Engines form the heart of any vehicle, and their durability plays a key role in long-term ownership costs.

Some engines are designed to endure hundreds of thousands of miles without requiring a rebuild, while others face recurring problems that make major repairs inevitable.

Understanding the difference between these two categories can help buyers select a vehicle that minimizes unexpected downtime and repair expenses.

Factors influencing engine longevity include the quality of materials, precision of engineering, cooling efficiency, and stress levels placed on internal components.

Engines that rarely require rebuilds benefit from robust design, proper lubrication, and well-tested manufacturing processes. Conversely, engines that frequently fail or require rebuilds often suffer from design shortcuts, inadequate cooling, or sensitivity to maintenance lapses.

This article examines two groups of engines: five that consistently operate for long periods without major internal repairs, and five that commonly need rebuilds within relatively short lifespans.

Each engine is discussed with a focus on design strengths or weaknesses, practical maintenance considerations, and real-world reliability.

By understanding which engines are dependable and which are prone to rebuilds, buyers and enthusiasts can make informed decisions about vehicle selection, ownership, and maintenance planning.

Also Read: 9 Engines That Survive Hard Racing Conditions

5 Engines That Rarely Need Rebuilds

Some engines achieve remarkable durability, operating reliably for hundreds of thousands of miles with minimal internal repairs. These engines are designed with strong components, precise engineering tolerances, and effective cooling and lubrication systems.

Owners of vehicles with such engines often experience consistent performance and minimal maintenance beyond routine oil changes, filter replacements, and inspections.

Engines that rarely require rebuilds usually benefit from several key factors. High-quality materials, such as forged pistons and steel crankshafts, reduce the likelihood of wear or failure.

Efficient cooling and oil circulation prevent overheating and component fatigue. Additionally, designs that distribute stress evenly across engine parts extend service life.

These engines are forgiving of occasional maintenance lapses and are generally easier to repair when minor issues arise, further enhancing reliability.

This section highlights five engines known for their longevity and minimal rebuild requirements.

Each description will examine the engineering decisions that contribute to durability, the types of driving and maintenance conditions the engine handles well, and why these models consistently outperform others in terms of reliability.

Understanding these engines provides valuable guidance for buyers seeking long-term performance, helping them select vehicles that offer both efficiency and peace of mind without the looming risk of costly engine rebuilds.

1. Toyota 2JZ-GTE Engine

The Toyota 2JZ-GTE engine is legendary for its durability and ability to withstand high mileage without requiring a rebuild.

This 3.0-liter inline-six, turbocharged engine was engineered with robust internal components, including forged steel crankshafts, high-strength pistons, and reinforced connecting rods.

These elements allow the engine to handle stress from both daily driving and high-performance tuning without significant wear.

One key factor in the 2JZ-GTE’s longevity is its precise engineering tolerances. Toyota’s design ensures consistent oil circulation, optimal cooling, and minimal internal friction, all of which reduce wear on critical components over time.

The cylinder heads and block are made from high-quality materials that resist warping and cracking, even under heavy loads or extreme temperatures.

Owners report engines exceeding 300,000 miles without major internal repairs, often achieving additional longevity with routine maintenance such as timely oil changes, spark plug replacements, and coolant inspections.

The engine’s turbo system is also designed to be durable, and careful attention to boost and oil pressure ensures that even forced-induction setups can remain reliable over long periods.

Beyond durability, the 2JZ-GTE offers consistent performance, smooth power delivery, and the ability to handle a range of fuel qualities without internal damage.

Its combination of strong construction, careful engineering, and ease of maintenance makes it a benchmark for engines that rarely need rebuilds, appealing to both enthusiasts and long-term vehicle owners seeking reliability alongside performance.

2. Honda K20 Series Engine

The Honda K20 series engine has earned a reputation for exceptional reliability and minimal need for rebuilds.

This 2.0-liter inline-four, found in models such as the Civic Si and Accord Sport, is engineered with high-strength aluminum alloy blocks and precision-machined internals.

The combination of lightweight design and durable materials allows the engine to deliver strong performance while maintaining longevity.

One of the main factors behind the K20’s durability is its variable valve timing system, which enhances efficiency without placing excessive stress on the valvetrain.

The engine features forged connecting rods and reinforced pistons in performance models, contributing to its ability to withstand high-revving driving without premature wear.

Cooling and lubrication systems are carefully designed to maintain consistent oil pressure and optimal operating temperatures, preventing overheating and component fatigue.

Owners frequently report that K20 engines can exceed 250,000 to 300,000 miles with only routine maintenance, such as oil changes, timing chain inspections, and air filter replacements. Even when subjected to spirited driving or aftermarket modifications, these engines are often resilient enough to avoid major internal repairs.

The Honda K20 series also benefits from widespread parts availability and straightforward maintenance procedures, making it easier to keep the engine in top condition over decades of use.

Its combination of engineering precision, robust materials, and forgiving design makes the K20 series a prime example of an engine that rarely requires a rebuild while offering reliable performance and strong fuel efficiency throughout its lifespan.

3. Toyota 1GR-FE V6 Engine

The Toyota 1GR-FE 4.0-liter V6 engine is renowned for its durability and minimal need for internal rebuilds.

Found in models such as the Toyota Tacoma, 4Runner, and FJ Cruiser, this engine features a cast-iron block with aluminum cylinder heads, offering a balance of strength and weight reduction.

Its internal components, including forged pistons and a robust crankshaft, are engineered to handle prolonged use under both daily driving and off-road conditions.

Cooling and lubrication systems are highly effective, ensuring consistent oil pressure and proper heat dissipation, which prevents premature wear on critical components.

The valvetrain and timing chain are designed for longevity, with many owners reporting over 300,000 miles without the need for major internal repairs. Regular maintenance, such as oil changes and coolant inspections, further enhances the engine’s lifespan.

The 1GR-FE also benefits from its versatile design. It provides sufficient power for towing and hauling while maintaining reliability, even under heavy loads. This resilience extends to its hybrid counterparts, as some models share the same durable block and head design.

Owners appreciate the engine’s predictable performance, straightforward maintenance, and ability to endure years of high-mileage driving without rebuilds, making it a benchmark for V6 reliability.

4. Ford 5.0L Coyote V8 Engine

The Ford 5.0L Coyote V8 engine combines performance with long-term reliability. Featured in the Ford Mustang GT and F-150, this engine uses an aluminum block with high-strength forged steel crankshafts and pistons in performance applications, ensuring durability.

Its dual overhead cam design with variable valve timing optimizes efficiency while reducing stress on internal components.

Cooling and oil circulation systems are engineered to prevent overheating and maintain consistent lubrication, essential for long-lasting engines.

Owners report that, with proper maintenance such as oil changes, spark plug replacement, and occasional valve inspections, the Coyote V8 can exceed 250,000 miles without requiring an internal rebuild.

The Coyote also benefits from modular design, allowing easier servicing and replacement of wear-prone components.

Its strong construction, combined with reliable electronics and engine management, ensures predictable performance under daily driving, towing, and spirited use.

The engine’s ability to handle aftermarket tuning without catastrophic failures is an added advantage, highlighting its robust design and engineering.

5. Chevrolet LS3 V8 Engine

The Chevrolet LS3 6.2-liter V8 engine is part of the long-standing LS family, renowned for durability and minimal rebuild requirements.

Found in models such as the Corvette and Camaro SS, it features an aluminum block, forged steel crankshaft, and robust piston assemblies. Its pushrod design simplifies the valvetrain, reducing points of failure compared with more complex overhead cam engines.

The LS3’s cooling and lubrication systems are engineered for consistent oil pressure and efficient heat dissipation, preventing wear and prolonging engine life.

Owners report that these engines can exceed 300,000 miles with routine maintenance, including oil and filter changes, spark plug replacement, and periodic inspection of belts and gaskets.

In addition to long-term durability, the LS3 is highly serviceable, with aftermarket support that allows owners to maintain or upgrade components without major rebuilds.

Its design balances performance with reliability, making it a favorite among enthusiasts and long-term owners alike.

The LS3 engine exemplifies how solid engineering, high-quality materials, and straightforward maintenance combine to produce an engine that rarely requires internal rebuilds.

5 Engines That Always Need Rebuilds

Not all engines are designed with long-term durability in mind. Some are prone to internal failures, making rebuilds a recurring requirement even with regular maintenance.

These engines often face challenges such as poor material quality, inadequate cooling, high-stress designs, or complex components that are difficult to service.

Understanding which engines frequently need rebuilds can help buyers anticipate maintenance costs and avoid vehicles with chronic reliability issues.

Engines that require frequent rebuilds typically suffer from excessive wear on pistons, valves, bearings, or timing components. Overheating, improper lubrication, and high-performance tuning can accelerate this deterioration.

Additionally, intricate designs, such as those with tightly packed electronics or turbocharged systems, can make minor issues escalate into major failures that demand a complete rebuild.

This section highlights five engines known for recurring rebuild requirements. Each entry will examine design weaknesses, common failure points, and maintenance challenges that contribute to their short lifespans.

By reviewing these engines, buyers and enthusiasts can recognize patterns of unreliability and better manage expectations for repair costs, downtime, and vehicle longevity.

Knowing which engines consistently require rebuilds provides practical guidance for selecting vehicles that balance performance and durability, reducing the risk of frequent, expensive repairs.

1. BMW N54 Turbocharged Inline-Six Engine

The BMW N54 3.0-liter turbocharged inline-six engine is celebrated for its performance but is notorious for frequent rebuilds. Found in models such as the 335i and 135i, this engine employs twin turbochargers that place significant stress on internal components.

Pistons, connecting rods, and the crankshaft often experience accelerated wear due to high cylinder pressures, particularly under spirited driving or aftermarket tuning.

Another common issue is the high-pressure fuel system, which can fail and damage injectors, leading to uneven combustion and added stress on the engine.

Cooling challenges exacerbate wear, as the N54’s turbos generate substantial heat that can lead to warped heads, gasket failures, or cracked components if not carefully monitored.

Owners report that even with meticulous maintenance cluding frequent oil changes, proper coolant management, and careful boost control, many N54 engines require rebuilds before 150,000 miles.

The combination of turbo heat, high compression, and complex engine electronics creates a scenario where internal failures become almost inevitable over time.

While the N54 delivers impressive acceleration and strong aftermarket support, its reputation for frequent rebuilds makes it less suitable for long-term reliability-focused ownership.

Enthusiasts seeking performance often accept these maintenance demands, but casual owners may find themselves facing costly internal repairs more often than with naturally aspirated, robustly designed engines.

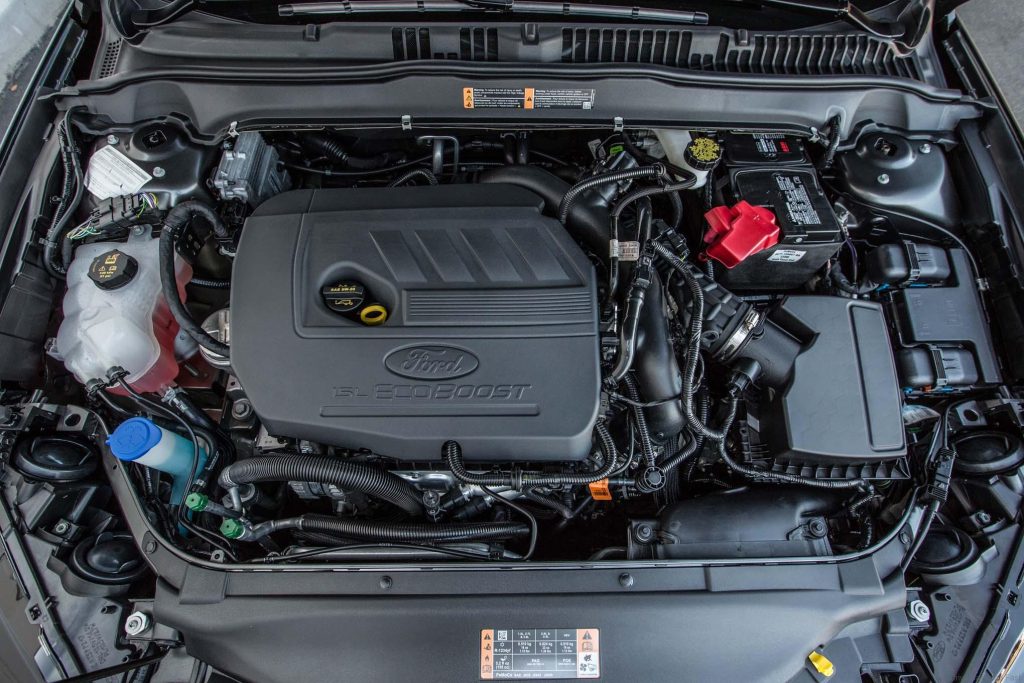

2. Ford EcoBoost 2.0L Turbo Engine

The Ford EcoBoost 2.0-liter turbocharged four-cylinder engine prioritizes performance and efficiency, but it has a documented history of internal issues that often necessitate rebuilds.

Found in models like the Ford Focus ST and Escape, the combination of turbocharging and direct injection can lead to carbon buildup on intake valves, which impairs airflow and causes uneven combustion.

Turbochargers generate high temperatures, placing stress on pistons, bearings, and cylinder heads. Cooling systems are adequate for moderate use but often struggle under prolonged high-load driving, leading to overheating and accelerated wear.

Oil consumption issues are common, and failure to maintain proper lubrication can cause significant internal damage.

Owners report that EcoBoost engines may require rebuilds before 150,000 miles, especially in vehicles with aggressive driving habits or minimal maintenance.

While the engine delivers strong power and fuel efficiency, its small displacement combined with high boost pressures creates conditions where internal components wear quickly.

Frequent rebuilds are further complicated by the complexity of the turbo and direct-injection system, which makes repairs more expensive and time-consuming.

Despite Ford’s improvements over the years, early EcoBoost engines remain prone to internal failures, making them less suitable for buyers seeking long-term reliability without major interventions.

3. Volkswagen 2.0T FSI Engine

The Volkswagen 2.0T FSI inline-four engine, featured in models like the Golf GTI and Jetta GLI, is known for its performance but suffers from recurring rebuild requirements.

Its high-compression direct-injection system increases efficiency but promotes carbon buildup on intake valves, leading to misfires, poor fuel economy, and stress on pistons and valves.

Cooling and lubrication challenges further reduce longevity. Turbocharged models generate additional heat that can warp cylinder heads, degrade head gaskets, and wear out bearings prematurely.

Owners report oil consumption issues that, if neglected, exacerbate internal wear and often necessitate a full rebuild before 150,000 miles.

Timing chain tensioners and camshaft components are also frequent failure points, and the compact, tightly packed design of the engine makes repairs more difficult and costly.

Even with regular maintenance, the combination of turbocharging, high compression, and direct injection creates conditions that accelerate wear on critical components.

While the 2.0T FSI provides lively performance and strong aftermarket support, its tendency toward early internal failures means many engines require rebuilds sooner than expected.

Buyers prioritizing durability often avoid these engines in favor of more robust naturally aspirated or less stressed turbocharged designs.

4. Nissan VQ35HR V6 Engine

The Nissan VQ35HR 3.5-liter V6 engine offers smooth performance but has a reputation for internal issues that often require rebuilds.

Found in vehicles like the 350Z and Altima V6, this engine is high-revving and incorporates variable valve timing, which places stress on timing chains and camshafts over time.

Common failure points include excessive oil consumption, worn pistons, and bearing degradation. Cooling and lubrication systems are adequate under normal conditions but can be insufficient under spirited driving, leading to overheating and accelerated internal wear.

Owners frequently report head gasket failures and valve guide issues that necessitate comprehensive rebuilds by 120,000 to 150,000 miles.

The VQ35HR’s high output and performance orientation, combined with relatively compact internals, means components experience continuous stress.

While routine maintenance such as oil changes, coolant inspections, and valve adjustments helps, many engines still require major internal repairs during their lifespan.

Despite offering smooth power delivery and responsiveness, the VQ35HR is less suitable for buyers focused on durability, as the likelihood of rebuilds is significant even with careful maintenance. Its performance capabilities come at the cost of long-term internal reliability.

5. Mitsubishi 4G63T Turbocharged Inline-Four Engine

The Mitsubishi 4G63T turbocharged 2.0-liter inline-four engine, featured in the Lancer Evolution series, delivers high performance but is notorious for frequent rebuilds.

The turbocharging, combined with high compression, generates significant stress on pistons, rods, and crankshafts, particularly in vehicles driven aggressively or tuned beyond factory specifications.

Cooling and lubrication systems are designed for standard conditions, but under high-load driving, overheating and insufficient lubrication accelerate wear on internal components. Timing belt or chain failures are another common issue that often leads to catastrophic internal damage if not addressed promptly.

Owners report that 4G63T engines frequently require rebuilds before 150,000 miles, especially in vehicles used for racing or high-performance driving. Even with routine maintenance, the combination of turbo pressure, high RPMs, and compact design ensures internal wear accumulates quickly.

While the engine is celebrated for its performance and tuning potential, its design prioritizes output over long-term durability. Buyers seeking reliability and minimal internal repairs often avoid the 4G63T, accepting that regular rebuilds are a likely part of ownership for these high-performance turbo engines.

Engines vary widely in reliability, and understanding which ones rarely need rebuilds versus those that frequently require major repairs is crucial for long-term vehicle ownership.

Among the engines that rarely require rebuilds, certain traits consistently contribute to their longevity.

The Toyota 2JZ-GTE, Honda K20 series, Toyota 1GR-FE V6, Ford 5.0L Coyote V8, and Chevrolet LS3 V8 all demonstrate robust engineering, high-quality materials, and efficient cooling and lubrication systems.

These engines typically use forged or reinforced internal components, strong crankshafts, and low-friction designs that reduce wear over time.

Their predictable performance and ease of maintenance allow them to surpass 250,000 to 300,000 miles without major internal repairs.

The combination of well-balanced stress distribution, effective thermal management, and readily available parts ensures owners can maintain these engines reliably for decades.

Conversely, engines that consistently require rebuilds share identifiable weaknesses. The BMW N54 inline-six, Ford EcoBoost 2.0L turbo, Volkswagen 2.0T FSI, Nissan VQ35HR V6, and Mitsubishi 4G63T turbo inline-four all experience high stress due to turbocharging, high compression, or complex designs.

These engines are prone to premature wear on pistons, bearings, timing components, and valvetrain systems. Cooling and lubrication limitations, combined with intricate electronics or tightly packed turbo systems, often accelerate internal damage.

Real-world reports indicate that these engines frequently require rebuilds before 150,000 miles, and maintenance alone may not prevent internal failures.

A clear pattern emerges: engines designed for longevity balance performance with durability, distribute stress evenly, and incorporate robust components.

Naturally aspirated engines with precise tolerances, reinforced internals, and efficient cooling are more likely to survive high mileage without rebuilds.

In contrast, engines optimized for high output, turbocharging, or compact packaging often sacrifice long-term reliability for performance gains, making rebuilds inevitable over time.

For buyers and enthusiasts, this comparison highlights the importance of evaluating engine design alongside performance. While turbocharged and high-output engines can offer exhilarating power, they carry increased risks of internal failures and costly repairs.

Choosing an engine that is proven for durability, with accessible maintenance and strong construction, provides peace of mind and lower long-term ownership costs.

Understanding these differences allows consumers to select vehicles that align with their priorities, whether for performance or dependable long-term reliability.

Ultimately, engine longevity depends on design philosophy, quality of materials, and stress management.

Those seeking minimal rebuilds benefit from proven, robust engines like the 2JZ-GTE, K20, 1GR-FE, Coyote, and LS3, while performance-focused turbo or high-compression engines require acceptance of frequent rebuilds as part of ownership.

Recognizing these trends empowers buyers to make informed decisions that balance performance, durability, and maintenance expectations.

Also Read: 10 Naturally Aspirated Engines That Last Longer Than Turbos