Truck buyers usually care about how strong and long-lasting the engine is before they even consider comfort or design. A pickup might look solid on the outside, but if the engine cannot stand many years of heavy use, then the truck loses its value quickly.

Diesel engines have always been known for toughness and long service life, which is why farmers, contractors, and truck owners often choose them. But not every diesel motor is built the same. Some engines keep running long after the truck itself has worn out, while others begin to fail once pushed too hard.

When people speak about reliable diesel engines, they often remember those power plants that keep moving under pressure, hauling heavy loads without showing weakness.

They also think about motors that stay strong after hundreds of thousands of miles, needing only routine care. But there are also those engines that do not meet expectations, where design flaws or weak parts make them break down faster than buyers had hoped.

For this reason, it is useful to separate the diesel engines that stand as true survivors from those that disappoint owners. The first group can be trusted for many years of dependable use, while the second group serves as a warning of what to avoid when shopping for a truck.

5 Diesel Engines That Outlive Pickups

1. Cummins 5.9L 12-Valve

The Cummins 5.9L 12-valve engine, used in Dodge Ram pickups through the early and mid-1990s, has become a symbol of long-lasting diesel strength. It is often described as an engine that could outlive the body and frame of the truck itself.

One major reason behind its reputation is the simple yet solid design. This motor does not depend on complicated electronics, which makes it less likely to fail because of wiring or sensors. Instead, it runs with a mechanical fuel system that can be serviced easily by experienced mechanics.

Owners of trucks powered by the 5.9L 12-valve often report running them well beyond 500,000 miles without serious trouble. With proper care, such as timely oil changes and attention to cooling, this engine can even reach one million miles.

Its ability to deliver steady torque at low speeds also makes it a favorite among those who use their trucks for towing or hauling. When compared with modern engines that require advanced computer systems, this Cummins model shows how durable a straightforward design can be.

The block is made from strong cast iron, and the internals are designed to handle stress. That is why farmers and workers who depend on their trucks daily still search for these engines today, even decades after they were first sold. Even though the trucks themselves may rust or wear down, the 12-valve Cummins keeps running with very little complaint.

This motor is often swapped into other vehicles as well, from older trucks to custom builds, simply because owners know they can trust its performance. Mechanics also enjoy working on it because parts are widely available and the system is not complicated.

For many truck enthusiasts, this engine represents the highest example of diesel toughness. Its long record of reliability has earned it respect across generations of pickup owners, making it one of the most durable diesel engines ever built.

Also Read: 5 Diesel Engines That Outlast the Vehicle and 5 That Constantly Fail

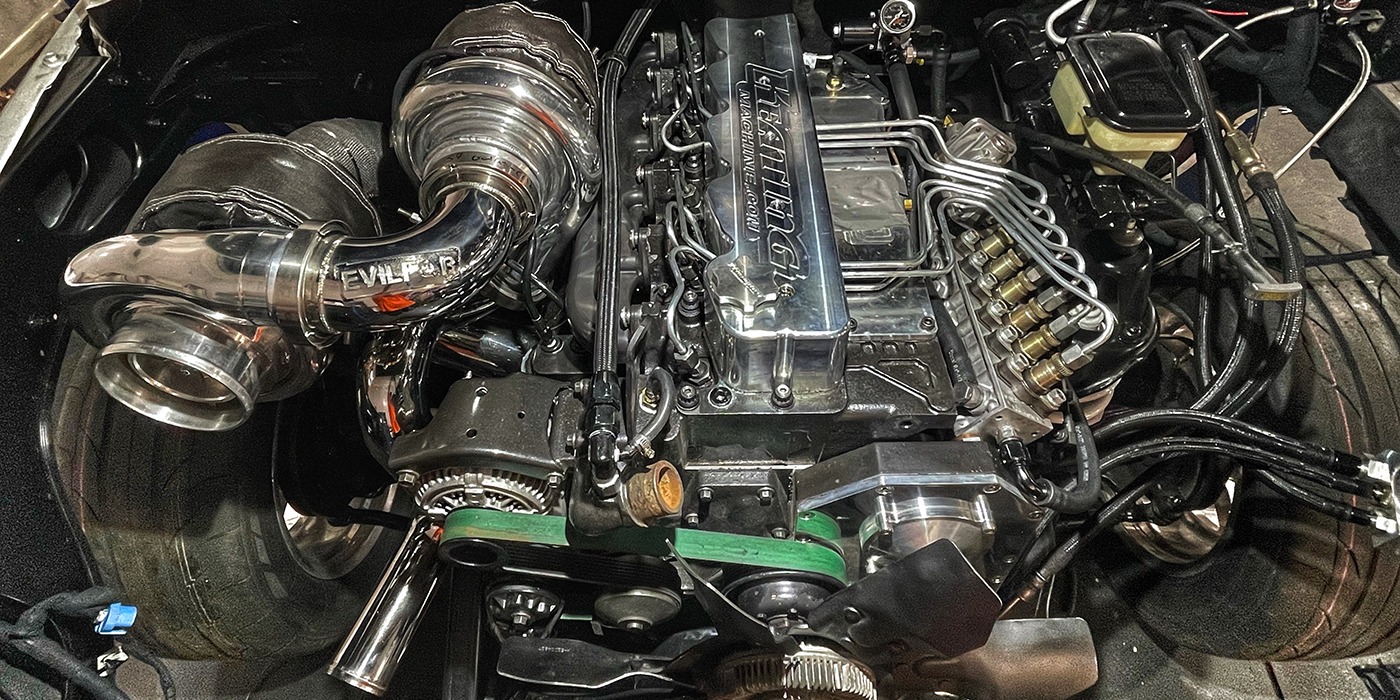

2. Duramax 6.6L LBZ

The LBZ version of the Duramax 6.6L engine, introduced in the mid-2000s, became one of the most respected diesel engines to appear in Chevrolet and GMC trucks. It managed to combine modern power with excellent service life. Many owners consider the LBZ to be the best Duramax ever made, partly because of its ability to handle heavy loads without constant issues.

One of the strongest points of the LBZ was its improved design compared to earlier versions. It used stronger internal parts, including forged steel rods, which gave it the ability to tolerate added horsepower from tuning. Truck owners often pushed this motor well past factory limits, and it continued to perform without major failures. Even stock versions were known to run for hundreds of thousands of miles with only routine maintenance.

The LBZ also benefited from a high-pressure common rail fuel system that improved both performance and fuel economy. While some diesel engines from that era faced emissions equipment problems, the LBZ avoided many of those headaches because it was built before the most restrictive emissions standards came into effect. That allowed it to maintain reliability without being weighed down by complicated after-treatment systems.

Drivers loved the way the LBZ delivered power smoothly while still being dependable under stress. Towing large trailers, climbing steep grades, or carrying heavy loads did not break its confidence. Owners often speak of trucks with LBZ engines reaching 400,000 miles and still starting with ease every morning.

Mechanics also appreciated that the LBZ was easier to maintain compared to some later designs. Parts were strong, and the systems were not overly complicated. This balance of power and simplicity made the LBZ not just a strong workhorse but also a diesel engine that has aged gracefully.

Even today, used truck buyers look for LBZ-powered models because they trust that the motor can still give many years of service. It stands as proof that a well-engineered diesel can deliver both strength and long life.

3. Ford 7.3L Power Stroke

The Ford 7.3L Power Stroke is one of the most celebrated diesel engines ever fitted into pickups, and its reputation continues long after it stopped being produced. Introduced in the mid-1990s, this engine powered Ford Super Duty trucks until the early 2000s and quickly became known as a benchmark for durability. Many owners still consider it the high point of Ford’s diesel program.

One of the main reasons for its staying power is the simple yet robust design. Unlike later diesel engines filled with complicated emission systems, the 7.3L Power Stroke relied on straightforward engineering. It used a hydraulically actuated, electronically controlled unit injector system that was reliable for its time. While some parts were more advanced than earlier diesels, they were still dependable and could handle long years of service.

Owners often talk about these trucks lasting 400,000 to 500,000 miles without major problems. Some even go beyond that mark with proper maintenance. The block and heads were strong cast iron, making them resistant to cracking or warping under stress. The turbocharger design also allowed for steady airflow, giving the engine enough power for towing and hauling while keeping stress levels manageable.

Another factor that made the 7.3L Power Stroke stand out was the availability of parts and ease of service. Mechanics found it easier to work on compared to some later Ford diesels that came with more electronic systems and emissions equipment. Even today, it is common to see owners search for older Super Duty trucks specifically because they want the 7.3L Power Stroke under the hood.

Towing performance also built its reputation. Drivers could haul heavy trailers, boats, or farm equipment without fear of the engine giving up. The torque delivery was steady, and the motor was not easily worn down, even by repeated use under pressure.

This combination of long service life, toughness, and steady performance is why so many Ford enthusiasts consider the 7.3L Power Stroke one of the best diesel engines ever sold in pickups. It earned its name as a workhorse that could serve for decades without breaking.

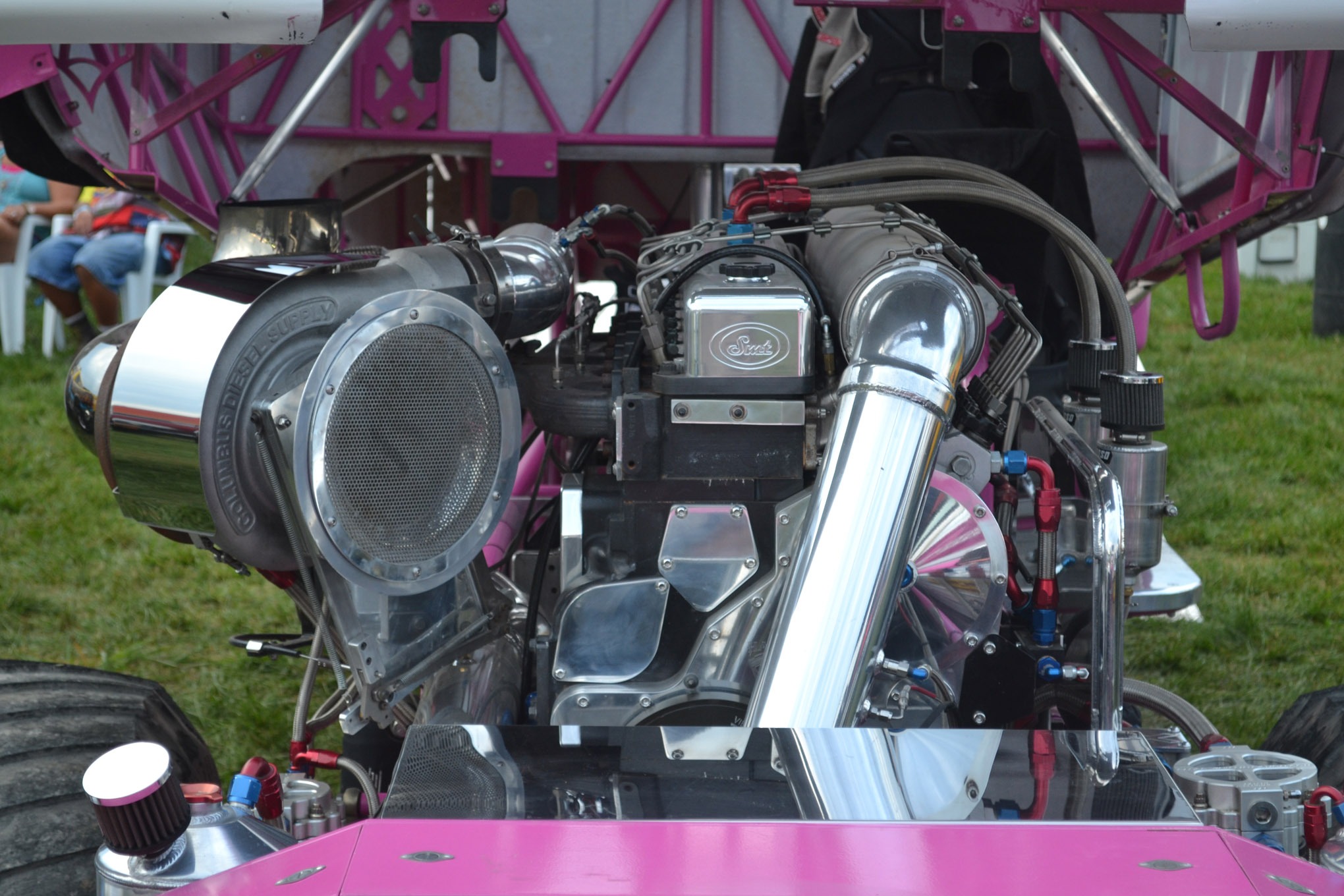

4. Caterpillar 3116/3126

When people think of Caterpillar, they usually imagine heavy construction machinery and big industrial engines. However, Caterpillar’s 3116 and later 3126 engines found their way into medium-duty trucks, school buses, and even some larger pickups, and they quickly gained respect for their endurance. While not as common as Cummins or Power Stroke, these Caterpillar diesels proved that they were built to last far beyond normal expectations.

One of the biggest advantages of these engines was their heavy-duty construction. They were designed originally for equipment that had to run all day under intense conditions, so placing them inside trucks meant they were often overbuilt for the job. Thick cast-iron blocks, large cylinder heads, and durable internals gave them the strength to handle stress without wearing out quickly.

Owners who drove trucks powered by the 3116 or 3126 often spoke of engines running half a million miles with basic care. These motors were not high-revving or overly powerful compared to some competitors, but what they lacked in raw numbers, they made up for with consistent, dependable output. For fleet owners, this kind of reliability was worth more than chasing the highest horsepower rating.

The Caterpillar diesels also had a reputation for being able to recover from hard use. Even when abused, they often kept running, which made them favorites among companies that could not afford downtime. Their fuel systems were sturdy, and their cooling systems were able to handle long hours of heavy hauling.

One challenge with these engines was that parts were sometimes harder to source for pickup owners compared to more common truck engines like Cummins. However, those who maintained them properly found they could rely on Caterpillar diesel engines for years without major breakdowns.

Even though Caterpillar eventually pulled out of the pickup and smaller truck engine market, the 3116 and 3126 left behind a reputation of ruggedness. Many of the trucks that carried them are still working today, proving that Caterpillar diesel engines had the strength to last longer than the vehicles themselves.

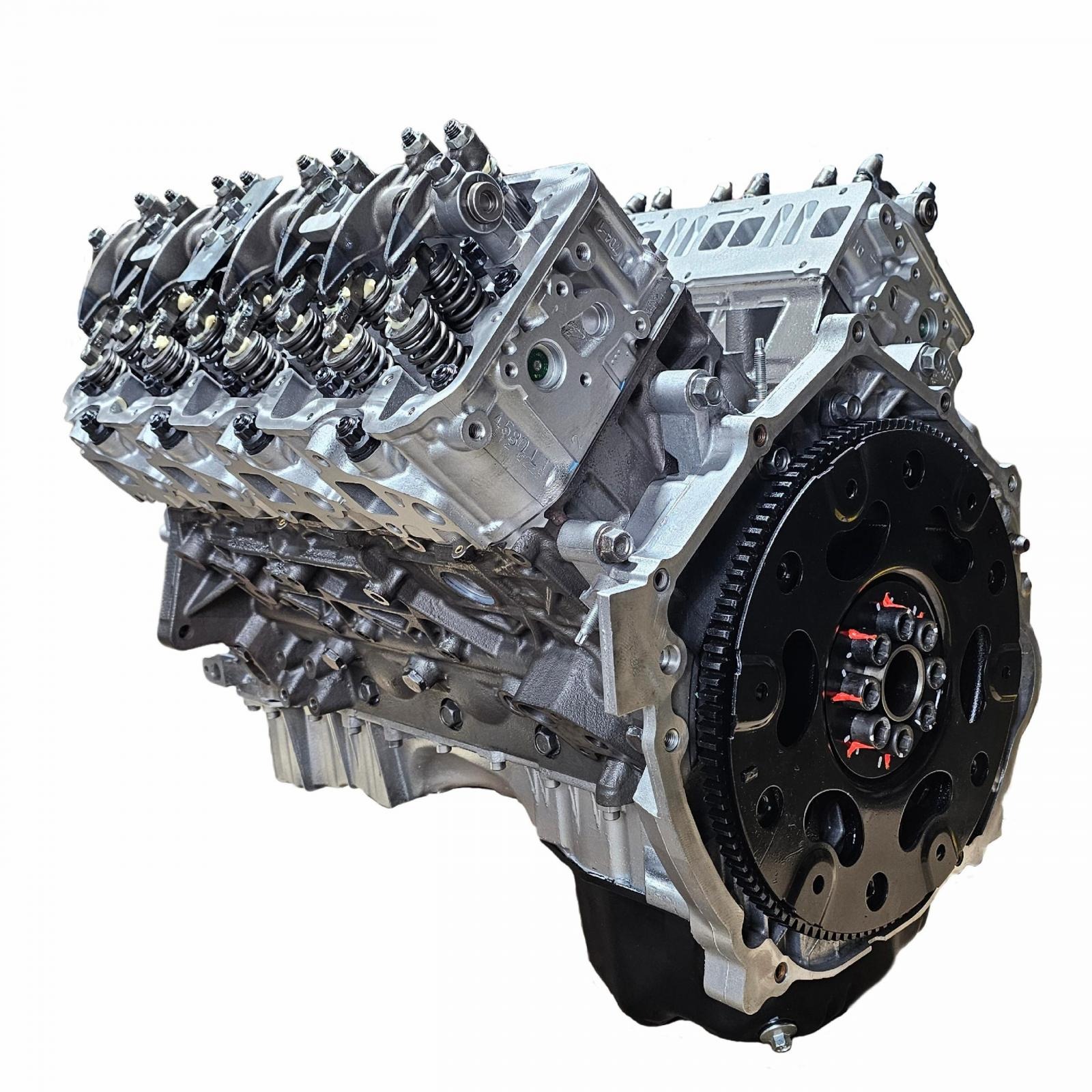

5. Cummins 6.7L (Early Versions)

The Cummins 6.7L diesel engine was introduced to replace the older 5.9L models, and although it faced early doubts, it has proven itself as a motor that can outlive the trucks it powers. Found in Ram heavy-duty pickups from 2007 onwards, this engine carries the heritage of Cummins toughness while also adapting to modern emissions requirements.

The block is cast iron with a forged steel crankshaft, which gives it a strong base for handling stress. Owners often praise its ability to produce massive torque at low RPM, making it perfect for hauling large trailers and equipment. Trucks with this motor are frequently used in construction, farming, and long-distance hauling, yet the engine continues to perform under pressure.

With proper care, the 6.7L Cummins can last 400,000 miles or more. Many trucks with this motor are still running strong after years of service. The design is flexible enough that it can also handle power upgrades. Many diesel enthusiasts add aftermarket tuning, bigger turbos, or stronger injectors, and the 6.7L holds up well without breaking down quickly.

While some of the earliest versions faced issues with emissions systems like the EGR and DPF, the core engine itself remained solid. Owners who performed regular maintenance found that the base motor was nearly indestructible. The cylinder walls, pistons, and rods were all built for endurance.

Because of its mix of modern performance and long service life, the 6.7L Cummins has kept Ram trucks at the front of the diesel pickup market. For buyers who need both power and reliability, this engine represents a trusted choice. It shows that even with changing technology, diesel engines can still deliver the same kind of toughness that made earlier generations so respected.

5 Diesel Engines That Crack Under Pressure

1. Ford 6.0L Power Stroke

The Ford 6.0L Power Stroke, introduced in the early 2000s to replace the legendary 7.3L, is remembered for all the wrong reasons. While Ford hoped this engine would meet stricter emissions standards and deliver more power, the result was a diesel that caused frustration for many truck owners. On paper, the 6.0L offered better horsepower and torque than the 7.3L, but in practice, it struggled with reliability.

One of the biggest weaknesses was the head gasket design. The engine often developed head gasket failures when exposed to heavy loads or tuning that pushed boost pressure higher. The bolts that held the heads in place were not strong enough, which meant blown gaskets became a common and expensive repair. Owners who pushed their trucks hard often found themselves stranded.

Another issue came from the EGR cooler, which tended to crack or clog. When that happened, coolant would leak, and overheating became a real problem. The oil cooler was also prone to failure, creating even more trouble. Many owners faced repeated visits to the repair shop, sometimes spending thousands of dollars just to keep the truck on the road.

The 6.0L Power Stroke also had complicated electronic controls that were more sensitive than previous engines. While technology was advancing, this engine showed how too much complication without enough durability could lead to headaches. Some owners managed to “bulletproof” their 6.0L engines by replacing weak parts with stronger aftermarket components, but that required spending large amounts of money.

For people who just wanted a dependable work truck, the 6.0L Power Stroke often failed expectations. Trucks that should have lasted 300,000 miles sometimes struggled to reach half that distance without costly repairs. While it produced good power and could tow heavy loads when running right, its lack of reliability gave it one of the most troubled reputations of any Ford diesel.

Even today, mechanics warn buyers about the 6.0L. It stands as a reminder that engineering strength cannot be sacrificed for complication. For many owners, this was the engine that cracked under pressure, leaving behind more frustration than trust.

2. GM 5.7L Oldsmobile Diesel

In the late 1970s and early 1980s, General Motors decided to move into the diesel pickup market with the 5.7L Oldsmobile diesel engine. At a time when fuel efficiency was becoming increasingly important, GM believed this engine would appeal to buyers seeking improved mileage. Instead, the 5.7L diesel became one of the most criticized engines in American truck history, leaving behind a reputation for weakness and failure.

One of the biggest issues was that the 5.7L was based heavily on a gasoline engine design. GM tried to convert an existing gas motor into a diesel, but the block and internals were not strong enough to handle the compression levels required by a diesel engine. As a result, many of these motors suffered from cracked heads, broken blocks, and early breakdowns.

Owners quickly became frustrated when engines failed after only a few years of use. While diesel engines are usually known for lasting hundreds of thousands of miles, the 5.7L Oldsmobile diesel often struggled to reach even 100,000 miles without serious trouble. The fuel system was also unreliable, with injection pumps that wore out too quickly.

To make matters worse, GM did not provide enough support for repairs. Many mechanics at the time were not trained to deal with diesel technology, so owners faced long waits and high costs. This added to the negative reputation of the engine and discouraged many people from trusting diesel pickups at all.

The 5.7L Oldsmobile diesel is often blamed for hurting the image of diesel vehicles in the United States during the early 1980s. Instead of being seen as tough and reliable, diesel trucks became linked with unreliability because of this poorly designed motor. It was an attempt to save money by adapting a gas design rather than engineering a true diesel from the start, and the decision backfired badly.

Even decades later, the 5.7L diesel is remembered as a warning. It shows that shortcuts in engine design can destroy customer trust. For truck buyers, this engine cracked under pressure long before it could prove itself as a true diesel contender.

3. Ford 6.4L Power Stroke

The Ford 6.4L Power Stroke, which followed the troubled 6.0L, was meant to restore confidence in Ford’s diesel program. Released in 2008, it promised more horsepower and torque, along with new emissions technology to meet regulations. While it delivered strong numbers, it quickly became clear that this engine was filled with issues that made ownership expensive and stressful.

One of the first complaints centered around fuel economy. The 6.4L consumed diesel at a faster rate than most owners expected. Trucks that were supposed to balance power with efficiency ended up costing drivers more at the pump. But fuel use was only the beginning of the problems.

The twin-turbo setup, while powerful, often caused reliability concerns. Many owners reported turbocharger failures that were costly to repair. The high-pressure fuel system also created problems, with pumps that could fail and send metal shavings throughout the engine. Once this happened, repairs were extremely expensive.

Another major weakness came from the emissions systems. The diesel particulate filter (DPF) and EGR system caused repeated trouble for owners. Regeneration cycles would waste fuel, and clogged filters could lead to loss of power. Many trucks spent too much time in repair shops dealing with emissions-related breakdowns.

The engine also ran hot under heavy loads, which created stress on internal parts. While some trucks made it past 200,000 miles with good care, many others failed much earlier. Mechanics often warned that keeping a 6.4L running required spending large amounts of money on maintenance and repairs.

While the 6.4L Power Stroke looked promising on paper, in practice, it often disappointed. Owners wanted a strong and dependable work truck, but instead they faced high costs and repeated failures. It became another chapter in Ford’s difficult stretch of diesel engines between the strong 7.3L and the later improved 6.7L.

For many buyers, the 6.4L proved that an engine can look powerful while still being unreliable. It could produce big numbers, but it cracked under pressure when tested in real-world conditions.

4. GM 6.5L Turbo Diesel

The GM 6.5L Turbo Diesel was introduced in the early 1990s to replace the aging 6.2L diesel. General Motors hoped it would provide more power for pickup buyers while still being reliable.

Unfortunately, this engine never lived up to expectations and often let owners down when placed under stress. While it did better than the disastrous 5.7L diesel from the 1980s, it still carried too many weaknesses to earn long-term respect.

One of the biggest issues was power output. Compared to competitors like the Cummins 5.9L or Ford’s 7.3L Power Stroke, the 6.5L simply lacked muscle. It struggled with towing heavy loads, which was supposed to be one of the main reasons buyers chose diesel pickups. For drivers who wanted to pull trailers or haul big equipment, the 6.5L did not provide enough torque to handle the job with confidence.

Durability was another concern. Many of these engines suffered from cracked cylinder heads and weak head gaskets. Overheating was a frequent problem, especially when trucks were pushed hard. The cooling system often could not keep up, leading to warped heads and expensive repairs.

The electronic injection pump was also a sore point. It had a reputation for failing, which left trucks stalling or refusing to start. Replacing the pump was costly, and many owners had to deal with it more than once. While some light-duty users managed to get decent service life from the 6.5L, those who worked their trucks hard often found themselves disappointed.

The engine might last if treated gently, but when asked to perform serious labor, it quickly revealed its limits. Compared to rivals that could run hundreds of thousands of miles under heavy load, the 6.5L felt like a weaker option that could not carry the reputation of a true workhorse.

Because of these issues, the 6.5L Turbo Diesel ended up being overshadowed by stronger engines on the market. Truck buyers wanted confidence, and this motor could not provide it consistently. While it represented a step forward from GM’s earlier failures, it still cracked under pressure when compared to the long-lasting diesels offered by competitors.

Also Read: 5 Diesel Engines with Pan-Drive Timing vs 5 with Belt-Drive Problems

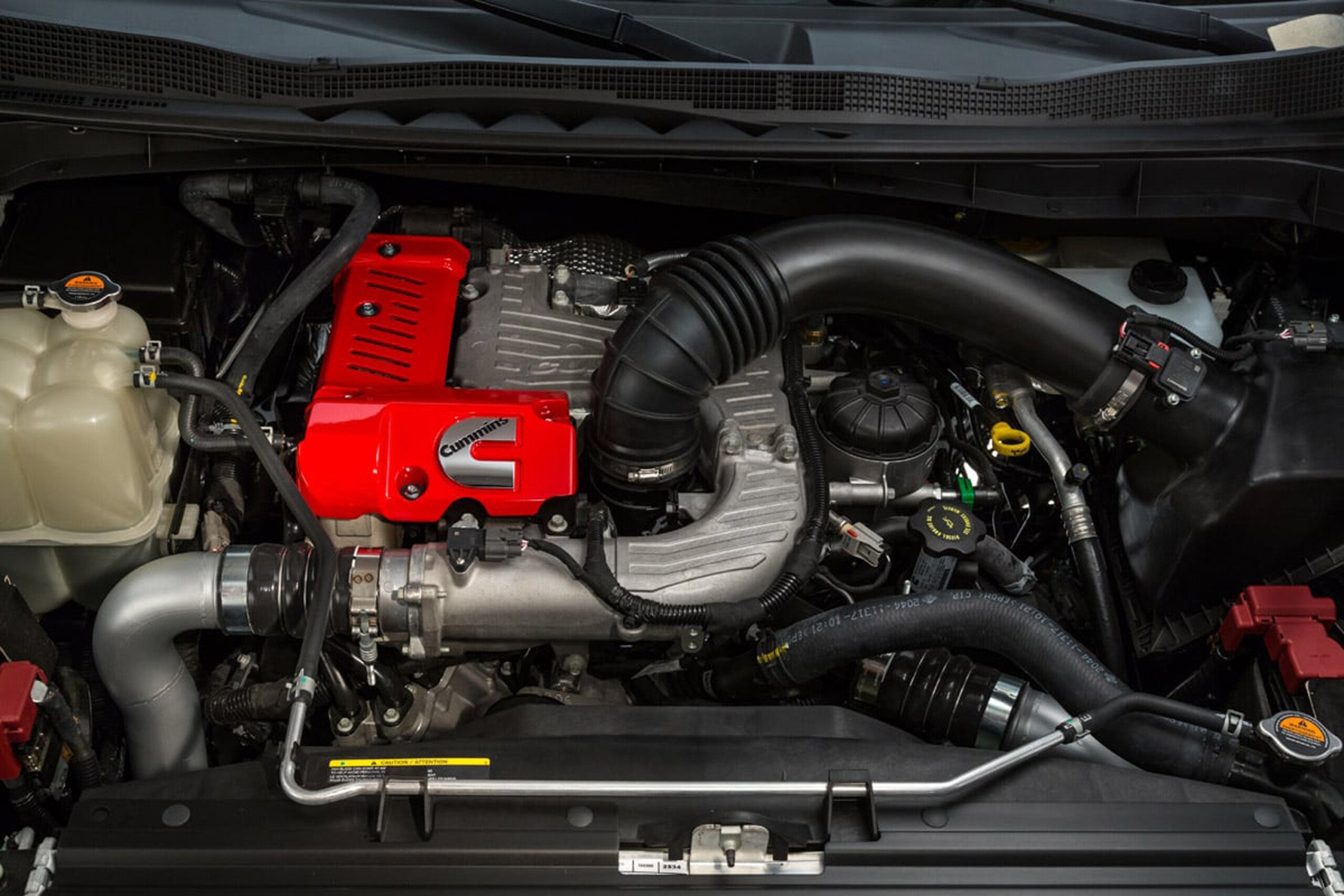

5. Nissan Titan XD Cummins 5.0L

When Nissan partnered with Cummins to create the Titan XD with a 5.0L V8 diesel, many truck enthusiasts were excited. The Cummins name had already built a strong reputation with its legendary 5.9L and 6.7L engines, so people expected the 5.0L to be another winner. Unfortunately, it turned out to be a disappointment, leaving many owners underwhelmed by its performance and reliability.

The 5.0L Cummins was designed to fit between light-duty and heavy-duty categories, targeting buyers who wanted more than a half-ton truck but less than a full heavy-duty pickup. On paper, this seemed like a smart idea. In reality, the engine struggled to find its place.

It did not have the raw strength of the bigger Cummins diesels, and it lacked the fuel efficiency expected from smaller motors. Owners often complained that it felt underpowered for the size of the truck. Reliability problems also hurt its image. Many Titan XD owners experienced turbocharger failures, fuel system issues, and emission equipment breakdowns.

The engine’s complication made repairs expensive, and because Nissan’s diesel program was limited, parts and service support were harder to find compared to Ford, Ram, or GM trucks. This left many owners frustrated when their trucks spent more time at the dealership than on the road.

The market also rejected the idea of a “middle-ground” diesel. Most buyers either wanted a true heavy-duty truck with proven engines like the 6.7L Cummins or a light-duty pickup with better fuel efficiency. The 5.0L Cummins failed to shine in either area. As a result, sales were poor, and Nissan eventually discontinued the diesel Titan XD altogether.

For many truck owners, the disappointment was not just about performance but also about expectations. Seeing the Cummins badge raised hopes of legendary toughness, but the 5.0L never delivered that kind of durability. Instead of being remembered as a breakthrough, it is often cited as an example of a diesel that cracked under pressure, unable to live up to its famous name.