When most people think about vehicle longevity, they often talk about the engine first. It’s the heart of any car, the piece of machinery that determines whether a vehicle has another hundred thousand miles left in it or is destined for the scrap yard.

But surprisingly, in many cases, the engine isn’t the first thing to go. Modern and classic vehicles alike have shown us that certain engines are built so tough, so resistant to wear, that the transmission often fails long before the engine even breaks a sweat.

For American drivers who rely on their cars and trucks for daily commutes, weekend road trips, or even heavy-duty work, these engines stand out as near-indestructible powerplants.

Below are twelve engines known for outlasting their transmissions, each with its own reputation for toughness, durability, and longevity.

1. Toyota 2JZ-GTE

No list of legendary engines would be complete without Toyota’s 2JZ. Found in cars like the Supra and Aristo, this inline-six turbocharged motor is notorious for handling massive amounts of power with little more than bolt-on upgrades.

Even when stock, the 2JZ is famous for racking up hundreds of thousands of miles with proper oil changes. Many enthusiasts joke that while the engine could push 1,000 horsepower on stock internals, the automatic transmissions it was paired with were often the weak link.

In the U.S., Supra owners have long discovered that the motor will keep going while gearboxes beg for mercy.

2. Honda K-Series

Honda’s K-series, used across Civics, Accords, and RSX models, is a masterpiece of modern four-cylinder engineering. With high-revving VTEC technology and bulletproof internals, these engines are practically unkillable if you keep oil in them.

Across the U.S., daily drivers and tuners alike have taken these engines well past 250,000 miles. But transmissions, especially the manual gearboxes in heavily modified Civics, are known to wear synchros or suffer from aggressive clutch abuse long before the engine needs rebuilding.

3. Ford 300 Inline-Six

If you grew up in the U.S. during the late 20th century, chances are you saw Ford’s 300 cubic-inch straight-six at work. Found in F-Series trucks and vans, this engine is the definition of overbuilt.

Farmers, contractors, and mechanics will tell you these engines are capable of running on neglect, even after decades of abuse.

But while the engine itself might last half a million miles, the old three- and four-speed transmissions they were paired with often required multiple rebuilds in that span.

The build began with reinforcing the block, where the team used Moroso engine block filler and converted the setup to hydraulic roller lifters for added strength and reliability. A forged crankshaft was installed along with Molnar forged rods, custom DSS Racing pistons, and a custom-ground billet camshaft.

Up top, they equipped the engine with a Promax Performance CNC-ported head, complete with Comp valve springs and secured by ARP studs. With a 9.2:1 compression ratio in its naturally aspirated state, the motor produced 300 horsepower and 334 lb-ft of torque.

When it came time for turbo testing on the dyno, the setup received a Stainless Header exhaust manifold, dual Hypergate 45 mm wastegates, and a Turbonetics Sylvia 7268 turbocharger.

At 12 psi (0.8 bar) of boost, output jumped to 555 horsepower (408 kW) and 623 lb-ft (844 Nm) of torque. Pushing the boost further to 16.5 psi (1.1 bar) unleashed 601 horsepower (442 kW) and an impressive 702 lb-ft (951 Nm) of torque, showcasing just how much potential the upgraded combination had under forced induction.

4. Toyota 22R/22RE

Toyota’s four-cylinder pickup engine is legendary in the off-road community. The 22R and its fuel-injected variant, the 22RE, are famous for their reliability in old Toyota trucks and 4Runners.

These engines have been seen hitting 400,000 miles with little more than routine maintenance.

But ask any Toyota truck owner from the 1980s or 1990s, and they’ll tell you the engines outlast the gearboxes manual or automatic. In many cases, the trucks’ frames would rust away before the engine ever gave out.

Toyota’s 22R and 22RE engines are among the most respected powerplants from the brand’s long-running “R” engine family, earning their reputation for simplicity, reliability, and durability.

Both engines became staples in Toyota’s compact pickups and 4Runners, and they continue to be highly regarded by off-road enthusiasts, restoration builders, and anyone who values long-lasting performance.

While the 22R and 22RE share many core design elements, including their 2.4L displacement and four-cylinder layout, their differences in fueling, cylinder head design, and internal components make each engine distinct in terms of power delivery, maintenance, and upgrade potential.

The 22R was first introduced around 1980 (with most applications referencing the 1981 model year) and came with a carbureted fueling system.

A couple of years later, in 1982, Toyota released the 22RE, which added electronic fuel injection (EFI). This change not only brought the engine in line with evolving emissions regulations but also improved efficiency and made the engine more adaptable to modern driving demands.

Both engines became popular choices in the Hilux pickup and 4Runner, where their rugged design and straightforward maintenance made them favorites among those tackling tough terrain.

From a fueling perspective, the 22R’s carbureted setup is mechanically simple and easy to work on, especially for those comfortable with tuning carburetors.

However, it requires periodic adjustments to stay in top shape. The 22RE, with its EFI system, offers more precise fuel delivery, better fuel economy, and higher horsepower potential.

The trade-off is a slightly more complex system that includes an ECU, sensors, and injectors, which adds to the learning curve for maintenance but generally provides greater long-term reliability.

Differences also extend to the cylinder heads and valvetrain. The 22R’s head was designed around carburetion, featuring smaller intake and exhaust ports, while the 22RE’s head was reworked with larger ports and a combustion chamber design optimized for fuel injection.

Valvetrain components differ as well, the 22R uses solid lifters, requiring periodic adjustment, while the 22RE incorporates hydraulic lifters, which are quieter and demand less frequent servicing.

The camshafts are also tuned differently, with the 22RE’s profile tailored to EFI needs through shorter duration and reduced lift.

Internally, Toyota revised several components for the 22RE to complement its fueling system. Pistons were reengineered for slightly lower compression, connecting rods and crankshaft specifications were altered, and the overall design balanced efficiency with power delivery.

These changes helped the 22RE generate a bit more horsepower than the 22R, though the carbureted 22R still retained a reputation for delivering strong low-end torque, which many off-road drivers appreciated.

In terms of performance, the 22RE edges out the 22R in horsepower thanks to its EFI precision and improved cylinder head flow, while the 22R shines with simplicity and torque delivery, making it a trusted workhorse.

Both engines remain highly modifiable, carb upgrades, EFI tuning, cylinder head porting, and aftermarket internals can all unlock additional performance.

Enthusiasts often select between the two based on whether they value straightforward mechanical systems (22R) or a more modern fueling approach with better efficiency (22RE).

5. Chevrolet Small-Block V8 (350)

Chevy’s small-block V8, particularly the 350, is as close to immortal as engines get. This powerplant has powered everything from Camaros to Silverados, and with its simple pushrod design and massive aftermarket support, it’s one of the most rebuilt and reused engines in American history.

Mechanics often see these engines still running strong after hundreds of thousands of miles, but the automatic transmissions paired with them like the TH350 or 700R4 often needed refreshes along the way. The motor’s durability simply outpaced the transmission’s life expectancy.

6. Mercedes-Benz OM617 Diesel

Mercedes’ OM617 five-cylinder diesel, found in the 240D and 300D models from the 1970s and ’80s, has one of the most loyal followings in the U.S. These engines were designed to last forever, with many owners reporting mileages exceeding 500,000.

They’ll run on low-quality diesel, biofuels, or even questionable home brews. But the transmissions, especially older automatics, often struggled under the long service life, requiring repairs while the engine itself just kept going.

Some engines are renowned for their ability to surpass 500,000 miles when given consistent care, and Mercedes-Benz stands out in this category thanks to its legendary diesel motors. Among them, the OM617A holds a special place, the turbocharged variant of the five-cylinder OM617.

In the 2000s, owners of Mercedes-Benz models equipped with this engine often reported odometer readings as high as 600,000 miles, with many confident the cars could go even further if routine servicing was maintained.

When Mercedes-Benz installed the turbocharged OM617 into the W116 chassis for select markets outside Europe, it marked the debut of the world’s first turbo-diesel sedan.

Over its production span, three slightly different versions of the OM617 turbo engine were built, with a mid-cycle revision of the first design providing the most noticeable boost in performance.

This powerplant found its way into several Mercedes-Benz models, including the 1978–1980 W116, the 1981–1985 W126 S-Class sedans, and various 1978–1986 W123-platform vehicles.

7. Jeep 4.0 Inline-Six

The Jeep 4.0-liter inline-six is another iron-block engine that earned its reputation through sheer toughness. Found in Cherokees, Wranglers, and Grand Cherokees for decades, this engine has a cult following in the U.S. for its ability to survive hard off-road use and high mileage.

Many owners will happily report 300,000-mile Jeeps with the original engine. But ask about the transmission, and you’ll hear about multiple rebuilds especially in older automatic variants that couldn’t match the engine’s resilience.

8. Cummins 6BT (12-Valve)

The 5.9-liter Cummins inline-six diesel, especially the early 12-valve versions found in Dodge Ram pickups, is one of the toughest engines ever sold in the U.S. Farmers and haulers love it because it can handle abuse, towing, and long hours of work without complaint.

Stories of these engines reaching a million miles aren’t rare. But the transmissions Dodge paired them with especially the automatics often failed under the torque load. For many truck owners, the only weak link in their Ram was the gearbox.

The Cummins 6BT stands as the most iconic engine in the company’s B-series lineup.

This 5.9-liter diesel was the first of its kind to be offered in full-size pickup trucks as a viable alternative to large V8 gasoline engines. Production began in 1984, with the engine originally developed for Case agricultural machinery.

Over time, however, the 6BT expanded well beyond its initial role, finding applications in light, medium, and even some heavy-duty trucks and buses.

The turbocharged 12-valve version of the Cummins 6BT became especially renowned when it was installed in Dodge Ram pickup trucks from the 1989 through 1998 model years.

Drivers praised it for delivering immense low-end torque across the entire rev range, as well as superior fuel efficiency compared to Dodge’s gasoline-powered V8 options.

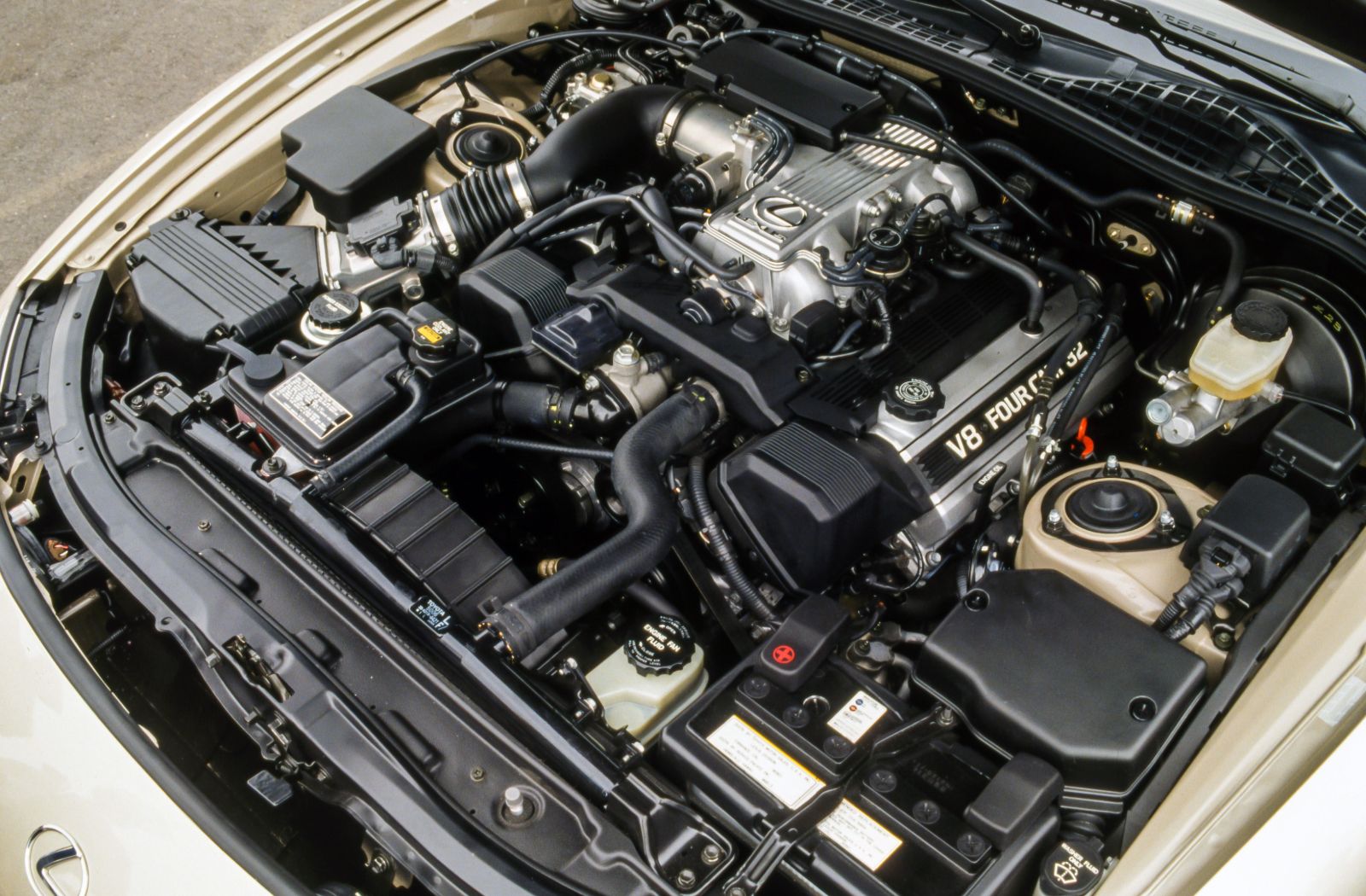

9. Lexus/Toyota UZ V8 (1UZ, 2UZ, 3UZ)

The Lexus LS400’s 1UZ-FE V8 and its later variants are a marvel of Japanese engineering. Smooth, powerful, and built to last, these aluminum-block V8s are famous for going 400,000 miles with regular maintenance.

In the U.S., many used LS400s and Toyota Land Cruisers still have their original engines running strong, but the transmissions often need replacement at much lower mileage. In fact, it’s common to see a second or third transmission paired with the same original engine.

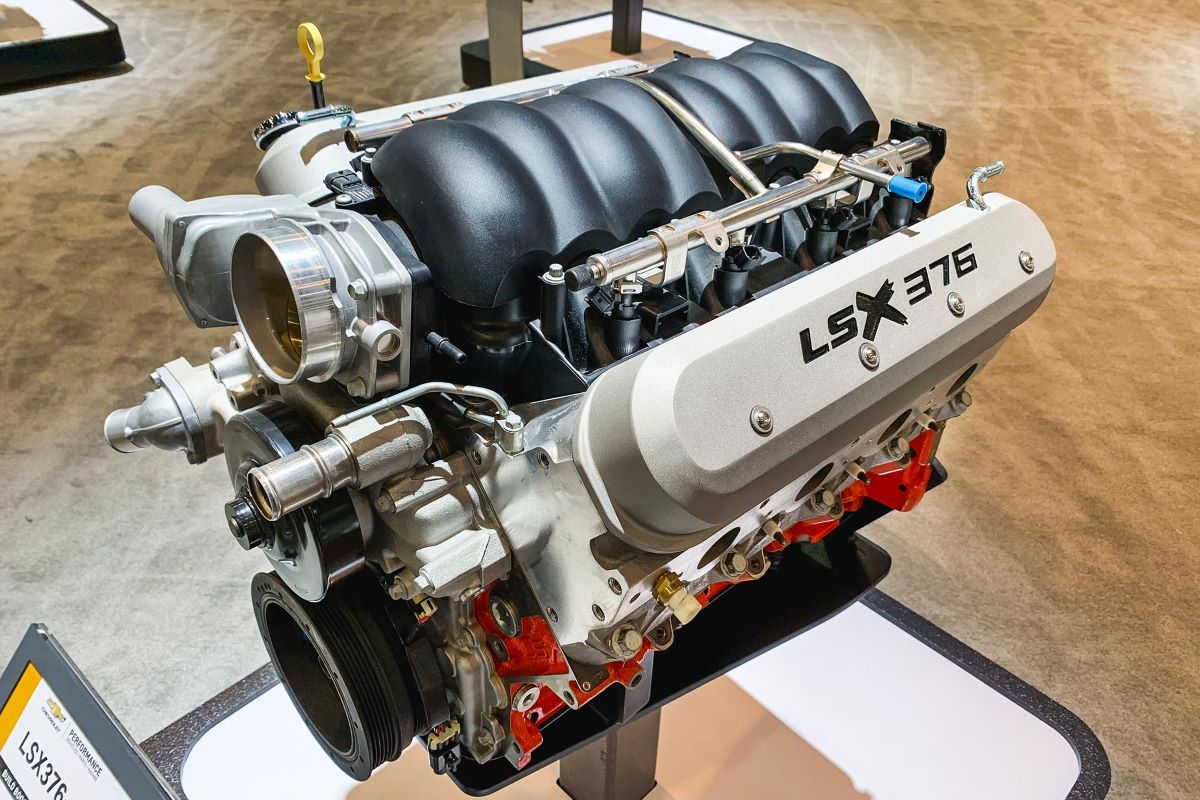

10. GM LS-Series Engines

The LS family of engines, introduced in the late 1990s, became the modern equivalent of the small-block. Used in Corvettes, Camaros, Silverados, and countless swaps, the LS engines have proven themselves nearly unbreakable under normal use.

Their simple yet effective design means they can handle power and mileage far better than most transmissions. Owners often see the gearbox fail long before the LS engine even considers retirement.

The General Motors LS engine has transformed the automotive landscape with its unparalleled mix of power, durability, and affordability.

Its compact size, lightweight build, and extensive aftermarket support quickly elevated it into a legendary platform for performance upgrades, engine swaps, and motorsports. Today, it remains one of the most influential and versatile engine families ever created.

Recognizing its potential early on, Holley wasted no time in responding to the LS wave. The company leaned on its subsidiaries to create dedicated performance solutions, including some of the most complete swap kits available.

Beyond providing hardware, Holley has fully embraced LS culture, even launching its own LS Fest event series, now held at multiple locations nationwide, as a celebration of the community that has grown around this engine.

This guide will dive into the LS’s engineering, adaptability, performance potential, and swap applications. It will also highlight key component combinations and upgrade paths that allow enthusiasts to maximize what this platform has to offer.

The LS made its production debut in 1997 with the C5 Corvette, though development began years earlier in 1993. At the time, GM knew the then-current LT1 and LT4 small-blocks faced mounting challenges: tightening emissions standards, Corporate Average Fuel Economy (CAFE) requirements, and the demand for higher output.

While GM kept the tried-and-true pushrod, single-cam V8 architecture, the LS was almost entirely reengineered, featuring innovations such as a deep-skirt block, next-generation cylinder heads, and even a revised firing order.

One of the most notable advancements was in cylinder head design. GM reduced the valve angle from 23 degrees to 15 degrees, which improved combustion chamber efficiency. The LS also featured a hydraulic roller camshaft and stock 1.7:1 rocker arms, compared to the traditional small-block’s 1.5:1 setup.

Intake and exhaust systems received major updates as well, with composite intake manifolds, large-diameter throttle bodies, and modern exhaust manifolds that greatly outperformed the restrictive log-style designs of earlier generations. These changes enhanced airflow, reduced back pressure, and boosted overall efficiency.

Further improvements included a reliable coil-near-plug ignition system, which replaced the troublesome Opti-Spark, and widespread use of aluminum blocks with iron sleeves to reduce weight.

For heavier-duty applications, such as trucks and SUVs, GM produced iron-block versions marketed under the Vortec brand.

11. BMW M50/M52 Inline-Six

While German cars don’t always have a reputation for reliability, BMW’s M50 and M52 inline-sixes are exceptions. Found in the 3-Series and 5-Series of the 1990s, these engines are known to go the distance with proper care.

U.S. enthusiasts often praise them as some of the most dependable BMW engines ever built. But as many E36 and E39 owners know, transmissions especially automatics are often the first expensive repair, while the engine soldiers on.

When it comes to performance tuning and upgrades, BMW’s M50, M52, and M54 engines are renowned for their durability, engineering strength, and tuning versatility.

Whether you are just entering the world of modifications or already an experienced enthusiast, understanding the differences between these engines and the upgrade paths available can unlock a wide range of performance opportunities.

The M50, M52, and M54 engines were instrumental in building BMW’s reputation for producing reliable and powerful inline-six motors. Found in popular models such as the E36, E39, and E46, these engines continue to attract attention from tuners because of how easily they can be modified.

The M50 debuted in 1990 with a dual overhead camshaft (DOHC) design, and early examples came without BMW’s VANOS variable valve timing system. Known for its strength and ability to rev high, the M50 is often considered a blank canvas for modifications.

The M52, introduced in 1994, improved on this foundation with the addition of single VANOS, enhancing low-end torque while retaining strong top-end performance. This balance between daily drivability and tuning potential made it one of the most versatile options for enthusiasts.

The M54 arrived in 2000 with double VANOS, offering smoother power delivery across the rev range and a more refined driving experience, while still leaving plenty of room for significant performance upgrades.

Among tuners, the M50 has become especially popular in its non-VANOS versions, such as the M50B20 and M50B25, because of their mechanical simplicity and reliability.

The absence of VANOS allows for easier adjustment of camshaft timing, making it well-suited to high-revving setups.

With its strong internals, the M50 can handle forced induction such as turbocharging or supercharging, but when aiming for higher horsepower, upgrading to forged pistons and connecting rods is highly recommended to ensure the engine can withstand the added stress.

The M52 is equally popular, particularly the M52B28, because it strikes a balance between smooth power delivery and high-revving capability. Its single VANOS system provides better torque at lower RPMs, while still allowing performance potential at higher speeds.

This makes it a versatile option for those who want both street usability and track capability. However, to safely extract more power, enthusiasts often invest in forged pistons and rods, such as those offered by KingTec Racing, which are designed to handle greater stress without sacrificing reliability.

An upgraded cooling system also becomes necessary once the engine is pushed well beyond its stock power limits.

The M54, used in cars such as the E46 330i, takes the formula further by introducing double VANOS, which improves torque at the low end while enhancing top-end output for a smoother, more consistent power band.

This refinement makes it an excellent choice for enthusiasts who want both performance and comfort, though its complexity requires careful tuning to get the most out of it.

When increasing horsepower through forced induction, reinforced internals become essential.

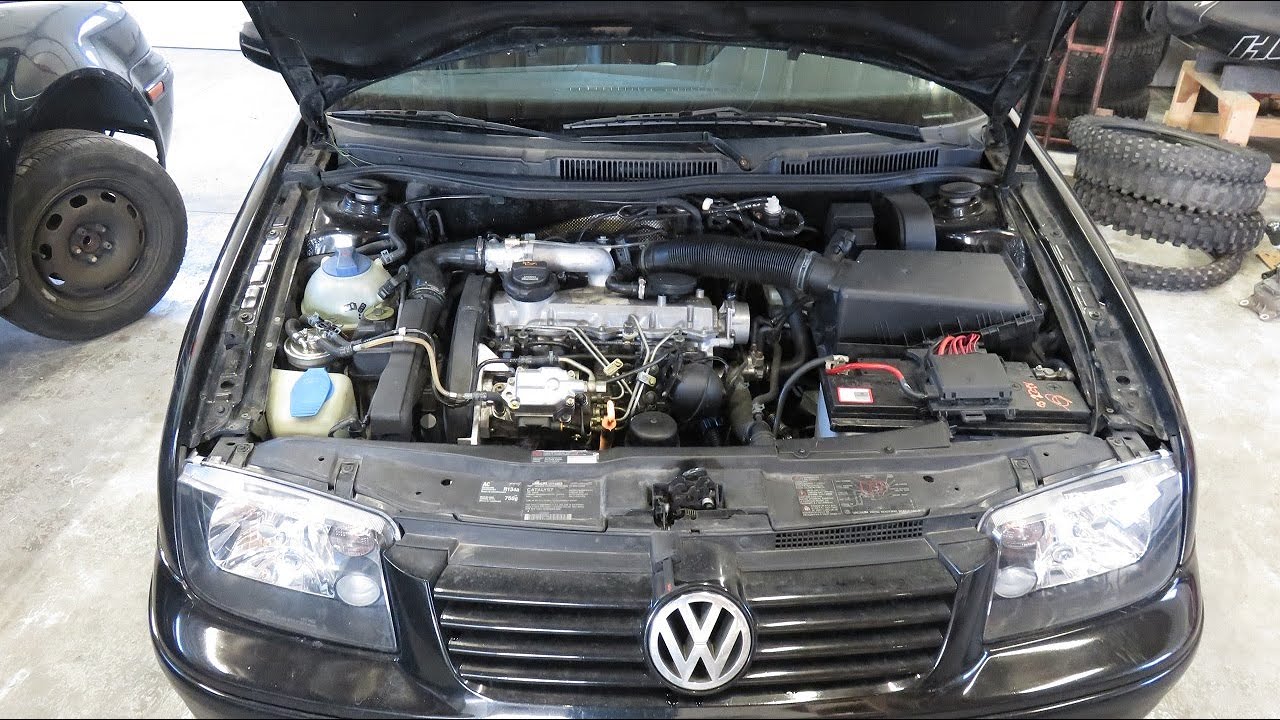

12. Volkswagen ALH TDI Diesel

For diesel fans, Volkswagen’s ALH TDI, used in late-1990s and early-2000s Jettas and Golfs, remains a high-mileage hero. These engines are known for reaching 400,000 miles or more with excellent fuel economy along the way.

The diesel engine itself rarely fails, but many owners report transmission replacements during the car’s life, especially with automatic models. It’s a classic case of the engine outliving everything around it.

For U.S. drivers, engine durability is often the deciding factor when buying used cars and trucks. But as these examples show, sometimes the engine is so well-built that the transmission becomes the weak link.

From Toyota’s 2JZ to the Cummins 6BT, these engines have earned legendary status not just because they’re powerful or efficient, but because they last so long they expose the shortcomings of the gearboxes paired with them.

Whether you’re an enthusiast restoring a classic or a driver looking for a reliable workhorse, these engines prove that the right motor can truly outlast just about everything else in the car.