Engines live or die by the strength of their moving parts, and few components play a more decisive role in long-term dependability than the water pump and bearings.

These are the quiet workers of any internal combustion engine one keeping the coolant flowing to prevent overheating, and the other ensuring the crankshaft spins freely under constant load.

When either part fails early, the entire motor’s future comes into question. That’s why comparing engines with trustworthy water pumps to those known for early bearing failures gives a clear view of how design, materials, and maintenance culture shape reliability.

A water pump’s reliability often depends on its bearings, seals, and impeller materials. Some automakers prioritize simple, belt-driven designs with long-lasting seals, while others pack the pump deep inside timing covers, making failure more costly.

When a water pump can go 150,000 miles or more without leaking or seizing, it earns its reputation. Engines like Toyota’s 2GR-FE or Ford’s 5.0 Coyote show how proper engineering can combine performance with durability, keeping owners confident long after warranties expire.

On the other side are engines where bearing wear shows up far too early. These are the designs that, despite power and refinement, suffer from lubrication flaws or weak metallurgy.

When bearings fail, they do not ask politely they knock, seize, and sometimes destroy the entire short block. Motors like the Subaru EJ25 or BMW N54 remind enthusiasts that performance often comes with compromises if durability isn’t prioritized.

This comparison isn’t about bashing or praising brands but about understanding engineering lessons. The engines highlighted here reveal how small differences in cooling system design or oil channeling can determine whether a car becomes a long-term companion or an expensive regret.

Also Read: 5 Timing-Belt Engines That Are Cheap To Service And 5 Interference Nightmares

5 Engines With Reliable Water Pumps

Reliability in an engine’s cooling system starts with its water pump. This small but crucial component circulates coolant through the block, head, and radiator, ensuring that temperatures stay balanced even under hard acceleration or in scorching weather.

When a water pump works quietly and efficiently for hundreds of thousands of miles, it speaks volumes about the engine’s design philosophy and attention to detail. A dependable water pump doesn’t just prevent overheating; it maintains consistent thermal control that preserves head gaskets, seals, and bearings.

Some manufacturers have mastered this balance through time-tested engineering. Toyota, Honda, Ford, GM, and Mazda have all produced engines that pair performance with cooling efficiency.

Their pumps use high-quality bearings, precision-machined housings, and corrosion-resistant impellers simple features that make a lasting difference.

What truly defines reliability here is not only longevity but also the ease of service and the absence of failure patterns in owner data. These engines stand out for having pumps that rarely leak, seize, or require premature replacement.

When we talk about “reliable” water pumps, we’re not just referring to units that last long; we’re recognizing entire cooling systems designed around them.

Engines like Toyota’s 2GR-FE V6 or Ford’s Coyote V8 demonstrate how proper belt routing, pump placement, and coolant flow design prevent stress buildup. Even under high performance or towing use, their pumps handle the load gracefully.

The goal of this section is to spotlight five engines that have built reputations for this kind of quiet dependability. They represent different eras, displacements, and driving purposes, but they share a common theme: cooling systems that simply work.

By looking closer at these engines, we can understand how strong design fundamentals keep them running smoothly long after their competition has overheated.

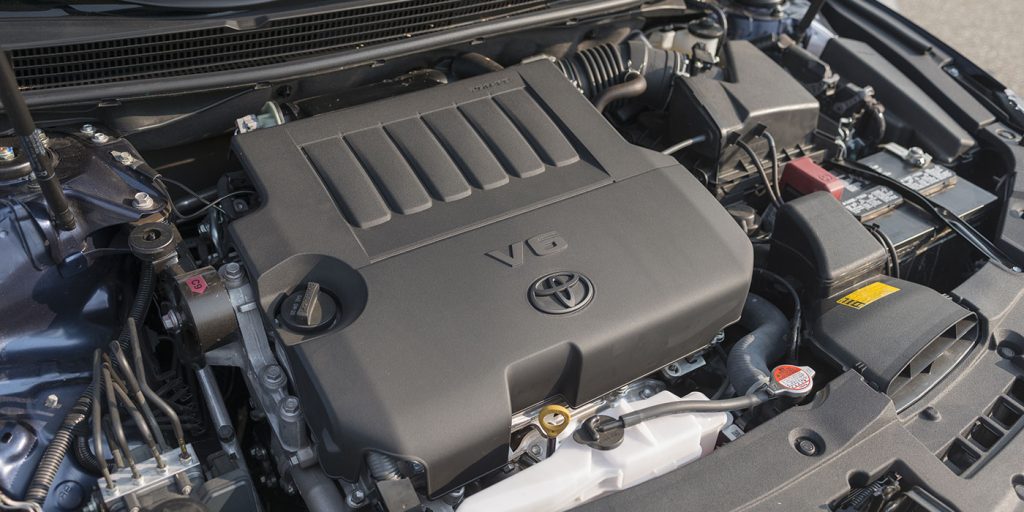

1. Toyota 2GR-FE V6

Toyota’s 2GR-FE V6 has become a benchmark for dependable cooling systems, proving that high output and long-term reliability can coexist. Found in vehicles like the Camry, Avalon, RAV4 V6, and Lexus ES350, this 3.5-liter engine is known for its smooth power delivery and simple yet durable water pump design.

The 2GR-FE uses a belt-driven water pump mounted externally on the front of the block. This straightforward layout makes service easy and minimizes failure points.

Its aluminum housing and precision bearings resist corrosion and wear, even after years of use. Owners frequently report pumps lasting beyond 150,000 miles without leaks or bearing noise.

Part of what makes the 2GR-FE special is Toyota’s attention to balance between temperature control and mechanical simplicity.

The cooling passages are evenly distributed, preventing localized hotspots, while the thermostat and pump work in harmony to regulate flow efficiently. This balanced cooling behavior helps preserve head gaskets and cylinder liners far into the engine’s life.

I’m writing about this engine because it represents Toyota’s golden era of practical reliability. The 2GR-FE doesn’t rely on exotic materials or complex cooling systems it relies on proven geometry and consistent manufacturing quality. Mechanics often note that even after years of heat cycles, these pumps rarely seize or develop play.

In an era where many manufacturers shifted to integrated water pumps buried behind timing chains, Toyota kept this design accessible and dependable.

The result is a V6 that not only performs well but earns trust mile after mile. Its success shows how a simple, well-built pump can quietly protect an engine for decades without fanfare or failure.

2. Honda K24A

Honda’s K24A engine is another shining example of mechanical balance and thermal control. Used in models like the Accord, CR-V, and Acura TSX, this 2.4-liter inline-four is known for its lively nature, clean emissions, and near-legendary longevity much of which comes from a robust cooling design.

The K24A’s water pump is belt-driven and mounted externally, allowing easy replacement and maintenance. Its high-quality bearing assembly and cast-aluminum impeller provide smooth coolant circulation through the block and head.

The pump’s seal design is particularly strong, resisting leaks that plague many other engines over time. Owners often go well beyond 180,000 miles before any cooling issues appear.

Honda designed this engine’s cooling system to handle sustained high RPM operation, which is common for the brand’s VTEC engines.

The pump efficiently manages rapid temperature changes, ensuring even thermal distribution during hard driving or stop-and-go conditions. This durability is a key reason why the K24A became a favorite among tuners and daily drivers alike.

I’m including the K24A here because it demonstrates how engineering refinement prevents long-term maintenance headaches. Instead of overcomplicating the cooling circuit, Honda focused on precision and material quality. The result is a water pump that rarely fails, even when the engine is modified or driven aggressively.

Many engines rely on replacement schedules to maintain reliability, but the K24A often defies them. It keeps flowing without noise, leaks, or bearing wear long after similar-aged motors begin showing fatigue. That reliability reinforces Honda’s reputation for engines that thrive on regular use and minimal fuss.

In short, the K24A’s water pump isn’t just dependable it’s a symbol of Honda’s consistent mechanical philosophy: keep it light, keep it simple, and build it right the first time.

3. Ford 5.0 Coyote V8

The Ford 5.0 Coyote V8 is widely respected not just for its power but also for its solid mechanical design, including a robust cooling system that’s proven itself in both everyday driving and track use.

Found in the Mustang GT and F-150, the Coyote shows that a high-revving performance engine can still deliver long-term durability when built right.

Its water pump sits at the front of the engine, driven by the accessory belt rather than buried behind timing components. This placement makes maintenance straightforward and helps prevent catastrophic failures if a leak develops.

The pump itself uses a heavy-duty bearing assembly and precision-balanced impeller, designed to move coolant evenly through both cylinder banks.

Ford engineered the Coyote’s pump to handle sustained high temperatures from track sessions or towing without cavitation or pressure loss.

The gasket design is also a highlight, sealing reliably under thermal expansion a frequent weak point in lesser designs. The combination of these factors allows the pump to last over 150,000 miles in many cases without needing replacement.

I’m writing about the Coyote because it’s one of the few modern performance engines that blends complexity and reliability successfully.

While many newer designs use internal pumps for packaging efficiency, Ford maintained an accessible, traditional setup that owners appreciate. The result is a strong, simple, and serviceable cooling system that mirrors the engine’s rugged character.

The Coyote’s water pump contributes directly to the engine’s reputation for longevity. Whether in daily driving, drag racing, or high-mileage F-150 duty, it remains dependable.

It’s proof that with the right materials and design discipline, even a high-performance V8 can cool cleanly and consistently through years of hard use.

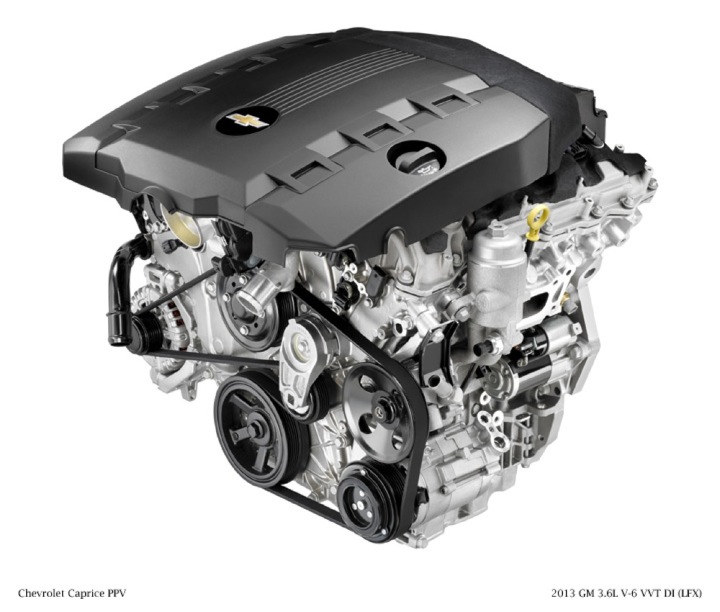

4. GM 3.6-L LFX V6

General Motors’ 3.6-liter LFX V6, used in vehicles like the Chevrolet Camaro, Impala, and Cadillac CTS, has earned a reputation as one of GM’s more reliable modern engines and its water pump plays a key part in that durability. The LFX builds on earlier 3.6-liter variants, addressing many of the cooling and lubrication weaknesses seen in older designs.

The LFX’s water pump uses a strong, cast-aluminum housing with an upgraded impeller and bearing assembly designed to resist corrosion and belt tension stress.

Positioned at the front of the block and driven by the serpentine belt, it’s easily accessible for service and rarely fails before 120,000–150,000 miles. Many owners report factory pumps lasting beyond 180,000 miles with no leaks or bearing play.

GM engineers focused on coolant flow efficiency, using optimized passages through the heads and block to prevent hot spots an area where earlier GM V6s struggled.

The LFX maintains consistent operating temperatures even under high loads, towing, or extended idling. That stability reduces wear on head gaskets, sensors, and oil viscosity over time.

I’m writing about the LFX because it demonstrates how incremental improvements can lead to lasting reliability. GM didn’t reinvent the water pump; instead, it refined the materials, bearing design, and coolant routing. The result is an engine that keeps its cool with minimal fuss.

While not as celebrated as Toyota’s or Honda’s motors, the LFX proves that GM’s late-2010s engineering caught up to its rivals in real-world reliability. The water pump in particular reflects thoughtful updates a rare case where longevity and performance coexist in a modern, high-revving V6.

The LFX may not shout about durability, but its quiet dependability has made it one of GM’s most underrated successes in the last decade.

5. Mazda Skyactiv-G 2.5

Mazda’s Skyactiv-G 2.5 engine, found in models like the Mazda3, CX-5, and Mazda6, is a lesson in how intelligent design and precision engineering can make even a high-compression gasoline engine remarkably dependable.

A large part of its success lies in its cooling strategy and water pump design, which manage temperature with calm consistency across a wide range of conditions.

The Skyactiv-G’s water pump is compact, belt-driven, and made with an aluminum housing that integrates cleanly into the front cover.

It features a reinforced impeller and carefully balanced bearings to handle the higher internal pressures created by Mazda’s 13:1 compression ratio. Despite that stress, failures are exceptionally rare, with pumps often lasting the life of the vehicle.

Mazda engineered its cooling passages and thermostat placement to maintain steady flow across all four cylinders, even under stop-and-go traffic or hot climates. This careful flow balance prevents localized overheating and reduces strain on seals and bearings. As a result, overheating incidents are virtually unheard of in stock Skyactiv engines.

I’m writing about this engine because it represents the modern balance between efficiency and mechanical durability. While many automakers chase complexity, Mazda refined simplicity. There are no electric water pumps or internal routing nightmares here just a well-built mechanical pump that does its job without complaint.

The Skyactiv-G 2.5 shows how design precision can replace brute force. Every component, from impeller geometry to bearing preload, was tuned to reduce drag and extend lifespan.

Owners regularly report 200,000 miles of service without coolant leaks or pump failure. It’s the quiet reliability of this system that earns Mazda’s engineering continued respect among enthusiasts and mechanics alike.

5 Engines With Early Bearing Failures

If water pumps define an engine’s cooling reliability, bearings define its survival under stress. Bearings are the heart of an engine’s rotation, holding the crankshaft steady and allowing power to move smoothly from piston to transmission.

When they fail early, it’s rarely a small problem. Bearing failure often signals deeper design flaws poor oil flow, inadequate material hardening, or excessive heat cycling that can doom an engine long before its expected life span.

Engines with early bearing wear tend to share a few traits. They’re often high-output designs where performance took precedence over endurance, or engines where cost-cutting affected internal metallurgy and oil circulation.

Sometimes, the issues appear after a few years as owners begin to notice cold-start knocking, oil starvation, or metallic debris in the sump. Once the bearings wear unevenly, repair often means a full rebuild or replacement an expense that can exceed the car’s value.

In this section, we’ll look at five engines that became known for these premature bearing issues. They include performance icons and mainstream motors alike, from Subaru’s flat-fours to BMW’s turbocharged sixes. Each example reveals how even respected automakers can stumble when balancing efficiency, performance, and durability.

I’m writing about these engines not to criticize but to understand why they failed. These case studies show how engineering compromises, maintenance sensitivity, and real-world use collide. Some suffered from thin oil passages, others from design shortcuts, and a few from underestimating the long-term impact of heat and lubrication stress.

By studying where these engines went wrong, we can better appreciate the ones that last and recognize the warning signs that separate a dependable powerplant from one destined for early retirement.

1. Subaru EJ25

The Subaru EJ25 is a well-known engine among enthusiasts, but its reputation is divided between fans who love its torque-rich character and those who’ve faced its bearing failures firsthand. Found in vehicles like the WRX, Forester XT, and Outback, this 2.5-liter flat-four became famous for its boxer rumble and infamous for its bottom-end wear.

The core issue lies in the design’s lubrication system. The horizontally opposed layout keeps the engine compact, but oil flow to the rod bearings can be inconsistent under high lateral G-forces or during hard acceleration.

When the oil thins from heat or neglect, the bearings suffer. Early models were particularly prone to rod bearing wear, often showing metallic flakes in the oil long before a knock became audible.

Compounding this problem, the EJ25’s crank journals and bearing surfaces were not always machined to tight tolerances, especially in the early 2000s.

Combined with small oil passages and limited sump capacity, the design left little margin for error. Even meticulous owners found that a few missed oil changes or aggressive driving in hot climates could shorten bearing life drastically.

I’m writing about the EJ25 because it represents one of the most widely discussed examples of how great performance potential can be undermined by a single weak link. Subaru fans love the EJ platform for its tunability, but its bearings remain a cautionary tale about oil starvation and heat management.

The lesson here is clear: even engines with loyal followings can fail when lubrication design doesn’t match real-world use. Many rebuilds include upgraded bearings and improved oil pumps fixes that, if implemented originally, might have saved countless EJ25s from early bearing death.

2. BMW N54

BMW’s N54 engine is a legend in its own right the twin-turbocharged inline-six that powered the 335i, 135i, and first-generation 740i. It combined incredible smoothness with impressive power, but beneath its brilliance lurked a well-documented problem: early bearing wear that often appeared long before 100,000 miles.

The N54’s rod bearings sit in a tight, high-compression environment where turbocharged pressure loads are immense. Although BMW designed an advanced lubrication system, it wasn’t enough to offset the engine’s internal heat and long oil-change intervals.

Over time, bearing clearances would tighten as metal fatigue set in, leading to that dreaded low-end knocking sound that signals a spun bearing.

Owners and mechanics alike noticed that aggressive driving, frequent heat cycles, and thin oil weights recommended by BMW accelerated the wear. Many enthusiasts switched to thicker oils or shortened service intervals, but by then, the damage was often already done.

Once a bearing began to fail, the crankshaft journals usually followed, making repairs extremely costly.

I’m including the N54 here because it’s a perfect study in the balance between performance and longevity. The engine proved that BMW could build a turbocharged masterpiece, but it also revealed how sensitive high-performance bearings can be when engineering margins are narrow.

Despite its issues, the N54 remains beloved for its tunability and smooth powerband. Many enthusiasts rebuild them with upgraded bearings and oiling modifications to eliminate the weakness entirely.

Still, its history serves as a warning that even the best engineering can falter if oil flow, bearing material, and thermal control aren’t perfectly aligned.

The N54’s story is both inspiring and cautionary proof that engineering innovation always comes with risk when durability takes a back seat to performance.

3. Hyundai 2.4 GDI Theta II

Hyundai’s 2.4-liter Theta II engine gained attention for the wrong reasons. Used in the Hyundai Sonata, Tucson, Kia Optima, and Sportage, this engine was designed to offer modern efficiency through gasoline direct injection and lightweight materials.

However, poor bearing longevity soon became one of its defining traits, leading to numerous recalls and extended warranties.

The core issue stemmed from machining debris and inconsistent lubrication during assembly. Metal shavings from the factory were sometimes left inside the crank passages, partially blocking oil flow to the connecting rod bearings.

Over time, the restriction led to heat buildup, oil starvation, and eventually, bearing seizure. Many owners reported knocking noises between 60,000 and 100,000 miles far too early for a modern engine.

Even after improved cleaning processes, the fundamental oil channel design in the Theta II left little margin for wear. The narrow passages and aggressive GDI combustion cycles created harsh conditions for thin, high-temperature oil. Once the bearings began to score, the crankshaft quickly followed, often requiring complete engine replacement.

I’m writing about the Theta II because it highlights how manufacturing precision is just as critical as engineering design. Hyundai had strong intentions building an efficient, high-compression engine but the smallest lapse in quality control turned it into a reliability nightmare.

To their credit, Hyundai acknowledged the issue and initiated one of the most extensive recall programs in their history, covering millions of vehicles. While the updated versions addressed some weaknesses, the damage to the Theta II’s reputation was lasting.

This engine’s bearing problems remind us that even the most promising designs can fail if production discipline slips. Durability isn’t only about blueprints it’s about execution on every assembly line, every time.

4. Nissan VQ35DE

Nissan’s VQ35DE is another case where performance and refinement masked an underlying durability issue. Used widely in the 350Z, Altima, Maxima, and Infiniti G35, this 3.5-liter V6 delivered excellent torque, sound, and smoothness.

Yet, despite its many strengths, a subset of VQ35DE engines experienced early bearing wear, particularly in high-heat or poorly maintained conditions.

The main culprit was oil starvation caused by sludge buildup and long oil-change intervals. The VQ35DE’s narrow oil galleries, combined with high operating temperatures, made the bearings highly sensitive to dirty oil.

In some production years, crankshaft machining inconsistencies and improper bearing clearances amplified the problem, leading to bottom-end failure even in relatively low-mileage vehicles.

Owners often first noticed faint knocking on startup or a rhythmic tapping at idle telltale signs of bearing distress. In many cases, by the time the noise became audible, the damage was already advanced. The crank journals would score, and the bearings would lose their overlay layer, leading to metal-to-metal contact and full engine failure.

I’m including the VQ35DE here because it serves as a reminder that even award-winning engines can suffer from design oversights. Nissan’s VQ family earned global recognition for its balance of power and refinement, but inconsistent quality control and marginal oil flow design hurt its long-term reputation.

Many enthusiasts rebuild these engines with upgraded oil pumps, larger galleries, and better cooling control, which often eliminate the issue entirely. That suggests the problem wasn’t in concept but in detail execution.

The VQ35DE’s story is ultimately about how small tolerances in lubrication systems can determine the difference between a 300,000-mile engine and one that fails at 100,000. It’s a powerful example of how durability always depends on the invisible science of oil movement.

5. Volkswagen EA888 Gen 1

The first-generation Volkswagen EA888 engine, found in models like the GTI, Passat, and Audi A4 from the late 2000s to early 2010s, combined turbocharged performance with efficiency. Yet beneath its impressive output, the early EA888 suffered from bearing wear that often appeared far sooner than expected.

The problem wasn’t always immediate but gradual. Oil starvation due to sludge buildup, carbon accumulation, and long factory oil-change intervals gradually reduced lubrication to critical bearing surfaces.

Over time, thin oil films couldn’t protect the crank and rod bearings from friction. Drivers would start to hear light ticking or thumping from the lower end, a warning of imminent failure.

In some cases, misaligned oil channels and balance-shaft vibrations further increased bearing stress. The combination of high turbo pressure and insufficient cooling around the crank area meant the bearings lived in near-constant thermal strain. Once the protective coating wore off, the damage accelerated rapidly.

I’m writing about the EA888 because it’s a clear example of how modern engine complexity can sometimes create new reliability risks. Volkswagen engineered remarkable power from a small displacement, but design compromises in oil routing and maintenance schedules left owners with expensive repairs.

Many enthusiasts now use upgraded oil pumps, revised bearing materials, and shorter oil intervals to prevent recurrence.

The EA888’s bearing issue didn’t erase its engineering achievements the later Gen 2 and Gen 3 revisions solved many weaknesses with improved flow and materials but it remains a case study in how innovation must always be balanced by durability.

The first generation’s troubles remind us that efficiency and longevity aren’t always aligned unless engineers plan for both from the start.

Also Read: 5 Models with Rock-Solid Wireless CarPlay and Android Auto