The Jeep Cherokee stands as one of America’s most beloved and enduring vehicles, earning its reputation through decades of reliable performance across diverse terrains and challenging conditions. This robust SUV has captured the hearts of countless drivers who value dependability, versatility, and the confidence that comes with owning a vehicle built to last.

Whether you’re commuting through city streets, tackling weekend adventures on mountain trails, or hauling family gear for summer vacations, your Cherokee deserves the best care possible to ensure it continues delivering the performance you depend on.

Proper maintenance represents the foundation of vehicle longevity, and the Cherokee responds exceptionally well to consistent attention and preventive care. Many owners discover that with the right approach to upkeep, their Cherokee can easily surpass 200,000 miles while maintaining excellent performance and reliability.

The secret lies in understanding the specific needs of your vehicle and implementing proven strategies that address both routine maintenance and potential problem areas before they become costly repairs.

The following ten maintenance hacks have been tested and refined by Cherokee enthusiasts, professional mechanics, and long-term owners who have successfully kept their vehicles running strong for years beyond typical expectations.

These strategies focus on practical, cost-effective approaches that any owner can implement, regardless of their mechanical experience level. Each hack targets critical systems and components that directly impact your Cherokee’s longevity and performance.

By incorporating these proven techniques into your regular maintenance routine, you’ll not only extend your Cherokee’s lifespan but also improve its fuel efficiency, reduce unexpected breakdowns, and maintain higher resale value. The investment in proper care today pays dividends in reliable transportation and peace of mind for many years to come.

1. Master the Art of Oil Change Intervals and Quality Selection

Your Cherokee’s engine represents its heart, and proper lubrication forms the lifeline that keeps this vital component operating smoothly for hundreds of thousands of miles. Understanding the relationship between oil quality, change intervals, and engine longevity can make the difference between a Cherokee that lasts 150,000 miles and one that easily surpasses 300,000 miles.

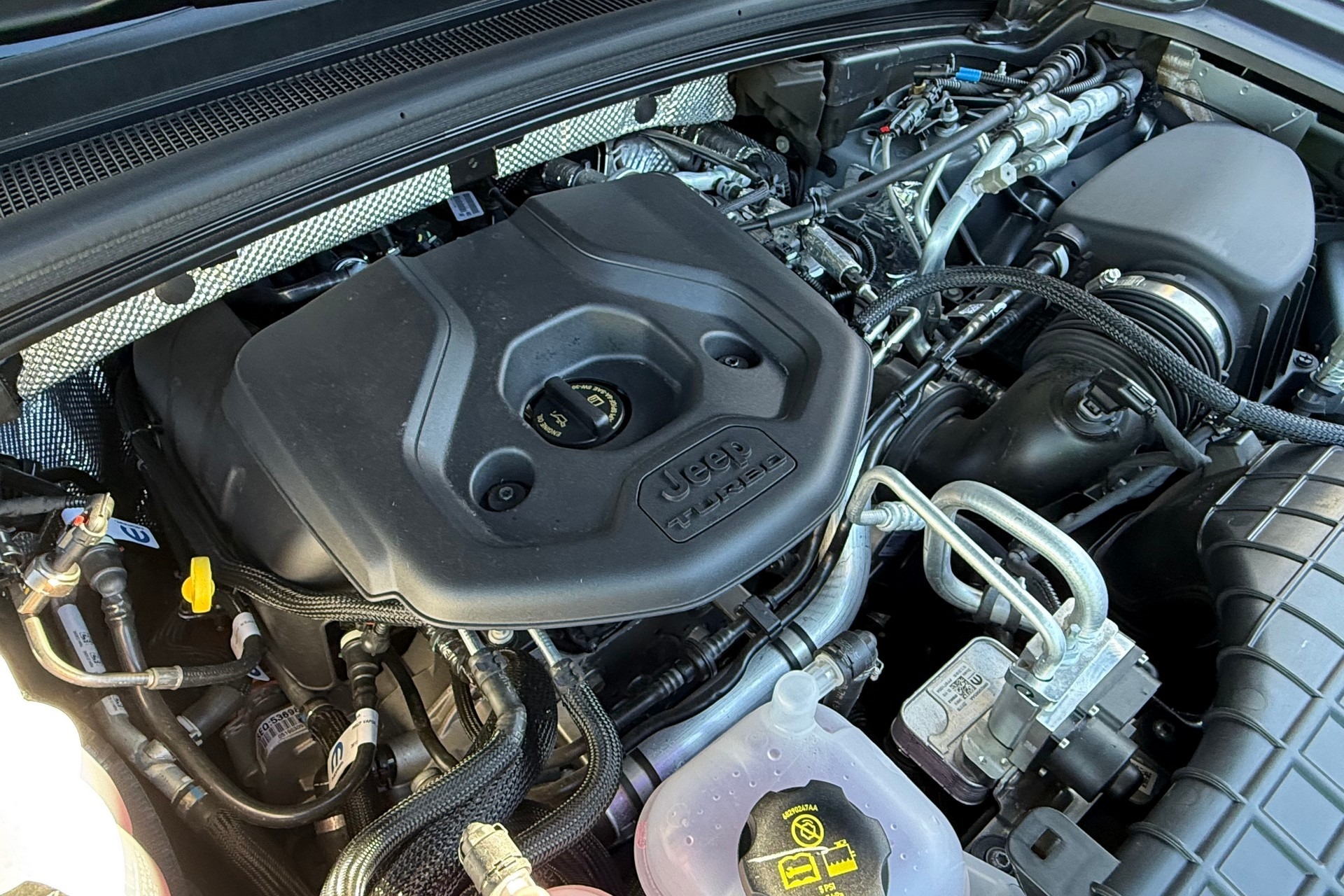

Modern Cherokee engines require high-quality motor oil that meets specific viscosity requirements and performance standards. The 3.7-liter V6 and 2.4-liter four-cylinder engines commonly found in Cherokee models perform best with 5W-20 or 5W-30 motor oil, depending on your specific model year and engine configuration.

However, the main lies not just in using the correct viscosity but in selecting oil that exceeds the minimum API requirements specified in your owner’s manual. Full synthetic oils provide superior protection compared to conventional or synthetic blend alternatives, especially in extreme temperature conditions and during extended driving periods.

These advanced lubricants maintain their protective properties longer, resist thermal breakdown better, and provide enhanced flow characteristics during cold starts when engine wear is most likely to occur. While synthetic oil costs more upfront, the extended drain intervals and superior protection make it a worthwhile investment for long-term engine health.

The timing of oil changes proves just as critical as oil quality. While many quick-lube facilities recommend 3,000-mile intervals regardless of oil type, modern synthetic oils in Cherokee engines can safely extend to 7,500 or even 10,000 miles under normal driving conditions.

However, severe driving conditions such as frequent short trips, extreme temperatures, dusty conditions, or towing require more frequent changes, typically every 5,000 miles. Regular oil analysis through companies like Blackstone Laboratories can provide valuable insights into your engine’s internal condition and help optimize change intervals specific to your driving patterns.

This scientific approach removes guesswork and allows you to maximize both protection and cost-effectiveness while monitoring wear metals, contamination levels, and additive depletion rates that indicate optimal change timing.

2. Implement a Comprehensive Cooling System Maintenance Program

The cooling system in your Cherokee works tirelessly to maintain optimal operating temperatures, preventing catastrophic engine damage that can result from overheating. A well-maintained cooling system not only protects your engine but also contributes to better fuel economy, reduced emissions, and extended component life throughout the drivetrain.

Coolant replacement represents one of the most overlooked yet critical maintenance procedures for long-term Cherokee reliability. Factory-fill coolant typically lasts 100,000 miles or five years, whichever comes first, but environmental factors and driving conditions can reduce its effectiveness.

Old coolant loses its ability to prevent corrosion, transfer heat efficiently, and protect against freezing and boiling, leaving your engine vulnerable to expensive damage. When replacing coolant, always use the specific type recommended by Jeep for your model year.

Mixing different coolant types can create chemical reactions that reduce effectiveness and potentially damage cooling system components. The process requires completely flushing the old coolant, cleaning the system with appropriate chemicals to remove scale and corrosion deposits, and refilling with fresh coolant mixed to the correct concentration.

Radiator maintenance extends beyond coolant changes to include regular cleaning of the radiator fins and checking for leaks or damage. Road debris, insects, and accumulated dirt can reduce cooling efficiency by blocking airflow through the radiator core.

Gentle cleaning with a soft brush and garden hose, working from the back of the radiator forward, removes these obstructions and restores optimal heat transfer capability. Thermostat replacement at recommended intervals prevents cooling system problems before they occur. A failing thermostat can cause overheating, poor heater performance, and reduced fuel economy.

Water pump inspection during major service intervals allows early detection of bearing wear, seal leakage, or impeller damage that could lead to sudden cooling system failure. These proactive measures cost far less than emergency repairs and protect against catastrophic engine damage.

Also Read: Jeep Cherokee Revival: Anticipation Builds for 2026 Model Launch

3. Establish a Rigorous Transmission Service Schedule

Your Cherokee’s transmission represents one of its most expensive and critical components, requiring specific maintenance procedures to ensure smooth operation and maximum service life. Whether equipped with a manual or automatic transmission, following a comprehensive service schedule prevents costly failures and maintains optimal performance characteristics.

Automatic transmission fluid serves multiple functions beyond simple lubrication, acting as a hydraulic medium, coolant, and cleaning agent within the transmission. This fluid endures extreme temperatures, pressures, and chemical stresses that gradually break down its protective properties.

Unlike engine oil, transmission fluid degradation is less obvious to most drivers, often leading to neglect until major problems develop. Complete transmission service involves draining the old fluid, replacing the filter, cleaning the pan, and refilling with fresh fluid that meets Jeep’s specifications.

This process removes accumulated debris, wear particles, and degraded fluid that can damage internal components if left in service too long. The transmission filter captures contaminants that could otherwise circulate through the system, causing accelerated wear and eventual failure.

Service intervals vary depending on driving conditions, but severe service schedules apply to most Cherokee owners. City driving with frequent stops, highway driving in mountainous terrain, trailer towing, and extreme temperature exposure all qualify as severe service conditions requiring more frequent transmission maintenance. Under these conditions, servicing every 30,000 to 50,000 miles provides optimal protection.

Manual transmission maintenance, while less complicated, requires equal attention to fluid quality and change intervals. Manual transmission fluid lubricates gears, synchronizers, and bearings while providing smooth shifting characteristics.

Worn fluid can cause difficult shifting, gear grinding, and accelerated component wear. Regular fluid changes every 60,000 miles or as specified in severe service schedules maintain smooth operation and prevent expensive repairs.

4. Develop a Proactive Air Filter Maintenance Strategy

The air filtration system in your Cherokee plays a crucial role in engine performance, fuel economy, and longevity by ensuring only clean air enters the combustion chambers. A comprehensive air filter maintenance strategy addresses both the engine air filter and cabin air filter, each serving distinct but important functions in vehicle operation and occupant comfort.

Engine air filter replacement directly impacts your Cherokee’s performance and efficiency. A clean filter allows optimal airflow to the engine, ensuring proper fuel mixture ratios and complete combustion.

As the filter becomes clogged with dirt, dust, pollen, and debris, airflow restriction increases, forcing the engine to work harder and consume more fuel while producing less power. Inspection intervals should occur every 15,000 miles or annually, with replacement typically required every 30,000 miles under normal conditions.

However, driving in dusty environments, construction zones, or areas with high pollen counts may necessitate more frequent replacement. Visual inspection provides a reliable indicator of filter condition, with heavily soiled or damaged filters requiring immediate replacement regardless of mileage.

High-quality aftermarket filters often provide superior filtration and longer service life compared to basic replacement filters. Brands like K&N, Fram, and Purolator offer filters engineered specifically for Cherokee applications, with designs that optimize airflow while maintaining excellent filtration efficiency.

Some performance-oriented filters can be cleaned and reused, providing long-term cost savings and environmental benefits. Cabin air filter maintenance affects occupant comfort and health by filtering the air entering the passenger compartment through the heating, ventilation, and air conditioning system.

A clogged cabin filter restricts airflow, reduces air conditioning efficiency, and allows pollutants, allergens, and odors to enter the cabin. Regular replacement every 15,000 to 20,000 miles maintains optimal air quality and HVAC system performance while preventing strain on the blower motor and related components.

5. Perfect Your Brake System Inspection and Maintenance Routine

Brake system maintenance represents a critical safety consideration that also impacts your Cherokee’s long-term reliability and operating costs. A comprehensive brake maintenance routine prevents expensive repairs, ensures optimal stopping performance, and extends component life through proactive care and timely replacement of wear items.

Brake fluid serves as the hydraulic medium that transfers force from the brake pedal to the wheels, operating under extreme pressures and temperatures that gradually degrade its performance characteristics.

Fresh brake fluid provides a consistent pedal feel, optimal stopping power, and protection against internal corrosion that can damage expensive brake system components. Brake fluid replacement every two years or 30,000 miles prevents moisture absorption that reduces boiling point and causes internal corrosion.

Contaminated brake fluid can lead to brake fade during heavy use, a spongy pedal feel, and premature component failure throughout the hydraulic system. The replacement process requires complete system flushing to remove old fluid and any accumulated contaminants that could affect performance.

Brake pad and rotor inspection should occur during every tire rotation, allowing early detection of wear patterns that indicate alignment issues, sticking calipers, or other problems that could cause premature wear or safety concerns. Measuring pad thickness and rotor condition provides objective data for replacement timing, preventing metal-to-metal contact that causes expensive rotor damage.

Quality brake components provide superior performance and longevity compared to economy alternatives. Premium brake pads offer better stopping power, reduced noise, and longer service life, while high-quality rotors resist warping and provide consistent performance over their service life. Investing in quality components reduces long-term costs and ensures reliable braking performance when you need it most.

Regular brake system bleeding removes air bubbles that can cause a spongy pedal feel and reduced stopping power. This procedure also provides an opportunity to inspect brake lines, hoses, and connections for signs of wear, damage, or leakage that could lead to brake failure.

6. Optimize Your Cherokee’s Electrical System Health

The electrical system in modern Cherokee models controls everything from engine management to comfort features, making its proper maintenance essential for reliable operation and component longevity. A comprehensive electrical maintenance approach addresses battery care, alternator performance, and connection integrity to prevent failures and extend system life.

Battery maintenance begins with regular inspection of terminals, cables, and mounting hardware for signs of corrosion, damage, or loose connections. Corroded terminals create electrical resistance that can cause starting problems, alternator overwork, and damage to sensitive electronic components.

Cleaning terminals with a wire brush and applying protective spray prevents corrosion and ensures optimal electrical flow. Battery testing should occur annually or whenever starting problems develop. Modern batteries can fail suddenly without obvious warning signs, leaving you stranded at inconvenient times.

Load testing and voltage checks provide objective measures of battery condition, allowing planned replacement before failure occurs. Quality batteries from reputable manufacturers provide longer service life and better performance than economy alternatives.

Alternator performance directly affects battery life and the entire electrical system operation. The alternator must provide sufficient voltage and current to power all electrical accessories while maintaining battery charge. Worn alternator components can cause undercharging that shortens battery life or overcharging that damages electrical components throughout the vehicle.

Ground connections throughout the chassis require periodic inspection and cleaning to maintain proper electrical flow. Poor grounds can cause erratic operation of electrical components, premature component failure, and difficult-to-diagnose electrical problems.

Cleaning ground connections and applying dielectric grease prevents corrosion and ensures reliable electrical operation. Modern Cherokee models include sophisticated engine management systems that rely on numerous sensors and actuators to optimize performance and emissions.

These components require clean, stable electrical power to function properly. Regular electrical system maintenance prevents problems that could affect engine performance, fuel economy, and emissions compliance.

7. Execute Strategic Drivetrain and Suspension Maintenance

The drivetrain and suspension systems in your Cherokee work together to provide smooth power delivery, comfortable ride quality, and precise handling characteristics. Proper maintenance of these interconnected systems prevents expensive repairs while maintaining the driving experience that makes Cherokee ownership enjoyable.

Four-wheel drive systems in Cherokee models require specific maintenance procedures to ensure reliable operation when traction conditions demand maximum capability. Transfer case fluid provides lubrication for gears and chains that transfer power between front and rear axles.

Old or contaminated fluid can cause difficult shifting, excessive wear, and eventual component failure that requires expensive repairs. Front and rear differential service maintains optimal performance of the final drive components that transfer power to the wheels.

Differential fluid lubricates gears operating under extreme loads and provides cooling for components generating significant heat during normal operation. Service intervals vary based on driving conditions, with severe service requiring more frequent attention.

Suspension component inspection should occur during regular service intervals, with particular attention to shock absorbers, struts, bushings, and ball joints that affect ride quality and handling precision. Worn suspension components not only reduce comfort but also cause accelerated tire wear, poor handling, and potential safety concerns during emergency maneuvers.

CV joints and axle components require periodic inspection for signs of wear, damage, or contamination that could lead to failure. Torn CV boots allow dirt and moisture to enter joints while allowing protective grease to escape, causing rapid wear and eventual joint failure. Early detection and boot replacement prevent expensive joint replacement and maintain smooth power delivery.

Regular alignment checks ensure optimal tire wear patterns and precise handling characteristics. Misalignment causes uneven tire wear, reduced fuel economy, and poor handling that affects both performance and safety. Alignment specifications should be checked annually or whenever new tires are installed to maximize tire life and maintain optimal vehicle performance.

8. Maintain Peak Fuel System Performance and Efficiency

Your Cherokee’s fuel system delivers clean fuel at precise pressures to ensure optimal combustion, emissions compliance, and maximum fuel economy. Maintaining this system through regular service and quality fuel selection prevents expensive repairs while optimizing performance and efficiency.

Fuel filter replacement removes contaminants that could damage expensive fuel injection components or reduce engine performance. Modern gasoline contains various additives and potential contaminants that can accumulate in the fuel system over time. A clean fuel filter ensures that only clean fuel reaches the engine while protecting sensitive injection components from damage.

Fuel injection cleaning removes deposits that accumulate on injector tips, intake valves, and combustion chambers as time goes on. These deposits can cause rough idle, poor acceleration, reduced fuel economy, and increased emissions. Professional cleaning services or high-quality fuel additives remove these deposits and restore optimal fuel delivery and combustion efficiency.

Quality fuel selection impacts long-term engine health and performance. Top-tier gasolines contain additional detergent additives that help prevent deposit formation while providing better engine protection compared to basic gasoline formulations.

While premium fuel is not required for most Cherokee engines, using quality fuel from reputable stations provides better long-term value through improved performance and reduced maintenance requirements. Fuel pump maintenance prevents sudden failures that can leave you stranded.

Modern electric fuel pumps operate continuously while the engine runs, generating heat and wear that gradually reduces performance. Keeping the fuel tank at least one-quarter full helps cool the pump and extend its service life, while fuel filter replacement prevents contamination that could damage pump components.

Carbon cleaning services remove deposits from intake valves and combustion chambers that direct-injection engines are particularly prone to developing. These deposits reduce performance, increase emissions, and can cause expensive engine problems if allowed to accumulate. Regular carbon cleaning maintains optimal engine performance and prevents costly repairs.

Also Read: Hidden Gem: Salvage Title Jeep Cherokee with Surprising Features

9. Implement Comprehensive Tire Care and Rotation Programs

Proper tire maintenance represents one of the most cost-effective ways to extend your Cherokee’s service life while improving safety, performance, and fuel economy. A comprehensive tire care program addresses inflation pressure, rotation schedules, alignment, and replacement timing to maximize tire life and vehicle performance.

Tire pressure monitoring should occur monthly, as properly inflated tires provide optimal contact patch, even wear patterns, and maximum fuel efficiency. Under-inflated tires generate excessive heat, wear prematurely, and reduce fuel economy while creating safety risks during emergency maneuvers. Over-inflated tires provide harsh ride quality, reduced traction, and uneven wear patterns that shorten tire life.

Rotation schedules help ensure even wear across all four tires, maximizing total tire life and maintaining optimal traction characteristics. Cherokee models with different front and rear tire sizes require modified rotation patterns, while all-wheel drive systems may have specific rotation requirements to prevent drivetrain stress.

Following manufacturer recommendations for rotation patterns and intervals prevents premature tire replacement and maintains optimal performance. Wheel alignment directly affects tire wear patterns, fuel economy, and handling precision.

Misalignment causes rapid tire wear, poor handling characteristics, and increased fuel consumption that can cost hundreds of dollars in premature tire replacement and reduced efficiency. Regular alignment checks ensure optimal tire contact with the road surface while maintaining precise steering response.

Tire selection impacts performance, longevity, and cost-effectiveness. Quality tires from reputable manufacturers provide better tread life, improved traction, and superior durability compared to budget alternatives. All-season tires work well for most Cherokee applications, while specialized tires for specific conditions or performance requirements may provide better value for particular use cases.

Spare tire maintenance ensures roadside assistance capability when needed. Regular inspection of spare tire pressure, condition, and mounting hardware prevents surprises when emergency tire changes become necessary. Full-size spare tires should be included in rotation schedules to ensure even wear and optimal performance when pressed into service.

10. Develop a Preventive Maintenance Documentation System

Establishing a comprehensive maintenance documentation system provides the foundation for optimal Cherokee longevity by ensuring no critical service items are overlooked while building valuable records for warranty claims, resale value, and troubleshooting purposes.

Service record keeping should include dates, mileage, parts used, and services performed for every maintenance procedure. This information helps identify patterns, optimize service intervals, and provides valuable documentation for warranty claims or resale transactions. Digital apps, spreadsheets, or traditional logbooks all work effectively when used consistently.

Parts quality documentation helps track component performance and identify reliable suppliers for future service needs. Recording part numbers, manufacturers, and performance observations helps optimize future purchasing decisions while identifying components that provide exceptional value or should be avoided.

Cost tracking provides insights into total ownership expenses and helps identify cost-effective maintenance strategies. Understanding the relationship between preventive maintenance costs and repair avoidance helps justify quality parts and services while optimizing maintenance timing for maximum value.

Maintenance scheduling prevents missed services that could lead to expensive repairs or component failures. Creating schedules based on mileage, time intervals, and driving conditions ensures all critical services receive attention before problems develop. Modern smartphone apps and calendar systems make scheduling and reminder systems simple to implement and maintain.

Professional service provider relationships provide access to expertise and specialized equipment that enhance maintenance quality while often reducing costs through volume discounts and loyalty programs. Building relationships with trusted mechanics, parts suppliers, and service facilities provides valuable resources for complicated repairs and expert advice when problems arise.

This systematic approach to Cherokee maintenance, combining these ten proven strategies with consistent execution and quality components, provides the foundation for exceptional vehicle longevity and reliable performance that can easily exceed 300,000 miles of trouble-free operation.