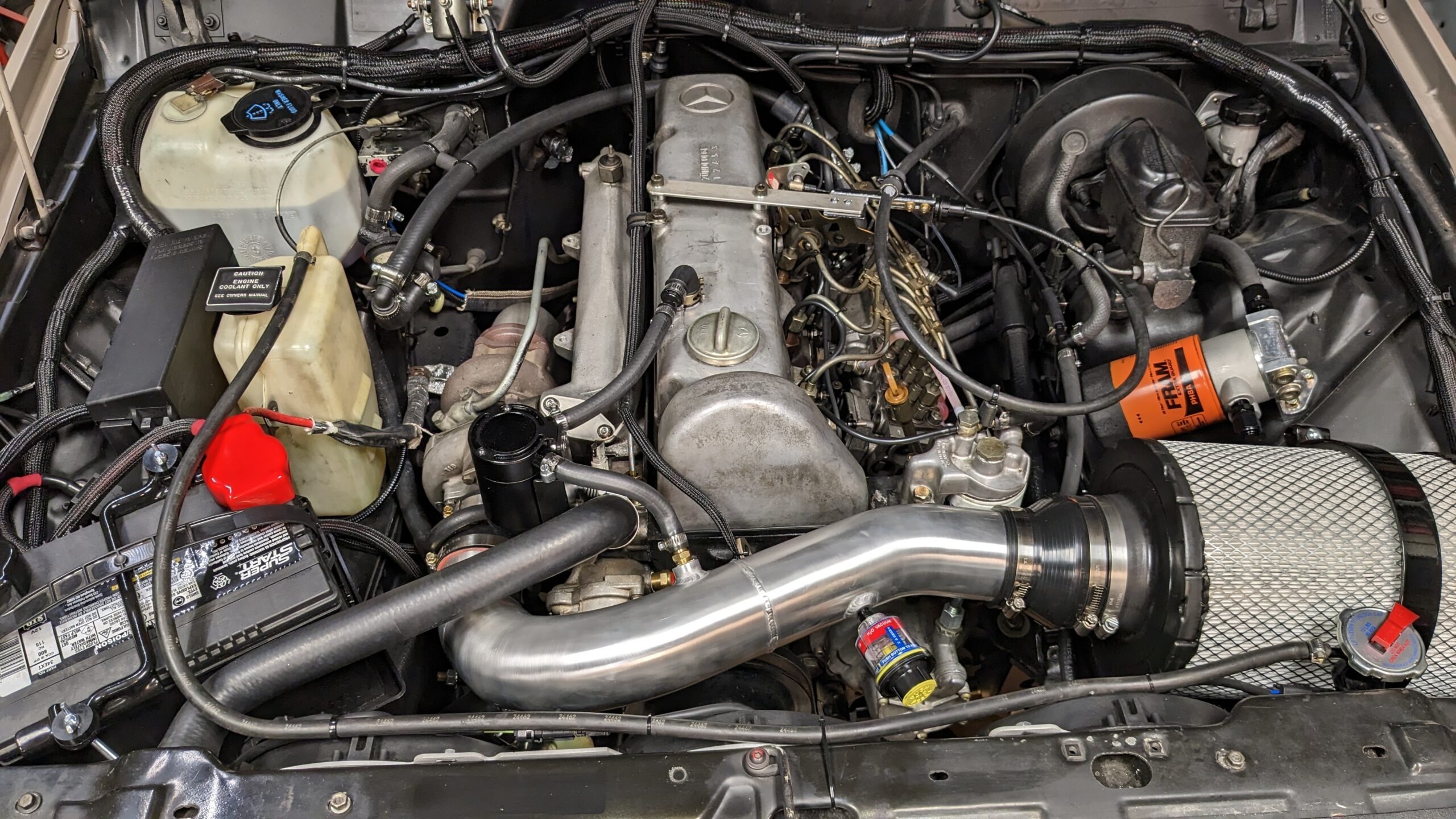

5. Mercedes-Benz OM617 Diesel

Among diesel engines, few are spoken of with as much respect as the Mercedes-Benz OM617. Produced from the 1970s into the 1980s, this five-cylinder diesel became famous for its ability to run nearly forever. Mechanics who have worked on these engines often describe them as unbreakable, and their design explains why.

The OM617 was overbuilt in nearly every way. Its cast-iron block and head, simple fuel injection system, and low-stress operating characteristics allowed it to achieve lifespans far beyond most engines. It was not uncommon for these engines to pass half a million miles before requiring major work. Mechanics appreciate engines that reward basic care with extraordinary longevity, and the OM617 is the textbook example.

While diesel engines can sometimes be difficult to work on, the OM617 is relatively straightforward. Filters and belts are accessible, and the fuel system is mechanical rather than electronic, which makes it easier to service. Mechanics enjoy working on engines that are logical in layout and do not require unnecessary disassembly.

Another reason it is respected is the predictability of its failures. When issues do occur, they are usually consistent and well understood. This makes repairs less frustrating because technicians know what to expect. Unlike engines that surprise with obscure design flaws, the OM617 provides confidence through familiarity.

For mechanics, this engine represents what happens when a manufacturer prioritizes strength over cutting-edge performance. It may not be fast, but it was designed to last decades. Many examples are still running today, proving the value of solid engineering. Mechanics respect it because it does not waste their time and because it gives owners long service without constant repair bills.

5 Engines That Mechanics Swear At

1. Chrysler 2.7L V6

While some engines inspire admiration, others earn only frustration, and the Chrysler 2.7L V6 is one such case. Introduced in the late 1990s, it quickly became infamous among mechanics for its frequent failures and poor serviceability. For many technicians, this engine represents one of the worst design decisions of its era.

One major issue is its tendency toward oil sludge. The design of the engine, combined with narrow oil passages and poor ventilation, causes sludge buildup that can lead to catastrophic failure.

Even with regular oil changes, many engines still suffered from this problem. For mechanics, this means a steady stream of repairs and replacements, but also the headache of dealing with an engine that should have lasted longer.

Access to parts is another frustration. Many critical components are buried deep within the engine, making simple repairs a time-consuming process. For example, replacing the water pump requires extensive disassembly, often involving the timing chain system. Mechanics dislike engines that punish them with hours of work for what should be a straightforward fix.

Durability is also poor compared to other engines of the same era. Many Chrysler 2.7L V6 engines failed well before 100,000 miles, leaving owners with high repair bills and mechanics with difficult jobs. The reputation was so bad that many technicians advised customers to avoid cars equipped with this engine altogether.

For mechanics, the Chrysler 2.7L V6 is remembered as a lesson in poor engineering choices. It created unnecessary work, wasted time, and left both owners and technicians frustrated. Even years later, it remains an engine that many mechanics swear at whenever it enters the shop.

2. Cadillac Northstar V8

The Cadillac Northstar V8 was introduced in the 1990s as a showcase of advanced technology, but for mechanics, it quickly became a source of frustration. While it delivered impressive power for its time, its reliability issues and complicated service requirements made it one of the least loved engines in workshops.

One of the most common problems with the Northstar was head gasket failure. The aluminum block and heads combined with poorly designed head bolts caused the gaskets to fail, leading to overheating and costly repairs. Mechanics dreaded these jobs because they were both time-consuming and expensive for owners.

Access to components was another headache. The engine bay was often cramped, and many repairs required removing large sections of the vehicle just to reach the parts. Something as simple as replacing a starter motor could involve hours of disassembly. Mechanics value engines that respect their time, and the Northstar did the opposite.

Another issue was oil consumption. Many Northstar engines burned excessive amounts of oil, frustrating owners and forcing mechanics to constantly reassure them that it was “normal” for this engine. For technicians who want to see reliable performance, this was a major disappointment.

While the Northstar represented Cadillac’s push into modern engineering, it left mechanics swearing because of its fragile design and endless service requirements. Even though it was powerful and smooth, the headaches it created in workshops have permanently damaged its reputation among technicians.

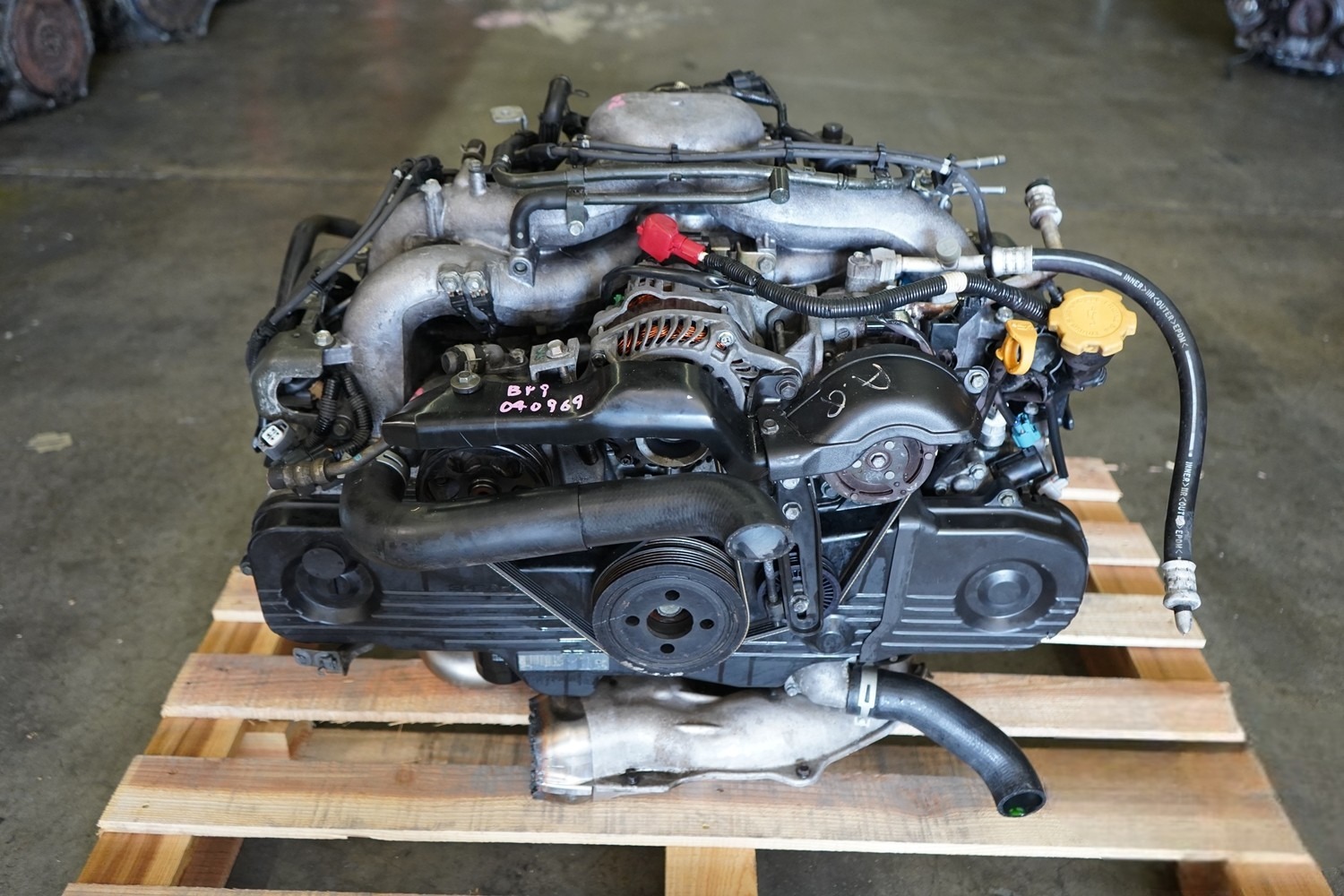

3. Subaru 2.5L EJ25

Subaru has produced engines that earned praise, but the 2.5L EJ25 is remembered for all the wrong reasons. Mechanics who have worked on this engine often groan when they see it because of its reputation for repeated head gasket failures. This problem haunted the engine for years and gave technicians endless repair jobs that felt avoidable.

The issue comes from a design flaw in the cooling passages and head gasket material. After some time, coolant leaks into areas it should not, leading to overheating and eventual gasket failure. Mechanics know that repairing a head gasket is a major job that takes time and costs a lot. When an engine repeatedly suffers from this same fault, it quickly earns a bad reputation.

Serviceability also leaves much to be desired. Subaru’s boxer engine layout places the cylinders horizontally, which makes access to certain components difficult. Replacing head gaskets requires removing the entire engine, a job that few mechanics look forward to. It turns what could be a manageable repair into a major project.

Another issue is oil leaks. The EJ25 often suffers from leaking seals and gaskets, which add to the frustration of keeping it in good condition. Mechanics do not enjoy engines that constantly drip fluids and stain workshop floors.

For many technicians, the Subaru 2.5L EJ25 is an engine they swear at because it combines frequent failures with a difficult layout. While Subaru’s all-wheel-drive cars are loved by owners, the engines powering them have left countless mechanics frustrated.

4. Volkswagen 1.8T

The Volkswagen 1.8T turbocharged engine, produced in the late 1990s and 2000s, promised strong performance in a small package. While it delivered power, it also delivered a host of frustrations for mechanics. Many still curse this engine because of its oil sludge issues and cramped design.

Like the Chrysler 2.7L V6, the 1.8T is prone to oil sludge buildup. Narrow oil passages and high operating temperatures often led to lubrication failure, which caused expensive damage. Mechanics saw too many engines destroyed because of this issue, even when owners claimed they maintained them properly.

Another complaint is access to components. Because of its compact size, many parts are difficult to reach. Turbocharger repairs, timing belt replacements, and even simple sensor changes can take much longer than expected. Mechanics dislike engines that force them to fight in tight spaces and awkward layouts.

Durability also proved disappointing. While some 1.8Ts lasted a long time with perfect maintenance, many failed prematurely. The combination of turbo stress and oil sludge left many owners with costly repairs, and mechanics with difficult jobs that felt unnecessary.

While Volkswagen lovers appreciated the performance of the 1.8T, mechanics often dreaded seeing it in the shop. Its design flaws and service challenges turned what could have been a respected engine into one that technicians frequently swore at.

Also Read: 5 Turbo Engines That Stay Reliable and 5 That Always Break

5. BMW N63 V8

The BMW N63 twin-turbo V8 represents modern engineering at its most complicated, and mechanics often swear at it for that reason. Introduced in the late 2000s, it promised impressive performance, but its reliability record and difficult servicing left technicians deeply frustrated.

One of the biggest problems is premature wear of critical components. The N63 suffers from issues with timing chains, fuel injectors, and turbochargers, often failing at relatively low mileage. Mechanics dislike engines that cannot deliver durability, especially when they are installed in high-priced luxury vehicles.

Serviceability is another issue. The engine bay is packed tightly, and reaching many components requires major disassembly. Even basic maintenance tasks like replacing spark plugs or valve cover gaskets can be time-consuming. For technicians, this translates to long hours of labor and unhappy customers facing huge repair bills.

Another frustration is the frequency of service bulletins and recalls. BMW issued multiple campaigns to address common N63 issues, including high oil consumption and failing components. Mechanics often see these engines come back again and again, creating a sense of endless work without resolution.

While the N63 delivers strong performance when working properly, mechanics remember it for the stress it brings to workshops. Its complications, lack of durability, and expensive parts combine to make it one of the most frustrating engines of recent years.

Engines are judged not only by how much power they produce but by how they treat the people who keep them running. Mechanics see the strengths and weaknesses of every design up close, which is why their respect or frustration carries so much weight.

The Toyota 2JZ, Honda K-Series, Chevrolet Small-Block, Ford 300, and Mercedes OM617 have earned admiration because they deliver durability, ease of maintenance, and predictable performance.

While the Chrysler 2.7L V6, Cadillac Northstar, Subaru EJ25, Volkswagen 1.8T, and BMW N63 are remembered for design flaws, repeated failures, and service challenges that waste time and money.

For technicians, these experiences shape how they speak about engines long after production ends. What drivers see as just a machine, mechanics see as either a trusted partner or a constant burden. That distinction is what makes some engines respected and others sworn at.