Few achievements in automotive engineering are as impressive as an engine that refuses to fade with time. While many power plants succumb to wear, neglect, or technological obsolescence, some engines achieve near-mythical longevity, delivering performance and reliability for decades.

From the legendary Chrysler Slant-Six, known as the “engine that refuses to die,” to Toyota’s bulletproof 1JZ and 2JZ inline-sixes, these powerhouses combine robust construction, intelligent design, and over-engineering to stand the test of time.

Whether it is the torque-rich Ford 300 Straight-6, the high-revving Honda K-Series, or the versatile GM LS V8, these engines have earned their reputations through consistent performance, minimal maintenance, and adaptability across vehicles and applications.

This compilation celebrates 12 engines that never lose power with age. These machines embody reliability, durability, and engineering foresight, proving that some power plants can outlast generations of vehicles.

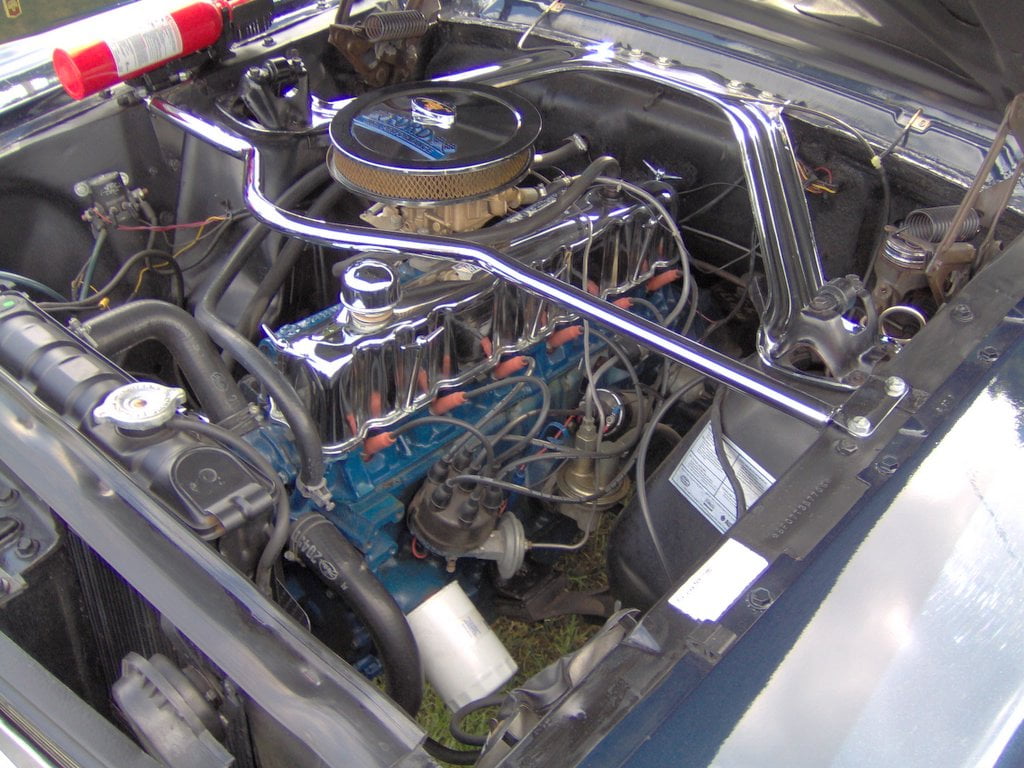

1. Chrysler Slant-Six/G-Engine: A Legend of Durability

The Chrysler Slant-Six, also known as the G-Engine, is one of the most iconic inline-six engines in automotive history. Produced from 1959 to 2000, it earned a reputation for unmatched durability, versatility, and longevity. Its distinctive 30-degree canted design allowed it to fit in a variety of vehicles, powering 31 different Chrysler, Dodge, and Plymouth models.

Notable applications include the Chrysler Cordoba, LeBaron, Fifth Avenue, Dodge Dart, Aspen, Challenger, Charger, Ram Van, Ram Pickup, and Plymouth Barracuda, Belvedere, Duster, and Gran Fury. Its ability to perform reliably across sedans, trucks, vans, and even industrial applications led to its nickname: the “engine that refuses to die.”

The Slant-Six was available in three primary displacements: 170, 198, and 225 cubic inches (2.8, 3.2, and 3.7 liters). Within these displacements, Chrysler offered multiple variations with differences in short and tall blocks, main bearing counts, and other internal components, while retaining the core design.

The engine was produced with both cast iron and aluminum blocks, yet maintained exceptional reliability regardless of material. Its canted layout, rigidity, and efficient cooling made it adaptable for a wide range of vehicles and even some motorsport applications.

The Slant-Six’s legendary durability stems from its robust engineering. A thick cast iron block and deep-skirt design enhanced structural integrity, while a seven-main-bearing crankshaft provided superior support, reducing wear over time.

It’s simple, overbuilt construction allowed the engine to endure extreme conditions, from taxi fleets and trucks to military service, often reaching hundreds of thousands of miles with minimal maintenance. Reports of taxis surpassing 400,000 miles illustrate their exceptional longevity.

The Slant-Six navigated the challenges of the 1970s, including fuel crises and stricter emissions standards, without requiring major modifications. Its combination of reliability, ease of maintenance, and potential for performance upgrades earned it a loyal following among enthusiasts and practical users alike.

Today, the Slant-Six remains a benchmark for durability and versatility, proving that an engine designed with simplicity and overengineering can outlast generations of vehicles. Its legacy endures as a symbol of Chrysler’s engineering excellence and a testament to the power of well-built machinery.

2. Ford 300 Straight-6: The Indestructible Workhorse

The Ford 300 Straight-6, introduced in 1965, is one of the most durable and reliable inline-six engines ever produced. A long-stroke evolution of Ford’s 240 engine, the 300 cubic inch (4.9-liter) motor debuted in the F-Series pickup, initially producing 170 hp.

Over its production life, power ratings shifted due to changes in measurement standards, dropping to 114 hp net in 1978 and later increasing to 122 hp in the 1980s, before reaching 150 hp with fuel injection in 1987. Despite modest horsepower, the engine became legendary for its torque, longevity, and ability to thrive in heavy-duty applications.

The Ford 300 was engineered with simplicity and strength in mind. Its traditional overhead valve design with an in-block camshaft and gear-driven valvetrain ensured durability and minimal maintenance.

The engine’s thick cast-iron block and cylinder head, combined with a massive crankshaft supported by seven main bearings, provided exceptional structural integrity. This overbuilt construction, along with robust pistons, a cooling system, and a long-stroke configuration, allowed the 300 to deliver strong low-end torque, ideal for hauling heavy loads or operating industrial machinery.

Over its three-decade production run, the Ford 300 powered a wide array of vehicles and equipment. From F-Series pickups and E-Series vans to dump trucks weighing up to 20,000 lbs, tractors, wood chippers, water pumps, ski lifts, and even UPS trucks, the engine proved its versatility.

It also achieved notable performance milestones, winning the Baja 1000 three times in a truck driven by Scott Donohue. Its ability to endure heavy use, neglect, or minimal maintenance earned it a reputation as “indestructible” among owners and mechanics alike.

The Ford 300’s legacy is defined by its longevity and resilience. Its simple, overbuilt design made it easy to maintain and capable of running hundreds of thousands of miles with minimal repairs.

While not designed for high horsepower, the engine’s focus on durability, low-end torque, and rugged construction made it perfect for trucks, vans, and industrial applications. Production officially ended in 1996, although the engine continued to be manufactured internationally and adapted for high-performance applications.

Today, the Ford 300 Straight-6 is celebrated as a benchmark of reliability and engineering excellence. Its combination of strength, simplicity, and versatility has left a lasting impression on truck enthusiasts, mechanics, and industrial operators, solidifying its place as one of the most dependable engines in automotive history.

3. Mercedes-Benz OM617: The Legendary Five-Cylinder Diesel

The Mercedes-Benz OM617 is a five-cylinder diesel engine renowned for its extraordinary reliability, longevity, and efficiency. Produced from 1974 to 1991, the 3.0-liter motor became a cornerstone of Mercedes-Benz’s reputation for durable, high-mileage vehicles, especially in taxis and long-haul fleet applications.

Its overbuilt design, cast iron block and head, and chain-driven single overhead camshaft allowed engines to exceed 500,000 miles, with some examples surpassing one million miles with proper maintenance.

The OM617 evolved from the OM616 four-cylinder diesel and debuted in the W115 chassis with 79 hp and 127 lb-ft of torque in naturally aspirated form. By 1976, turbocharged versions offered up to 187 hp, famously powering the Mercedes C111-IID concept car and setting 16 world land speed records.

Later upgrades in 1978 increased output to 227 hp, adding another nine records to the C111’s legacy. The engine combined mechanical simplicity with robust engineering, including a Bosch inline injection pump, forged steel crankshaft, and non-interference valve setup, contributing to its “unbreakable” reputation.

The OM617’s legendary durability stems from its mechanical simplicity and over-engineering. The lack of complex electronics reduces potential failure points, while its cast-iron components and chain-driven overhead valves ensure long-term structural integrity.

Regular maintenance, including oil changes every 5,000 miles, fuel filter replacements, coolant upkeep, and valve adjustments, is key to sustaining its longevity. Both naturally aspirated and turbocharged variants are exceptionally reliable, though naturally aspirated examples often achieve higher mileage due to lower operating stress.

The OM617 powered a range of vehicles, from the W115 and W123 sedans to the W116 300SD, the first North American turbodiesel production sedan. Its combination of reliability, torque, and fuel efficiency also made it popular for industrial and fleet use.

Today, it enjoys a dedicated aftermarket community and is a sought-after swap engine for vehicles such as Jeep Cherokees and Toyota Land Cruisers, though it often performs best in its original Mercedes chassis.

The OM617 remains one of the most respected diesel engines in automotive history. Its balance of durability, simplicity, and performance allows it to deliver decades of trouble-free service.

For enthusiasts, mechanics, and long-haul operators alike, the OM617 symbolizes Mercedes-Benz’s engineering excellence, proving that with careful design and routine maintenance, an engine can reliably exceed half a million miles, often outlasting the vehicle itself.

4. Toyota 1/2/3UZ-FE: The Bulletproof V8

The Toyota UZ family of V8 engines, produced from 1989 to 2013, is renowned for its combination of reliability, refinement, and performance. Introduced in the Lexus LS 400, the 90-degree V8 powered a wide range of vehicles, including luxury sedans, SUVs, pickup trucks like the Tundra, and off-road models such as the Land Cruiser, Sequoia, and Lexus LX/GX.

Beyond automotive applications, the UZ engines have even been adapted for marine and aviation use, a testament to their robust engineering and versatility.

The UZ family includes three main displacements: 4.0 liters in the 1UZ, 4.7 liters in the 2UZ, and 4.3 liters in the 3UZ, with additional racing-oriented versions producing up to 5.0 liters for Super GT and Grand American Road Racing (Grand Am) series. Naturally under-stressed, these engines offered power outputs ranging from 256 to 500 hp, striking a balance between performance, reliability, and smooth power delivery.

The UZ-FE engines are widely regarded as “bulletproof” due to their robust construction and precision engineering. Features such as six-bolt main bearings, steel crankshafts, aluminum blocks, and high-quality internal components contribute to exceptional durability.

The engines were developed over six years with a massive budget exceeding $1 billion, ensuring refinement, low NVH (noise, vibration, harshness), and long-term reliability. When properly maintained, these engines commonly surpass 200,000 miles, with some examples reaching far beyond that threshold.

Despite their reliability, UZ engines are not completely maintenance-free. Common age-related issues include oil leaks from valve cover gaskets, cam seals, and rear main seals, as well as coolant leaks from head gaskets.

Timing belt replacement requires careful attention, as errors can damage the crankshaft position sensor or other critical components. Engines with VVTi (Variable Valve Timing with intelligence) are particularly sensitive to oil quality and sludge buildup, making regular oil changes and proper maintenance essential for longevity.

The UZ family’s reliability and versatility have made it a popular choice not only in luxury vehicles but also in high-demand off-road and commercial applications. Its engineering excellence and durability have earned it a reputation as one of the most dependable V8 engines globally.

For enthusiasts and daily drivers alike, the Toyota 1/2/3UZ-FE V8 stands as a benchmark for reliability, refinement, and long-lasting performance in modern engine design.

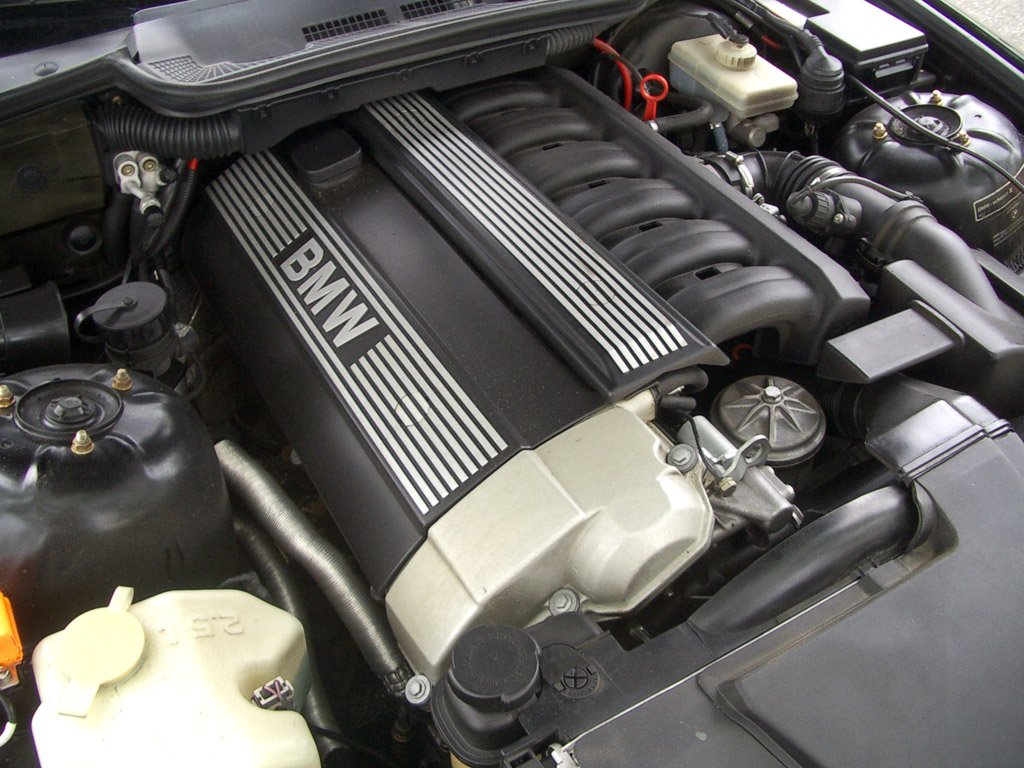

5. BMW M50: The Inline-Six That Laid the Foundation

The BMW M50 inline-six engine, produced from 1990 to 1996, is widely regarded as one of the most reliable and durable BMW engines of its era. Introduced in the E34 5 Series to replace the M20, the M50 offered displacements ranging from 2.0 to 2.5 liters, with power outputs between 148 and 189 horsepower.

In 1992, BMW added a single VANOS variable valve timing system to the intake cam, making the M50 the company’s first engine to feature this technology. Its robust design and engineering laid the foundation for future BMW six-cylinder engines and served as the basis for the high-performance S50 used in the E36 M3, which produced 282-316 horsepower.

The M50’s reliability stems from its straightforward, mechanically sound design. Featuring a cast iron block and aluminum cylinder head, the engine combines strength with efficiency.

Its simplicity, lacking complex modern electronics, makes it easy to maintain and work on, appealing to enthusiasts and mechanics alike. The robust construction also allows many M50 engines to handle forced induction applications, including turbocharging, without significant modification.

While the M50 is known for its durability, age-related issues primarily affect the cooling system. Water pumps typically fail every 60,000 to 80,000 miles, and coolant expansion tanks are prone to cracking around 80,000 to 100,000 miles. Radiators, hoses, and cooling fans can also develop problems as the engine ages.

Preventive maintenance, including a full cooling system refresh, is strongly recommended for engines now approaching 30 years old. Regular oil changes, inspection of gaskets and seals, and timely replacement of rubber components further ensure long-term reliability.

The M50’s mechanically sound design, ease of maintenance, and longevity have made it a benchmark among BMW six-cylinders. It set the stage for future BMW engines by combining reliability with performance potential, as evidenced by its role in the E36 M3’s S50 variant. High-mileage examples continue to operate reliably, demonstrating the enduring strength of BMW’s engineering during this era.

Owners of M50-equipped vehicles should prioritize regular maintenance, especially cooling system components, to prevent age-related failures. Replacing rubber components, gaskets, and seals, along with consistent oil changes, will help preserve the engine’s legendary durability. With proper care, the M50 remains a reliable, high-performing engine capable of decades of use.

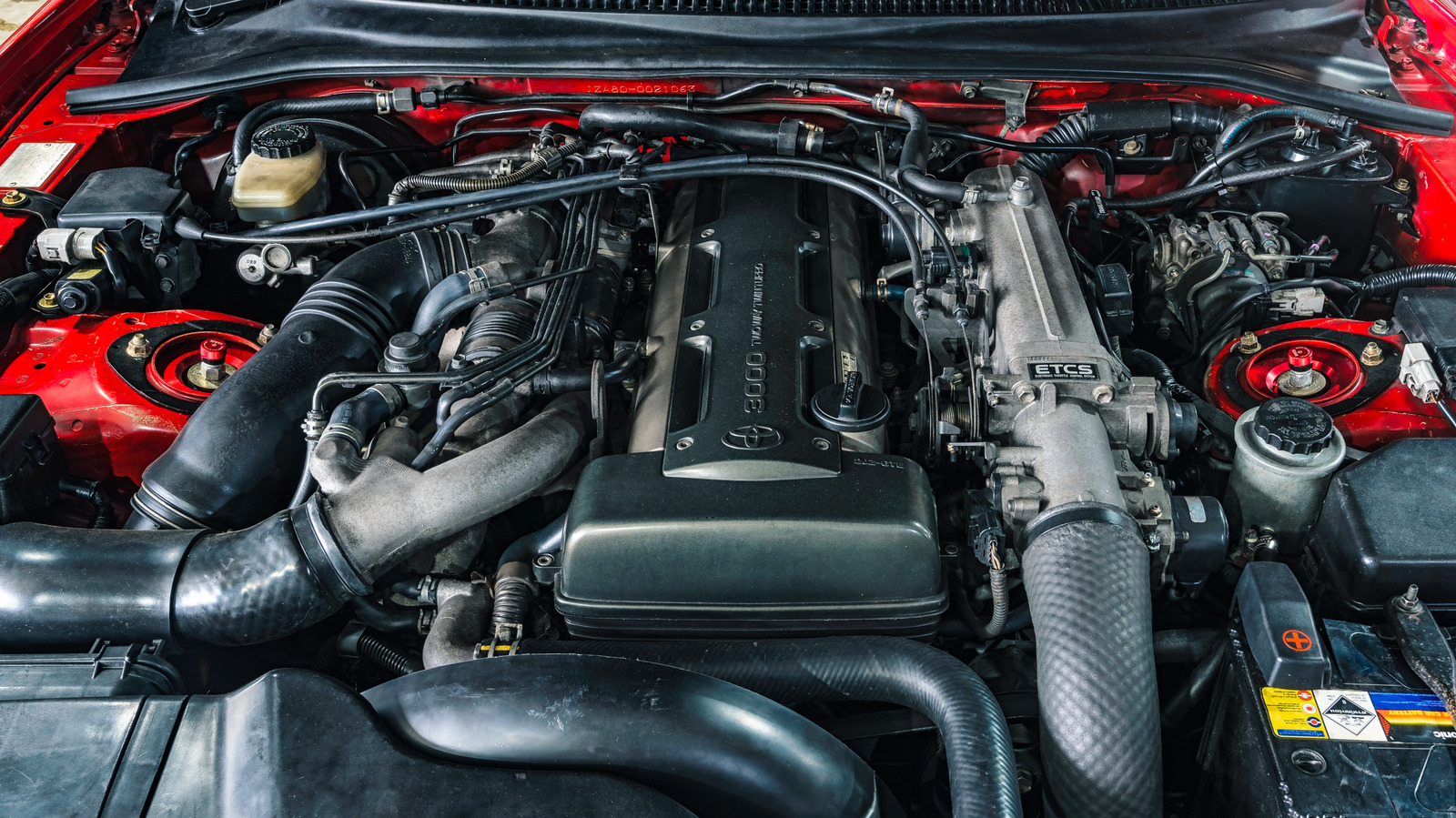

6. Toyota 1JZ/2JZ: The Bulletproof Inline-Six

The Toyota 1JZ and 2JZ inline-six engines, produced from 1990 to 2007, are legendary for their reliability, durability, and immense tuning potential. Found in vehicles such as the Mk IV Toyota Supra and other high-performance Toyota models, these engines combine robust construction with the ability to handle extreme power outputs, making them a favorite among enthusiasts and professional tuners alike.

The 1JZ is a 2.5-liter variant producing 168–276 hp, while the 2JZ is a 3.0-liter version delivering 212–320 hp in stock form, with highly tuned examples reaching nearly 1,000 hp on factory internals.

The 1JZ/2JZ engines are built around a cast-iron block and aluminum cylinder head, providing exceptional strength and heat resistance. Over-engineered internal components, including forged steel crankshafts, durable connecting rods, and robust pistons, enable the engines to handle significantly more power than factory ratings.

The 2JZ-GTE turbocharged variant features high-flow fuel pumps, large injectors, and an intercooler to manage boost levels efficiently. This combination of engineering foresight and mechanical simplicity has contributed to their “bulletproof” reputation.

These engines are renowned for their ability to run hundreds of thousands of miles with minimal issues when properly maintained. Routine maintenance, including timely oil changes, timing belt replacements, and attention to gaskets and valve seals, is generally sufficient to keep them running smoothly.

Even with high-mileage or performance-modified examples, the core engine architecture has proven extremely durable. Owners frequently report engines lasting well over 200,000 miles with stock internals, demonstrating the inherent reliability of Toyota’s engineering.

Despite their robustness, the 1JZ/2JZ engines are not entirely immune to age or abuse. Potential issues include worn gaskets, timing belt tensioner failures, oil pump seal wear, and crank pulley degradation.

The sequential twin-turbo system on some 2JZ-GTE models can also pose reliability concerns, prompting many tuners to convert to a single-turbo setup. Proper inspection and maintenance are essential for ensuring longevity, especially in older engines or those previously driven hard.

The 1JZ and 2JZ engines remain iconic in the automotive world, celebrated for combining extreme reliability with high-performance potential. They are highly sought after in the tuner community and for high-power applications due to their strength, simplicity, and adaptability.

With correct care, these engines continue to perform reliably, solidifying their status as some of Toyota’s most durable and capable powerplants ever produced.

Also Read: 10 Cars From the 2010s Already Nearing Collector Status

7. Volkswagen ABF: The Reliable 16-Valve Inline-Four

The Volkswagen ABF engine, produced from 1992 to 1999, is a 2.0-liter 16-valve inline-four known for its reliability, rev-happy nature, and performance potential. Found in the Mk III Golf GTI and fourth-generation Passat across various markets, the ABF delivered 148 hp at 6,000 rpm and 133 lb-ft of torque at 4,800 rpm.

Its cast iron block and aluminum cylinder head, combined with hydraulic lifters and fuel injection, made it a durable and responsive powerplant. While short-lived, the ABF remains a favorite among enthusiasts for engine swaps and high-revving applications.

The ABF’s design emphasizes durability and performance. A robust cast iron block provides strength, while the aluminum head reduces weight and improves heat dissipation. Hydraulic lifters reduce maintenance needs, and the 16-valve configuration allows for efficient airflow and rev-happy performance.

Its simplicity contributes to longevity, allowing the engine to achieve upwards of 250,000 miles with proper care even under aggressive driving conditions.

The ABF is considered extremely reliable when maintained, though attention to certain wear points is crucial. Common issues include oil leaks from rocker covers and distributor O-rings, crank sensor corrosion due to its location behind the front engine mount, throttle body micro switch failures causing erratic idling, and minor coolant or alternator belt problems.

Timing chain guides can also wear prematurely if maintenance is neglected, potentially leading to chain jumping. Regular oil changes, high-quality gaskets, and timely replacement of components like water pumps and sensors are key to preserving longevity.

Operating conditions and maintenance history significantly affect the ABF’s reliability. Engines subjected to frequent cold starts, aggressive driving, or poor maintenance can experience accelerated wear, particularly on the timing chain and sensors. Conversely, engines with documented service histories and stable idling tend to remain robust and dependable even after decades of use.

Prospective ABF owners should inspect maintenance records, check for stable idle and signs of oil or coolant leaks, and examine the crank sensor wiring for corrosion. Ensuring these aspects are addressed helps maintain the ABF’s legendary durability and performance potential.

Though no longer in production, the ABF continues to enjoy a reputation as a reliable and high-revving performance motor. Its strength, straightforward design, and rev-friendly characteristics make it a popular choice for engine swaps, tuning projects, and enthusiasts seeking a dependable Volkswagen four-cylinder capable of enduring hundreds of thousands of miles.

8. GM LS V8: The American Small-Block Legend

The General Motors LS family of small-block V8 engines, produced from 1997 to the present, is renowned for its reliability, versatility, and tuning potential. Spanning three generations with a fourth upcoming, the LS has powered a wide range of GM vehicles, from the Chevy Silverado to the Camaro and Corvette.

With displacements ranging from 4.8 to 7.4 liters and stock power outputs from 255 to 755 hp, the LS platform has also been pushed to extreme levels, reaching 1,250 hp in modified applications based on the LT7 from the Corvette Z06.

LS engines feature a strong aluminum block and simple pushrod design, where the camshaft sits in the V of the engine. This architecture reduces potential failure points compared to more complex overhead cam designs while maintaining structural strength.

Their modularity and straightforward construction make them easy to maintain and repair, and the widespread availability of parts ensures solutions are accessible for almost any issue. This combination of simplicity, strength, and adaptability has made the LS a favorite for both daily drivers and high-performance tuners.

The LS family is widely regarded as highly reliable, with many examples exceeding 300,000 miles under regular maintenance. Routine oil changes, timely cooling system upkeep, and adherence to proper maintenance schedules are usually sufficient to ensure long-term durability.

Common issues such as water pump failures, bent pushrods, and minor oiling concerns are generally inexpensive and well-understood, with readily available fixes. Specific variants, like the LS3 L99 with Active Fuel Management (AFM), are more prone to lifter failures, though aftermarket solutions like AFM deletion or tuners’ software fixes are effective.

Several design factors make LS engines durable: the strong aluminum block provides a robust foundation; the pushrod design reduces mechanical complexity and wear points; the engine’s modular construction simplifies maintenance; and the extensive aftermarket support ensures parts and knowledge are readily available for repairs and upgrades. These elements collectively create an engine platform that is both dependable and highly tunable.

The LS V8 has earned a legendary status in the automotive world, balancing reliability, high performance, and adaptability. Its strength and simplicity have made it a top choice for trucks, performance cars, and custom builds.

Whether stock or heavily modified, LS engines continue to demonstrate exceptional durability, making them a benchmark for modern V8 design and one of the most celebrated American engines of the past 25 years.

9. Honda K-Series: The High-Revving DOHC Inline-Four

The Honda K-Series, launched in 2001, is a highly regarded family of dual-overhead cam (DOHC) inline-four engines celebrated for reliability, performance, and tunability. Spanning displacements from 2.0 to 2.4 liters, these engines have powered a wide range of Honda and Acura models, including the Civic Type R, Integra, Accord, CR-V, and RDX.

Known for their VTEC variable valve timing, high-revving characteristics, and robust engineering, K-Series engines have become a favorite among enthusiasts for swaps and performance builds.

K-Series engines are available in both naturally aspirated and turbocharged configurations, with outputs ranging from 150 to 320 hp depending on the model and modifications. The K20 and K24 variants are the most popular, combining strong factory internals with high-rev capability and smooth power delivery.

Turbocharged K-Series engines have proven particularly durable, making them ideal for high-performance applications where reliability under stress is critical.

The K-Series’ reliability stems from its robust construction and advanced technology. Engines feature high-strength components, precise DOHC valve timing, and VTEC systems that optimize efficiency and performance.

With regular maintenance, these engines are capable of exceeding 300,000 miles. Extensive aftermarket support further enhances reliability, providing options for performance upgrades and replacement components that maintain engine longevity.

While generally reliable, certain K-Series engines have known wear points. The K24 is prone to front crankshaft seal leaks, typically occurring around 100,000 to 150,000 miles. Some K20 variants may experience exhaust cam lobe wear, particularly if oil maintenance was neglected or improper oil was used. Additionally, improperly tuned engines can develop rough idle, oil sealing issues, or vibrations.

To maximize K-Series reliability, owners should perform regular oil changes, monitor oil levels closely, and promptly address any leaks. Using manufacturer-recommended engine oil is crucial to protect camshafts and internal components. Proper tuning and attention to preventative maintenance ensure the engine remains durable even under high-performance conditions.

The Honda K-Series has earned a reputation as one of the most reliable, high-revving four-cylinder engines of its era. Its combination of advanced engineering, performance potential, and durability makes it a favorite for enthusiasts, daily drivers, and engine swap projects alike.

With proper care, the K-Series continues to deliver long-lasting performance, maintaining Honda’s legacy of dependable engineering and mechanical excellence.

10. Toyota 2GR: The Reliable 3.5-Liter V6

The Toyota 2GR is a 3.5-liter, 60-degree V6 engine produced from 2005 to the present, renowned for its reliability, versatility, and global use. Part of the GR engine family, the 2GR has powered a wide range of Toyota and Lexus vehicles, including the Tacoma, Camry, Highlander, Avalon, ES, GS, IS, and RX, as well as specialty applications like the Lotus Evora and racing variants in the Corolla.

Its combination of modern engineering, robust construction, and proven durability has made it a staple among consumers seeking dependable performance.

Constructed with a die-cast aluminum block and aluminum cylinder head, the 2GR-FE delivers outputs between 237 and 316 hp depending on the application. It features a timing chain rather than a timing belt, designed to last the life of the engine, reducing long-term maintenance.

Toyota’s rigorous engineering standards and extensive testing ensure high-quality materials and precision assembly, resulting in an engine that performs reliably in a wide range of vehicles and conditions.

The 2GR-FE is celebrated for its long-term durability, often reaching 200,000 to 250,000 miles with basic maintenance such as regular oil changes.

Its robust engineering and quality components make it largely trouble-free, though some early examples exhibited minor issues such as water pump failures, deteriorating rubber oil feed lines, and occasional timing cover leaks. Later revisions addressed these concerns, further enhancing the engine’s reliability.

Several key features contribute to the 2GR’s reputation for dependability: solid engineering and high-quality materials provide structural integrity; the timing chain reduces routine maintenance compared to belt-driven engines; and Toyota’s rigorous testing procedures help identify and correct potential issues before production.

The engine’s widespread adoption also ensures ample parts availability and support worldwide.

While generally robust, early 2GR engines may experience water pump failure, timing cover leaks, or oil feed line deterioration. These are typically minor and easily addressed with preventive maintenance. The engine’s design and improvements over its production run have minimized these problems in later models.

The 2GR-FE remains one of Toyota’s most successful and reliable engines, valued for its combination of performance, longevity, and adaptability. Its widespread use across sedans, SUVs, and specialty applications, along with consistent high-mileage performance, reinforces its status as a globally trusted engine capable of delivering decades of dependable service.

11. Toyota 2JZ-GE/GTE: The Iconic Inline-Six

The Toyota 2JZ engine, introduced in 1991, quickly became an icon, particularly in its turbocharged 2JZ-GTE form as the heart of the Mk IV Supra. Designed during an era when Toyota deliberately over-engineered its engines, the 2JZ was built to last.

Its cast-iron block provides exceptional rigidity, while the GTE version’s forged steel internals, seven main bearing caps, and under-piston oil squirters allow it to withstand extreme power without sacrificing durability.

This engineering enables the 2JZ to handle massive horsepower upgrades, with tuners routinely surpassing 1,000 bhp, yet stock examples consistently reach 200,000 to 300,000 miles on standard maintenance. The sequential twin-turbo system ensures smooth and predictable power delivery, making the engine suitable for both high-performance applications and long-term reliability.

The 2JZ’s design simplicity further contributes to its legendary status. While it includes a basic variable valve timing system, the engine avoids unnecessary complexity, reducing potential failure points and making maintenance straightforward.

Its robust oiling system and durable bottom-end components allow it to perform under stress, while Toyota’s production standards have resulted in engines that are consistent and long-lasting. Enthusiasts and owners benefit from the extensive aftermarket support, ensuring replacement parts and performance upgrades are readily accessible.

Despite its reputation for bulletproof reliability, the 2JZ is not entirely free from age-related considerations. Components such as gaskets, timing belts, and valve stem seals may require attention over time, particularly in engines that have been heavily tuned or poorly maintained.

Engines subjected to extreme abuse may show accelerated wear, and minor electrical issues have been reported, though these are generally peripheral to the engine’s mechanical reliability.

Ultimately, the Toyota 2JZ-GE and 2JZ-GTE represent the pinnacle of over-engineered performance engines. Their combination of structural strength, high-rev capability, and adaptability to both stock and highly tuned configurations has earned them a legendary reputation.

Known for remarkable longevity and the ability to handle tremendous power levels, the 2JZ continues to set the standard for inline-six engineering, illustrating how durability, precision, and foresight in design can produce an engine that remains relevant for decades.

12. Toyota 22R / 22R-E Engine: Legendary Reliability in a Four-Cylinder

The Toyota 22R and its fuel-injected variant, the 22R-E, are among the most reliable four-cylinder engines Toyota has ever produced, known for their longevity and simplicity. Manufactured between 1981 and 1997, these 2.4-liter engines powered a wide range of vehicles, including the Hilux pickup, 4Runner, and Celica.

Built with a cast-iron block and aluminum head, the 22R was designed to prioritize durability over complexity, and its chain-driven timing system eliminates the frequent maintenance requirements associated with timing belts.

The engine’s relatively low power output ensures that internal components are never overstressed, allowing many examples to surpass 300,000 miles, with some reaching 400,000 miles or more without requiring a major rebuild. Its ease of maintenance, availability of parts, and straightforward design have contributed to its popularity among owners and mechanics alike.

The 22R-E fuel-injected model offers improved efficiency and slightly enhanced reliability compared to the carbureted 22R, but both versions share the same fundamental robustness.

The engine’s longevity depends on basic maintenance such as regular oil changes, cooling system care, and attention to components that may wear with age, including seals, gaskets, and the timing chain.

While the chain-driven system is more durable than a belt, it should still be inspected and possibly replaced around the 150,000-mile mark to prevent damage. Additionally, the 22RE is susceptible to vacuum leaks from its various rubber hoses, which can cause lean running conditions if not addressed.

When considering a used 22R or 22R-E, a well-documented maintenance history is a strong indicator of continued reliability. Inspecting the engine for signs of neglect, excessive wear, or previous abuse is important, as these engines are often found in high-mileage trucks that may have experienced heavy use.

Despite their age, the 22R and 22RE remain highly regarded for their simple, durable construction, and their ability to provide decades of dependable service has solidified their status as some of Toyota’s most trusted engines.

Engines like the Mercedes-Benz OM617 diesel, BMW M50, and Toyota 22R show that longevity is no accident. It results from careful design, quality materials, and thoughtful engineering.

From luxury sedans to workhorse pickups, these engines have powered vehicles across decades, often surpassing hundreds of thousands of miles without compromise. They demonstrate that durability does not require sacrificing performance.

Instead, it reflects a balance between mechanical simplicity, robust construction, and proper maintenance. Whether you are an automotive enthusiast, a mechanic, or a driver seeking reliability, these 12 engines offer proof that some powerplants truly defy age. They are more than just motors.

They are legacies that continue to deliver power, efficiency, and peace of mind long after their introduction. Highlighting these remarkable engines honors the enduring spirit of engineering excellence that ensures some machines never lose their edge.

Also Read: 5 Cars That Stay Fun to Drive vs 5 That Get Old Fast