When you put a car on a racing circuit, the engine becomes the most tested part of the machine. Track days are meant to push both driver and car to the highest limits, and while suspension, tires, and brakes are important, the engine often determines if the car will last long on the track or break down before the day ends.

Car lovers who enjoy driving at high speeds understand that not every motor is built to handle the extreme heat, constant acceleration, and heavy demands that a track day requires. Some engines are known for their toughness, giving drivers the confidence to stay out longer without fear. Others have gained a reputation for failing under stress, sometimes leaving the driver stranded before the session is done.

The truth is that engineers design engines for different purposes. Some motors are produced to make daily commuting easy, and others are made with racing and track durability in mind. Heat management, oil control, cooling design, and material strength are factors that separate an engine that lasts from one that fails when used under extreme conditions.

Drivers who want to enjoy track days without constant repairs often look out for cars powered by engines that already have a strong history of surviving high-load conditions. On the other side, some engines come with weaknesses such as poor cooling systems, weak pistons, or unreliable timing chains that often lead to breakdown when pushed too hard.

Our discussion here will focus on ten engines that are often mentioned whenever track use is considered. Five of them are praised for staying reliable after long hours of hard driving, while the other five are known for problems when exposed to similar treatment.

Understanding the difference can help drivers choose wisely before heading to a track event. Let us now look at each category one by one, starting with those engines that continue to run strong when tested.

Engines That Survive Track Days

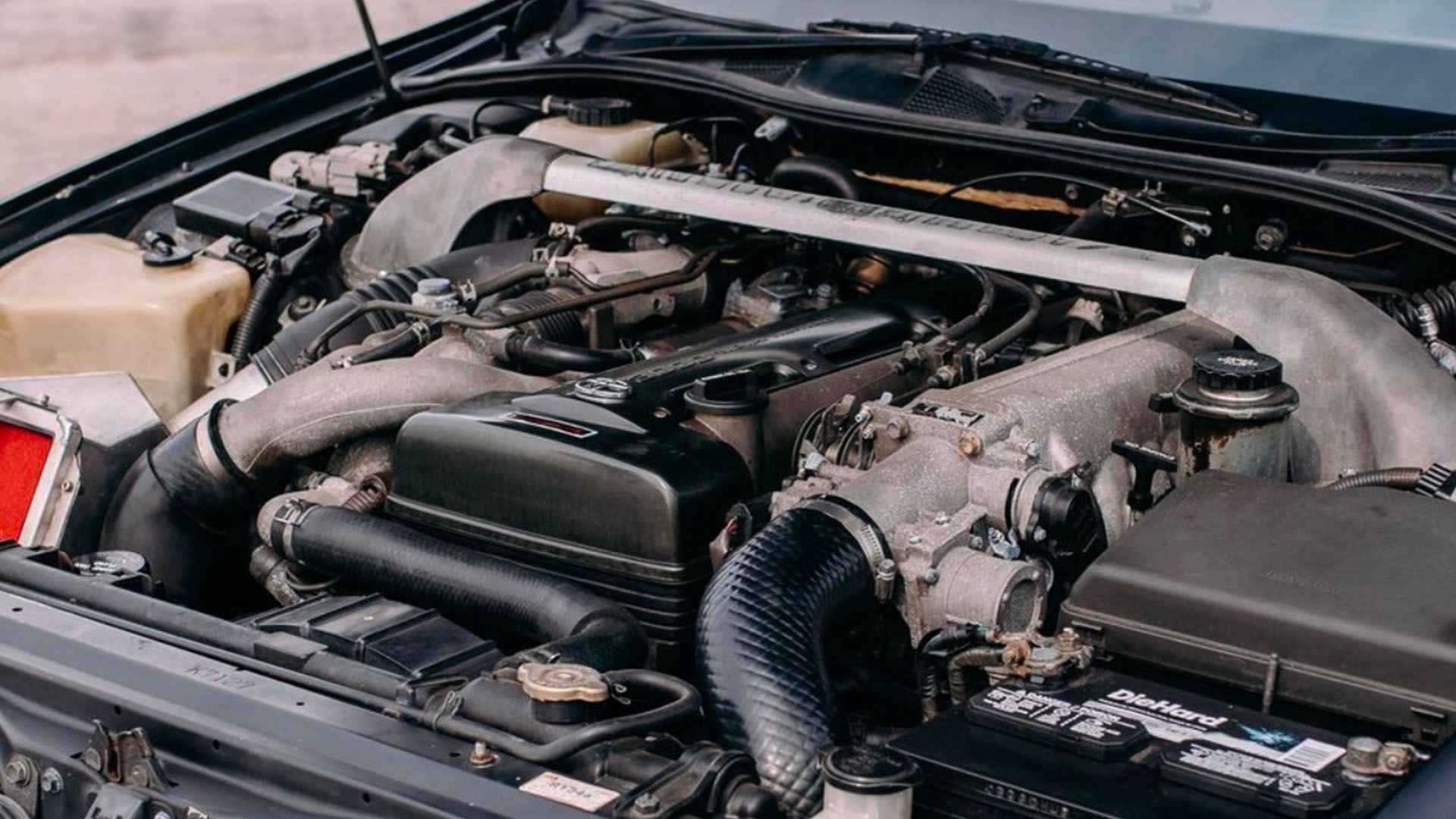

1. Toyota 2JZ-GTE

Toyota’s 2JZ-GTE engine has been celebrated for decades, especially among people who enjoy racing and performance driving. It is a 3.0-liter inline-six engine fitted with twin turbochargers. Built during the 1990s for the Toyota Supra, it quickly became famous for being almost indestructible.

The motor is made with a very strong iron block, which means it can handle huge power without cracking or warping under stress. Even when used on track days where the throttle stays open for long periods, the 2JZ-GTE continues to deliver smooth power without overheating.

One of the reasons drivers trust this engine is because of its oiling system and cooling design. The engineers at Toyota gave it a solid foundation, so the oil circulation stays consistent even at very high RPMs.

When a car is pushed hard on a track, oil starvation is a common problem, but the 2JZ handles it much better than many rivals from its era. That reliability has made it one of the most modified engines in car history. It is common to see 2JZ engines producing well above 600 or 700 horsepower without internal damage.

Another factor that helps the 2JZ-GTE is its aftermarket support. Many companies produce stronger parts, better cooling kits, and upgraded turbos, making it easy for drivers to prepare their cars for long track sessions.

Even without modifications, the engine has shown that it can withstand repeated abuse. Car enthusiasts who own Supras or cars with swapped 2JZ engines often share stories of going through full track weekends without any sign of trouble.

For those who enjoy track days, the 2JZ-GTE represents peace of mind. It delivers strong power, responds well to modifications, and continues to perform even when others give up. That is why decades after its production ended, it remains a legend among engines that survive heavy driving.

2. Honda K20

Honda’s K20 engine is another motor that drivers see as a strong performer during track sessions. Found in models like the Civic Type R and Acura RSX, the K20 is a 2.0-liter naturally aspirated four-cylinder engine that is known for its high-revving nature. Honda designed it to spin close to 8,000 RPM, which means it loves to be pushed hard, and that matches perfectly with track use.

What makes the K20 so dependable is its solid engineering. Honda gave it a strong aluminum block, an advanced VTEC system, and a well-balanced crankshaft. These features allow it to handle stress while keeping reliability.

Drivers who track cars with K20 engines usually enjoy the thrill of staying in high revs without worrying about sudden failure. Even when used for hours on circuit driving, the K20 rarely suffers catastrophic breakdowns, provided that proper maintenance is done.

Cooling is another area where the K20 performs well. The compact size of the engine allows for good airflow in the engine bay, and Honda equipped it with an efficient cooling system that reduces the chance of overheating.

Oil control is also strong, so the engine maintains proper lubrication during high cornering forces on the track. Many drivers have reported that even after several sessions of intense driving, the engine continues to feel healthy.

One reason why the K20 is so loved by track drivers is also its tuning potential. While it is already reliable in factory form, adding performance modifications like upgraded intake, exhaust, or ECU tuning brings out more power without reducing its life.

Unlike some engines that lose durability when tuned, the K20 remains dependable. For car enthusiasts who want a mix of reliability, rev-happy character, and strong aftermarket support, the K20 stands as one of the most trusted choices for track days.

Also Read: 5 Engines That Rarely Fail Smog and 5 That Always Fail Tests

3. BMW S54

The BMW S54 engine is one of the most respected inline-six engines produced by the German company. Found mainly in the E46 M3, it is a 3.2-liter naturally aspirated motor that produces both strong horsepower and excellent response.

What makes this engine shine on track days is its ability to handle continuous hard driving without losing performance. It was designed with motorsport in mind, and that makes it an ideal companion for drivers who push their cars often.

The S54 uses high-strength internals such as forged pistons, solid connecting rods, and a reinforced crankshaft. This design allows it to operate at high RPM levels without breaking apart. When track drivers take their M3 to the circuit, they often enjoy revving it close to its 8,000 RPM redline, and the engine keeps performing without signs of weakness. Unlike some engines that begin to overheat or lose oil pressure during extended use, the S54 maintains stability.

Another strong point of the S54 is its throttle bodies. This feature not only makes the engine more responsive but also helps it breathe more efficiently during constant acceleration and deceleration that happens on a track. The cooling system is also well-engineered, giving drivers confidence that the engine will not overheat after several laps.

Owners who service their S54 engines regularly often speak about how dependable they are for track days. While it requires consistent oil changes and attention to small details like valve adjustments, the payoff is an engine that can last many years of track use. Even when tuned for more power, the S54 continues to show resilience as long as the modifications are done properly.

For anyone who values precision driving and loves a strong, high-revving engine, the S54 remains a trusted choice. It has carried BMW’s motorsport image for many years, and even today it is respected as one of the engines that can take on the heavy demands of track days without giving up easily.

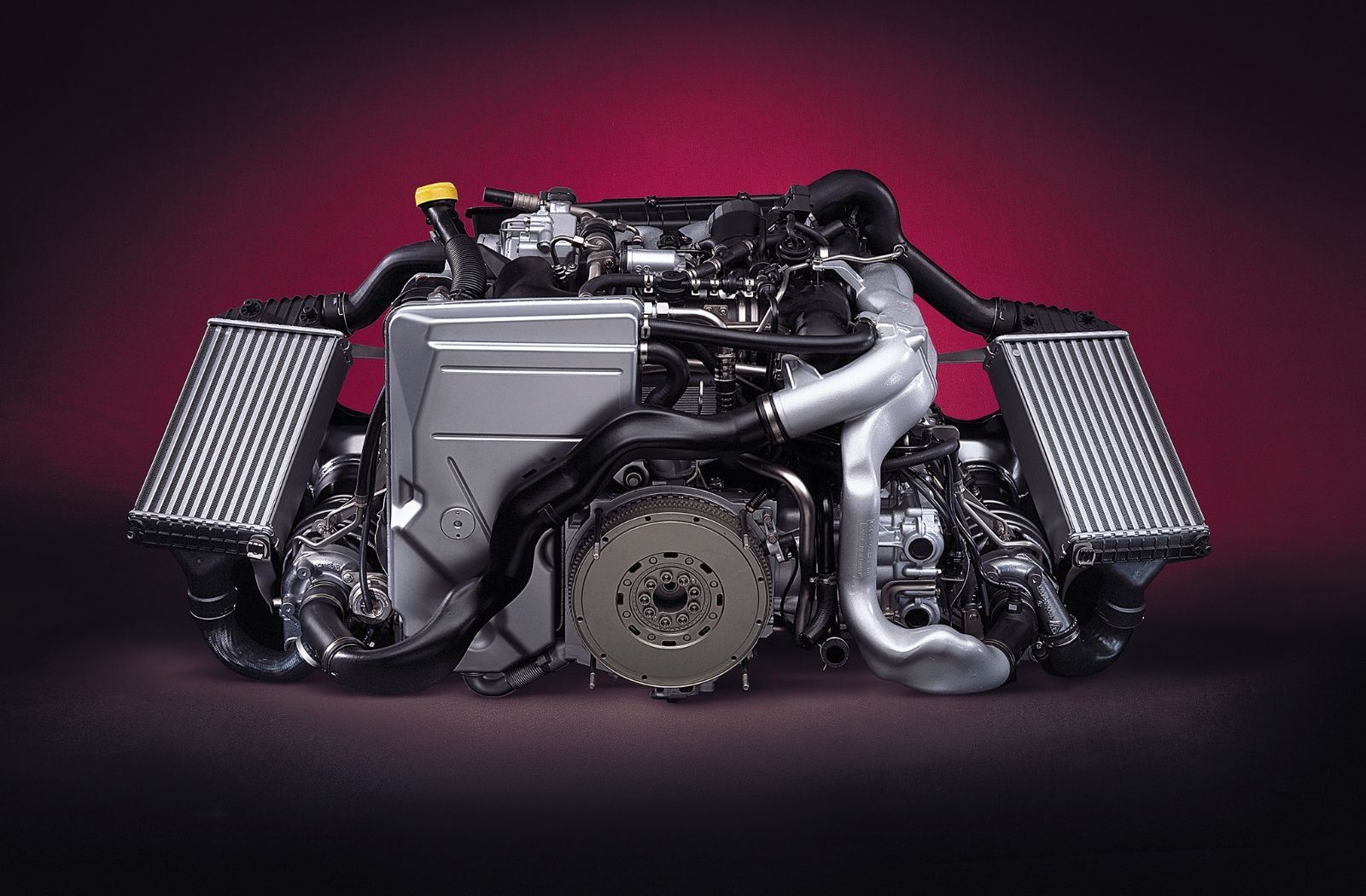

4. Porsche Mezger Flat-Six

Porsche built its reputation around flat-six engines, and the Mezger unit is often seen as one of the strongest ever made. Used in models like the 996 and 997 911 Turbo, GT2, and GT3, this engine became known for its ability to take abuse on the track and still deliver flawless performance. The Mezger engine was developed from Porsche’s racing technology, which explains why it handles stress so well.

The Mezger design separates it from other Porsche flat-six engines because it does not suffer from problems like intermediate shaft bearing failures that affected some other models. Instead, it uses a motorsport-based dry sump lubrication system, which ensures that the engine always has proper oil flow, even under heavy cornering forces that would starve weaker engines.

This dry sump setup makes the Mezger especially suited for track conditions where g-forces are very high. Durability is another feature that makes the Mezger special.

Its block and internals are extremely strong, which allows it to handle very high horsepower without cracking. Many tuners push Mezger engines to more than 700 horsepower, and yet the motor continues to last. On the track, drivers can rely on the Mezger to provide consistent power throughout the session.

Another point in its favor is the cooling system, which is highly effective. With track driving generating extreme heat, an engine with poor cooling would fail quickly. The Mezger, however, keeps its temperature stable, which builds trust for drivers who want to spend hours on the track.

When Porsche enthusiasts talk about dependable engines for circuit use, the Mezger is always on the list. It blends heritage from racing with practical strength, making it a true track warrior. For drivers who want a machine that will not melt down under pressure, the Mezger flat-six is one of the best engines ever created.

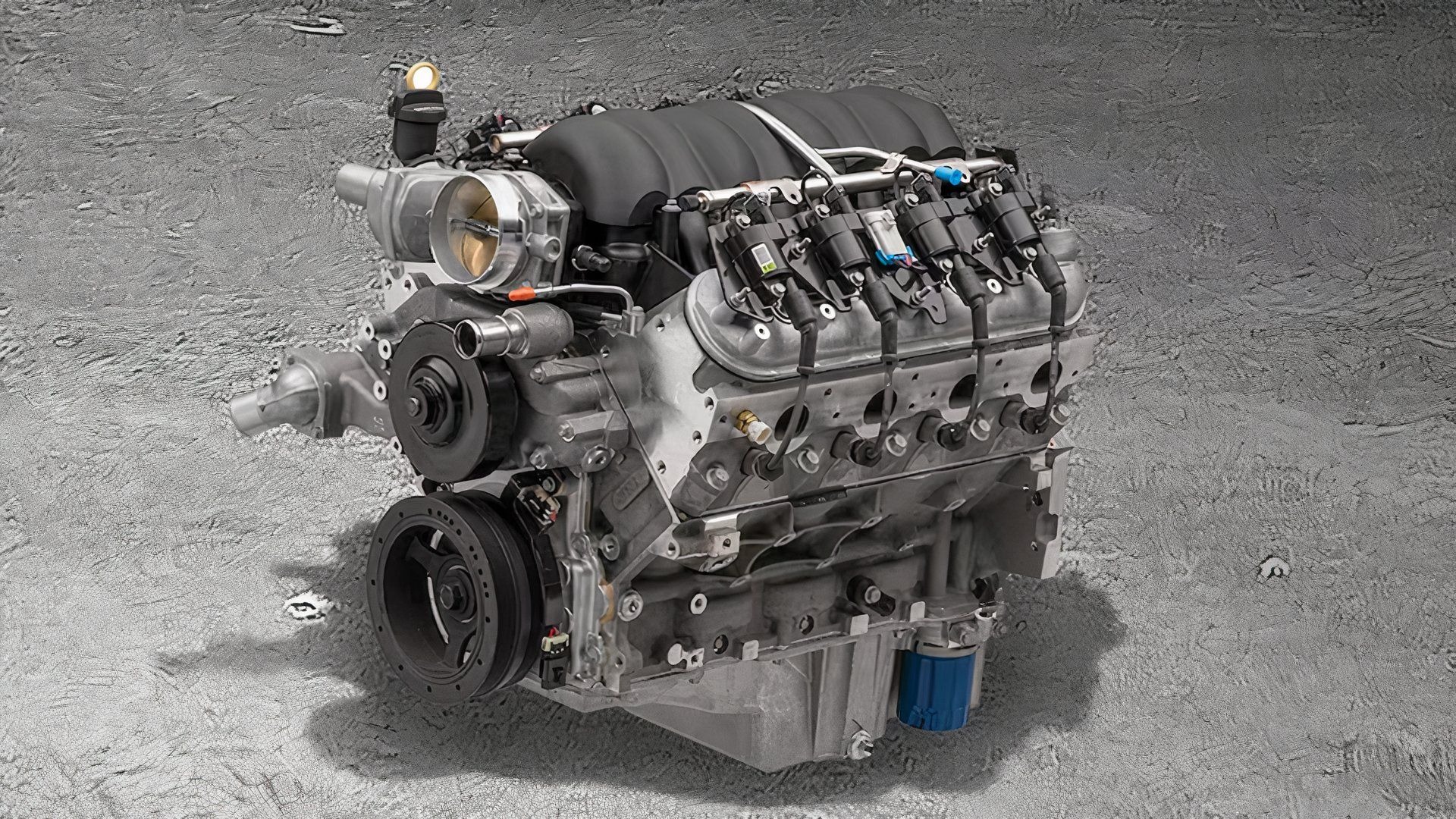

5. Chevrolet LS3

American V8 engines have long been known for raw power, and the Chevrolet LS3 is one that also combines strength with reliability. Found in cars like the Corvette C6 and Camaro SS, this 6.2-liter V8 is a favorite for drivers who attend track days. It offers strong torque across the range, making it enjoyable to drive, while also holding up very well under long sessions of hard use.

The LS3 is designed with a sturdy aluminum block and strong internals that can manage abuse without failure. One reason why it lasts on the track is its relatively simple pushrod design, which has fewer moving parts compared to some complicated engines. This simplicity reduces the likelihood of breakdown when the motor is constantly under stress.

Cooling and oiling are handled well by the LS3. Even though it produces plenty of heat because of its size, the engine bay in cars like the Corvette is designed to allow sufficient cooling airflow. That helps the LS3 remain stable even after repeated hot laps. The oil system also does a good job, so drivers do not worry about sudden starvation when cornering hard.

Another reason the LS3 is highly respected is its aftermarket support. Many upgrades are available for drivers who want more performance on track days, and these modifications do not take away the reliability of the engine. Whether kept in stock form or tuned for higher horsepower, the LS3 maintains its reputation for toughness.

For drivers who enjoy American muscle and want an engine that will not only produce great power but also stay alive during track abuse, the LS3 is an excellent option. It is proof that big displacement engines can still deliver dependable service under the toughest driving conditions.

Engines That Melt Down on Track Days

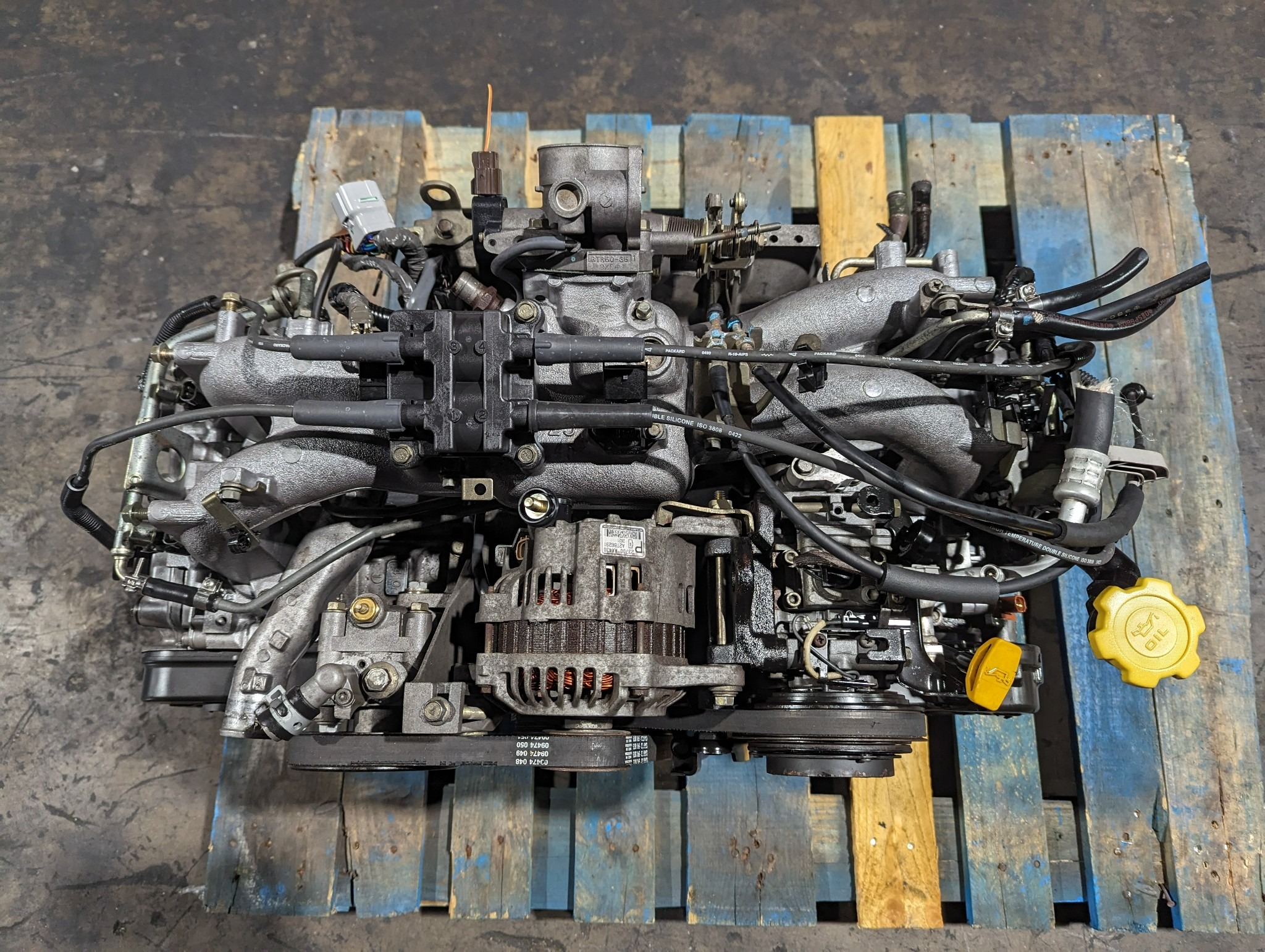

1. Subaru EJ25

While Subaru is popular among car lovers for its rally heritage and turbocharged engines, the EJ25 has often been criticized for weakness when used on track days. This 2.5-liter flat-four engine, found in models like the WRX and WRX STI, produces good power but has a history of reliability problems when pushed too hard.

The most common issue with the EJ25 is its head gasket failure. Drivers who take their cars to the track often face overheating problems that lead to blown head gaskets. Once that happens, the engine loses compression and requires major repairs. The design of the EJ25 makes it difficult to completely solve this issue, which is why it has earned a reputation for not surviving heavy track use.

Another problem is the risk of ringland failure. The pistons in the EJ25 are not strong enough to handle prolonged high boost and extreme heat. During track driving, where the engine is constantly under load, these weak points often appear. Many drivers have experienced engines seizing or losing power completely because of broken pistons.

Oil control is also a weakness for the EJ25. The flat-four layout makes it more prone to oil starvation under high cornering forces, which is exactly what happens during track driving. Without proper oil flow, bearings wear out quickly, and the engine can fail.

While some enthusiasts install aftermarket upgrades like stronger head gaskets, forged pistons, and improved oil systems to make the EJ25 survive longer, the truth is that in factory form, it is not dependable for long track sessions. Many people love Subaru cars for their character and all-wheel-drive system, but the EJ25 remains an engine that often melts down under the heat and pressure of track use.

2. Mazda Rotary 13B

Mazda’s rotary engines are loved by car enthusiasts for their unique design and exciting high-revving sound, but when placed under the demands of a track day, the 13B often shows its weak side. Found in the RX-7, this rotary engine is small in size yet delivers impressive power. However, its construction brings challenges that reduce reliability under extended heavy use.

The 13B does not operate like traditional piston engines. Instead of pistons moving up and down, it uses rotors spinning inside chambers to produce power. While this design gives smooth delivery and high RPM potential, it also produces excessive heat.

Heat management is a constant problem with rotary engines, and on the track where constant throttle is required, overheating becomes a serious risk. Drivers often struggle with coolant temperatures rising quickly, which can force them to end their session earlier than planned.

Another weakness of the 13B is its oil consumption. Rotary engines naturally burn oil as part of their design, which means they require constant monitoring. On track days where cars spend long periods at high revs, oil can run low quickly, leading to premature wear or even complete failure. Many owners carry extra oil to track events just to keep the engine alive for the day.

Durability is also questionable when the 13B is pushed hard. Apex seals, which are the small components that seal the rotors inside the housing, often wear out or break under stress. Once that happens, compression is lost, and the engine requires a rebuild. Rebuilding rotary engines is both costly and time-consuming, which discourages many people from using them for repeated track events.

While the 13B is fun to drive and gives a unique experience, its weaknesses in cooling, oil use, and apex seal reliability make it one of the engines that often fail during track days. Enthusiasts admire it for character and performance in short bursts, but for long and repeated track use, it is not dependable.

3. Ford 5.4L Modular V8 (as found in early GT500)

Ford’s 5.4-liter Modular V8, used in cars such as the Shelby GT500 of the mid-2000s, is known for delivering huge torque, but when taken to track days, it often struggles with heat and durability. While the engine is capable of producing big horsepower figures, its weaknesses become clear under extended high-stress driving.

The main issue with this engine is heat management. The iron block design is heavy and holds heat longer than aluminum alternatives. During track use, this often leads to overheating problems. Drivers report that coolant and oil temperatures rise too quickly, forcing them to cut short their sessions. Unlike engines designed specifically for racing, the 5.4 V8 does not have efficient cooling pathways, which makes it unreliable for repeated hot laps.

Another area of weakness is its size and weight. Being a physically large engine, it puts extra strain on the front of the car, which negatively affects handling and puts more load on components like suspension and brakes. On a track where balance and control are critical, this makes the car less effective and the engine more prone to stress.

Oil starvation has also been reported during high cornering. Without a true dry sump system, the 5.4 V8 struggles to keep oil flowing consistently when subjected to extreme g-forces. That leads to bearing wear and, in some cases, full engine failure. Enthusiasts who modify these engines for track reliability often need to spend a lot of money upgrading cooling and lubrication systems.

While the 5.4 Modular V8 provides an exciting straight-line experience and sounds great, it is not a motor that survives well during long track sessions. It was engineered more for drag racing and highway pulls than continuous circuit use. For drivers planning serious track days, this engine is one that often gives more stress than enjoyment.

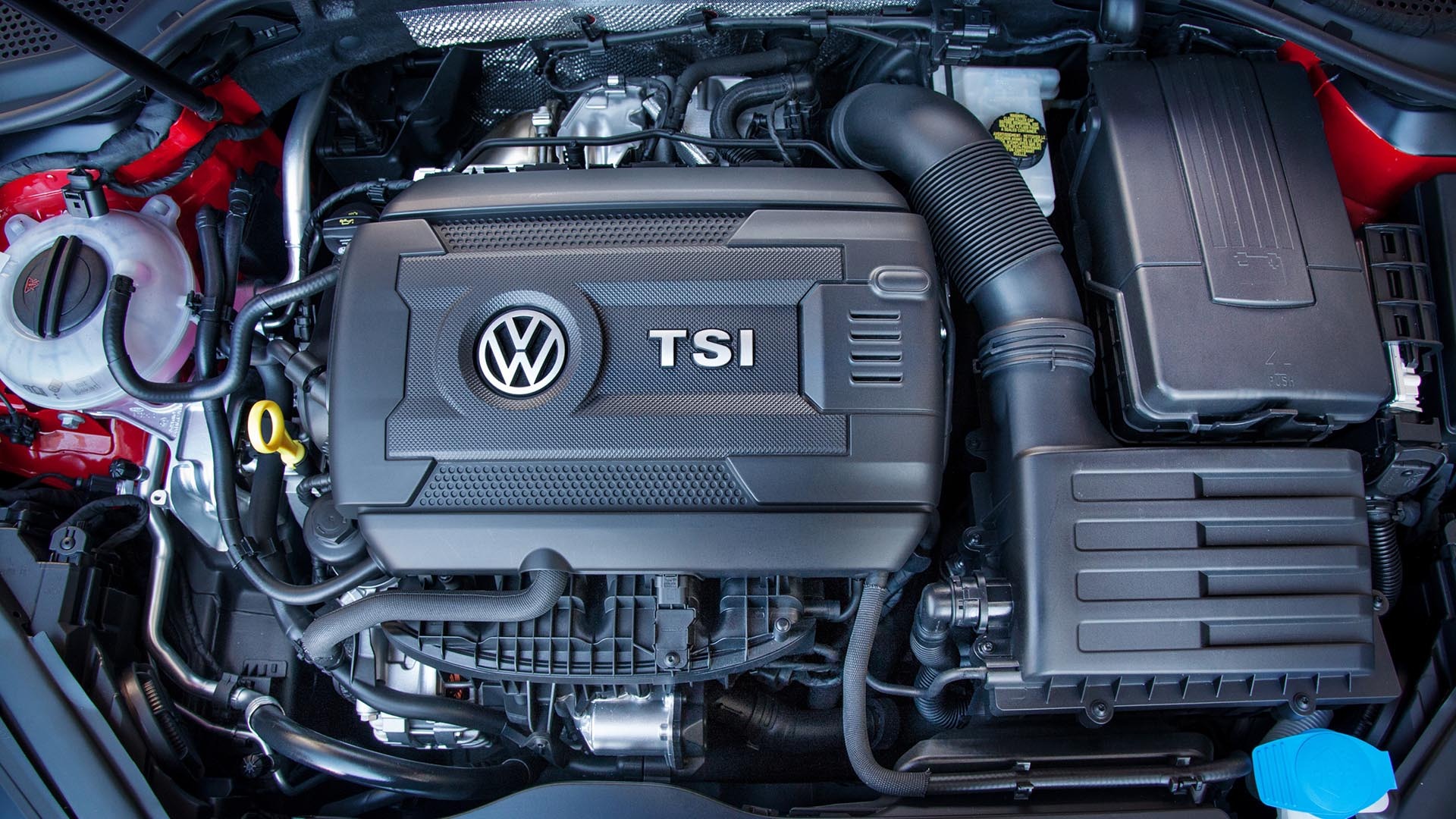

4. Volkswagen EA888 (Early Generations)

Volkswagen’s EA888 turbocharged four-cylinder engine has been used in many cars, like the Golf GTI and Audi A3. While later versions are more dependable, the earlier generations of this engine developed a reputation for failing when subjected to hard driving, especially in track environments.

The biggest problem faced by the EA888 in its earlier forms was related to timing chain tensioners. These components often failed unexpectedly, leading to catastrophic engine damage. On the track, where engines are constantly pushed to redline, this weakness appeared more frequently. Many owners experienced sudden engine failure due to stretched chains or broken tensioners.

Another issue is oil consumption. The early EA888 engines are known to burn oil at an unusual rate. On track days where high RPM driving is constant, oil levels can drop dangerously low, causing bearing wear or piston damage. Drivers who forget to check oil levels regularly often face engine seizure.

Cooling performance is also a weakness of the early EA888. The turbocharger adds heat, and when combined with continuous full-throttle driving, temperatures rise beyond safe levels. Without upgraded cooling systems, many of these engines fail under repeated track use.

Carbon build-up is another known issue. Because of direct fuel injection, intake valves accumulate heavy deposits as time goes on, reducing airflow and performance. On a track where maximum airflow is required for efficiency, this build-up causes power loss and further stress on the engine.

While modern versions of the EA888 have improved and are now used reliably in many Volkswagen Group cars, the early ones are not trusted for track driving. Many car enthusiasts recommend avoiding them for serious circuit use, since the risk of breakdown is high. For those who want to enjoy track days, the EA888’s early generations stand out as engines that often melt down before the day is over.

Also Read: 5 V8 Engines That Refuse to Quit and 5 That Self-Destruct

5. BMW N54

BMW’s N54 engine, a 3.0-liter twin-turbocharged inline-six found in cars like the 335i and early 1 Series, was praised for strong performance and tuning potential. However, on track days, it is often described as one of the least reliable engines to depend on. While it delivers exciting power, it suffers from several issues that show up when pushed hard.

The N54 has well-documented problems with its high-pressure fuel pump. Failures are common, and when driving on a track, a failed pump can end the session instantly. Many owners have faced repeated pump replacements, which damages the reputation of the engine.

Turbocharger reliability is another weakness. The stock turbos tend to wear out quickly, especially when used under high heat for extended periods. Drivers often experience wastegate rattle, loss of boost, or full turbo failure. On a track where a constant boost is required, this becomes a serious problem.

Cooling is also poor in the N54. The engine bay becomes very hot due to twin turbos, and the factory cooling system struggles to maintain safe levels during continuous laps. Overheating often leads to limp mode, where the engine reduces power to protect itself, cutting short the driving experience.

Carbon build-up is another issue similar to the Volkswagen EA888, since the N54 also uses direct injection. Intake valves clog up, reducing performance and creating more strain on the motor. When combined with turbo and fuel pump problems, this makes the engine highly unreliable under stress.

While tuners love the N54 for its ability to produce big horsepower with modifications, the truth is that without major upgrades, it does not survive track days well. Many drivers who have taken it to circuits have reported repeated breakdowns. It remains one of BMW’s most exciting but also most fragile engines when used under heavy conditions.