When you talk to seasoned mechanics, they’ll often say that cars come and go, but engines are what really leave an impression. Some powerplants are so reliable, so well-engineered, and so easy to work on that they earn a kind of legendary status in the garage.

Whether it’s the way they handle abuse, the simplicity of their design, or the sheer performance they can deliver without constant headaches, certain engines become the go-to favorites for mechanics across the United States.

While automakers have experimented with thousands of designs over the decades, only a select few earn respect as both reliable workhorses and enthusiast treasures.

For American drivers, these engines often represent more than just mechanical parts they symbolize trust, long-lasting value, and in some cases, iconic performance.

From Toyota to Ford, Honda to Cummins, these engines prove that excellence comes in many different forms, whether that’s bulletproof reliability, high horsepower, or easy serviceability.

Below, we’ll explore twelve engines that mechanics consistently rank among their favorites and why each one deserves a spot on the list.

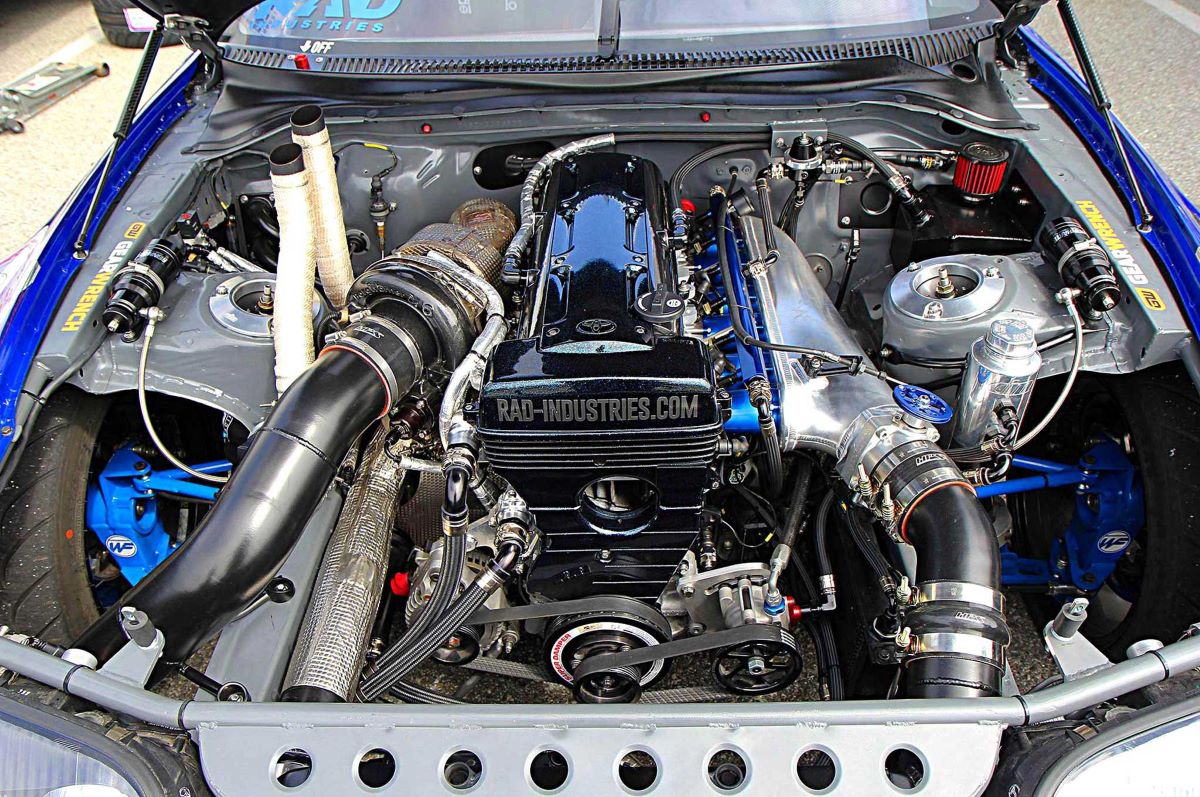

1. Toyota 2JZ-GTE

If there’s one Japanese engine mechanics almost unanimously love, it’s Toyota’s 2JZ-GTE. Introduced in the early 1990s and most famous for powering the fourth-generation Toyota Supra, this inline-six is overbuilt in almost every sense.

Its cast-iron block, strong internals, and simple layout make it nearly indestructible. Even stock, the engine produces impressive power, but what makes it legendary is how it handles aftermarket upgrades.

Mechanics know they can build a 2JZ to handle 800, 1,000, or even more horsepower without sacrificing reliability. Add to that Toyota’s reputation for long-lasting parts, and you’ve got a motor that’s as much fun for tuners as it is easy for mechanics to keep running.

2. Honda K-Series

For Honda fans and everyday drivers alike, the K-series engines particularly the K20 and K24 are nothing short of brilliant. Debuting in the early 2000s, these engines offered a perfect blend of efficiency and performance.

Mechanics love them because they’re straightforward to service, have excellent aftermarket support, and rarely suffer from catastrophic issues.

The K-series became a darling of both the tuning world and daily commuters, offering reliability whether you’re wringing it out on a racetrack or driving to work every day. In a mechanic’s eyes, a K-series under the hood means fewer headaches and plenty of smiles.

3. Ford 302 (5.0 Windsor)

Ask an American mechanic about small-block Ford engines, and chances are they’ll have a story about the 302. This V8, known as the 5.0 Windsor, is one of the most beloved in muscle car history.

Produced for decades, it powered everything from Mustangs to F-150s, proving its versatility and durability. Its simple pushrod design, ease of access, and massive parts availability make it a mechanic’s dream.

You can find replacement parts at almost any auto shop in the country, and rebuilding one doesn’t require specialized tools or training. For mechanics, the 302 isn’t just an engine it’s a symbol of old-school American engineering done right.

Among small-block V8 engines, few are as legendary as the Ford 302, more commonly recognized today as the 5.0L.

Introduced in the late 1960s, this powerplant quickly became a cornerstone of Ford performance and utility, powering everything from the timeless Mustang to rugged Ford trucks, including the ever-popular Bullnose models of the 1980s.

ts enduring reputation comes from its blend of reliability, performance, and aftermarket support, which has made it a top choice for restorers, hot rodders, and engine builders.

Whether you are bringing a classic Ford back to life or chasing more horsepower from a Bullnose truck, understanding the foundation of the 302 is essential.

The Ford 302 was designed to be compact, lightweight, and versatile, making it an engine that could serve both everyday drivers and performance applications.

At its core, the 302 is a 90-degree OHV V8 with a displacement of 302 cubic inches, or 5.0 liters. It features a bore and stroke of 4.00 inches by 3.00 inches and carries a compression ratio that varied between 8.0:1 and 9.5:1 depending on the specific year and model.

In terms of weight, the engine typically came in around 460 to 475 pounds when equipped with iron heads and intake components.

Early versions of the 302 made use of flat tappet camshafts, while later high-output (HO) models, particularly those built between 1982 and 1995, were fitted with roller camshafts.

Cylinder heads also evolved over time, starting with cast-iron heads featuring smaller valves in early engines and progressing to better-flowing designs with larger valves in the HO models, which significantly improved performance.

This change in firing order was one of several refinements Ford made as the engine evolved over the years.

In terms of performance output, the early Ford 302 engines produced between 140 and 200 horsepower, depending on the configuration and application.

As the engine was refined into the HO variants, horsepower figures climbed to as high as 225 horsepower in factory form. Torque output was also impressive for a small-block V8, ranging from about 240 to 300 lb-ft depending on the year and setup.

This balance of horsepower and torque made the 302 a flexible engine, equally at home in muscle cars and work trucks.

Fuel delivery systems for the 302 varied across its production run. Many early versions relied on carburetors, with most using two-barrel carburetors and select models featuring four-barrel options.

As technology advanced, Ford introduced electronic fuel injection (EFI) on later models, which improved fuel efficiency, drivability, and reliability.

Regardless of setup, the 302 was designed to run on regular unleaded gasoline, making it accessible and cost-effective for owners.

Physically, the engine maintained compact proportions that contributed to its popularity in a wide range of vehicles.

It measured approximately 27 inches in length, 29 inches in width, and 27 inches in height, with a dry weight hovering around 450 pounds. These dimensions made it relatively easy to fit into different chassis while still delivering respectable power.

Thanks to its compact size, dependable construction, and extensive aftermarket support, the Ford 302 has cemented its place as one of the most versatile V8s ever produced.

Builders appreciate the engine’s adaptability, whether the goal is a stock restoration, a mild street upgrade with intake and exhaust modifications, or a full-blown stroker build designed for racing.

Decades after its introduction, the Ford 302 continues to inspire enthusiasts with nearly endless possibilities for performance and customization.

4. Chevrolet LS V8

No modern American engine has gained the reputation of GM’s LS series V8. Found in everything from Camaros to Corvettes and Silverado trucks, the LS platform has become the go-to choice for engine swaps.

Mechanics love the LS because it’s compact, powerful, reliable, and has endless aftermarket support. Whether you want a 400-horsepower daily driver or a 1,000-horsepower drag car, the LS can do it all.

Its aluminum-block versions offer surprising lightness, while iron-block models can take punishment without blinking. From the perspective of a mechanic, the LS is easy to install, easy to maintain, and practically indestructible.

5. Toyota 22R/22RE

If you’ve ever known someone with a 1980s Toyota pickup, chances are they were driving a truck with the famous 22R or 22RE under the hood. These four-cylinder engines became synonymous with indestructibility.

Farmers, off-roaders, and everyday drivers trusted them to keep going well past 300,000 miles. The 22RE’s fuel injection made it even more efficient without compromising simplicity.

Mechanics adore these engines because they rarely break down, and when they do, the fixes are inexpensive and straightforward. For anyone who wanted a truck that could last forever with only basic maintenance, the 22R/22RE was the answer.

The Toyota 22R-E is a 2.4-liter (2,366 cc, 144.38 cu·in) inline four-cylinder, four-stroke, naturally aspirated gasoline engine that belongs to Toyota’s R-family.

Produced by Toyota Motor Corporation between 1983 and 1995, it became one of the brand’s most well-regarded and dependable powerplants during that era.

This engine was built with a cast-iron block paired with an aluminum cylinder head, featuring a single overhead camshaft (SOHC) and two valves per cylinder for a total of eight valves.

It carried a compression ratio of 9.0:1, while its cylinder bore measured 92.0 mm (3.62 in) and the piston stroke was 89.0 mm (3.5 in).

The 22R-E came equipped with an electronic fuel injection (EFI) system along with an ignition setup that used a mechanical distributor.

In 1985, Toyota introduced a redesign for the 22R engine. As a result, several components of the updated 22R-E, including the cylinder head, block, pistons, timing chain and cover, as well as the water and oil pumps, were no longer compatible with parts from the earlier pre-1985 version.

Power output for the 22R-E ranged from 106 PS (78 kW; 105 HP) at 4,800 rpm to 114 PS (84 kW; 113 HP) at 4,800 rpm. Torque figures were equally respectable for its size, spanning from 185 N·m (18.9 kg·m, 136 ft·lb) at 2,800 rpm up to 190 N·m (19.4 kg·m, 140 ft·lb) at 3,600 rpm.

6. Honda B-Series

Before the K-series took over, the Honda B-series was the benchmark for reliable, rev-happy four-cylinders. Found in Civic Si, Integra, and CR-V models, the B16 and B18 became favorites among both tuners and mechanics.

They featured Honda’s early VTEC system, giving them a mix of fuel economy and performance. What makes them special in a mechanic’s eyes is how tough they are. Abuse them, miss oil changes, or run them hard these engines keep ticking.

Plus, their modular design and huge aftermarket make them easy to repair and upgrade. For many mechanics, working on a B-series feels like revisiting an old friend.

7. Cummins 6BT 5.9L Diesel

When it comes to diesel engines, few names command the respect of the Cummins 6BT, also known as the 12-valve 5.9L. Introduced in Dodge Ram trucks in the late 1980s, this straight-six diesel quickly became a mechanic’s favorite for its sheer toughness.

With a mechanical fuel injection system, no complex electronics, and an iron block built to last, it’s nearly unstoppable.

Mechanics know these engines can run for half a million miles with proper care, and even neglected ones often keep going. For truck owners who need durability and torque, the Cummins 6BT is as good as it gets.

8. BMW M50

Not every mechanic’s favorite engine is American or Japanese. The BMW M50, produced in the early 1990s, stands out as one of the most durable engines to ever come out of Germany.

Known for its smooth inline-six layout, the M50 was over-engineered, with a cast-iron block and robust internals. While modern BMW engines are often criticized for complexity and reliability issues, the M50 represents a simpler era.

Mechanics appreciate that these engines are relatively easy to work on, deliver silky-smooth performance, and can handle high mileage without major failures.

As electric vehicles continue to gain traction, many automakers have shifted their focus toward SUVs. The logic behind this move is clear, SUVs provide more space to package batteries efficiently, and they align with what the majority of buyers are currently seeking.

Still, not every driver is looking for a large utility vehicle. For those who prefer something smaller, sportier, and more engaging behind the wheel, the 2023 BMW i4 offers an appealing alternative.

Introduced just last year, the i4 represents BMW’s effort to merge electrification with its long-standing tradition of crafting luxury sport sedans.

Delivering an estimated driving range of up to 301 miles and performance characteristics reminiscent of the brand’s renowned 3 Series and 4 Series models, the i4 stands out as one of the few non-SUV EVs available today.

For the 2023 model year, the most notable update is the arrival of the new entry-level i4 eDrive35, which starts at around $52,000 and is estimated to provide 260 miles of range on a full charge.

Meanwhile, the midrange eDrive40 and the high-performance M50 return to the lineup with minimal changes, continuing to offer the blend of range and athleticism that has made the i4 so attractive.

9. Chrysler 426 HEMI

For muscle car enthusiasts and the mechanics who work on them, the 426 HEMI is nothing short of legendary. Nicknamed the “Elephant Engine” for its size and power, it became a racing icon in the 1960s and ’70s. Even today, it’s one of the most revered V8s ever built.

Mechanics admire it not just for its horsepower, but for its durability under extreme stress. While not the most common engine to service today, working on a 426 HEMI is like touching a piece of history. For those lucky enough to rebuild one, it’s both a challenge and an honor.

The 426 Hemi was never developed as an overhead cam engine. While Chrysler did design a dual overhead cam (DOHC) version of the 426 Hemi in 1964, the project never reached completion and was never placed into production.

NASCAR ultimately banned non-production engines, and as a result, the DOHC Hemi was discontinued before it could compete on the track.

Even so, a prototype of this unique engine still exists today, and its design remains a fascinating piece of engineering history.

If the sight of a traditional Hemi is impressive, this particular engine feels like something even more extraordinary.

When Chrysler introduced the 426 Race Hemi into NASCAR, its dominance quickly drew attention and concern from Ford.

The superiority of the Hemi design was clear, and Ford soon developed a response in the form of the 427 SOHC engine, also known as “The Cammer” or the “90 Day Wonder.”

The Ford engine, with its overhead cam layout, was capable of producing more than 600 horsepower, making it more powerful than Chrysler’s 426 Race Hemi.

Although Ford’s engine had not yet been approved, Chrysler anticipated the potential threat and began working on a countermeasure.

Staying true to its philosophy of responding with something bigger and better, Chrysler initiated development of its own dual overhead cam version of the 426 Hemi.

Each of its aluminum cylinder heads housed dual overhead camshafts, creating a total of four cams.

By eliminating the bulky valvetrain components of the traditional Hemi, such as rocker arms and long pushrods, the new design promised reduced frictional losses, improved efficiency, and the potential for much higher rpm operation.

The A-925 prototype used four valves per cylinder arranged in a pentroof combustion chamber, which allowed for better breathing and more efficient combustion.

Externally, each cylinder head was fitted with a cog wheel at the front. These cog wheels were driven by a crank-driven cog belt, similar to the type used in supercharger systems.

The cog wheels, in turn, powered a series of gears inside the cylinder heads, which drove the overhead camshafts.

This sophisticated head design represented a significant leap forward, as it allowed for greater engine efficiency and performance potential.

The intake system featured a magnesium manifold equipped with a single four-barrel carburetor and eight runners on each side, providing the airflow needed to match the advanced valvetrain.

10. GM Small-Block 350

The Chevy small-block 350 has been called the backbone of American motoring. Produced for decades and used in countless cars and trucks, it’s one of the most prolific engines in history.

Mechanics love the 350 for the same reasons they love the Ford 302: simplicity, durability, and parts availability. If you need to rebuild a 350, every part is on the shelf somewhere in America, and often at affordable prices.

These engines also respond well to modifications, making them equally popular among hot-rodders and classic restorers. For many mechanics, the 350 is the ultimate “bread-and-butter” V8.

When it comes to upgrading or replacing an engine, the Chevy 350 / 5.7-liter small-block continues to be one of the most popular choices among automotive enthusiasts.

Known for its long-standing reputation for both performance and reliability, the 350 has proven itself to be a versatile engine suitable for a wide range of vehicles.

With countless options available on the market, however, selecting the right turn-key engine for your specific needs can feel overwhelming.

Whether your project is a hot rod, a street machine, or a full-fledged race car, this guide will point you toward the perfect turn-key engine to suit your build.

The history of the Chevy 350 crate engine is nearly as legendary as the engine itself. First introduced in 1967, the 350 quickly earned recognition as a reliable and powerful small-block V8, becoming a staple in Chevrolet’s lineup.

Although the engine has undergone multiple revisions and refinements over the decades, its fundamental design has remained consistent.

In the 1980s, Chevrolet began offering the 350 as a crate engine, giving the aftermarket an easy and affordable way to access this proven powerplant.

Since then, the popularity of the 350 crate engine has only grown. Today, buyers can find a wide selection ranging from stock-style replacements to high-performance versions capable of producing more than 500 horsepower.

Because of its balance of affordability, power, and durability, the Chevy 350 crate engine remains a favorite among hot rod builders, race car drivers, and anyone seeking a dependable upgrade that can breathe new life into their vehicle.

11. Nissan SR20DET

The Nissan SR20DET became a cult classic in the 1990s, powering cars like the Silvia and 180SX. For mechanics, it’s a joy because of its balance between performance and reliability.

With a strong iron block and turbocharged setup, the SR20 is capable of impressive power without frequent breakdowns.

Its simple four-cylinder layout also makes it relatively easy to work on compared to more complex engines. While not as indestructible as a Toyota 22RE, mechanics appreciate its balance of strength and excitement.

12. Jeep/AMC 4.0L Inline-Six

Ask a Jeep mechanic which engine they prefer, and nine times out of ten, they’ll say the 4.0 inline-six. Introduced in the 1980s and used well into the 2000s, this engine is legendary for its longevity.

Known for running past 300,000 miles with minimal trouble, the 4.0 was a staple in Jeep Cherokees, Wranglers, and Grand Cherokees.

Mechanics love its simplicity, torque-rich performance, and ease of repair. Whether you’re off-roading in Moab or commuting in New Jersey, the Jeep 4.0 earns respect for just refusing to quit.

While every engine has its quirks, the twelve listed here share one thing in common: mechanics genuinely enjoy working with them. Whether it’s Toyota’s indestructible inline-sixes, Honda’s precise four-cylinders, or America’s small-block V8s, these engines inspire confidence.

They’re the ones mechanics recommend to friends and family, the ones they see holding up under abuse, and the ones they secretly smile about when a car with one rolls into the shop.

In the end, an engine that earns a mechanic’s respect isn’t just good on paper it’s proven itself in the real world, over years and sometimes decades of service.

These twelve engines represent the best of the best, the powerplants that mechanics call their favorites because they make the work easier, the cars stronger, and the driving more enjoyable.