Rev your engine to 6,000 RPM and you’ll learn everything about its character in seconds. Some powerplants spin smoothly like a Swiss watch, humming beautifully even after 150,000 miles of hard use.

Well, they vibrate like an old washing machine on spin cycle, rattling and shaking so badly you worry something’s about to break loose and punch through the hood.

High-RPM smoothness isn’t just about bragging rights or racing heritage. It reveals fundamental engineering quality, manufacturing precision, and how well an engine will age. Smooth engines last longer because their components aren’t battering each other with vibrations.

They’re more pleasant to drive, making highway merging and spirited driving enjoyable rather than stressful. And they typically cost less to maintain because internal wear stays minimal when everything’s balanced properly.

But here’s what most people don’t realize until it’s too late: engines that start life smooth can turn rough with age if they’re not built right.

Cheap internal components wear unevenly, balance gets thrown off, and that silky powerplant you fell in love with becomes a vibrating mess by 80,000 miles. You’re left wondering if you should spend thousands fixing it or just trade the car in and take the depreciation hit.

We’re about to examine seven engines that purr like kittens at any RPM and any mileage, then contrast them with seven others that turn into agricultural tractors as they age. Your next car purchase should probably depend on knowing this difference.

Silky Smooth Forever: Engines Built Right

1. BMW M340i B58 3.0L Inline-Six (2021)

Inline-six configuration provides inherent balance that V6 and four-cylinder engines can’t match. When pistons move in a straight line with perfect spacing, primary and secondary forces cancel naturally.

This B58 engine takes that natural advantage and perfects it through precision manufacturing that keeps tolerances incredibly tight. Every component is balanced individually before assembly, and then the complete engine gets balanced again.

Crankshaft design uses seven main bearings supporting a forged steel shaft. This many bearing points prevent flexing at high RPM, maintaining perfect rotational balance.

When crankshafts don’t flex, they don’t create vibrations that make engines feel rough. BMW invested in forging rather than casting because forged components have superior strength and a more consistent internal structure.

Variable valve timing on both intake and exhaust provides smooth power delivery across the RPM range. When engines produce strong torque everywhere, you don’t need to rev them desperately to access power.

But when you do push the B58 to 6,000 RPM, it responds with enthusiasm rather than protest. Valvetrain components stay controlled at high speeds because BMW used proper spring rates and lightweight materials.

Balancer shaft isn’t needed because inline-six engines are naturally balanced. Fewer components mean fewer things to wear out or create vibrations.

This simplicity helps explain why inline-sixes maintain smoothness better than more complicated engine layouts. When your basic architecture is sound, you don’t need band-aid solutions to mask problems.

Long-term owners report B58 engines maintaining their smoothness well past 100,000 miles. Forums are full of high-mileage examples still revving cleanly to redline without vibrations or harshness.

This real-world durability proves the engineering works, delivering smoothness that lasts rather than fading away as components wear. BMW built this engine properly from the start.

2. Honda Civic Type R K20C1 2.0L Turbo Four (2019)

Four-cylinder engines usually vibrate more than sixes, but Honda engineering overcame these limitations brilliantly.

Crankshaft uses eight counterweights carefully calculated to cancel out imbalance forces. Each counterweight is machined to precise specifications, creating a balance so good that this engine feels smoother than many six-cylinder powerplants.

Connecting rods are forged rather than cast, providing strength without excessive weight. Lighter rods reduce reciprocating mass, which decreases vibrations and allows higher safe RPM limits.

Honda then balances each rod to within grams of its mates, ensuring all four cylinders contribute equally to smoothness rather than fighting each other.

Pistons use a design with minimal skirt area to reduce friction and weight. Less mass means less force trying to shake the engine apart at high RPM.

These pistons are also balanced carefully, with weight matched across all four cylinders. When components weigh the same and move in perfect harmony, smoothness follows naturally.

Dual balance shafts spin at twice crankshaft speed, canceling secondary vibration forces that normally plague four-cylinder engines.

Honda’s balance shaft design is particularly effective, using gear drive rather than chains for precise timing that never changes. When balance shafts stay perfectly synchronized, they eliminate vibrations that would otherwise make the engine feel coarse.

High-mileage Type R engines maintain their smoothness remarkably well. Owners with 80,000+ miles report engines still revving smoothly to 7,000 RPM without developing harshness.

This sustained refinement proves Honda built these engines to last, using materials and machining quality that don’t deteriorate with use. Racing heritage shows in components that handle abuse without complaining.

Also Read: 10 Engines That Tolerate Cheap Gas Without Knocking Or Failures

3. Porsche 911 Carrera 3.0L Twin-Turbo Flat-Six (2020)

The boxer engine layout places cylinders horizontally opposite each other, creating perfect primary balance. When pistons move in opposite directions simultaneously, their inertial forces cancel completely.

This inherent balance gives flat-six engines smoothness advantages that V-configuration engines can’t match without adding balance shafts and other complications.

Crankshaft runs in seven main bearings with incredibly tight clearances. Porsche’s manufacturing quality ensures bearings fit precisely with minimal play. This precision prevents the looseness that develops in cheaper engines, maintaining smooth rotation even after years of enthusiastic driving. When components fit properly from the factory, they stay tight longer.

Turbochargers add power without compromising smoothness. Exhaust pulses that might create vibration in other engines get smoothed by the turbine housings before exiting.

This dampening effect actually helps high-RPM refinement while providing the power boost turbos are famous for. Porsche tuned these turbos for broad power delivery rather than peaky characteristics.

Engine mounts use sophisticated hydraulic systems that isolate vibrations from the chassis. Even if the engine developed slight roughness, passengers wouldn’t feel it through these mounts.

But combined with the engine’s inherent smoothness, these mounts create a driving experience where you feel power delivery without any unpleasant vibrations.

Porsche 911 owners expect their engines to run smoothly forever, and this generation delivers on that expectation.

Used car markets show high-mileage examples still commanding premium prices because buyers know these engines last. When engines maintain their character through hard use, it proves engineering quality that justifies Porsche’s premium pricing.

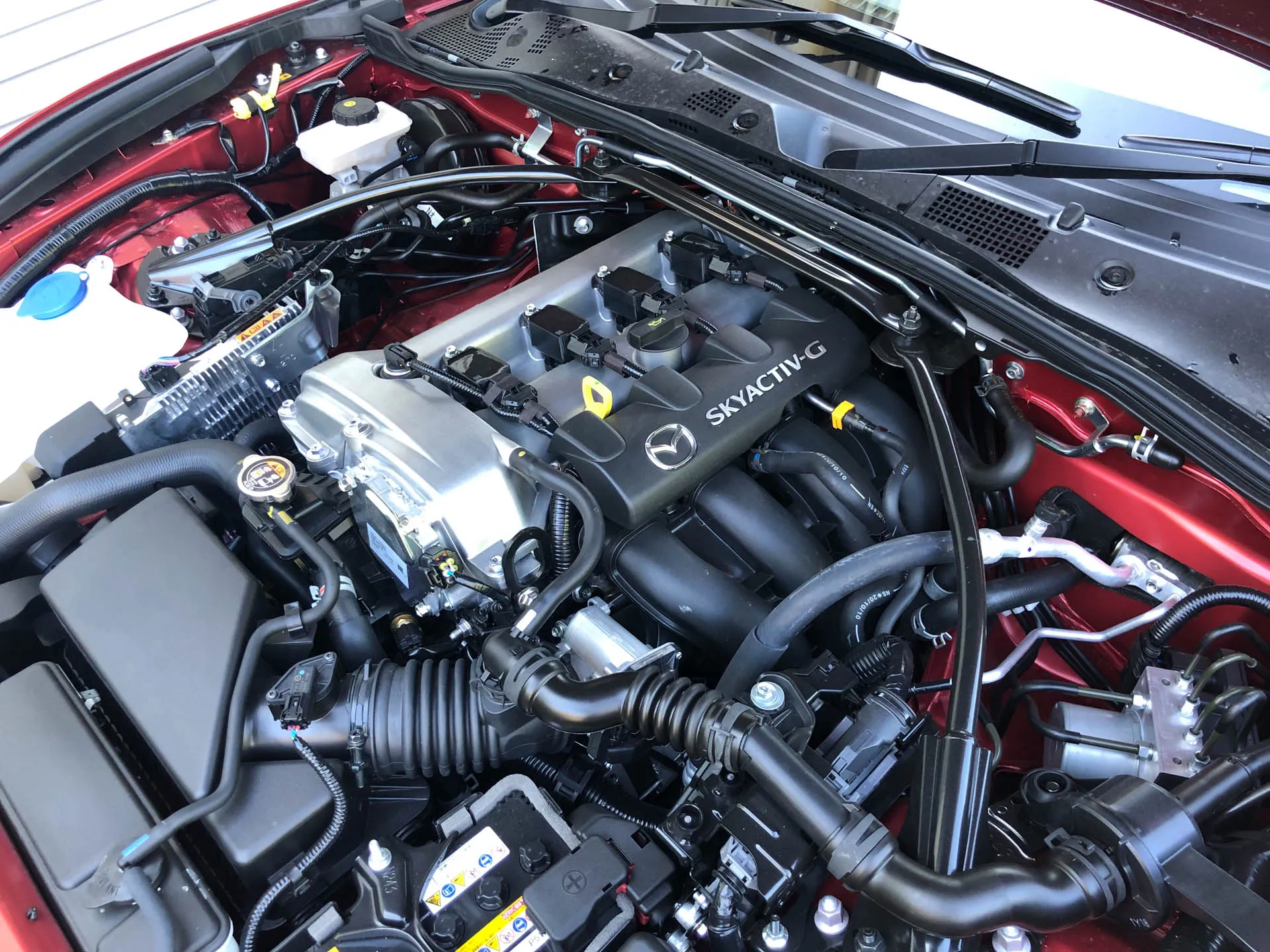

4. Mazda Miata MX-5 2.0L Skyactiv-G (2022)

Small displacement doesn’t mean rough operation when engineering is done properly. This 2.0-liter four-cylinder uses lightweight components balanced to tight tolerances.

Crankshaft, pistons, and connecting rods are all weight-matched before assembly, creating an engine that spins freely without vibrations that would indicate imbalance.

High compression ratio of 13:1 creates strong power throughout the RPM range. When engines produce good torque at low RPM, they don’t feel strained at high RPM.

This broad power delivery makes the Skyactiv-G feel smooth and responsive everywhere, encouraging drivers to use the full RPM range. Engines that love to rev are engines built properly.

Valvetrain uses roller rocker arms that reduce friction compared to sliding designs. Less friction means less power lost to internal resistance, and it also means less wear.

When components don’t wear as quickly, engines maintain their smoothness longer. Roller rockers cost more but deliver benefits that last throughout engine life.

Dual balance shafts eliminate secondary vibrations that normally make four-cylinder engines feel buzzy. Mazda’s implementation is particularly refined, using a precise gear drive that maintains perfect timing.

When balance shafts do their job correctly, four-cylinder engines can feel as smooth as sixes. Miata owners often comment on how their engines feel smoother than much larger powerplants.

Long-term reliability data shows Skyactiv-G engines maintaining smoothness well past 100,000 miles. Mazda forums are full of high-mileage examples still running quietly and smoothly.

This proven durability comes from quality materials and careful manufacturing that create engines able to handle enthusiastic driving without developing problems. Mazda built these engines right from the beginning.

5. Lexus IS 500 5.0L V8 (2022)

Naturally aspirated V8 architecture provides smoothness advantages through its firing order and inherent balance.

This 5.0-liter V8 uses a 90-degree V-angle that creates even firing intervals, producing smooth power delivery without the pulsing that makes some engines feel rough. When power strokes are evenly spaced, engines run smoothly.

Crankshaft is forged from high-strength steel and runs in five main bearings. Toyota’s manufacturing precision ensures this crank spins true with minimal runout.

Perfectly straight crankshafts don’t create vibrations even at high RPM. Combined with careful balancing, this crankshaft creates rotational smoothness that four-cylinder and V6 engines struggle to match.

Connecting rods use an I-beam design that’s both strong and lightweight. Each rod is weight-matched to its mates within extremely tight tolerances.

When all eight cylinders have identical reciprocating masses, the engine stays balanced throughout its life. This attention to detail separates engines that stay smooth from those that develop vibrations as they age.

Variable valve timing on both camshafts optimizes power delivery across the RPM range. This flexibility keeps the engine operating efficiently whether you’re cruising at 2,000 RPM or attacking an on-ramp at 6,000.

Engines that work well at all speeds are engines designed properly, without compromises that create roughness in certain situations.

Owners report this V8 maintaining its smoothness after years of use. Lexus’s reliability reputation isn’t just marketing; it’s backed by engines that run smoothly for 200,000+ miles.

When people talk about Toyota building engines that last forever, this 5.0-liter V8 is exactly what they mean. Smoothness that doesn’t fade with age proves quality engineering.

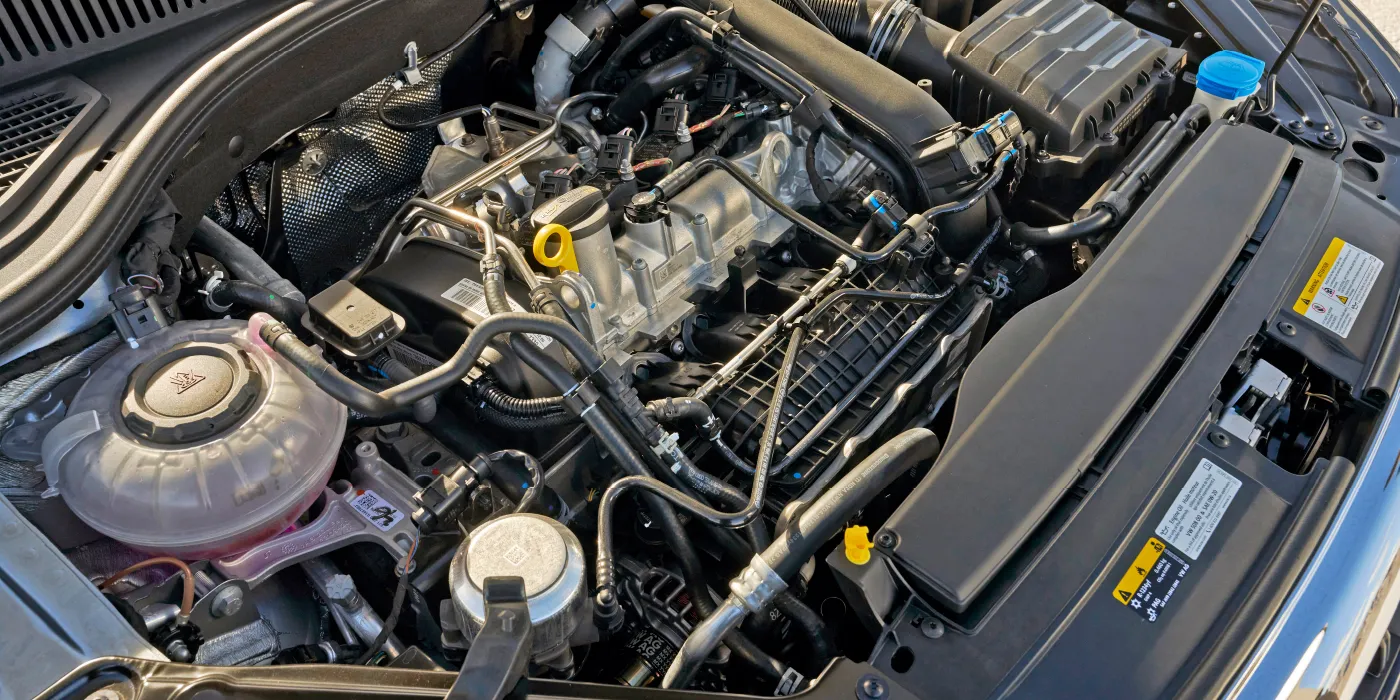

6. Volkswagen Golf R 2.0L Turbo Four (2021)

German engineering’s obsession with refinement shows throughout this turbocharged four-cylinder. Despite being a four-cylinder forced-induction engine, it runs remarkably smoothly even at high RPM.

Balance shafts eliminate secondary vibrations, while careful crankshaft balancing handles primary forces. This multi-pronged approach to smoothness creates an engine that feels more refined than its simple specification suggests.

Forged internals handle boost pressure without flexing or failing. Strong components don’t just improve reliability; they maintain tighter tolerances that keep engines running smoothly.

When pistons, rods, and crankshafts don’t flex under load, they don’t create the vibrations that make engines feel harsh or coarse.

Turbocharger integration smooths power delivery while adding performance. Rather than feeling like an on/off switch, this turbo provides progressive power that encourages high-RPM use.

When turbos are sized and tuned correctly, they enhance smoothness rather than creating the surging that makes some turbocharged engines feel unrefined.

Engine mounts use sophisticated designs that isolate vibrations from the chassis. Even if minor vibrations exist in the engine itself, passengers don’t feel them through well-designed mounts. But combined with the engine’s inherent smoothness, these mounts create a refined driving experience that rivals six-cylinder engines.

High-mileage Golf R examples maintain their smoothness impressively well. Enthusiast forums show owners with 80,000+ miles reporting engines that still rev cleanly without developing harshness. This sustained refinement proves VW built quality into the engine from day one rather than relying on tight tolerances that loosen with age.

7. Subaru WRX STI EJ257 2.5L Boxer Four (2019)

Boxer engine layout provides natural balance advantages that help this turbocharged four-cylinder run smoothly. Horizontally opposed pistons move in perfect opposition, canceling their inertial forces.

This configuration eliminates vibrations that plague inline and V-configuration engines, creating smoothness without needing balance shafts or other complications.

Forged internals handle boost pressure and high RPM without flexing. Strong crankshafts, rods, and pistons maintain their shape under stress, preserving the precise balance Subaru engineered into the engine.

When components don’t bend or stretch, they don’t create vibrations that would make the engine feel rough.

Equal-length headers improve exhaust flow while creating the characteristic Subaru sound. These headers also smooth power delivery by ensuring all cylinders see equal backpressure.

When cylinders fire into equal-length pipes, they work in harmony rather than fighting each other, contributing to smoothness.

Turbocharger size and tuning create broad power delivery that encourages revving. When engines produce strong torque everywhere, drivers don’t hesitate to use high RPMs.

This STI engine delivers power willingly throughout its range, feeling smooth and strong whether you’re at 3,000 or 6,000 RPM.

Long-term reliability proves this engine maintains its smoothness through hard use. Rally heritage means Subaru built this engine to survive abuse, and that durability extends to maintaining refinement as mileage accumulates.

Owners report EJ257 engines running smoothly well past 150,000 miles when maintained properly, proving the basic engineering is sound.

Rough Riders: Engines That Deteriorate

1. Nissan Altima QR25DE 2.5L Four (2015)

Four-cylinder engines face inherent balance challenges, and this Nissan powerplant doesn’t overcome them well.

Initial smoothness is acceptable, but as mileage accumulates, vibrations develop that make the engine feel increasingly coarse. Balance shaft wear causes secondary vibrations to increase, creating buzzing that worsens with age.

Timing chain tensioners wear prematurely, allowing the chain to slacken, which creates rattling. This mechanical noise adds to roughness perception, making the engine sound and feel agricultural.

When chains rattle, it indicates wear throughout the timing system that will only worsen without expensive repairs.

Connecting rod bearing wear creates knocking sounds at higher RPM. Nissan apparently didn’t size these bearings adequately for enthusiastic driving, and they develop excessive clearance as mileage accumulates.

This looseness creates vibrations and noise that make the engine feel rough, especially when pushed hard.

Engine mounts deteriorate faster than expected, allowing vibrations to transmit into the chassis. Rubber mount material breaks down, losing its damping properties.

When mounts fail, even moderate engine vibrations get transmitted to passengers, making the car feel rough and unrefined.

Owner complaints about roughness and vibration are common on higher-mileage Altimas. Forums show countless posts from owners wondering why their engines developed harshness around 80,000 miles.

This pattern indicates design problems rather than maintenance neglect, proving Nissan didn’t engineer this engine for long-term refinement.

2. Ford EcoBoost 1.0L Three-Cylinder (2017 Fiesta)

Three-cylinder engines have fundamental balance problems that even modern engineering struggles to solve.

This tiny EcoBoost starts life with noticeable vibrations that worsen as components wear. Turbocharging adds heat and stress that accelerate internal wear, making roughness develop faster than in naturally aspirated engines.

Balance shaft design attempts to smooth vibrations but becomes less effective as wear develops. When balance shaft bearings develop play, the shaft’s timing relationship with the crankshaft changes slightly.

This timing variation means the balance shaft can’t cancel vibrations properly, allowing harshness to increase as the engine ages.

Piston design uses thin rings to reduce friction, but these wear quickly under boost pressure. Worn rings allow blowby that reduces compression and creates power loss.

Engines with reduced compression feel rougher because combustion becomes less consistent. This ring wear happens earlier than in more conservatively designed engines.

Engine mounts use small rubber elements that deteriorate quickly. When mounts fail, the inherent imbalance of the three-cylinder design gets transmitted directly to the chassis.

Drivers feel every vibration, making the car unpleasant to drive and giving the impression that the engine is about to fall apart.

Resale values reflect knowledge of these roughness problems. Used Fiestas with 1.0 EcoBoost engines sell for less than equivalent models with different powerplants.

Buyers avoid these engines because they know refinement deteriorates quickly, making them poor choices for anyone planning to keep their car beyond the warranty period.

3. Volkswagen Jetta 1.4T Four-Cylinder (2016)

Small-displacement turbocharged engines face challenges in maintaining smoothness as they age. This 1.4-liter develops noticeable harshness around 60,000 miles as internal components wear.

Turbocharger bearings develop play, creating vibrations that pulse through the drivetrain. These vibrations make the entire car feel rough, especially during acceleration.

The timing belt stretches with age, affecting valve timing precision. When timing becomes inconsistent, combustion smoothness suffers.

Cylinders firing at slightly different times create roughness that wasn’t present when the engine was new. This timing variation worsens progressively as the belt ages.

Connecting rod bearings use a design that wears faster than expected. As clearances increase, rods develop lateral play that creates knocking.

This mechanical noise combines with vibrations to make the engine feel coarse and unrefined. Bearing replacement requires complete engine disassembly, making repairs expensive.

Engine mounts deteriorate by 70,000 miles in most cases. When the mount rubber hardens and cracks, it loses its damping ability.

Failed mounts transmit every engine vibration to the chassis, making minor roughness feel much worse. Replacing mounts helps, but doesn’t address the underlying engine wear.

Owner satisfaction drops dramatically as these engines age. Initial reviews praised the 1.4T for its refinement, but long-term owners tell different stories.

Forums are full of complaints about roughness, vibrations, and general lack of refinement in higher-mileage examples. This pattern proves the engine doesn’t age well.

4. Mazda CX-5 2.5L Skyactiv-G Four (2014)

Earlier Skyactiv engines haven’t aged as gracefully as Mazda hoped. This 2.5-liter develops a coarse feel around 80,000 miles as balance shafts wear.

When balance shaft bearings develop excessive clearance, secondary vibrations increase dramatically. What started as a smooth engine becomes buzzy and unpleasant at higher RPMs.

A direct injection system develops carbon buildup on intake valves. This buildup causes rough idle and inconsistent combustion, which makes the engine feel harsh.

Without port injection to clean valves, carbon accumulates progressively, worsening roughness as mileage increases. Cleaning requires an expensive walnut blasting service.

Piston ring wear allows oil consumption that wasn’t present when new. Engines burning oil lose compression and develop rougher combustion.

Some owners report adding a quart every 1,000 miles after 100,000 miles. This consumption indicates wear that will only worsen without engine rebuilding.

Variable valve timing actuators develop sluggish response as internal components wear. When VVT can’t adjust timing quickly, engine response becomes lazy, and roughness increases.

Replacing actuators helps temporarily, but underlying engine wear continues progressing. This makes repairs feel like throwing good money after bad.

The resale market shows buyers avoiding these earlier Skyactiv engines. Later versions improved durability, but 2013-2016 models are known for developing roughness.

Smart shoppers seek newer CX-5s or different engines entirely, leaving early Skyactiv examples languishing with low resale values.

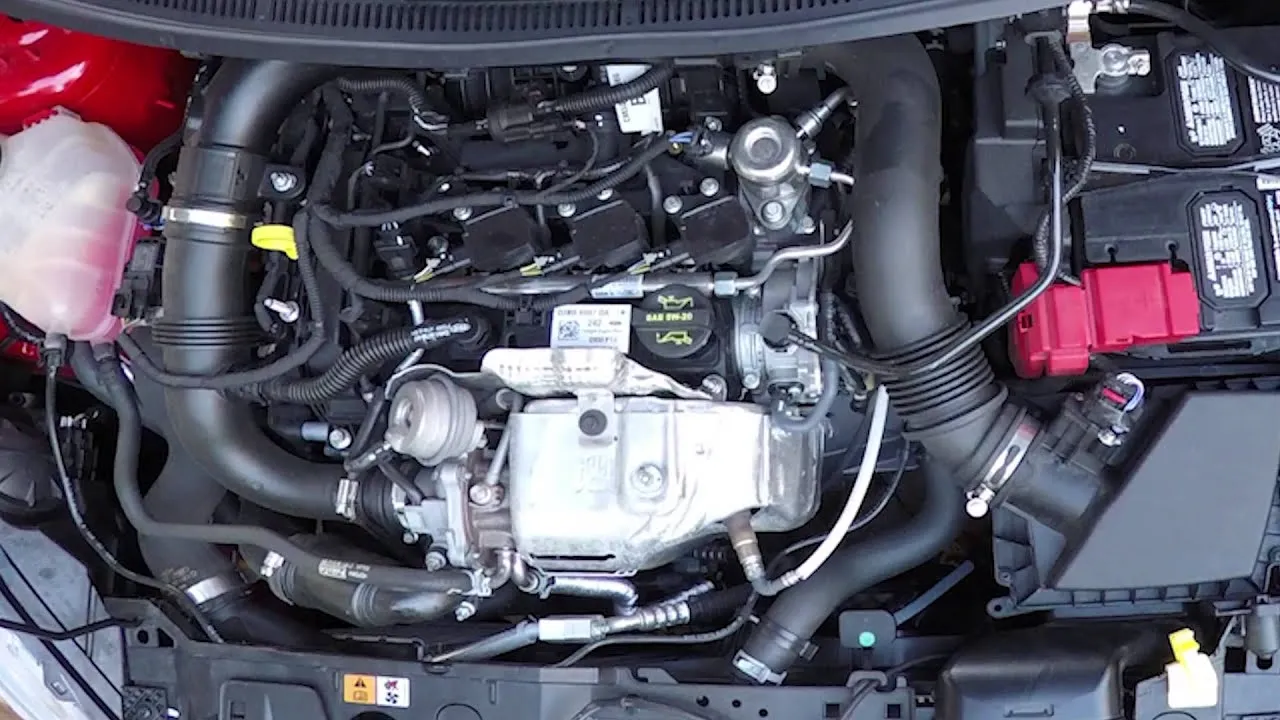

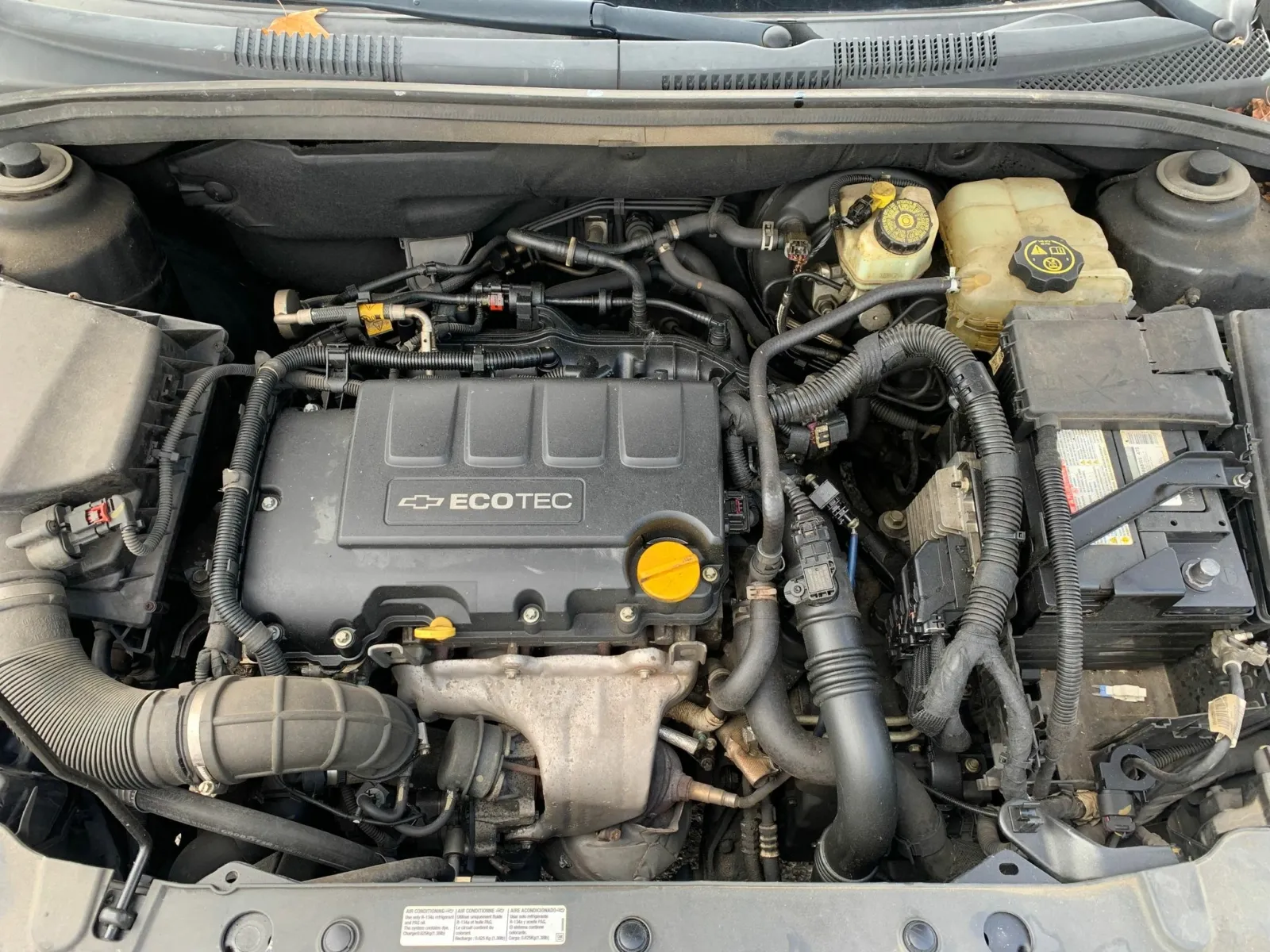

5. Chevrolet Cruze 1.4L Turbo Four (2013)

Turbocharged four-cylinder design creates challenges; this Chevy engine doesn’t handle well. Initial smoothness deteriorates rapidly as components wear.

Turbocharger shaft play develops by 70,000 miles, creating vibrations during boost. This makes acceleration feel rough and unrefined compared to when the engine was new.

The timing chain stretches prematurely, requiring replacement around 100,000 miles. Before replacement, stretched chains cause valve timing variations that create roughness.

Cylinders firing at inconsistent times produce uneven power delivery that feels coarse. Chain replacement is expensive and doesn’t address other wear.

Piston ring wear causes oil consumption problems. Many owners report burning a quart every 2,000 miles after 80,000 miles.

This consumption indicates rings not sealing properly, which reduces compression and creates rough combustion. Lower compression means less consistent power delivery and increased vibrations.

Engine mounts use rubber that deteriorates quickly. Failed mounts allow engine movement that transmits vibrations to the chassis.

Even minor engine roughness feels much worse when mounts can’t isolate it. Replacing mounts costs hundreds but only addresses symptoms rather than the underlying engine wear.

Owner forums are filled with complaints about Cruze 1.4T roughness and vibration. This consistent pattern across thousands of owners proves design problems rather than isolated defects. General Motors never adequately addressed these issues, leaving customers to deal with engines that become increasingly unpleasant to live with.

6. Jeep Cherokee 2.4L Tigershark Four (2016)

Chrysler’s four-cylinder design starts showing roughness surprisingly early in its life. Balance shafts can’t fully compensate for inherent imbalance, creating vibrations that worsen as components wear. By 60,000 miles, many owners notice increased harshness that wasn’t present when the vehicles were new.

A variable valve timing system uses components that wear prematurely. When VVT actuators develop sluggish response, engine smoothness suffers.

Timing variations between cylinders create roughness that makes the engine feel agricultural. Replacing actuators provides temporary improvement, but wear continues in other systems.

Connecting rod bearings develop excessive clearance as mileage accumulates. This looseness creates knocking sounds and vibrations at higher RPMs.

Bearing wear happens faster than in better-engineered engines, indicating Chrysler didn’t adequately size these components for long-term durability.

Engine mounts fail early, allowing vibrations to transmit into the cabin. Chrysler apparently used low-quality mount rubber that deteriorates quickly.

When mounts fail, every engine vibration gets transmitted to passengers, making the Cherokee feel rough and cheap. Multiple mount replacements become necessary throughout ownership.

Reliability ratings show Tigershark engines scoring poorly for long-term refinement. Consumer Reports and other testing organizations document increasing roughness as these engines age.

This independent verification proves problems aren’t just perception but real deterioration in smoothness and refinement.

Also Read: 10 Engines That Don’t Struggle With Oil Consumption

7. Mitsubishi Outlander Sport 2.0L Four (2017)

Budget engineering shows in every aspect of this engine’s aging characteristics. Initial roughness is noticeable even when new, and it worsens dramatically as mileage accumulates.

The balance shaft system uses components that wear quickly, allowing secondary vibrations to increase.

The timing chain tensioner design is inadequate, allowing chain slack that creates rattling. This mechanical noise adds to roughness perception, making the engine sound like it’s falling apart.

Replacing chains and tensioners temporarily improves things, but wear in other systems continues creating coarseness.

Piston design uses thin skirts that reduce friction when new, but wear rapidly. As the skirts wear, piston slap develops, creating knocking sounds during warmup.

This mechanical noise makes the engine feel rough and poorly built. Many owners assume major problems exist based on these alarming sounds.

Engine mounts use the cheapest possible rubber that hardens and cracks within three years. Failed mounts transmit every vibration to the chassis, making even minor engine roughness feel unbearable.

Mitsubishi’s cost-cutting on mounts reveals their priorities, choosing initial profit over customer satisfaction.

Resale values reflect these quality problems, with Outlander Sport models depreciating faster than competitors.

Buyers avoid these vehicles because of the roughness problems that are widely known. Smart shoppers choose alternatives, leaving Mitsubishi products to buyers who don’t research reliability before purchasing.