The Chevrolet Cobalt holds a special place in the hearts of many American drivers who sought an affordable, compact vehicle during its production years from 2005 to 2010. This small car promised reliability and fuel efficiency at a budget-friendly price point, making it an attractive option for first-time buyers, college students, and families looking for a dependable second vehicle.

However, beneath its appealing exterior and reasonable sticker price lurked numerous mechanical and electrical issues that would prove costly for owners. Despite General Motors’ intentions to create a competitive entry-level vehicle, the Cobalt suffered from a multitude of problems that shortened its lifespan.

Many owners discovered that their seemingly reliable transportation developed serious issues well before reaching the decade mark. These problems ranged from minor inconveniences to major safety hazards that could leave drivers stranded or worse.

The reality for Cobalt owners became clear as repair bills mounted and reliability declined. What started as an economical transportation solution often transformed into a financial burden that many drivers could not sustain. From electrical gremlins to transmission failures, power steering problems to ignition switch defects, the Cobalt’s reputation suffered as word spread about its numerous shortcomings.

Understanding these common failure points can help current Cobalt owners prepare for potential issues and assist prospective buyers in making informed decisions. The following eighteen problems represent the most frequent and destructive issues that plague this vehicle, often leading to premature retirement or costly repairs that exceed the car’s value.

1. Ignition Switch Defects

Among all the problems tied to the Chevy Cobalt, the ignition switch defect is the one that received the widest attention because of how dangerous it was. The switch tended to slip out of the “run” position into “accessory” or “off” without the driver’s input. When this happened while the car was moving, the engine would shut off suddenly.

That meant the steering became heavy, the brakes lost power assistance, and the airbags were disabled. In short, the driver lost control features that were needed in emergencies, leaving both the driver and passengers at great risk.

The issue was triggered by very simple actions. Something as small as a heavy keychain bouncing while driving could cause the switch to turn by itself. Rough roads or normal vibrations from the engine also increased the chances of it happening. Drivers often did not realize the danger until the vehicle stalled on the highway or failed to respond in a critical moment.

General Motors was forced to announce a massive recall that covered millions of cars, including the Cobalt. Even though repairs were offered, many cars had already been involved in accidents by the time the recall came.

Families of drivers who lost loved ones in crashes tied to this defect pushed for accountability, which further cemented the ignition switch issue as one of the most infamous failures ever linked to the Cobalt.

For owners who ignored the recall or never had their switch replaced, the car remained unsafe. That made this defect one of the most common reasons a Cobalt was retired earlier than expected.

2. Power Steering Failure

The power steering system in the Chevy Cobalt had its own set of weaknesses that left many drivers frustrated and, at times, unsafe. Unlike older vehicles that used hydraulic power steering, the Cobalt relied on an electric power steering setup. While it reduced maintenance needs compared to fluid-driven systems, it was far more prone to sudden failures.

Owners often reported that the steering assist would cut out without warning. One moment the wheel turned easily, and the next it became heavy, especially at low speeds when the driver needed the most help.

Parking or making tight turns suddenly became a difficult task, particularly for younger or smaller drivers who could not muscle the steering wheel. This problem occurred across several model years, proving it was not isolated to a single batch of cars.

At the heart of the issue was the electric steering motor and its control module. Both were sensitive to heat, electrical surges, and wear. Once they failed, the car needed new parts to restore steering assist. The cost was another problem.

Repairs often ranged from eight hundred to fifteen hundred dollars, which was a heavy amount for owners of a car that had already lost value with age. Even after repair, some Cobalts developed the same steering problem again years later.

This created a cycle of breakdown and repair that pushed many owners to give up on their cars. For some, the risk of losing steering assist while driving was enough to park the vehicle permanently. This made steering failure one of the clearest reasons the Cobalt often did not last a decade.

Also Read: 5 Chevrolet Malibu Models With Rock-Solid Engine

3. Transmission Failures

The transmission system in the Chevy Cobalt was another weak link that sent many cars to the junkyard earlier than expected. Both the four-speed and five-speed automatic variants suffered from premature failures, making them expensive to maintain. Owners faced issues such as rough or delayed shifting, slipping between gears, loss of certain gears altogether, and total failure of the transmission unit.

The four-speed automatic was especially vulnerable in its valve body and solenoid pack assemblies. When these components wore out, gear changes became erratic. Some drivers noticed the car jolting violently during changes, while others had gears that refused to engage.

On the five-speed automatic, torque converter failures and premature clutch wear were common. These problems required either a rebuild or a replacement, both of which cost far more than what most owners were willing to spend on an aging compact car.

Transmission repair was rarely cheap. A remanufactured transmission with installation often costs between two thousand and four thousand dollars. For a car like the Cobalt, which already had a modest resale price, many owners decided that it was not worth spending that kind of money. Instead, they abandoned the car altogether once the transmission failed.

Even the manual versions of the Cobalt were not free from issues. The clutch often wore out quickly in city traffic, and drivers who ignored the signs faced complete clutch failure. When transmission failure struck, it usually spelled the end of the road for the car, making this one of the most common reasons a Cobalt died before ten years.

4. Engine Oil Consumption Problems

Another common issue that cut short the lifespan of many Chevy Cobalts was excessive oil consumption. This was especially frequent in models fitted with the 2.2-liter Ecotec engine. Instead of lasting smoothly between oil changes, many of these engines burned through oil at alarming rates.

Some owners reported adding a quart of oil every one thousand miles, which was far above normal expectations. The cause was linked to design weaknesses inside the Ecotec engine. Piston rings did not always seal correctly, allowing oil to seep into the combustion chambers where it was burned off.

Valve stem seals also wore down early, letting oil slip into places it did not belong. To add to the problem, the PCV (positive crankcase ventilation) system sometimes malfunctioned, making oil consumption even worse.

Running low on oil created serious damage. Without enough lubrication, the engine’s internal components, such as bearings, camshafts, and pistons, began to wear out quickly. Drivers who failed to check their oil levels often faced catastrophic engine failure long before the car reached 100,000 miles.

Once the engine was damaged this way, repairs were extremely costly, often requiring a complete engine replacement. The issue frustrated many owners because it was not always easy to detect until damage had already been done. Some drivers only realized the problem after their engine seized on the road.

Since replacing or rebuilding an engine often costs more than the car’s value, many Cobalts were scrapped at this stage. For that reason, oil consumption problems became one of the strongest reasons the Cobalt failed to make it to a decade of use.

5. Air Conditioning System Failures

While not as dangerous as some of the other issues, air conditioning problems played a major role in making Chevy Cobalts unpleasant to own, especially in hot climates. The air conditioning system had several weak components that frequently failed and left drivers without proper cooling during the summer months.

The compressor was the most common point of failure. Once the compressor failed internally, it often spread metal debris throughout the refrigerant system. That meant not only replacing the compressor but also flushing or replacing other parts such as the condenser, expansion valve, and lines. These repairs added up quickly, making the bill too high for a budget compact car.

Evaporator core leaks were another widespread problem. The evaporator was located deep inside the dashboard, which meant repairing it required removing much of the dashboard assembly. The labor alone could take eight to twelve hours, making it one of the most expensive repairs relative to the car’s value. Many owners simply gave up on fixing their A/C once they discovered how much work was involved.

Electrical issues also contributed to system failures. Faulty relays, switches, or control modules sometimes caused the air conditioning to stop working even when the mechanical parts were fine. Tracing these faults required skilled technicians, adding more expense for owners.

Driving a car without air conditioning might be bearable in cooler regions, but in areas with hot summers, it made the Cobalt very uncomfortable. Many owners sold or scrapped their vehicles rather than deal with repeated A/C problems. For that reason, air conditioning failures added to the list of factors that shortened the lifespan of this model.

6. Fuel Pump Problems

Fuel pump failures frequently sideline Chevrolet Cobalts, often without warning signs that would allow owners to prepare for repairs. The electric fuel pump assembly, located inside the fuel tank, experiences various problems, including motor failure, pressure regulator issues, and fuel level sensor malfunctions.

Fuel pump motor failures typically manifest as intermittent stalling or difficulty starting, particularly when the fuel tank is less than half full. Some pumps develop internal problems that allow them to run but fail to generate adequate pressure. Replacement costs can be substantial because accessing the pump requires dropping the fuel tank, adding considerable labor time.

7. Coolant System Leaks

Cooling system problems frequently destroy Chevrolet Cobalt engines through overheating damage that occurs when coolant leaks develop and go unnoticed. These vehicles experience various cooling system failures, including radiator leaks, water pump failures, thermostat problems, and cooling hose deterioration.

Water pump failures represent particularly common problems, often occurring around sixty to eighty thousand miles. The pump may develop external leaks or internal problems that prevent proper coolant circulation.

Radiator problems frequently develop as vehicles age, with plastic tank failures being especially common. The plastic end tanks can crack or separate from the aluminum core, causing rapid coolant loss.

8. Electrical System Malfunctions

Electrical problems plague many Chevrolet Cobalts throughout their operational lives, creating frustrating intermittent issues that can be expensive and time-consuming to diagnose and repair.

Body control module failures represent some of the most expensive electrical problems. This module controls numerous functions, including interior lighting, power windows, door locks, and security systems.

When it fails, multiple systems may stop working simultaneously. Replacement modules must be programmed to match the specific vehicle, requiring specialized equipment. Alternator failures frequently occur as vehicles accumulate mileage, while wiring harness problems create challenging diagnostic situations.

9. Suspension Component Wear

Suspension problems frequently develop in Chevrolet Cobalts as vehicles accumulate mileage and age. The front suspension system experiences heavy wear on struts, control arms, ball joints, and sway bar links.

Front struts commonly fail, causing poor ride quality, excessive bouncing, and reduced handling capability. Ball joint failures create potentially dangerous situations because these components connect control arms to steering knuckles.

When ball joints wear excessively, they can separate, causing loss of vehicle control. Control arm bushings deteriorate prematurely, causing handling problems and allowing excessive movement in the suspension system that creates vibrations and poor handling characteristics.

Also Read: 5 Chevrolets That Stay Affordable Long Term vs 5 That Cost a Fortune

10. Brake System Deterioration

Brake system problems frequently affect Chevrolet Cobalts, creating safety concerns and expensive repair requirements. The brake components often wear more rapidly than expected, requiring premature replacement of pads, rotors, and other system components.

Brake rotor warping represents a common problem that causes pedal pulsation and reduced stopping performance. The thin rotor design makes them particularly susceptible to heat-related warping during heavy braking.

Brake caliper problems frequently develop as vehicles age, with pistons sticking due to corrosion. ABS malfunctions can disable important safety features and create expensive diagnostic challenges.

11. Timing Chain Problems

Timing chain issues frequently plague Chevrolet Cobalts equipped with Ecotec engines, creating expensive repair situations that can destroy engines if left unaddressed. Timing chain stretch represents the most common problem, occurring as the chain lengthens due to wear and loses its ability to maintain proper timing.

Stretched chains cause timing to retard, resulting in poor performance and potential valve interference. Timing chain tensioner failures can cause rapid, catastrophic damage because the tensioner maintains proper chain tension.

When it fails, the chain can skip teeth or become loose enough to allow piston-valve interference. Repair costs are substantial because accessing components requires extensive disassembly.

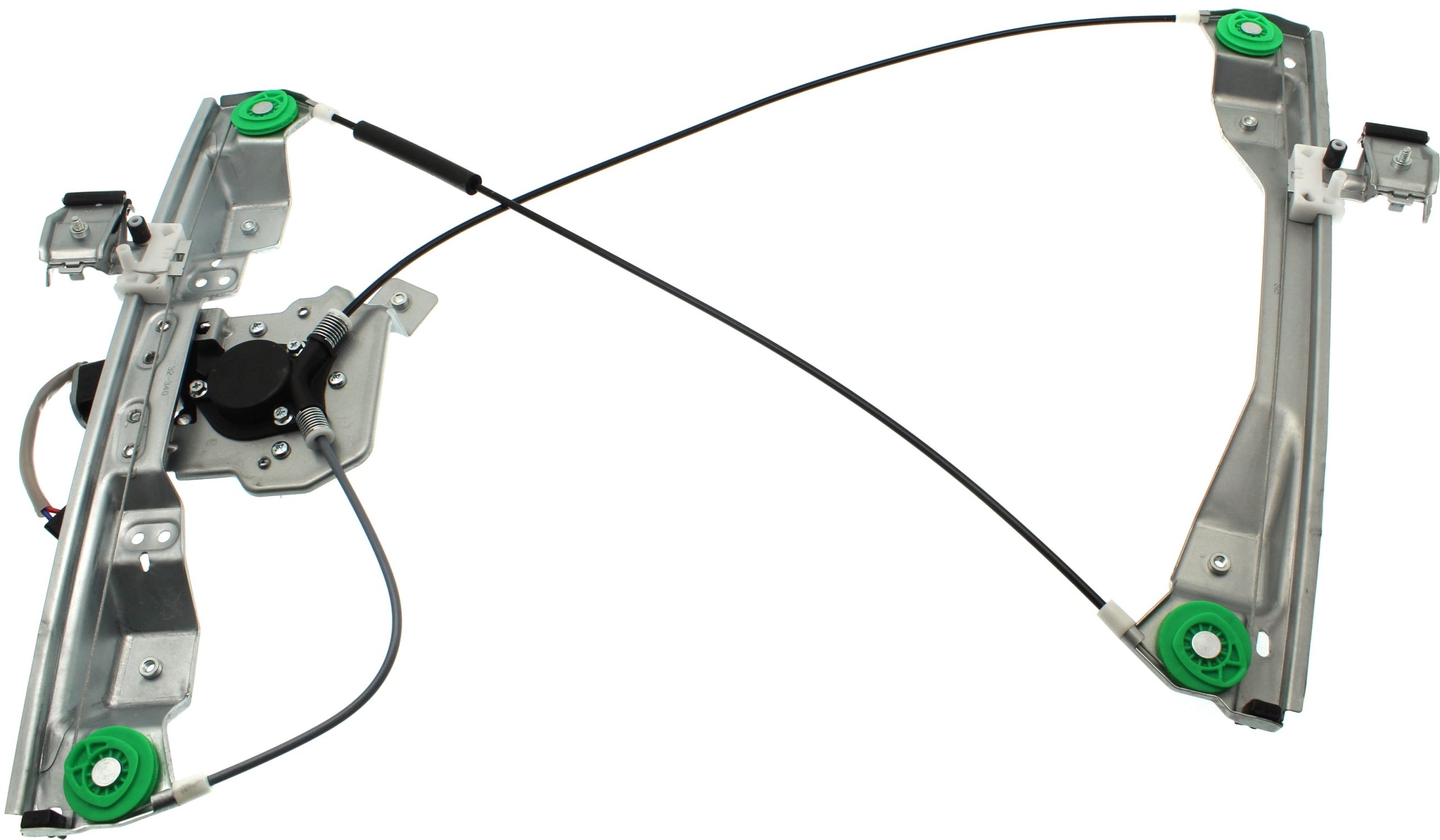

12. Window Regulator Malfunctions

Power window problems frequently affect Chevrolet Cobalts, with regulator failures occurring across all doors but being particularly common in front windows. Cable failures represent the most common problem, occurring when steel cables that raise and lower windows stretch, fray, or break completely.

When cables fail, windows may drop unexpectedly or become impossible to raise. Motor failures within regulator assemblies create situations where windows become completely inoperable.

The electric motors may burn out due to excessive load or age-related deterioration. Repair costs vary depending on which components fail and whether professional installation is required.

13. Fuel System Contamination

Fuel system contamination problems frequently affect Chevrolet Cobalts, particularly as vehicles age and accumulate higher mileage. Water contamination typically enters through condensation in the fuel tank or contaminated fuel from gas stations.

Water cannot be burned in the engine and can cause corrosion throughout the fuel system. Water in fuel causes rough running, stalling, and difficulty starting, particularly in cold weather when water may freeze in fuel lines.

Fuel injector problems frequently develop due to contamination or fuel quality issues. The injectors may become clogged with debris, causing uneven fuel distribution. Carbon deposits throughout the fuel system cause various performance problems requiring expensive cleaning services.

14. Exhaust System Corrosion

Exhaust system problems frequently plague Chevrolet Cobalts due to corrosion, impact damage, and normal wear as vehicles age. Catalytic converter failures represent the most expensive exhaust repairs because replacement converters cost several hundred dollars and require professional installation.

The catalyst material can become contaminated or damaged due to engine problems such as oil consumption or misfiring. Muffler and exhaust pipe corrosion commonly occurs as cobalt age, particularly in regions where road salt is used during winter. Corrosion begins at joints and low points where moisture accumulates, eventually creating holes that allow exhaust gases to escape.

15. Security System Malfunctions

Anti-theft system problems frequently disable Chevrolet Cobalts, creating situations where the vehicle refuses to start despite having no mechanical problems. Passlock sensor failures represent the most common security system problem, occurring when the sensor in the ignition switch fails to recognize the correct key.

When this happens, the security light illuminates, and the engine cranks normally but will not start. Body control module problems can also affect the security system and prevent engine operation. The module may lose programming or develop internal faults. Wiring problems within the security system cause various malfunctions that are difficult to diagnose and repair.

16. HVAC Blower Motor Issues

Heating, ventilation, and air conditioning blower motor problems frequently affect Chevrolet Cobalts, causing loss of cabin air circulation that can make driving uncomfortable or dangerous. Blower motor resistor failures commonly cause problems with fan speed control, typically resulting in the blower operating only on the highest speed setting.

Blower motor bearing failures create noise problems that become extremely annoying for occupants. Worn bearings cause squealing, grinding, or rattling noises that typically worsen as time goes on. Accessing the blower motor for replacement often requires extensive dashboard disassembly, which makes labor costs substantial.

17. Rust and Corrosion Problems

Corrosion problems frequently affect Chevrolet Cobalts, particularly in regions where road salt is used during winter months or where high humidity accelerates oxidation. These vehicles show particular susceptibility to rust formation around wheel wells, door frames, rocker panels, and exhaust system components.

Body panel corrosion often begins around wheel wells and door openings, where water and debris accumulate. The paint system may not provide adequate long-term protection against corrosion.

Frame and structural component corrosion creates safety concerns because these components provide crash protection. Salt and moisture can cause rapid deterioration of suspension mounting points and exhaust hangers.

Also Read: 5 Chevrolets That Hold Value at Trade‑In vs 5 That Dealers Ignore

18. Engine Mount Deterioration

Engine mount problems frequently develop in Chevrolet Cobalts as rubber components deteriorate due to age, heat, and vibration. Failed engine mounts allow excessive engine movement that can cause various problems, including vibration, noise, and potential damage to connected components such as exhaust pipes and wiring harnesses.

The symptoms include increased vibration during idle, clunking noises during acceleration, and visible engine movement. Replacement of engine mounts requires proper support of the engine during repair, making this job challenging. The cost varies depending on which mounts fail and whether OEM or aftermarket parts are used.

Chevrolet Cobalt owners face numerous potential problems that can destroy their vehicles well before reaching ten years of age. These eighteen issues represent the most common and destructive problems that plague this vehicle, often creating repair costs that exceed the car’s value and forcing owners to seek alternative transportation solutions.

The Chevy Cobalt was designed to be an affordable car that could serve as a daily driver for students, young professionals, and families on a budget. While many owners enjoyed years of use from their vehicles, recurring problems made it difficult for the Cobalt to last beyond a decade without heavy repairs.

Issues such as ignition switch defects, power steering failure, transmission breakdowns, and high oil consumption damaged the trust people had in the model. Other concerns, like weak suspension, electrical faults, and air conditioning failures, added to the list of reasons why the car often ended up retired earlier than expected.

A Cobalt that received consistent care, timely fluid changes, and careful driving habits often survived longer than those that were neglected. Still, the design weaknesses meant that even well-maintained cars sometimes faced expensive repairs that outweighed the vehicle’s value. This forced many owners to make the hard choice of moving on from the car before it reached its full potential lifespan.

Looking back, the Cobalt remains a lesson in how affordability alone is not enough to guarantee lasting reliability. Without addressing core engineering issues, even a popular car can quickly fade from the roads long before its time.