Engines form the heart of any vehicle, and their durability directly impacts reliability, maintenance costs, and long-term ownership satisfaction.

While some engines are known to run for hundreds of thousands of miles with minimal issues, others develop persistent problems that require frequent repairs. Mechanics have firsthand experience identifying which engines earn a reputation for being indestructible and which are prone to failure.

Engines deemed “indestructible” combine robust engineering, quality materials, and simple, service-friendly designs that withstand high mileage and heavy usage.

These engines maintain consistent performance over time, resist common mechanical failures, and benefit from readily available replacement parts. Owners can rely on these engines for decades with routine maintenance, making them highly valued in both daily drivers and work vehicles.

Conversely, engines that break or fail prematurely often exhibit design weaknesses, low-quality components, or sensitive systems that are prone to wear.

Even minor issues can escalate into major repairs, and long-term reliability becomes uncertain. Understanding which engines fall into these categories helps buyers, enthusiasts, and fleet operators make informed decisions and avoid costly mistakes.

This article highlights five engines mechanics consider nearly indestructible alongside five that are known to break. Each example explains the factors influencing durability, providing insight into what makes an engine reliable or problematic over time.

Also Read: 5 Cars That Are Dealer Favorites vs 5 They Avoid

5 Engines That Mechanics Say Are Indestructible

Certain engines achieve near-mythical status among mechanics due to their long-term reliability, durability, and resistance to failure. These engines often feature robust construction, high-quality materials, and straightforward designs that simplify maintenance and reduce the likelihood of costly repairs.

Mechanics value engines that consistently perform under demanding conditions, maintain oil pressure, resist overheating, and exhibit minimal internal wear.

Durable engines also often have proven designs that remain reliable across multiple model years, offering predictability for owners and repair professionals alike. High-mileage examples often run smoothly with routine maintenance, and parts are typically easy to source and install.

This section focuses on five engines that have earned professional respect for their longevity and dependability.

Each engine demonstrates the characteristics that allow it to perform reliably for hundreds of thousands of miles, from resilient internal components to simple, effective engineering.

By examining these engines, readers can understand why certain designs outperform others, how engineering decisions influence durability, and why mechanics consistently recommend these powertrains for long-term use.

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE, the twin-turbo inline-six engine used in the legendary Toyota Supra, is frequently cited by mechanics as nearly indestructible. Its combination of robust construction, high-quality materials, and forgiving design has made it a benchmark for longevity and performance.

This engine is built with a cast-iron block and forged internals that resist warping, cracking, and premature wear, even under high stress. The iron block’s durability, paired with aluminum cylinder heads, creates a balance of strength and weight efficiency.

The 2JZ-GTE’s engine management and fuel injection system are straightforward, reducing the likelihood of complex electrical or sensor failures common in other performance engines.

Mechanics also highlight the engine’s ability to tolerate high mileage with routine maintenance. Timing belt changes, oil service, and basic inspections are typically sufficient to maintain reliable operation beyond 300,000 miles.

The engine’s turbocharging system, when maintained properly, adds power without compromising reliability, which is rare among high-performance engines.

Another reason for its indestructible reputation is the availability of high-quality aftermarket parts. Mechanics note that when maintenance is performed correctly, failures are extremely rare, and rebuilds can handle significantly more power than stock configurations without sacrificing reliability.

Including the 2JZ-GTE demonstrates that careful engineering, strong materials, and simple yet effective design can produce an engine that consistently earns professional trust. Its reputation for longevity, even under high performance, makes it a prime example of an indestructible engine.

2. Honda K20/K24 Series

The Honda K-series engines, particularly the K20 and K24 variants, are widely recognized by mechanics for their remarkable reliability and durability.

Found in models like the Honda Civic, Accord, and CR-V, these engines combine efficient engineering with robust construction, allowing them to endure high mileage and heavy usage with minimal issues.

One reason for their indestructible reputation is the use of high-quality internal components. Forged pistons, durable connecting rods, and strong cylinder walls contribute to consistent performance even under extended stress.

The engines are also designed for smooth airflow and effective cooling, which prevents overheating and reduces wear on critical components over time.

Mechanics note that routine maintenance such as timely oil changes, spark plug replacement, and periodic timing chain inspection, is usually sufficient to maintain the engine’s reliability. Unlike some modern engines, the K-series avoids overly complex systems that frequently fail, which simplifies servicing and reduces the likelihood of electrical or mechanical faults.

Another factor contributing to their longevity is the wide availability of replacement parts and aftermarket performance upgrades.

Whether the engine remains stock or is mildly tuned, its internal strength and reliable components ensure long-term durability. Many high-mileage examples exceed 300,000 miles with minimal repairs.

Including the Honda K20/K24 series in this list emphasizes that thoughtful engineering, strong materials, and straightforward design can produce engines that stand the test of time.

Their consistent performance, low maintenance requirements, and durability make them a favorite among mechanics and enthusiasts seeking reliable powertrains.

3. Chevrolet LS Small-Block

The Chevrolet LS small-block engine is widely regarded by mechanics as one of the most indestructible engines in automotive history.

Used across GM vehicles ranging from trucks to sports cars, the LS series combines robust construction, versatility, and ease of maintenance, resulting in an engine that consistently performs at high mileage.

The LS engine features a cast-iron block (and later aluminum variants) with strong forged internals in many configurations.

Pistons, connecting rods, and crankshafts are engineered for durability, allowing the engine to handle both stock and high-performance applications without major failures. Cooling and lubrication systems are highly effective, preventing overheating and minimizing wear on critical components.

Mechanics note that routine maintenance oil changes, filter replacements, and spark plug servicing is typically sufficient to keep LS engines running for hundreds of thousands of miles. The engine’s simplicity, compared to more modern and electronically complex designs, reduces the likelihood of sensor failures or electrical issues.

Another key factor in the LS small-block’s durability is the widespread availability of parts and aftermarket support.

Replacement components, performance upgrades, and rebuild kits are readily accessible, allowing mechanics to service and rebuild these engines efficiently. This accessibility ensures that even high-mileage examples remain operational and reliable.

Including the Chevrolet LS small-block demonstrates how robust engineering, high-quality materials, and service-friendly design create engines capable of enduring decades of use.

Its reputation for reliability under both normal and high-stress conditions makes it an iconic example of an indestructible powertrain.

4. Toyota 22R/22RE

The Toyota 22R and 22RE engines, found in pickups and SUVs from the 1980s through the mid-1990s, are often described by mechanics as nearly indestructible. Known for simplicity, durability, and longevity, these engines have powered countless Toyota trucks across decades with minimal issues.

One of the keys to their reliability is the engine’s straightforward design. The 22R series features a robust cast-iron block and aluminum cylinder head, along with a timing chain instead of a belt, which reduces the likelihood of catastrophic failure.

Components such as pistons, rods, and crankshaft are engineered for longevity, even under heavy workloads or high-mileage conditions.

Mechanics emphasize that routine maintenance oil changes, valve adjustments, and occasional timing chain inspection is typically enough to keep these engines running well past 300,000 miles. The engines are known for smooth operation, consistent oil pressure, and resistance to overheating, all of which contribute to their long-term reliability.

Another factor is the abundance of replacement parts and the relative ease of repairs. Simple mechanical systems and minimal electronic components make troubleshooting straightforward for mechanics, which reduces downtime and repair costs.

Including the Toyota 22R/22RE in this list highlights how conservative design choices, robust materials, and service-friendly construction can create an engine that outlasts many modern counterparts.

Its reputation among mechanics as a durable, long-lived engine exemplifies why certain designs remain relevant and trusted for decades.

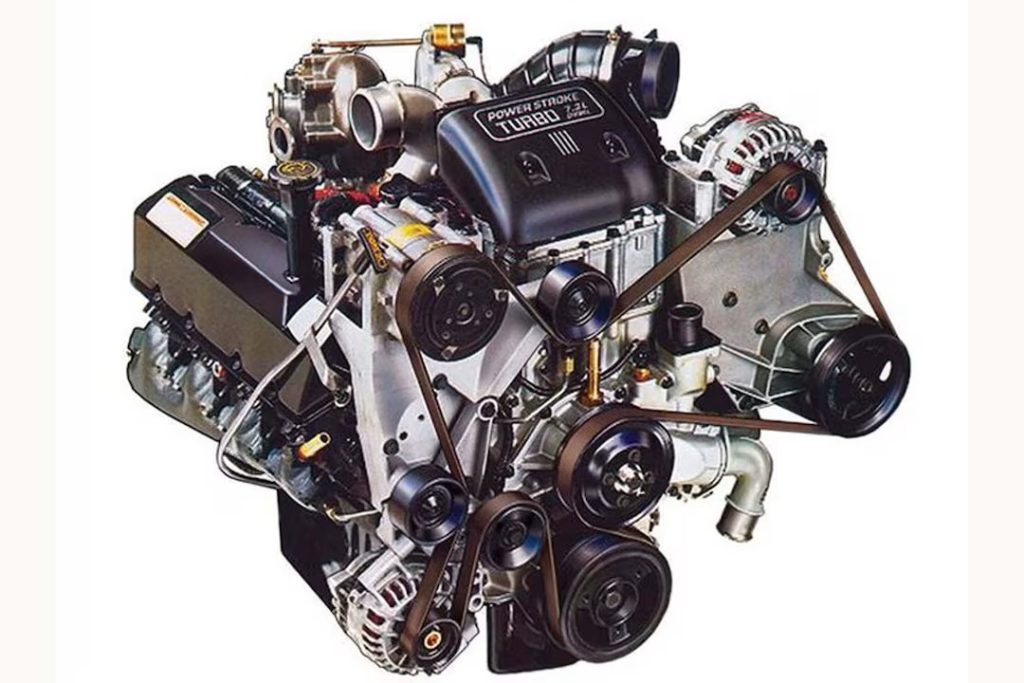

5. Ford 7.3L Power Stroke Diesel

The Ford 7.3L Power Stroke Diesel engine, produced from 1994 to 2003, is widely recognized by mechanics as one of the most indestructible diesel engines ever built.

Used in Ford Super Duty trucks, this engine is known for its exceptional reliability, high torque, and long-term durability, making it a favorite for heavy-duty applications.

Mechanics praise the 7.3L Power Stroke for its cast-iron block, forged steel crankshaft, and robust internals, which allow the engine to handle high mileage, towing, and demanding workloads without major issues.

Its direct injection system and mechanical fuel components are simple and serviceable, reducing the likelihood of electronic failures that plague later diesel engines.

Routine maintenance, including oil changes, fuel filter replacement, and turbo inspections, is typically sufficient to ensure longevity.

Many 7.3L Power Stroke engines exceed 500,000 miles with minimal repairs, and well-maintained examples continue to perform reliably beyond 750,000 miles. Cooling and lubrication systems are also highly effective, preventing overheating and reducing wear on critical components.

The availability of parts and aftermarket support further enhances the engine’s reputation. Mechanics note that repairs, rebuilds, and upgrades are relatively straightforward, allowing these engines to remain in service for decades.

Including the Ford 7.3L Power Stroke Diesel demonstrates how careful engineering, strong materials, and simple yet effective systems create engines capable of enduring extreme conditions. Its status as a trusted and durable powertrain makes it a prime example of an indestructible engine.

5 Engines That Break

While some engines achieve legendary durability, others are notorious for frequent failures, costly repairs, and short lifespans.

Engines that break or underperform often suffer from design flaws, low-quality components, complex systems, or sensitive engineering that cannot tolerate high mileage or heavy use. Mechanics regularly encounter these powertrains in repair shops, noting recurring issues that reduce reliability and increase ownership costs.

Engines prone to failure can create frustration for owners and affect resale value, as recurring mechanical, cooling, or electrical problems often appear even with routine maintenance.

These engines may initially perform well but tend to develop issues such as head gasket failures, oil consumption, timing chain or belt problems, and excessive wear on internal components over time.

Understanding which engines fall into this category helps buyers, enthusiasts, and fleet operators make informed choices. Knowing the weak points of these powertrains can prevent costly surprises and highlight the importance of service-friendly, robust designs.

This section examines five engines that mechanics commonly identify as prone to early failures or persistent issues. Each example explains why the engine struggles, the factors influencing reliability, and how maintenance challenges affect long-term performance.

By comparing these engines to indestructible powertrains, readers gain insight into what separates durable engineering from design prone to breakdowns.

1. BMW N54 Twin-Turbo (2006–2010)

The BMW N54 twin-turbo inline-six engine, used in models like the 335i and 135i, is often cited by mechanics as prone to failure despite its strong performance credentials. While it delivers impressive power and responsiveness, the N54 struggles with long-term reliability, earning a reputation for high maintenance costs.

One common issue is the high-pressure fuel system, which can fail and cause fuel leaks or misfires. Turbochargers, particularly the wastegate actuators, are also prone to wear and failure, which can lead to reduced boost, engine codes, or catastrophic turbo damage.

Mechanics frequently report problems with the direct injection system, including clogged fuel injectors and carbon buildup on intake valves, affecting performance and longevity.

Cooling system failures are another concern. Water pumps and thermostats are known to fail prematurely, risking overheating and potential engine damage. Oil leaks from valve cover gaskets and turbo seals are also common, requiring regular monitoring and repairs.

The combination of high-performance tuning, complex systems, and sensitive components makes the N54 a challenge for long-term ownership. Mechanics note that while careful maintenance can extend its life, the engine is far less forgiving than simpler or more robust designs.

Including the BMW N54 in this list highlights how engineering aimed at performance, rather than durability, can result in an engine prone to failures. Its high maintenance demands, recurring issues, and component sensitivity illustrate why mechanics often categorize it as an engine that breaks.

2. Volkswagen 2.0T EA888 (2008–2015)

The Volkswagen 2.0T EA888 engine, used in models like the Golf GTI, Jetta GLI, and Passat, is frequently cited by mechanics as prone to mechanical and oil-related failures.

While the engine delivers solid performance and efficiency, it struggles with reliability over high mileage, creating significant maintenance challenges for owners.

One of the primary concerns is excessive oil consumption, particularly in first-generation EA888 variants. Piston ring wear, PCV system issues, and turbocharger lubrication problems contribute to this recurring issue.

Turbochargers themselves are prone to failure if oil change intervals are extended or low-quality oil is used, leading to reduced performance and expensive repairs.

Mechanics also report timing chain tensioner failures, which can result in engine noise, misalignment, or catastrophic failure if not addressed promptly.

Cooling system components, including water pumps and thermostats, sometimes fail prematurely, increasing the risk of overheating. Carbon buildup on intake valves, common in direct-injection engines, further reduces efficiency and requires periodic cleaning.

Electrical and sensor-related issues, such as camshaft and crankshaft sensor failures, complicate diagnostics and maintenance, adding to repair costs. While the engine can last with diligent upkeep, it is far less forgiving than indestructible engines, and minor neglect can accelerate failures.

Including the Volkswagen 2.0T EA888 in this list demonstrates how a well-performing, efficient engine can still struggle with durability due to component wear, design sensitivities, and complex systems. Mechanics regularly encounter these engines with recurring issues, confirming its reputation as a powertrain prone to failure.

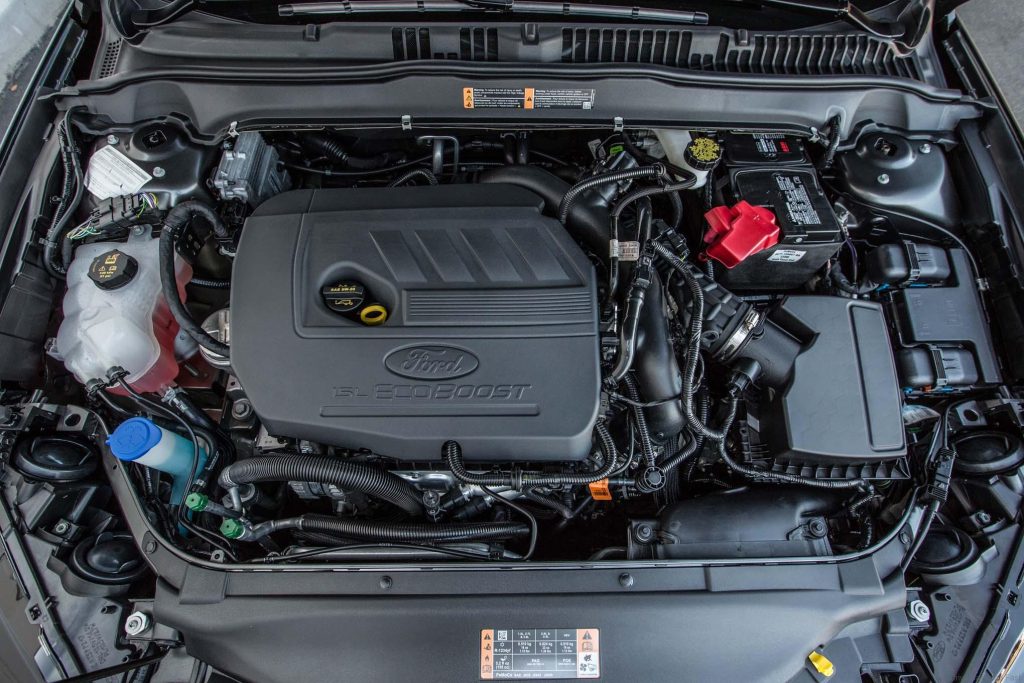

3. Ford 2.0L EcoBoost (2009–2015)

The Ford 2.0L EcoBoost engine, used in vehicles such as the Fusion, Escape, and Focus, is often flagged by mechanics as prone to early failures and reliability issues.

While it offers strong performance and fuel efficiency, the combination of turbocharging and complex engineering creates vulnerabilities that can lead to costly repairs.

One of the most common problems is carbon buildup on intake valves, which reduces airflow, lowers efficiency, and can trigger misfires.

Turbochargers, operating under high heat and pressure, are susceptible to premature wear, particularly if oil changes are delayed or low-quality oil is used.

Mechanics frequently report coolant leaks, failing water pumps, and thermostat issues, which can result in overheating and engine damage if not addressed promptly.

The engine also has a history of timing chain tensioner and camshaft problems, potentially causing misalignment or severe mechanical failures.

Electrical components, including sensors for camshaft and crankshaft position, often fail or trigger error codes, complicating diagnostics. Oil leaks from gaskets and seals are another recurring issue noted by mechanics.

Despite careful maintenance, the 2.0L EcoBoost is considered less forgiving than simpler, naturally aspirated engines. Its combination of turbocharging, direct injection, and complex components increases the likelihood of issues over time.

Including the Ford 2.0L EcoBoost in this section demonstrates how modern engines, engineered for efficiency and performance, can struggle with long-term reliability.

Mechanics’ experiences with recurring failures, high maintenance requirements, and sensitive components underscore why this engine is classified as prone to breaking.

4. Nissan VQ35DE (2002–2006)

The Nissan VQ35DE, a 3.5-liter V6 used in models such as the 350Z, Altima, and Maxima, is often cited by mechanics as prone to reliability issues despite its strong performance. While delivering impressive power and smooth operation, the engine suffers from recurring problems that affect long-term durability.

A primary concern is oil consumption and valve guide wear, which can lead to misfires and excessive oil use over time.

The timing chain tensioners are prone to failure, creating noise and potential catastrophic damage if neglected. Mechanics also report issues with the intake manifold gaskets, which can leak coolant or air, reducing performance and efficiency.

High-mileage examples may experience premature wear of the camshaft and crankshaft bearings, particularly if maintenance schedules are not rigorously followed.

Cooling system components, including water pumps and thermostats, are another weak point, often requiring replacement to prevent overheating. Electrical issues, such as sensor failures and wiring harness problems, further complicate maintenance and increase repair costs.

While the VQ35DE is capable of high performance, mechanics note that these engines demand consistent maintenance and vigilance to avoid failures. Neglect or extended use under stress often leads to expensive repairs.

Including the Nissan VQ35DE in this list highlights how design weaknesses and component vulnerabilities, even in a performance-focused engine, can reduce reliability. Its history of recurring mechanical and electrical issues confirms its classification as an engine prone to breaking.

5. Volkswagen 1.8T EA827/EA113 (1999–2005)

The Volkswagen 1.8T engine, part of the EA827/EA113 family and used in models like the Golf, Jetta, Passat, and Audi A4, is frequently flagged by mechanics as prone to premature failures. While it offers strong performance and turbocharged efficiency, this engine exhibits recurring mechanical and reliability issues that reduce long-term dependability.

One common problem is excessive oil consumption, often caused by worn piston rings or valve guide seals. Turbochargers, operating under high heat and pressure, are prone to failure if maintenance is neglected or low-quality oil is used. Mechanics frequently report timing belt tensioner failures, which can lead to catastrophic engine damage if not addressed promptly.

Cooling system failures, including water pump, thermostat, and radiator issues, are also common, increasing the risk of overheating and engine damage. Carbon buildup in the intake manifold, common in direct injection variants, reduces airflow and engine efficiency, contributing to misfires and reduced performance.

Electrical and sensor problems, such as mass airflow sensor or camshaft position sensor failures, further complicate diagnostics and increase repair costs.

While diligent maintenance can extend the engine’s lifespan, the 1.8T remains far less forgiving than indestructible engines with simpler designs and more robust components.

Including the Volkswagen 1.8T EA827/EA113 in this list demonstrates how a combination of design sensitivities, high-performance components, and maintenance-intensive systems can create an engine prone to failures. Mechanics regularly encounter these engines with recurring issues, confirming its reputation as an engine that breaks.

Also Read: 5 Cars That Rarely Blow Turbos vs 5 That Constantly Fail